History of RAM Technology & Industry

advertisement

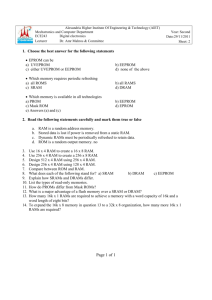

Morin 1 A History of RAM Technology & Industry CNIT 176 Prof. Raymond Hansen By. Nathan Morin Morin 2 Introduction When we think of computing systems, RAM is one of the first and most important components we think of. It would be hard if not impossible to imagine a computing world without RAM working as main memory. However, it’s development and architectures are often overlooked in favor of “flashier” CPU architectures. After all, the CPU is the core. This paper seeks to explain the development and technology behind this sometimes overlooked part of computing. I will describe the theories leading to RAM’s development from the 1970’s. Along the way, I will describe the companies that made RAM’s into a mature technology and the steps leading to our modern RAM systems. Finally I will take a look at what the future may look like. Throughout this journey, I hope to show how RAM technology has developed into the integral and complex part of computing we rely on every day. In addition, I hope to show how future technologies may totally change the basic RAM designs created in the 1970’s and used until today. Early RAM development (1970-1975) In the early days of computing, data was stored in magnetic memory systems. These early sequential data storage systems were slow and unreliable. However, because transistor technology was so expensive, they were used as main memory to record and access data. However, this all began to change as transistors became cheaper and the theoretical MOSFET transistor design became a reality. Although the MOSFET design is a given in current memory systems, early MSOFET memory designs faced competition from other memory designs. Most important among these Morin 3 was bipolar memory. In fact, early MSOFET systems were actually slower than bipolar memory. Although bipolar memory was originally faster, MOSFET gained traction because of its “processing simplicity and layout advantages.” The basic design of early MOSFET circuits was relatively simple. They consisted of a source, a drain, and a gate to decide whether electricity would flow from the source to the drain. As designers began building MOSFET chips, two main circuit designs developed: NFET and PFET. The main difference between NFET and PFET designs is that NFET designs use bodies charged with electrons, while PFET types Figure 1 - NFET & PFET (Hu 199) do not have this modification (see Figure 1). This difference makes NFET and PFET circuits inverse (when NFET is on PFET will be off). Each circuit type had an advantage: NFET is faster, but PFET does not leak electricity. Early designs used PFET memory because leakage was too large an obstacle in the NFET designs. As designers developed technology to improve the NFET design, they started combining PFET and NFET designs onto the same circuit. Theses circuits were called CMOS. These new designs used the inverse relationship between N and PFET designs to slow electricity flow through MSOFET circuits, saving power in the process (Hu 196-200). These designs allowed for the MOSFET memory design to become a reality and eventually displace bipolar and magnetic memory. Morin 4 Throughout this time period, the market was dominated by a handful of key US players. Largest among these was Intel. The original Intel founders pioneered the change from magnetic memories to RAM chips (Kang J. 8). Although volatile memory is now accepted, at that time it was a major leap to move from relatively stable, cheap and fast magnetic tape memory to volatile expensive RAM memories. Because of this, Intel's first RAM products were small SRAM chips: 256-bit MOS and 64-bit bipolar products. According to Goorden More, Intel founder, “they [these early RAM chips] still did not approach cost competitiveness with the established magnetic cores. The bipolar one filled the need for very fast, small memories, while the MOS product was competitively priced with magnetic core memories in small memory sizes”. The first product Intel produced that proved RAM and especially MOSFET DRAM was a viable alternative to magnetic memories was the i1103, a 1K (1024 bit) DRAM chip. This was a major leap in an industry that had major concerns about the volatility of even SRAM. However, Intel developed a refresh method that allowed these DRAM chips to be cheaply produced. In addition, the smaller size and speed advantages finally made RAM an attractive alternative to traditional magnetic technologies (Moore 6). However, Intel was far from the only player in the early RAM industry. Another early player in the US market was Texas Instruments. Although TI did not create the initial revolutionary innovations Intel produced, they were not far behind (Kang J. 8). TI actually had the opportunity to