Chapter 6. Fracture, Fatigue and Creep.

advertisement

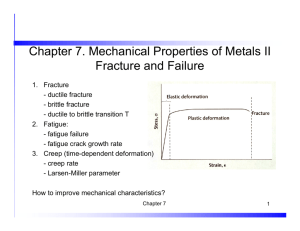

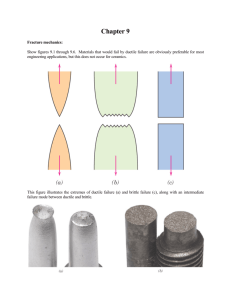

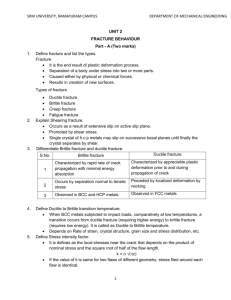

Chapter 6. Fracture, Fatigue and Creep. After studying this chapter you will be able to: • • • • • • • Distinguish between ductile and brittle fracture. Describe a stress concentrator (also called stress raiser) and the danger it represents. Distinguish between the resistance to deformation and to fracture, and name their units. Explain why hard materials are more brittle than soft metals. Explain why ceramics are unreliable in tensile stresses. Describe fatigue, its mechanism, its consequences and what can be done to the material in order to improve fatigue resistance. Measure and describe creep and name the important engineering situations where it plays a major role. Under certain circumstances, materials break. Fracture is a failure that can cost human lives, lead to the destruction of costly structures or machines or interfere with manufacture. If we want to avoid fracture, we must know how and under what conditions materials break and what can be done to prevent it. In this chapter we will discuss the ductile and brittle fracture of metals and the fracture of ceramics and glasses, which is always brittle. We will examine the concept of stress concentration and learn why strong and hard materials are brittle while softer materials are capable of absorbing much more energy before they break. Finally, we will examine the phenomena of fatigue and creep which can lead to failure at stresses well below the yield stress, where one would expect the piece to be safe. Figure 6.1. Schematic Stress-strain curve of a metal. 6.1. Ductile Fracture of Metals. Let us look again at the stress-strain curve of a metal (Figure 6.1). After a certain amount of plastic deformation, a neck forms in the tensile test specimen, the force for further deformation decreases and, finally, the piece breaks. When fracture occurs after extensive plastic deformation, the test piece fails by ductile fracture. Ductile metals neck and display the cup-cone fracture morphology shown in Fig.6.2. A. The process of ductile fracture may be broadly viewed in terms of the sequential microvoid nucleation and growth processes, schematically indicated in Fig.6.3. Te earliest stage of fracture spawns isolated microscopic cavities. These nucleate at inclusions, second phase particles and probably at grain boundary junctions. Microvoids coalesce then form an elliptical crack that spreads outward toward the periphery of the neck. Finally, an overloaded outer ring of material is all that is left to connect the specimen halves, and it fails by shear. Further examination reveals equiaxed or spherical dimples on the flat crater bottom loaded in tension, and elongated ellipsoidal dimples on the shear lips oriented at 45o (Fig.6.4). In high purity FCC and BCC metals free of inclusions, necking to ~ 100 percent area reduction (i.e., to a point) is possible. A B Figure 6.2. Fracture of metallic tensile test specimens. (A) Ductile Fracture. (B) Brittle Fracture. Figure 6.3. Model of ductile fracture. From left to right: application of stress, nucleation of microvoids, coalescence of microvoids, formation of elliptical crack, shearing of collar and separation. Figure 6.4. Ductile fracture surface of a metal. 6.2.Brittle fracture of metals and ceramics. Brittle fracture is the most feared of all. It often occurs under static loading without advance warning of impending catastrophe. Figure 6.2.B shows a metal bar that failed by brittle fracture. Higher magnification reveals that transgranular cracking often occurs during brittle fracture, especially at low temperatures. In such cases the crack propagates across the grain interiors. (Figure 6.5A) When cracks propagate along grain boundaries, we speak of intergranular fracture. Such failures (Fig.6.5B) reveal clearly outlined grains that appear to be deeply etched or stand out in relief like rock-candy. 6.2.1. Cracks and stress concentrations. We are not capable of predicting the initiation of a crack, but once a crack exists, fracture mechanics describes its propagation. Cracks at the surface or the interior of objects under load generate local stresses that are much larger than the stress one would compute from the force and the geometry of the piece. This fact is illustrated in Fig.6.6 where a body (plate) containing elliptical shaped surface and interior holes or cracks, is pulled by uniaxial forces, F. The undisturbed force lines in the defect-free portion of the plate mean that the stress distribution is uniform there at a level σa. The force lines are concentrated in the vicinity of cracks; stress is magnified there because there are effectively more force lines per unit area. At the tip of the crack of half-length c and radius of curvature ρ, the local tensile stress is σ = σa 2(c/ρ)1/2 (6.1) Figure 6.5. (A) Scanning electron microscope image of transgranular brittle fracture in Fe-2.5 wt% Si tested at -195oC. (B) Scanning electron microscope image of intergranular fracture in a nickel-based superalloy. Courtesy of G.F. Vander Voort, Carpenter Technology Corporation. Figure 6. 