Industrial Crops and Products 41 (2013) 386–391

Contents lists available at SciVerse ScienceDirect

Industrial Crops and Products

journal homepage: www.elsevier.com/locate/indcrop

Salt-independent thermophilic ␣-amylase from Bacillus megaterium VUMB109:

An efficacy testing for preparation of maltooligosaccharides

Malabendu Jana a , Chiranjit Maity b , Saptadip Samanta b , Bikas Ranjan Pati b , Syed Sirajul Islam c ,

Pradeep K. Das Mohapatra b , Keshab Chandra Mondal b,∗

a

Department of Neurological Sciences, Rush University Medical Center, Chicago, IL 60612, USA

Department of Microbiology, Vidyasagar University, Midnapore 721102, West Bengal, India

c

Department of Chemistry and Chemical Technology, Vidyasagar University, Midnapore 721102, West Bengal, India

b

a r t i c l e

i n f o

Article history:

Received 4 February 2012

Received in revised form 24 April 2012

Accepted 29 April 2012

Keywords:

␣-Amylase

Oligosaccharides

Maltotriose

Maltopentose

Bacillus megaterium

a b s t r a c t

An amylase (est. Mw 150 kDa) was purified 27.39-folds from the culture broth of Bacillus megaterium

VUMB109. The purified enzyme was not inhibited by p-chloromercuro benzoate and iodoacetamide

(10 mM), it rapidly decolorized the blue color of starch–iodine complex and produced ␣-anomeric products from starch hydrolysis, thus, it is an endo-attacking ␣-amylase. The enzymatic activity was not

affected by any metal ion and EDTA, therefore, it is not in the class of metalloenzyme. The purified ␣amylase showed higher affinity (Km = 1.5 M; Vmax /Km = 0.38 and Kcat /Km = 2.5 × 106 ) to starch than other

tested substrates like amylose, amylopectin and glycogen. Maltooligomer mixture with high proportion

of maltopentaose (G5) and maltotriose (G3) was produced during hydrolysis of starch, amylopectin and

amylose. It exhibited high degree of hydrolysis on raw potato starch than wheat, rice and corn starches.

Thus the studied ␣-amylase could be exploited as a useful catalyst in the bioprocessing of maltooligomer

mixture as food supplement for baby and aged people.

© 2012 Elsevier B.V. All rights reserved.

1. Introduction

Starch-degrading amylolytic enzymes are now of great significance in biotechnological applications in industries as these replace

over 75% acid hydrolysis process of starch. The ␣-amylase is mostly

used in starch saccharification, and finds wide applications in baking, brewing, detergent, textile, paper and distilling industry (Aiyer,

2005; Lin et al., 1997; Pandey et al., 2000). The enzyme can be

derived from many sources such as plants, animals and microbes

(Jana and Pati, 1997; Maity et al., 2011), but microbial amylases

especially those from bacterial origin generally meet industrial

demands for their cost-effective production and thermostability

(Pandey et al., 2000; Fossi et al., 2009).

Generally most of the amylases produce glucose and maltose as main products from starch hydrolysis, but only a few

amylases can produce specific oligosaccharides like maltotriose,

maltotetraose and maltopentaose (Fossi et al., 2009; Kobayashi

et al., 1990; Ratanakhanokchai et al., 1992; Yang and Liu, 2004;

Samanta et al., 2009; Maity et al., 2011). These oligosaccharides

∗ Corresponding author. Tel.: +91 03222 276554/555x477;

fax: +91 03222 275329.

E-mail addresses: riwkchiranjit@yahoo.co.in (C. Maity), mondalkc@gmail.com

(K.C. Mondal).

0926-6690/$ – see front matter © 2012 Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.indcrop.2012.04.048

have several useful properties like they (i) are low calorigenic;

(ii) are less sweet than sucrose (30%, using 3% solution at 20 ◦ C);

(iii) inhibit the growth of harmful intestinal microflora; (iv) have

low viscosity, high moisture-retaining capacity, and low water

activity, convenient for controlling microbial contamination (Dey

et al., 2003). Branched oligosaccharides such as isomaltose and

panose are also effectively used as anticarcinogenic saccharides

(Nakakuki, 2002). These oligosaccharides are highly water soluble

and produce clear tasty solutions, which are used as nutrients for

infant and aged persons (Fogarty and Kelly, 1990). The Japanese

Government legislated for Foods for Specified Health Use (FOSHU)

and Foods with Nutrient Function Claims (FNFC), which enlisted

223 items, more than 50% of which incorporate oligosaccharides

as the functional components. The market for oligosaccharides is

already substantial and continues to expand gradually. In Japan,

several oligosaccharides were produced on an industrial scale by

the catalysis of microbial enzymes and annual demands of these

saccharides are about 15,000 tons (Nakakuki, 2002). Research

and development of novel oligosaccharides with physiologically

functional properties is now continuing.