create a 1K chip but declined it because of sketchy “insufficient design resources” (TI 3.3). After Intel developed their 1K chip, TI started development of the next generation of DRAM chips: 2K and beyond. By 1974, both Intel and TI had developed 4K DRAM memory chips. The DRAM industry was now a race to larger capacities and faster speeds. “Each new generation of DRAM stores four times as many bits as Morin 5 does the previous one; new generations are introduced approximately every three years” (Moore 10). In this race, Mosteck, another American company founded by former TI employees, overtook both companies (Phipps 24-25). Mosteck gained the lead in the 3rd generation of DRAM, the 16K DRAM chip. While Intel developed a chip using a three-transistor design, Mosteck was able to create a cheaper chip with only one transistor (Moss 71). This innovation propelled Mosteck into the lead in the later 1970’s. Throughout this period, US companies dominated the development and production of RAM chips. However, this all changes in the later years of 1970 and into the 1980’s. During this period the RAM industry matured into an integral part of the computing industry, an industry dominated by Japanese innovators who developed RAM into PC age. The Japanese takeover (1975-1980) Although the US dominated the early of computing development and in particular RAM development, foreign competitors began making significant innovations in the 1980’s that propelled them to the forefront of the RAM industry. In particular, Japanese companies focused on reducing the cost of RAM and producing the large quantities needed for a massive market growth. One of the difficulties developing RAM or any transistor technology is the capitalintensive nature of the business. This requires producers to minimize production and development cost to stay competitive. Starting in the late 1970’s, Japanese businesses did just that. A few factors gave Japanese businesses the advantage. First, the Japanese government encouraged collaboration on research, reducing development cost. Second, Japanese businesses had access to capital necessary to make those innovations. Third and finally, Japanese Morin 6 businesses tuned their manufacturing processes to produce larger quantities of higher quality products. This focus along with the developmental advantages allowed Japanese firms to achieve 70% to 80% yields compared to the 50% to 60% yields US businesses achieved (Kang J. 10). These impressive innovations pushed most US companies out of the RAM manufacturing industry. As can be seen, by 1987, Figure 2 - RAM Industry 1975 (qtd. in Kang J. 11) the vast majority of the most profitable companies were foreign companies. In the US Intel continued developing DRAM chips as the industry moved toward 64-bit and 256-bit designs. However, they were losing money trying to compete with Japanese companies’ low prices. By 1985, they reached a turning point. They could continue DRAM development by constructing a new $400 Million plant or they could leave the market for more profitable products. As they looked toward the 1 MB DRAM chip, they decided to sell their intellectual property and look toward other designs. According to Gordon Moore, “we decided to abandon the largest semiconductor product type, one that we had created and that had been critical to our early success, and focus our efforts on other areas where there was a greater chance to succeed” (Moore 74). Instead they looked toward SRAM and EPROM (Erasable Morin 7 Programmable ROM) as less saturated markets where they could find profitable products. EPROM was an especially profitable area for Intel. Before their shift away from DRAM, they had marketed EPROM as a niche product only a few designers would use. However, they realized the ability to recode ROM memory had implications far beyond design mockups and started marketing it to a larger audience in the late 1980’s (More 73-74). What of TI, the other large US innovator in the early development of RAM? TI took a more aggressive strategy in response to the increased competition in the RAM market. They continued production through the 1980’s, testing one of the first 4MB DRAM chips in 1988. However, the costs of development proved to large to continue isolated development. In 1988 when developing the 16MB DRAM chip, they partnered with Hitachi to cover development costs. According to TI, this made “it possible for both companies to produce new products faster and at a lower cost” (TI 3.4). This allowed them to continue production into the early 1990’s. However, the early days of US domination were over. As the computer industry moved into the PC age, the industry influencers would be global. The PC Age (1980 - 2000) As the computer industry moved from the mainframes and industrial computing that defined the