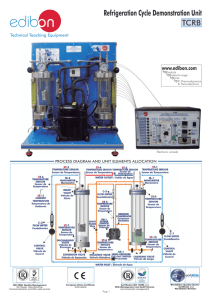

Refrigeration Cycle Demonstration Unit R634

advertisement

P.A.Hilton Ltd Refrigeration Cycle Demonstration Unit R634 Figure 1: R634 Unit shown with R634A and R634B fitted Ozone friendly, low pressure, non-toxic working fluid allows evaporation and condensation to be safely observed in glass cylinders. A Bench top unit specifically designed for unsupervised operation. Fast response to controls allows efficient use of laboratory time. Negligible operating and maintenance costs. Two-year warranty. Page 1 of 5 Version 3 P.A.Hilton Ltd Experimental Capabilities Demonstration of the vapour compression refrigeration and heat pump cycle with visual observation of all-important processes. Investigation and demonstration of the pressure-temperature relationship during evaporation and condensation. Demonstration of: Charging Pumping over or pumping down the refrigerant charge into the condenser. The effect of air in refrigeration systems. Determination of effect of evaporating and condensing temperatures on the refrigeration rate and condenser heat output. Investigation of the effect of compressor pressure ratio on system performance. Determination of overall heat transfer coefficient in a simple shell and tube type heat exchanger. With the addition of the optional temperature indicator R634A: Development of a refrigeration cycle diagram on a pressure - enthalpy chart. With the addition of the optional digital wattmeter R634B: Measurement of the electrical power used to drive the vapour compression refrigeration and heat pump cycle. Insert 2: Optional Digital Wattmeter Upgrade R634B Insert 1: Optional Digital Temperature Indicator upgrade. R634A Page 2 of 5 Version 3 NOTE: The policy of P.A.Hilton Ltd is one of continual improvement and we reserve the right to change this specification without notice. P.A.Hilton Ltd Special Design Features Specifically designed for safe unsupervised operation by students. Low-pressure non-toxic working fluid (Pentafluorobutane / Perfluoropolyether ) enables both evaporation and condensation to be safely observed in glass components. No Ozone Depleting Potential and non- flammable working fluid allows world wide support with no shipping restrictions. Self contained bench top unit requiring only minimal electrical power and cooling water. Visual impact of the unit aids student understanding of a complex process. Low thermal inertia allows a large range of experiments to be carried out in a short period. Optional factory, or user fitted, upgrades to give digital temperature readout (R634A) and compressor electrical power consumption (R634B). Description The vapour compression refrigeration and heat pump cycle is of paramount importance in food and drug preservation, air conditioning, heat pumps as well as other industrial and commercial process. The importance of the efficient and safe use of refrigeration systems has now been added to by the problems of ozone depletion and global warming. It is therefore more essential than ever before that students have a thorough understanding of both the practical aspects of refrigeration and the thermodynamic processes affecting the performance of the cycle. Often the most difficult aspect for new students to grasp is the process of evaporation at low pressure and condensation at high pressure. By utilising a non-toxic working fluid with a low vapour pressure, the evaporation and condensation processes are clearly visible in thick walled glass chambers. The evaporator consists of a closed, thick walled glass chamber containing a pool of working fluid into which is immersed a specially treated copper coil. An hermetic compressor draws vapour from the evaporator and compresses this before discharging it to the condenser. The reduction in evaporator pressure causes the refrigerant to boil, so extracting heat from the water flowing through the coil and generating more vapour to be drawn into the compressor. From the compressor the high-pressure vapour passes to the condenser, which is of similar construction to the evaporator but contains a nickel-plated water-cooled copper coil. Vapour condenses on the surface of the coil and falls to the bottom of the chamber. The heat given up by the refrigerant phase change is transferred to the cooling water flowing through the cooling coil. A float controlled expansion valve at the base of the condenser chamber controls the flow of high pressure refrigerant liquid returning to the evaporator. After passing through the expansion valve the refrigerant expands to form a liquid vapour mixture at the same pressure as the