In our laboratory, we have isolated a bacterium Bacillus megaterium VUMB109 that can produce thermostable, salt-tolerant and

raw starch degrading amylase (Jana et al., 1997). The present

paper is concerned with the purification and characterization of

malto-oligosaccharide producing ␣-amylase from B. megaterium

M. Jana et al. / Industrial Crops and Products 41 (2013) 386–391

VUMB109. This amylase is quite different with respect to the product specificity from the amylases produced by other strains of B.

megaterium (Ghollasi et al., 2010; Takasaki, 1989).

2. Materials and methods

2.1. Microorganism

Previously isolated and identified B. megaterium VUMB109 (Jana

et al., 1997) was used in this study.

2.2. Submerged fermentation

An enriched culture media (pH ∼8.2) containing (w/v) 0.2%

starch, 0.4% (NH4 )2 HPO4 , 0.05% MgSO4 ·7H2 O and 0.1% KCl was used

for submerged fermentation. Enzyme production was carried out

in a 250 ml flask containing 50 ml liquid media for 24 h at 40 ◦ C on a

rotary shaker (200 rpm). Fermented broth was collected after centrifugation (5000 × g for 10 min) and the resultant supernatant was

used as the source of enzyme.

2.3. Purification of the amylase

The concentrated culture broth was treated with solid

(NH4 )2 SO4 (80% saturation) and kept at 4 ◦ C for 12 h. The precipitate

was collected by centrifugation (12,000 × g for 30 min, at 4 ◦ C) and

dissolved in phosphate buffer (10 mM, pH 7.75). Enzyme solution

was dialyzed against the same buffer for 24 h at 4 ◦ C with a periodical change of the buffer solution. The dialyzed enzyme was passed

through a DEAE-cellulose column (Merck, Mumbai, India). The

active fraction of amylase was eluted with a linear gradient of KCl

(0.001–0.2 M). Then the enzyme was passed through Sephadex G100 column (1.5 cm × 92 cm) that was pre-equilibrated with 10 mM

phosphate buffer (pH 7.5) and eluted with the same buffer. The

active fractions were collected, concentrated through lyophilization and kept at 4 ◦ C for further use.

The homogeneity of the purified amylase was tested through

SDS-polyacrylamide (12%) gel electrophoresis according to the

method of Laemmli (1970). After electrophoresis, the gel was

stained with coomassie brilliant blue (R250) and the molecular

weight of the amylase was determined against marker proteins

(Genei, Bangalore, India).

387

Martins (2000). The substrate solution of 1.0 ml [1% (w/v) soluble starch (Himedia, Mumbai, India) in phoshphate buffer, 0.02 M,

pH 7.2] was incubated with 0.1 ml of the enzyme at 90 ◦ C for

30 min. Enzymatic reaction was periodically stopped by adding

10 ml of 0.1 N HCl. Then this solution was diluted 10 times with

iodine reagent (0.05% iodine and 0.5% potassium iodide) and the

absorbance was measured at 660 nm.

2.7. Measurement of optical rotation of hydrolyzed products

The purified amylase was employed for complete hydrolysis

of potato starch. A reaction mixture (1 ml) consisting of 1% (w/v)

starch solution in 10 mM phosphate buffer (pH 7.75) and 100 l

of purified amylase was added to 1 cm cell (cuvette). The optical

rotation of the mixture was periodically measured in polarimeter (Perkin Elmer) using sodium light. The mutarotation of the

hydrolysate was determined by adding 5.0 mg of solid sodium carbonate per milliliter of mixture after the optical rotation became

almost constant (Konsula and Liakopoulou-Kyriakides, 2004).

2.8. Degree of hydrolysis of starchy foods

Different starchy foods (1%, w/v in phosphate buffer, pH 7.75)

like wheat, potato, rice and corn were separately mixed with

enzyme solution (1.0 U/ml) and incubated at 90 ◦ C. Acid hydrolysis

was carried out by treating the food stuffs with 6.0 M HCl at 100 ◦ C

for 2 h. Total reducing sugar as maltose equivalents was estimated

by DNS method (Dubois et al., 1956).

Degree of hydrolysis (%)

=

reducing sugar produced by enzyme hydrolysis

reducing sugar produced by acid hydrolysis

2.9. Chromatographic studies for product identification

Soluble protein was estimated following the procedure of Lowry

et al. (1951) using bovine serum albumin (fraction V) as the standard.