early computing industry to the PC age when every business and many people had a computer, the need for RAM expanded greatly. This spurred a new generation of RAM technologies and standards. These technologies would allow PC’s to hold much more information and use graphics in ways early mainframe designers could only dream. They also allowed these larger chips to fit inside newly created laptops while saving valuable power. Morin 8 Going back to the early 1980’s when the industry standard for DRAM was 64-Kbit, three key development areas improved the reliability and cohesiveness of DRAM chips: array noise reduction, and voltage normalization, and CMOS designs. The first of these, array noise reduction, was accomplished with a combination of two techniques: Folded-bit-lines (FoldedBL) and half-VDD pre-charging. Folded-BL, first developed in the 1970’s differ from the then standard open-bit-lines (Open-BL) in that Folded-BL are designed in parallel, close together while Open-BL bit lines are designed more independently. The integrated nature of Folded-BL allows the amplifier to cancel noise across the bit lines. Half-VDD capacitor pre-charging design was implemented to increase the time before a capacitor would lose charge and therefore reduce array noise in the bit lines. The second development area, voltage normalization, was important to both reduce the complexity of supporting devices and allow for miniaturization of designs. Before the 1980’s many different voltage inputs were used to power DRAM chips. At this point, all those different inputs were standardized into a single 5-V supply. Inside the DRAM chip, developers also created Voltage Down Converters (VDC). This basically allowed for the internal voltage to decrease as the circuits became smaller while the external supply voltage stayed constant. This allowed for developers to miniaturize DRAM circuits without worrying about high input voltages. The third and final major advancement was the actual implementation of the CMOS design I mentioned earlier. The first CMOS designs were implemented in the 1980’s with the 1MB DRAM (Kiyoo 28-29). These increases in technology were complemented with new RAM I/O standards. Morin 9 The first of these innovations was SDRAM. SDRAM was developed in the mid 1990’s. The basic idea of SDRAM very simple; perform memory reads/writes on the rising edge of the clock pulse, allowing for more efficient data transfer (Ikeda 686). According to Steve Cullen, memory analysis for marketing researchers Cahners, “there was a fast transition to synchronous RAM” (Paulson 17). However, as developers continued increasing clock speeds to increase data flow rates, they found RAM clock speeds would not be able to keep pace with the significant improvements processors had been making. This led to the development of DDR SDRAM. DDR is also, on the surface, a fairly simple manipulation of the clock cycle. Instead of using just one clock edge for reads/writes, it uses two. Actually, a request is sent on the rising edge and data can be Figure 3 - RAM Technology Development (Cosoroaba 391) sent on either edge. This improvement alone doubled data bandwidth, helping DRAM keep up with processor requests. This also helped reduce the need for caching to bridge the gap between processor and memory speeds (Cosoroaba 388). As figure 3 clearly shows, DDR SDRAM quadrupled DRAM data access rate in just a few years. Morin 10 During this period, improvements were also made to the physical interfaces RAM chip used to interact with the system bus. In 1988, Wang Figure 4 – Original Patent Image For SIMM (Clayton) Laboratories created the SIMM (Single Inline Memory Module) interface standard. This original design used 9 DRAM chips placed on a single board, allowing the SIMM to interface as a whole with the bus interface. As the original patent image (figure 4) shows, this early design used a 30-pin architecture (Wang Labs 2-6). As DRAM capacity and processor speeds increased, increasing the number of pins on a SIMM module was not enough. In response to this, DIMM (Dual Inline Memory Module) was created. This used separate pins on the front and back of a memory module, effectively allowing for double the data transfer rate. In addition, this allowed DRAM chips to be placed Figure 5 - DDR3 DIMM (JEDEC DDR3 25) on both sides of a DRAM module, greatly increasing data density. This DIMM construction is the current standard for DRAM modules. Jedec, the standards body for DIMM provides this graphic (figure 5) for a current DDR3 memory module. It clearly shows how the SIMM module Morin 11 design has been essentially mirrored across the module to double both data storage and access bandwidth. All these improvements were developed in conjunction. Simplification and miniaturization of RAM chips allowed for the creation of