6. The concentration of tensile stresses around internal and surface cracks in a uniformly stretched solid. Parallel lines denote uniform stress. A stress concentration factor k σ, can be defined as the ratio of amplified local- to background stress, i.e., kσ = σ/σa. For flat elliptical surface cracks the maximum value of kσ is at the crack tip and given by kσ = 2 (c /ρ)1/2. (6.2) Here c is half the length of the major axis and ρ is the radius of curvature at the crack tip. It is apparent that longer and sharper cracks raise kσ. This has important consequences for the design of pieces that must sustain a load and for the mechanical properties of materials. 1. A crack or a notch is a stress concentrator. If the radius of curvature ρ is small enough, the local stress is many times larger than the average stress; it can be large enough to rupture bonds and lead to the propagation of the crack. 2. The propagation of a crack can be arrested by increasing the radius ρ. In a plate, for instance, a crack can be arrested by drilling a hole of sufficient diameter. 3. In soft metals (with a low yield stress) plastic deformation under the local 4. 5. 6.3. stress σ increases the radius ρ (i.e. blunts the crack) and the stress concentration: the crack is arrested. In hard materials, this plastic deformation does not take place, the stress concentration is large and the crack propagates. As a rule, hard materials are brittle and soft materials are ductile. A look at figures 5.18 and 5.22 shows that strengthening a metal decreases its ductility. Ceramic materials are very hard and do not deform plastically under tensile stress, but break abruptly after elastic deformation. Ceramic materials and glasses are brittle. Ceramic materials contain small cracks as a consequence of their processing. The length of these cracks cannot be controlled and the stress concentration factor kσ is poorly known, therefore the average (design) stress σa that leads to fracture in a ceramic cannot be determined with certainty. Ceramics are unreliable in tension; they should be designed in such a way that they are subjected to compressive stresses only. This will be immediately apparent when we compare the shapes of a stone bridge and a steel bridge. Fracture Toughness. The resistance to fracture is known as the critical stress intensity factor or fracture toughness __ KIC = Yσ√πc. (6.3) The fracture toughness represents the combination of stress and crack length at which a crack propagates. When K < KIC, the crack is stable. But when K> KIC the crack is unstable and will rapidly open. Y is a numerical factor that depends on the geometry of the crack. Y = 1 for the through crack in the body of the specimen (Figure 6.6) and Y = 1.1 for a crack at the surface of a plane specimen. The fracture toughness has dimensions MPa√m or ksi√in. 1 ksi√in = 1.1 MPa√m. Values of KIC for a number of materials are entered in Table 6.1. The high values of KIC for metals are due to the plastic zone at the crack tip. Among the important trends gleaned from this table are the following: 1. Glasses and simple metal oxides have the lowest values of KIC. They are typically a 10 -100 times smaller than fracture toughness values for ductile metals. 2. KIC for some of the toughened ceramics are much higher than for glasses but are still well below (by a factor of ~10) the level for metals. EX.7-7 What is the ratio of the critical crack sizes in aluminum relative to aluminum oxide when stressed to their maximum respective elastic stresses? ANS. At the maximum elastic stress, σ = σy (the yield stress), and c = 1/π (KIC /σy)2. The required ratio is From Table 7-5, for Al: KIC = 44 MPa-m1/2 and σy= 345 MPa, and for Al2O3: KIC = 3.7 MPam1/2 and σy = 270 MPa. (This is not a yield stress, alumina does not deform plastically; it is the fracture stress of alumina which we will discuss later). For aluminum, the crack length is 5.3 10-3 m = 5.3 mm. In aluminum oxide, the crack length is 6 10-5 m = 60 µm, which is 85 times shorter. The different response to flaw size of metals relative to ceramics can be qualitatively understood from this example. Large cracks in the more defect - tolerant metals can often be detected during inspection and possibly repaired by sealing them shut. But, the much smaller flaws of critical size in ceramics are more effectively hidden and easier to overlook, a combination that makes ceramics fracture prone in service. 