The enzymatic hydrolyzed products of different polysaccharides

were detected on 1 mm Whatman no. 1 chromatographic paper.

Starch, amylase and amylopectin [1 g% (w/v) in 10 mM phosphate

buffer, pH 7.5] were digested with the purified amylase at 93 ◦ C

and the periodic hydrolytic products (100 l) were spotted on

the papers. For identification of hydrolyzed products, the maltooligosaccharide marker (Sigma, USA) was employed. A descending

mode of solvent system of n-butanol–acetic acid–water (4:1:5,

v/v) was used for paper chromatography. Chromatogram was

developed by dipping the papers in alkaline silver nitrate/sodium

hydroxide reagent (1.2% AgNO3 + 0.1% KOH + 5% Na2 S2 O3 ).

The quantity of maltooligosaccharides in the enzymatic

hydrolyzate was determined in thin layer chromatography following the principle of HPTLC. For thin layer chromatography,

Merck classical silica TLC plate (silica gel 60 on aluminum backed,

10 cm × 20 cm) was used. 10 l of sample was spotted on activated

plate and dried with hair drier. The plates were then dipped in the

twin trough chamber with solvent system of n-butanol, methanol

and 16% (v/v) aqueous ammonia (5:4:3). After 10 min of run, plates

were dried and the oligosaccharides were stained by spraying a

mixture of 2.4% (w/v) phosphomolybdic acid, 5% (v/v) H2 SO4 and

1.5% (v/v) H3 PO4 . In similar manner known quantities of different

oligosaccharides (Sigma, USA) were also run simultaneously. The

quantity of each oligosaccharide was estimated through scanning

densitometry study using Immage Lab 2.0 software (Bio Rad) and

expressed as relative percentage.

2.6. Determination of blue loss percentage of starch

2.10. Estimation of kinetic parameters

The reduction in starch–iodine color intensity upon enzyme

hydrolysis was determined following the method of Teodoro and

The kinetic parameters of purified amylase like Km and Vmax

were estimated from Eadie–Hofstee plot (v0 vs. v0 /[s]) using

2.4. Assay of amylase

Saccharification activity of amylase was measured following

the method of Achi and Nijoku-Obi (1992). Briefly, reaction mixture contained 0.5 ml of 1% (w/v) soluble starch, 0.4 ml of 10 mM

phosphate buffer (pH 7.75) and 0.1 ml of enzyme solution. Then

the mixture was incubated at 93 ◦ C for 5 min. The liberated

reducing sugar in the reaction mixture was quantified using 3,5dinitrosalicylic acid (DNS) as coloring reagent and absorbance was

measured at 540 nm. One unit of enzyme activity was defined as the

amount of enzyme that released 1 mol reducing sugars (measured

as glucose) ml−1 min−1 under the specified assay conditions.

2.5. Estimation of protein

388

M. Jana et al. / Industrial Crops and Products 41 (2013) 386–391

Table 1

Summary of the purification of ␣-amylase from the culture broth of B. megaterium VUMB109.

Purification steps

Volume (ml)

Total activity (Units)

Crude extract

Ammonium sulfate precipitation

DEAE cellulose Chromatography

Sephadex G-100 chromatography

100

4.00

4.00

4.00

2000.0

1800.0

1712.0

768.6

enzyme kinetics software v1.3 (Sigmaplot, USA). The rate of reaction (v) was expressed as the number of micromoles of reducing

sugar (as glucose equivalents) released in 1 min by 1 mg of total

protein in the enzyme sample.

Total protein (mg)

228

48.92

28

3.2

Specific activity (U mg−1 )

Purification fold

8.77

36.79

61.14

240.19

1

4.19

6.97

27.39

Yield (%)

100

90

85.6

38.43

from B. megaterium VUMB109 was much higher compared to

other bacterial ␣-amylases (Takasaki, 1989; Ghollasi et al., 2010).

These data are in accordance with the amylase from Lactobacillus

amylovorus reported by Imam et al. (1991).

3. Results and discussion

3.2. Effect of metal ions and other effectors

3.1. Purification of the amylase

The successive recovery of enzyme from the fermented broth by

various steps of purification is shown in Table 1. At the final stage,

the enzyme was purified about 27.39 folds with a specific activity

of 240.19 U mg−1 and 38.43% yield. Though the traditional methods

gave lower yield, yet it was much better and comparable than other

advanced methods like chromato-focussing and HPLC techniques

(Rao et al., 2002; Shaw et al., 1995). The purification of ␣-amylase

from microbial source in most cases has involved sequential

chromatographic techniques after crude isolation by precipitation

and membrane separation. In these steps, a considerable amount

of enzyme is lost due to autolysis and some remain physically

adsorbed on the matrix. To overcome these constrains, single step

purification systems like affinity chromatography, counter current chromatography, expanded bed chromatography, etc., are now

been employed (Sivaramakrishnan et al., 2006), but the homogeneity of the purified enzyme was less than conventional methods (Rao

et al., 2002).