effective DIMM modules. Improved reliability allowed developers to create DDR modules that doubled data throughput. All these improvements allowed PC makers to develop compact, powerful computers that revolutionized the computing industry. The Modern Age (2000-2014) The 21st century. XP was new, Google was just a small company, and the Internet was something most people just didn’t use. This new period did not bring revolutionary new RAM technologies or standards. Instead, companies and organizations refined and expanded the previous RAM technologies. Although there were no large shifts, there were some interesting developments in embedded systems that pushed RAM to interesting new places. In the theme of continued improvement, Samsung, now the dominant RAM manufacturer in the world, created the first 512MB DRAM chip in 2000. Samsung continued making significant improvements. According to Samsung, they “developed the worlds' first 50nm 1G DRAM” in 2006 and “ the world's first 2Gb 50 NANO” in 2008 (Samsung). These impressive increases, quadrupling DRAM capacity in under a decade, along with their well-known business acumen placed Samsung in the top spot in the DRAM market. According to iSupply, Samsung held a 34% share of DRAM sales in 2009 (qtd in. Kang 13). In parallel with this big business investment into larger DRAM modules, embedded DRAM (eDRAM) was developed to overcome some of the problems associated with commodity Morin 12 DRAM. First, commodity DRAM is relatively expensive. Although creating non-standard eDRAM systems may seem more expensive. eDRAM system remove the significant bussing and interfacing costs standardized systems require. In addition, commodity DRAM must be added to a system in relatively large blocks. eDRAM reduces both these costs. Second, DRAM is power hungry. All those busses require larger input voltages than the core DRAM architecture: 3.3 vs. 1.8. By removing these interfaces, the system can operate entirely on the lower voltage. Third and finally, DRAM is slow. eDRAM improves speed by allowing for variable bus size. Larger busses mean greater bandwidth and transfer rates. Simplified eDRAM architectures mean less time to access data. Finally, eDRAM can be customized for specific applications (Keitel-Schulz 10). Despite these improvements in cost, power use, and speed, eDRAM has its disadvantages: higher development costs and less flexibility. So, why would a designer use eDRAM vs. commodity DRAM. eDRAM is important for less traditional computing systems: networking, embedded systems, hard disks, and mobile technologies. For the vast majority of traditional computing applications, the development costs and low flexibility make eDRAM impractical. Basically, if savings from the production of large volume justify the higher development costs, eDRAM would be used. If power is limited or performance is imperative, eDRAM may also be a good choice. So far, the first decades of the 21st century have produced three new DDR standards. DDR2 doubled the access speed of DRAM chips just like DDR did for previous DRAM chips. This was accomplished by a number of changes. JEDEC, the standards organization in charge of DDR, envisioned a single DDR2 chip becoming as large as 4 Gb. Their official standard defined a “minimum set of requirements for JEDEC-compliant 256 Mb through 4 Gb for x4, x8, and x16 DDR2 SDRAM devices” (JEDEC DDR2 1). This long, detailed requirements document boils Morin 13 down to a few basic changes. Most significantly, DDR2 improves how the DRAM chip communicates over the buss. In the DDR standard, there is a delay between accessing the RAS (Row Access Strobe) and CAS (Column Access Strobe). This caused the bus accessing the RAM module to operate at less than half capacity (Kirihata). The DDR2 standard increased the internal clock speed and accessed the CAS directly after the RAS (Fujisawa 38). This improvement approximately doubled the access speeds of DDR2 over DDR1. In conjunction with these speed improvements, DDR2 introduced lower voltage and more accurate signaling. Even as DDR2 was entering producing, Jedec and their partners started development on the next generation of DDR, aiming to yet again double the access speed of DRAM modules. In 2004 Samsung produced the first DDR3 prototype. With access rates of ~1600 Mbps, Samsung achieved Jedec’s requirements of the DDR3 standards (Chang 8). Similar to DDR2, DDR3 decreased the input power over the previous generation, going from 1.8V/0.1V to 1.5V/0.075V. In addition, the number of RAM modules was increased to a minimum of x8 (Chang 4). Samsung’s published comparison in partnership with Jedec shows the across the board improvements in DDR3 (figure 6). Figure 6 - DRR Comparison (Chang 4) Morin 14 DDR3, now the current industry standard, will be replaced by the next generation