UBC Sustainable Bollard - UBC Sustainability

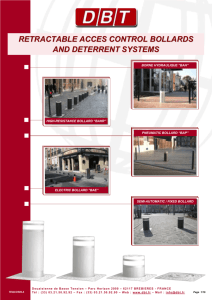

advertisement