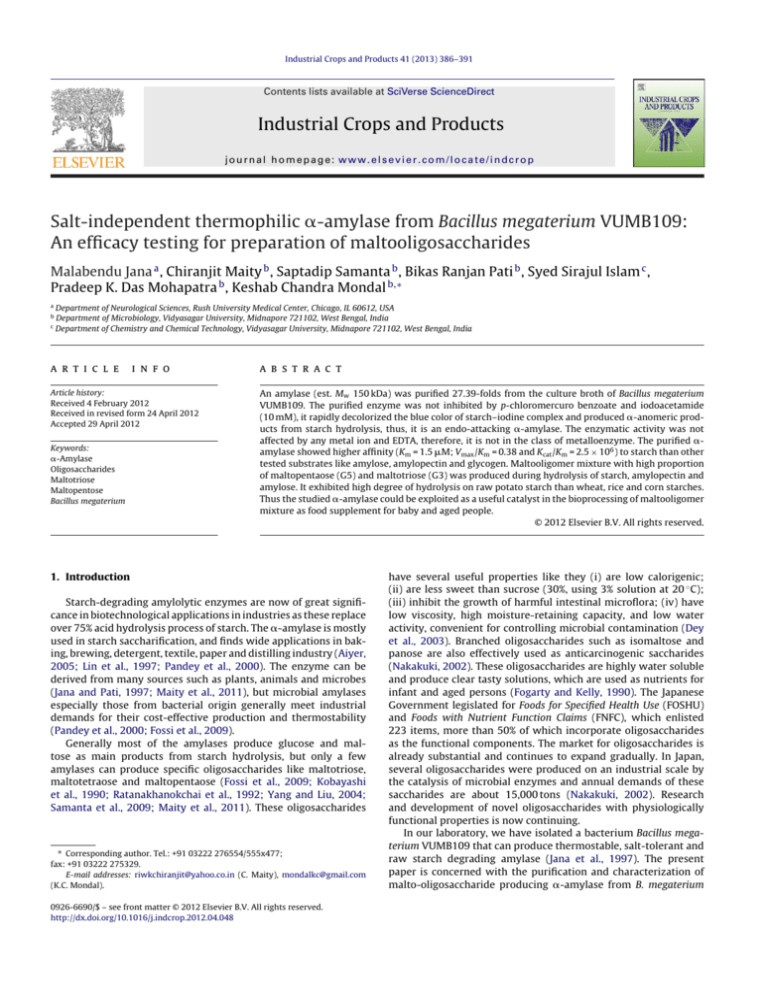

The molecular weight of the amylase was estimated to be

150 kDa in SDS-PAGE (Fig. 1). The molecular weight of the amylase

Metal ions are produced from corrosion of equipment, specially

when subjected to acid hydrolysis, or catalytic reaction is carried

out in the harsh environment. Apart from this, any requirement of

co-factor for enzymatic activity is also evaluated. So, the effect of

some metal ions at the different concentrations on the activity of

␣-amylase was investigated. The data depicted in Table 2 do suggest that no metal ion has significant stimulatory effect on enzyme

activity. Mg2+ , Sn2+ and K+ enhanced enzyme activity was in little

amounts. However, heavy metal ions like Hg2+ , Cu2+ , Fe3+ , Mn2+ ,

and Zn2+ completely inhibited the enzyme activity at concentration of 10 mM (Table 2). Such metal-independent amylase activity

was also noted in the literature (Malhotra et al., 2000; Ghollasi

et al., 2010). Normally, thermostable amylases are Ca2+ dependent

(Koch et al., 1991) but our amylase was quite unlike those as its

optimum temperature was 93 ◦ C (Jana et al., 1997) and not Ca2+

dependent. This is further established that presence of EDTA in the

reaction mixture did not drastically affect the enzymatic activity

(Table 2). Ca2+ independent thermostable ␣-amylase is advantageous in starch saccharification, as because there is no need of

Ca2+ removal from the product streams by using ion-exchangers

(Malhotra et al., 2000).

It was also reflected in Table 2 that iodoacetamide and pchloromercuro benzoate had no inhibitory effect on the activity of

␣-amylase. This property is the reverse to the characteristic of amylase. The activity of this enzyme was enhanced in the presence

of -marcaptoethanol and glutathione by 45% and 10%, respectively (Table 2). This indicated that the enzyme from B. megaterium

VUMB109 was not a type of -amylase.