of DDR. As was inevitable, DDR4 breaks the doubled rate each generation tradition. Although it did not double access rates, it increased DRAM speeds by 50% (~2400Mbps). Similar to previous generations, it decreased power usage by 30% (~1.2V). This new generation should enter production soon, Samsung and other manufacturers demonstrating their designs and Intel readying their processors for the new memory (Shah par. 1). However, DDR4 may be the last generation of DDR DRAM. Although speeds continue to improve, DDR DRAM is still a volatile memory type. Other non-volatile memories such phase-change, RRAM (Resistive RAM), and MRAM (Magnetoresistive RAM) may become the standard primary memory type in future computing systems (Shah par. 4). Although the first decade of the 21st century may not have brought radical change to the RAM industry, it set the stage for the memory used in every server, laptop, and iDevice. The Future (2014-) RRAM is one of those promising technologies that may replace the current DRAM standard. There are three main reasons to move toward a technology such as RRAM: stability, efficiency, and CMOS compatibility (Lee B. 3270). Stability is perhaps the greatest advantage of these new RAM technologies. RRAM is a non-volatile memory technology: it retains data even without power. This could potentially allow for a computer to be powered off and resumed from the exact same spot, instantly. Efficiency, both in speed and power, is another significant reason to move toward a new RAM technology. Tom Coughlin, founder of Coughlin Associates, said “RRAM will eventually deliver 20 times faster write performance, 20 times less power consumption and 10 times more durability than NAND flash memory” (qtd. in Williams Morin 15 par. 5). Finally compatibility with CMOS allows RRAM to work seamlessly with existing systems. So, what is the technology behind RRAM and other potential DRAM replacements? RRAM is a classification of many different technologies implementing the same basic idea: use the resistive properties of two sandwiched materials to hold a charge. This overall category is divided into many different types by different materials, operation mechanisms, and polarities. RRAM is not the only promising non-volatile RAM technology. MRAM, another non-volatile RAM technology, uses magnetism to store data. MRAM technologies, used in combination with spin transfer torque (STT) magnetic technology, has the potential to greatly increase speed and capacity (Shah par. 4). According to Wang Kang from University of Paris-Sud, these spintronics technologies have the capacity to continue Moore's law past want CMOS designs can achieve (Kang W. 1). Although both RRAM and MRAM are more reliable, faster, and power efficient, they have one significant disadvantage. They are currently only produced on small scales and with large costs. The challenge is to design manufacturing practices that can break Rock’s law using these new technologies to reduce production cost. Even as these technologies promise increases in the next few decades, other technologies may totally revolutionize how we design computing systems in the future. One such technology is Quantum Dot memory. Basically, as transistor designs continue to decrease in size, Quantum mechanical rules start to apply and conventional designs cannot just be made smaller. Quantum dot memory aims to solve this size problem by using self-organizing dot semiconductors. This allows billions of these transistors to be placed on a circuit without using complicated printing methods (Nowozin 183-185). In another memory system, quantum states are used to store and manipulate data, Oxford University developed just last year a system that held a quantum state Morin 16 for almost 40 minutes, smashing the previous record of under a minute at room temperature. This memory not only has the potential to hold vast amounts of data, but because of quantum laws, any single bit can be both 1 and 0. This allows these systems to perform multiple calculations simultaneously (Morgan par. 1). Stephanie Simmons from Oxford University department of materials said, “[These] qubits [dual value bits] could prove very helpful for anyone trying to build a quantum computer” (qtd. in Morgan par.2). As we continue to develop the DRAM technologies originally developed in the 1970’s, these new technologies may in the future create entirely new computing architectures with capabilities as different just as revolutionary as those first MOSET designs. Conclusion RAM technology has come a long way from those early MOSFET designs created in the 1960’s and 1970’s. Those early designs allowed for a revolution in computing, allowing designers to create computing systems that quickly and securely managed data. This would have been impossible with the alternative