6.3.The measurement of fracture resistance. 6.3.1. Fracture toughness To determine KlC values of materials, specimens in the form of plates are fashioned containing machined cracks of known length as shown in Fig. 6.7a. As tensile loads are applied the specimen halves open, and the resulting crack extension is continuously monitored (Fig.6.7b). Noting the critical crack size and stress necessary to induce fracture, use of Eq.6.3 yields the value for KlC. The measured toughness of a metal depends on its size. Ductile metals require large specimens for reliable fracture toughness measurements, brittle materials can be measured with smaller specimens. Figure 6.7. Measurement of fracture toughness. 6.3.2. Indentation Toughness of Ceramics. For routine measurements of toughness, the fabrication of ceramic samples as shown in figure 6.7 is expensive. A more convenient but less reliable measurement is afforded by high-load Vickers indentations. When a material is brittle and the indentation is made at sufficiently high load (minimum 20 Newton, but generally 100 Newton or 10 kg), radial cracks form at the tip of the indentation. (A figure 6.8 will be provided soon.) Empirical equations provide the fracture toughness from a measurement of the crack length and the hardness provided by the indent. Such measurements, while not as precise as the one described above, have the advantage of being convenient and allowing to measure local variations of hardness. The method cannot be used with metals which are too ductile to form radial cracks. Figure 6.8. Vickers indentation in a ceramic. The size of the indentation determines the hardness, as described in Chapter 5. The length of the radial cracks is used to measure the toughness. 6.3.3. Charpy and Izod Measurements of Notch Toughness. The widely used Charpy impact test is a standard way to assess toughness in notched specimens. In this test a standard bar specimen, with a square cross section and a V- shape notch cut into it, is strained very rapidly to fracture by means of a swinging, pendulum-like hammer (Fig.6.9). The difference between the initial and final potential energies of the hammer (measured by the initial and final hammer heights), is the impact energy absorbed by the specimen. Charpy and Izod test methods differ only in the position of the sample as shown in figure 6.9. Figure 6.9.Impact toughness tests. (A) Specimen used for Charpy and Izod impact tests. (b) A schematic of an impact testing machine. The hammer of weight W is released from height h breaks the sample as it swings and stops at height h’. The difference in potential energies: W (h-h’) is the impact toughness. Charpy and Izod tests differ in the placement of the specimen as shown. Chirpy and Izard impact toughness values measure the energy needed to fracture the specimen and are expressed in foot-pounds (ft-lb). They are more convenient but less reliable than the fracture toughness tests of figure 6.7. 6.3.4. Rupture Strength of Ceramics. Ceramics are brittle, they do not deform plastically under tensile stress but fracture. The strength of ceramics is often measured in a bend test shown in figure 6.10. F F F F Figure 6.10. Four point bend test. A thin plate of ceramic is placed between four cylinders to which forces are applied as shown in the figure. These forces tend to bend the plate elastically and generate a tensile stress on the lower surface. Once the stress is large enough, the plate fractures. The stress at which the plate fractures has several names: flexural strength, modulus of rupture, fracture strength or bend strength. Flexural strengths of several ceramics are shown in Table 6.2. Note that the flexural strengths, given in MPa or ksi, are indicated with a wide uncertainty. This is easy to understand with a look at equation (6.3). The toughness of ceramics is a reasonably well defined quantity. It involves a stress (which is measured in the bend test) and a crack length. The dispersion in fracture stresses stems from the random occurrence of small cracks the length of which is not known. 6.4. Ductile to Brittle Transition Temperature. Steels often display an alarming drop in notch toughness resistance at the socalled transition temperature. This is shown in Fig.6.11 for several types of ship steels used during the Second World War, when all too many ships suffered brittle fracture of varying severity. In these ships the steels underwent a ductile to brittle transition too close to room temperature. This is one reason among others that, even today, structures like storage tanks, oil rigs and even ships fracture catastrophically more often in winter than in summer. Figure 6.10. Charpy impact energies of various World War II ship steels as a function of test temperature. Transition temperatures can be lowered through alloying. Reducing the carbon content of steel has a potent effect in this regard; it also raises the magnitude of the (absorbed) impact energy. Alloying with nickel is particularly beneficial in toughening steel and lowering the transition temperature. Alloying elements in steel affect toughness in complex ways depending on composition, matrix structure and heat treatment. Ductile face centered cubic metals are tough even at low temperatures and do not exhibit a ductile-to-brittle transition. Table 6.2 from Callister. 