3.3. Percentage of blue loss

It was observed that the amylase rapidly reduced the

starch–iodine color (Fig. 2). This indicated that the enzymatic attack

is endolytic in nature. Akerberg et al. (2000) opined that amylolysis of starch by the exo-attacking enzymes was accompanied by a

relatively little reduction of the iodine staining capacity of the substrate. But the present study indicated that rapid loss of percentage

of starch–iodine color was due to multiple attacks on substrate by

the enzyme.

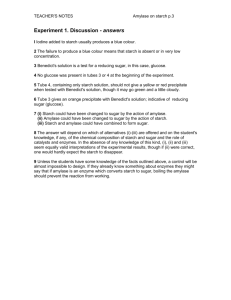

3.4. Anomeric form of the hydrolyzed products

Fig. 1. SDS-PAGE (12%) analysis of amylase from the concentrated culture broth

(lane Ca), Sephadex G100 chromatography (lane Pa) with protein markers (Genei,

Bangalore, India) (lane M).

The optical rotation of starch hydrolyzed products was shifted

downward (Fig. 3), indicating that hydrolyzed products have an

␣-anomeric configuration. This study confirmed that the studied

enzyme belonged to ␣-amylase family. Similar types of findings

of anomeric product formation were observed by Kobayashi et al.

(1990) and Anindyawati et al. (1998).

M. Jana et al. / Industrial Crops and Products 41 (2013) 386–391

3

Table 2

Effect of metal ions and inhibitors on the activity of purified ␣-amylase. Purified

amylase (0.5 ml) was incubated with different concentration of metal salts and

0.01 M of each inhibitor in 0.2 M of phosphate buffer (pH 7.75) at 4 ◦ C for 30 min,

and then residual activities were assayed under the standard conditions.

+

Relative

activity (%)

Stimulation or

(inhibition) %

No metal ions

100

–

0.1

1

10

127

100

0

27

0

Cu2+

0.1

1

10

105

95

0

5

(5)

0

Ca2+

0.1

1

10

100

94

98

96

16

(6)

(2)

(4)

(84)

Hg2+

0.1

1

68

0

(32)

0

Pb2+

0.1

1

10

90

80

0

(10)

(20)

0

0.1

1

10

116

116

49

16

16

(51)

K+

0.1

1

10

108

108

114

8

8

14

Mg2+

0.1

1

10

114

114

116

14

14

16

Fe3+

0.1

1

10

87

81

0

(13)

(19)

(0)

Mn2+

0.1

1

10

93

87

0

(7)

(13)

(0)

Zn2+

0.1

1

10

84

84

0

(16)

(16)

(0)

102

115

140

90

96

2

15

40

(10)

(4)

Ag

Sn2+

Inhibitors (0.01 M)

p-Chloro-mercuro benzoate

Glutathione

-Marcaptoethanol

Iodoacetamide

EDTA

2.5

Optical rotation (degree)

Control

Concentration

(mM)

389

R 2 = 0.8905

2

1.5

1

0.5

0

0

5

10

15

20

Reaction time (min)

25

30

Fig. 3. Optical rotation of starch hydrolysate by the action of ␣-amylase from B.

megaterium VUMB109. Details of procedure mentioned in Section 2.

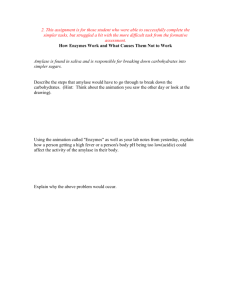

3.5. Action pattern of the enzyme

The kinetic parameters of purified ␣-amylase were determined

by Eadie–Hofstee plot, which is more suitable and reliable (not

involving reciprocal data) to estimate the kinetic constants than the

Lineweaver–Burk reciprocal plot. The substrate with the lowest Km

value and high Vmax /Km ratio has the highest apparent affinity of

the enzyme or is considered to be the best substrate. It is evident

from Fig. 4 that the purified amylase from B. megatarium VUMB109

showed lowest Km (1.5 M) and highest Vmax /Km ratio (0.38) for

starch than amylopectin, amylose and glycogen. The Kcat (turn

over number) and second order rate constant, Kcat /Km ratio of the

enzyme for starch were 3.8 × 106 (s−1 ) and 2.5 × 106 (mM−1 s−1 )

respectively. These values are also comparatively higher than the

other tested substrates. All the tested kinetic parameters indicated

that starch is the best substrate and the amylase is catalytically

more efficient in presence of this substrate.