tape and disk memory systems. The designers who made RAM a cornerstone of modern computing systems built upon those early designs by increasing RAM size and speed. As RAM systems became larger, new standards for data transfer and architecture such as DIMM and DDR allowed DRAM, the most common RAM type, to enter new fields and systems. All along this development path, designers and developers in the US and abroad drove this race toward greater security, speed, and efficiency. In the early days, US designers and manufacturers dominated the industry. However, as the industry matured, new competitors from abroad and especially Japan made innovative technical and manufacturing designs that propelled Morin 17 them into the RAM industry forefront. In particular, Samsung, the current industry leader, leads production and development of current RAM chips. Throughout all these changes in technology and business, the basic concepts of RAM have stayed the same. However, this may change. New technologies are pushing the boundary of how small we can design circuits and how we fundamentally interact with computing systems. These changes may usher in a new era as revolutionary to the computing industry as those original RAM designs. Morin 18 References Chang, Jaci. Design Considerations for the DDR3 Memory Sub-system. Jedex San Jose 2004, SanJose. Samsung Electronics, 2004. Print. Clayton, James. "Single In-Line Memory Module." United States Patent 4727513. Feb. 23, 1988. Print. Cosoroaba, A.B. "Double data rate SYNCHRONOUS DRAMs in high performance applications." 1997. 387-391. Print. Fujisawa, Hiroki, et al. "1.8-V SOO-Mb/s/pin DDR2 and 2.5-V 400-Mb/s/pin DDRl Compatibly Designed 1Gb SDRAM with Dual Clock Input Latch Scheme and Hybrid Multi-Oxide Output Buffer." 2004 Symposium On VLSl Circuits Digest of Technical Papers, (2004): Print. Hu, Chenming. Modern Semiconductor Devices for Integrated Circuits. University of California, Berkeley, 2010. Print. Ikeda, H. and H. Inukai. "High-speed DRAM architecture development." Solid-State Circuits, IEEE Journal of, 34. 5 (1999): 685-692. Print. JEDEC. DDR3 Unbuffered SO-DIMM Reference Design Specification. 2013. 4.20.18. Print. JEDEC. DDR2 SDRAM SPECIFICATION. 2009. 79.2-F Print. Kang, Wang, Weisheng Zhao, Zhaohao Wang, Yue Zhang, J Klein, Claude Chappert and D Ravelosona. "DFSTT-MRAM: Dual Functional STT-MRAM Cell Structure for Reliability Enhancement and 3D MLC Functionality." IEEE, Print. Kang, Joonkyu. "A study of the DRAM industry." Diss. MIT, 2010. Print. Keitel-Schulz, D. and N. Wehn. "Embedded DRAM development: Technology, physical design, and application issues." Design Test of Computers, IEEE, 18. 3 (2001): 7-15. Print. Kirihata, Toshiaki, et al. A 113mm2 600Mb/s/pin 512Mb DDR2 SDRAM with Vertically-Folded Bitline Architecture. ISSCC 2001 / SESSION 24 / DRAM, ISSCC 2001, 2001. 24.3. Print. Morin 19 Kiyoo Itoh, B.S. "The History of DRAM Circuit Designs - At the Forefront of DRAM Development;." Solid-State Circuits Society Newsletter, IEEE, 13. 1 (2008): 27-31. Print. Lee, Byoungil and H-SP Wong. "Fabrication and characterization of nanoscale NiO resistance change memory (RRAM) cells with confined conduction paths." Electron Devices, IEEE Transactions on, 58. 10 (2011): 3270--3275. Print. Moore, Gordon E. "Intel - memories and the microprocessor." Daedalus 125.2 (1996): 55+. Biography in Context. Web. 22 Feb. 2014. Morgan, James. "Quantum 'world record' smashed." BBC News, 2014. Web. 12 Apr 2014. <http://www.bbc.com/news/science-environment-24934786>. Nowozin, Tobias, Martin Geller and Dieter Bimberg. "Quantum Dot-Based Flash Memories." CRC Press, (2013): 183--200. Web.http://dx.doi.org/10.1201/b16236-11. Paulson, Linda Dailey. "Faster RAM tackles data and marketplace bottlenecks." Computer, 35. 4 (2002): 17-19. Print. Phipps, Charles. "Oral History of Charles Phipps." Interview. By Rosemary Remacle. 5/28/2009. 2009. Web. 22 Mar. 2014. Samsung Corp. "SAMSUNG." Samsung, 2014. Web. 23 Feb 2014. <http://www.samsung.com/us/aboutsamsung/samsung_group/history/>. Shah, Agam. "Intel set to bring next-gen DDR4 DRAM memory to computers later this year | PCWorld." PCWorld, 2014. Web. 4 Mar 2014. <http://www.pcworld.com/article/2085880/intel-set-to-bring-ddr4-dram-to-computers -in-third-quarter.html>. TI Corp. "Texas Instruments History of Development." Ti.com, 2014. Web. 23 Feb 2014. <http://www.ti.com/corp/docs/company/history/timeline/popup.htm>. WANG LABORATORIES, INC., Plaintiff-Appellant, v.MITSUBISHI ELECTRONICS AMERICA, INC. and MITSUBISHI ELECTRIC CORPORATION UNITED STATES COURT OF APPEALS FOR THE FEDERAL CIRCUIT. 2007. Print. Williams, Martyn. "New types of RAM could revolutionize your PC." PCWorld, 2014. Morin 20 Web. 2 Mar 2014. <http://www.pcworld.com/article/2084240/new-types-of-ram-couldrevolutionize-your-pc.html>.