evaporator and the cycle is repeated. The standard instrumentation fitted enables measurement of the condenser and evaporator pressures and temperatures as well as water flow rates and water temperatures. The condensing and evaporating pressures are varied by adjustment of the water flow rate to the evaporator and condenser coils using integral control valves on individual flowmeters. An optional Digital Temperature Indicator Upgrade R634A, allows the measurement of the above temperatures plus the compressor discharge and condensed liquid temperatures to 0.1C resolution. The addition of these parameters allows a complete refrigeration cycle diagram to be plotted on an SES36 Pressure-Enthalpy Diagram. An optional Digital Wattmeter Upgrade R634B allows measurement of the instantaneous electrical power being consumed by the compressor. Range 0-1999W resolutions 1 W. Page 3 of 5 Version 3 NOTE: The policy of P.A.Hilton Ltd is one of continual improvement and we reserve the right to change this specification without notice. P.A.Hilton Ltd Figure 2: Data showing pressure temperature relationships for refrigerant Pressure vs Temperature at Saturation with Experimental data 300 Vapour Pressure Condenser Data Saturation Vapour Pressure (kNm-2) 250 Evaporator Data 200 150 100 50 0 0 10 20 30 40 50 60 70 80 Saturation Vapour Temperature (°C) Figure 3: Data showing the effect of air in refrigeration systems Vapour Pressure and Temperature in the Condenser, With and Without Air Present 300 Saturation Vapour Pressure (kNm-2) 250 200 150 100 50 Vapour Pressure Condenser Pressure (Without Air) Condenser Pressure (With Air) 0 0 10 20 30 40 50 60 70 80 Saturation Vapour Temperature (°C) Page 4 of 5 Version 3 NOTE: The policy of P.A.Hilton Ltd is one of continual improvement and we reserve the right to change this specification without notice. P.A.Hilton Ltd Specification Electrical Specification General Refrigeration Cycle Demonstration Unit with lowpressure non-toxic refrigerant and water cooled cylindrical glass evaporator and condenser. Either: Detailed A bench mounted vapour compression refrigeration cycle demonstration unit using a hermetic compressor and water cooled flooded glass condenser and evaporator. Unit operates on low-pressure non-toxic ozone friendly refrigerant. Internal electrical and mechanical safety devices allow for unsupervised operation by students. Standard instrumentation fitted enables measurement of the condenser and evaporator pressures and temperatures as well as water flow rates and water temperatures. Unit supplied with a detailed experimental operating and maintenance manual giving example experimental results and sample calculations. Equipment supplied with spares and accessories for two years normal operation together with a full twoyear warranty. Further specification details available on request A: 220/240V Volts Single Phase 50Hz (with earth/ground) B: 110/120 Volts Single Phase 60Hz (with earth/ground) Or Shipping Specifications Net Weight: 64kg.(220/240v) 71kg (110/120v) Approximate Gross Weight: 100kg (220/240v) 107kg (110/120v) Packing Case Dimensions: 0.92 x 0.65 x 1.05m Packing Case Volume: 0.63m3 Accessories and Spares Unit supplied with: One experimental operating and maintenance manual in English, French, or Spanish (Other languages on request). Accessories and spares for 2 years normal operation. Also Available On Request An optional digital temperature indicator upgrade allows measurement of all system temperatures to 0.1C with the addition of compressor discharge and condensed liquid temperatures so enabling a cycle diagram to be drawn on a Pressure-Enthalpy chart. Further detailed specification. Additional copies of instruction manual. Recommended list of spares for 5 years operation. Services required P.A.HILTON Ltd. Electrical: A: 220/240 Volts Single Phase 50Hz (with earth/ground). Line current up to 4.5A at 230v. B: 110/120 Volts Single Phase 60Hz (with earth/ground). Line current up to 9.0A at 115v Water: 6 litre/minute at a minimum of 28m head. Horsebridge Mill, King’s Somborne, Stockbridge, Hampshire, SO20 6PX, England. Fax: National (01794) 388129 International +44 1794 388129 Ordering Information E-mail: Website: sales@p-a-hilton.co.uk www.p-a-hilton.co.uk Order as: R634 Refrigeration Cycle Demonstration Unit Optional extras: R634A Digital Temperature Indicator Upgrade R634B Digital Wattmeter Upgrade Telephone: National (01794) 388382 International +44 1794 388382 Page 5 of 5 Version 3 NOTE: The policy of P.A.Hilton Ltd is one of continual improvement and we reserve the right to change this specification without notice.