Action pattern of the purified amylase on soluble starch,

amylose and amylopectin has been studied through paper chromatography (Fig. 5). Chromatogram indicated that major hydrolytic

products were maltohexaose (G6), maltopentaose (G5), maltotetraose (G4), maltotriose (G3) and maltose (G2). Maltose and

Loss of iodine colour (%)

100

80

60

40

R2 = 0.9917

20

0

0

5

10

15

20

Time (minute)

25

30

Fig. 2. Reduction in iodine staining power of starch by the action of purified amylase

from B. megaterium VUMB109 at 90 ◦ C and pH 7.2.

Fig. 4. Eadie–Hofstee plot for determination of Vmax (intercept on the v axis), Km

(slope of the plot), Vmax /Km (intercept on the v/s axis) and other kinetic parameters

of purified ␣-amylase for various substrates.

390

M. Jana et al. / Industrial Crops and Products 41 (2013) 386–391

Fig. 5. Paper chromatographic analysis of the hydrolyzed products of starch, amylose and amylopectin by the action of purified ␣-amylase of B. megaterium. The reaction

mixture contained I % substrate in 10 mM phosphate buffer (pH 7.5) at 93 ◦ C and samples were taken at various time intervals. Solvent system was n-butanol–acetic acid–water

4:1:5 (upper phase). Spots were resolved by silver nitrate staining.

maltotriose were not further hydrolyzed into glucose (G1). This

indicated that the enzyme randomly attacked the bonds in the

inner region of polysaccharides and produced various maltooligosaccharides. The enzyme was unable to hydrolyze pullulan or

␣-cyclodextrin as substrate (data not shown).

Quantity of malto-oligomers produced from different polysaccharides by the enzymatic attack was represented in Table 3. Upon

hydrolysis, amylopectin produced G3 (15%) and G5 (33%), but from

amylose and starch hydrolysis, different proportions of G3 (∼30%)

and G5 (∼40%) were liberated. Quantities of maltotriose (G3) and

maltopentaose (G5) were always higher in respect of the other

hydrolytic products when ␣-amylase reacted upon starch, amylose

and amylopectin. Generally ␣-amylase on starch hydrolysis yielded

higher quantity of G3 (Aiyer, 2005; Yang and Liu, 2004), but the

studied amylase produced higher quantity of G5 than G3. There was

also evidence of G4 product dominating amylase (Murakami et al.,

2008). The maltooligomer mix dominated by G3 and G5, having

tremendous importance in food industry specially, is used as a substitute of sucrose and other saccharides in baby and aged peoples

food.

our recent publication, we have also reported an ␣-amylase from

Bacillus thuringiensis CKB19 able to hydrolyze raw potato starch

more quickly than other raw starches (Maity et al., 2011). Hydrolysis of raw starch at sub-gelatinization temperatures (100–110 ◦ C)

has gained importance in consideration of factors like energy

costs, utilization of natural resources and viscosity problems

(Sivaramakrishnan et al., 2006). It turns out to be an economically

superior alternative to the conventional processes, which use pregelatinized starch as substrate. Goyal et al. (2005) reported that

a thermostable ␣-amylase from Bacillus sp. hydrolyzed 12.5 g% of

raw potato starch within 12 h. Iefuji et al. (1996) reported that

␣-amylase from Cryptococcus sp. S-2 exhibited a stronger digestibility toward raw potato starch and weaker activity for wheat, corn,

rice and sweet potato starches. So, the studied enzyme can be

made useful in the bioprocessing of starchy vegetables and other

food-stuffs.

3.6. Digestion of raw starchy foods by purified ˛-amylase

The degree of hydrolysis of rice, potato, wheat and corn starch

by the purified enzyme was studied (Fig. 6). The result showed

that the potato starch which is normally resistant to enzymatic

hydrolysis, degraded more rapidly than other three starchy foods

e.g., rice, wheat and corn (Fig. 6). There are many evidences of

the occurrence of potent amylase inhibitors in potato and wheat

(Rekha and Padmaja, 2002; Valencia-Jiménez et al., 2008), but the

studied amylase was not affected by these types of inhibitors. In

Table 3

Comparison of hydrolysis of different polysaccharides by the purified amylase from

B. megaterium VUMB109 (detail mentioned in Section 2). The hydrolyzed products

are represented as their proportional level (%).

Substrates

Starch

Amylose

Amylopectin

Product distribution (%)

G2

G3

G4

G5

G6

Higher oligomers

14

15

4.6

30

31

15

10

11

12

40

41

33

6

1.2

1

ND

0.8

34.4

Fig. 6. Digestion of various raw starches by the action of ␣-amylase from B. megaterium VUMB109 at 90 ◦ C. The amount of reducing sugar generated was measured

following the method Dubois et al. (1956).

