Reflux

CHEM 231 Lab

T e c h n i q u e P r i m e r

Reflux

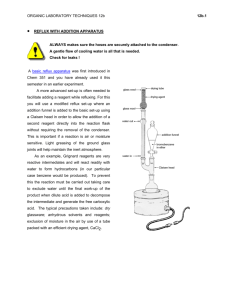

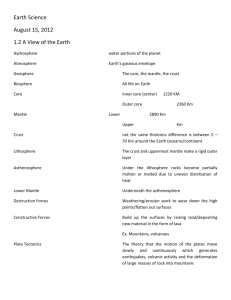

The highest temperature attainable in an open vessel is limited by the boiling point of the reaction solvent. Thus, for reactions that require high temperature, it is often necessary to boil the reaction for extended periods, a technique that requires special provisions. To keep the reaction from boiling dry, the contents are placed in a roundbottom flask, to which is attached a West condenser cooled by tap water; the reaction flask is then warmed by means of a heating mantle (Figure 1). As the solvent vapor rises into the condenser it is cooled and converted back to liquid form, at which point it flows back into the reaction vessel. This technique is known as reflux (literally, to flow back).

West condenser boiling flask heating mantle

Figure 1 . Glassware setup for reflux (image from organicchem.org)

There are a few issues of safety and technique to keep in mind when conducting a reflux. First, it is advisable to use a boiling chip whenever heating a mixture to the boiling point. The process of boiling requires nucleation sites for bubbles to form (Figure

2). When these sites are lacking, the liquid can temporarily superheat and then release the energy sporadically, unpredictably, and sometimes violently.

Boiling chips provide multiple nucleation sites and thus ensure smooth boiling.

Figure 2 . Carbon dioxide bubbles forming around nucleation sites on a finger (image from Wikiimedia)

Second, a reflux apparatus should never be sealed .

Note in Figure 1 that the top of the West condenser is open to the atmosphere. This is necessary to prevent inadvertent overpressure within the glassware, which can result in an explosion.

Water should flow into the condenser from the bottom and out through the top. This allows bubbles within the system to rise to the top and be forced out. Moreover, the water flow should be just enough to cool the condenser. High flow rates lead to pressure in the line, which can cause a hose to disconnect. This, in turn, creates two safety hazards: the water from the disconnected hose can flood the lab; and the reflux apparatus can boil dry and overheat (in some cases, leading to explosion) without a water supply to the condenser.

Finally, a few guidelines should be observed with respect to the heating mantle. Note in Figure 1 that the heating mantle is elevated (supported by an iron ring)—this allows for rapid removal of heat should the reaction exhibit a sudden exotherm. Also note that the round-bottom flask is securely clamped about the neck, so that the heating mantle can be removed without disturbing the rest of the apparatus. The power cord for the heating mantle should be connected to a voltage-controlled outlet

(aka rheostat)—plugging the mantle directly into an unregulated wall outlet will result in rapid overheating. Also take care to keep any cords and hoses well away from the heating mantle, as the hot surface can melt through the polymer and create an electrical and/or thermal hazard.