road pavements - unbound, cement and other

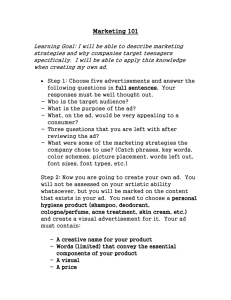

advertisement