M. Jana et al. / Industrial Crops and Products 41 (2013) 386–391

4. Conclusion

Much work has been done on ␣-amylase production from

microbial origin but little has been stated on its specific productforming property. The ␣-amylase from B. megaterium VUMB109 is

unique in respect of its characteristics and mode of action. The novel

characters of this enzyme are that (i) it is highly thermotolerant

but not metal dependent, (ii) it produced G3 and G5 as the major

hydrolytic products (G5 > G3) from different linear and branched

plant polysaccharides, and (iii) it showed high degree of hydrolysis

of raw potato starch, which is generally resistant to amylase action.

Acknowledgement

The authors are indebted to the Director, DIPAS, DRDO, Govt. of

India for financial support under the Task project.

References

Achi, O.K., Nijoku-Obi, A.N.U., 1992. Production of a raw starch saccharifying amylase

by Bacillus alvei grown on different agricultural substrates. World Journal of

Microbiology and Biotechnology 8, 206–207.

Aiyer, P.V., 2005. Amylases and their applications. African Journal of Biotechnology

4, 1525–1529.

Akerberg, C., Zacchi, G., Torto, N., Gorton, L., 2000. A kinetic model for enzymatic

wheat starch saccharification. Journal of Chemical Technology & Biotechnology

75, 306–314.

Anindyawati, T., Melliawati, R., Ito, K., Lizuka, M., Minamjura, N., 1998. Three different types of ␣-amylases from Aspergillus awamori Kt-11: their purifications,

properties, and specificities. Bioscience, Biotechnology, and Biochemistry 62,

1351–1357.

Dey, G., Singh, B., Banerjee, R., 2003. Immobilization of exo-amylase production

by Bacillus circulans GRS 313. Brazilian Archives of Biology and Technology 46,

167–176.

Dubois, M., Gilles, K.A., Hamilton, J.K., Rebers, P.A., Smith, F., 1956. Colorimetric

method for determination of sugars and related substances. Analytical Chemistry 28, 350–356.

Fogarty, W.M., Kelly, C.T., 1990. Recent advances in microbial amylases. In: Fogarty,

W.M., Kelly, C.T. (Eds.), Microbial Enzymes and Biotechnology, vol. 17b, 2nd ed.

Elsevier Science Publishers, New York, pp. 71–132.

Fossi, B.T., Tavea, F., Jiwoua, C., Ndjouenkeu, R., 2009. Screening and phenotypic

characterization of thermostable amylases producing yeasts and bacteria strains

from some Cameroonian soils. African Journal of Microbiology Research 3,

504–514.

Ghollasi, M., Khajeh, K., Naderi-Manesh, H., Ghasemi, A., 2010. Engineering of a

Bacillus ␣-amylase with improved thermostability and calcium independency.

Applied Biochemistry and Biotechnology 162, 444–459.

Goyal, N., Gupta, J.K., Soni, S.K., 2005. A novel raw starch digesting thermostable

␣-amylase from Bacillus sp. I-3 and its use in the direct hydrolysis of raw potato

starch. Enzyme and Microbial Technology 37, 723–734.

Iefuji, H., Chino, M., Kato, M., Iimura, Y., 1996. Raw starch-digesting and thermostable

␣-amylase from the yeast Cryptococcus sp. S-2: purification, characterization,

cloning and sequencing. Biochemical Journal 318, 989–996.

Imam, S.H., Burgess-Cassler, A., Cote, G.L., Gordon, S.H., Baker, F.L., 1991. A study of

cornstarch granule digestion by an unusually high molecular weight ␣-amylase

secreted by Lactobacillus amylovorus. Current Microbiology 22, 365–670.

Jana, M., Chattopadhyay, D.J., Pati, B.R., 1997. Thermostable, high salt-tolerant amylase from Bacillus megaterium VUMB109. Acta Microbiologica et Immunologica

Hungarica 44, 281–289.

391

Jana, M., Pati, B.R., 1997. Thermostable, salt tolerant ␣-amylase from Bacillus sp. MD

124. Journal of Basic Microbiology 37, 323–326.

Kobayashi, S., Okemoto, H., Hara, K., Hashimoto, H., 1990. Preparation and some

properties of a novel maltopentaose forming enzyme of Pseudomonas species.

Agricultural and Biological Chemistry 54, 147–156.

Koch, R., Lemka, K., Antranikian, G., 1991. Purification and properties of a hyperthermophilic ␣-amylase from the archaebacterium Pyrococcus woesei. Archives

of Microbiology 155, 572–578.

Konsula, Z., Liakopoulou-Kyriakides, M., 2004. Hydrolysis of starches by the action

of an ␣-amylase from Bacillus subtilis. Process Biochemistry 39, 1745–1749.

Laemmli, U.K., 1970. Cleavage of structural protein during the assembly of the head

of bacteriophage T4. Nature 227, 680–685.

Lin, L.L., Hsu, W.H., Chu, W.S., 1997. A gene encoding for ␣-amylase from thermophilic Bacillus sp. strain TS-23 and its expression in Escherichia coli. Journal

of Applied Microbiology 82, 325–334.

Lowry, O.H., Rosebrough, N.J., Farr, A.L., Randall, J.R., 1951. Protein measurement

with the Folin phenol reagent. Journal of Biological Chemistry 193, 265–275.

Maity, C., Samanta, S., Halder, S.K., Das Mohapatra, P.K., Pati, B.R., Mondal, K.C., 2011.

Isozymes of ␣-amylases from newly isolated Bacillus thuringiensis CKB19: production from immobilized cells. Biotechnology and Bioprocess Engineering 16,

312–319.

Malhotra, R., Noorvez, S.M., Satyanarayana, T., 2000. Production and partial characterization of thermostable and calcium independent ␣-amylase of an extreme

thermophile Bacillus thermooleovorans NP54. Letters in Applied Microbiology 31,

378–384.

Murakami, S., Nagasaki, K., Nishimoto, H., Shigematu, R., Umesaki, J., Takenaka,

S., Kaulpiboon, J., Prousoontorn, M., Limpaseni, T., Pongsawasdi, P., Aoki, K.,

2008. Purification and characterization of five alkaline, thermotolerant, and

maltotetraose-producing ␣-amylases from Bacillus halodurans MS-2-5, and production of recombinant enzymes in Escherichia coli. Enzyme and Microbial

Technology 43, 321–328.

Nakakuki, T., 2002. Present status and future of functional oligosaccharide development in Japan. Pure and Applied Chemistry 74, 1245–1251.

Pandey, A., Nigam, P., Soccol, C.R., Soccol, T.V., Singh, D., Mohan, R., 2000.

Advances in microbial amylases. Biotechnology and Applied Biochemistry 31,

135–152.

Rao, D.M., Purnima, A., Ramesh, D.V., Ayyanna, C., 2002. Purification of ␣-amylase

from Bacillus licheniformis by chromatofocusing and gel filtration chromatography. World Journal of Microbiology and Biotechnology 18, 547–550.

Ratanakhanokchai, K., Kancko, J., Kamio, Y., Izaki, K., 1992. Purification and properties of a maltotetraose- and maltotriose-producing amylase from Chloroflexus

aurantiacus. Applied and Environmental Microbiology 58, 2490–2494.

Rekha, M.R., Padmaja, G., 2002. Alpha-amylase inhibitors changes during processing

of sweet potato and taro tubers. Plant Foods for Human Nutrition 57, 285–294.

Samanta, S., Jana, M., Maity, C., Kar, S., Mohapatra, P.K.D., Pati, B.R., Mondal, K.C.,

2009. The potential of immobilized bacterial ␣-amylase on coconut coir, a smart

carrier for biocatalysts. Biocatalysis and Biotransformation 27, 131–135.

Shaw, J.F., Lin, F.P., Chen, S.C., Chen, H.C., 1995. Purification and properties of an

extracellular ␣-amylase from Thermus sp. Botanical Bulletin of Academia Sinica

36, 195–200.

Sivaramakrishnan, S., Gangadharan, D., Nampoothiri, K.M., Soccol, C.R., Pandey, A.,

2006. ␣-Amylases from microbial sources – an overview on recent developments. Food Technology and Biotechnology 44, 173–184.

Takasaki, Y., 1989. Novel maltose producing amylase from Bacillus megaterium G-2.

Agricultural and Biological Chemistry 53, 341–347.

Teodoro, C.E.S., Martins, M.L.L., 2000. Culture conditions for the production of thermostable amylase by Bacillus sp. Brazilian Journal of Microbiology 31, 298–302.

Valencia-Jiménez, A., Arboleda, V.J.W., Grossi-De-Sá, M.F., 2008. Activity of ␣amylase inhibitors from Phaseolus coccineus on digestive ␣-amylases of

the coffee berry borer. Journal of Agricultural and Food Chemistry 56,

2315–2320.

Yang, C.H., Liu, W.H., 2004. Purification and properties of a maltotriose-producing

␣-amylase from Thermobifida fusca. Enzyme and Microbial Technology 35,

254–260.