6.4. Fatigue Fatigue is the failure (by fracture) of structures that are subjected to repeated or cyclic loading. By cyclic loading we mean almost any reasonably periodic stress-time variation, e.g., (a) axial tension-compression, (b) reversed bending and (c) reversed torsion or twisting. Undetected flaws or incipient cracks grow to macroscopic dimensions through incremental propagation during each stress cycle and the component quickly undergoes fracture without warning when a crack of critical size is reached. This sequence of events has been repeated in components of rotating equipment such as motor and helicopter shafts, train wheels and tracks, pump impellers, ship screws and propellers, and gas turbine discs and blades. Even surgical prostheses implanted into the human body have suffered fatigue failure in service. What is difficult to design against is the fact that under cyclic loading, failure can occur significantly below the tensile or yield stress σy of the material. Fatigue of materials is measured by means of a fatigue testing machine (Fig.6.12). A bar specimen that narrows in diameter toward the middle is mounted horizontally and rotated at high speed with a motor. A hanging load tilts the grips so that reversed bending moments are transmitted to the specimen, stressing its surface alternately in tension and compression during rotation. This test provides a sinusoidal loading about a zero mean stress level (Fig.6.12b). For the case of arbitrary sinusoidal loading, maximum (σmax.), minimum (σmin.), mean (σm) stress, and stress range (σr) values are defined in Fig.6.12c. The number of rotations to failure is counted at specific specimen stress amplitude. Then a new specimen is mounted, a different load is chosen yielding a new Figure 6.12. (A) Fatigue testing machine. (B) Sinusoidal loading. (D) Arbitrary loading with definition of mean, maximum, minimum stress and stress amplitude. Figure 6.13 S-N data for various metals and polymers. peak stress level and the number of cycles to failure is determined once again, etc. In this tedious manner sufficient data points are accumulated to generate an S-N (or stressnumber of cycles) curve. Amid a typically large scatter band, the S-N response for assorted materials is displayed in Fig.6.13. Here S is the stress and N the number of cycles to failure. Most steels can rotate indefinitely below a stress level known as the endurance or fatigue limit (the curve horizontal). Some high strength steels and many non ferrous metals (e.g., Al and Cu), on the other hand, do not exhibit an endurance limit. Polymers display similar fatigue characteristics. To guard against fatigue, stress levels should not exceed 1/3 σUTS. Combating fatigue damage is fairly straight forward once it is recognized that the following factors affect fatigue strength in adverse ways: 1. Stress Concentrators. Keyways on shafts, holes, abrupt changes in cross sections, sharp corners etc., all stress raisers, are design features that should be avoided in components subjected to repetitive loading. Stress concentrators mean operation at higher stress levels on the S-N curve (Fig.6.13). This in turn reduces the number of stress cycles to failure. 2. Polished Surfaces. Crack nucleation is facilitated at micro-crevices and grooves on rough surfaces. Grinding, honing and polishing of surfaces remove these sources of potential cracks. 3. Residual Stresses. Residual stresses at the surface add themselves to the applied stress: residual tensile stresses reduce fatigue life. Residual compressive stresses in surface layers, introduced by shot peening or diffusion, higher levels of applied tension can be tolerated. As a result, fatigue strength and life can be increased. 4. High Strength Surfaces. Strengthening surfaces can enhance fatigue resistance; carburization and deposition of hard coatings are ways to achieve this. 5. Corrosion and Environmental Attack. Localized chemical attack will always reduce fatigue life. Metal removed from exposed grains and grain boundaries leave a generally rough surface, pits and corrosion products behind, that serve as incipient cracks. 6.5 Creep At temperatures of about half the melting point (0.5TM) and above, materials undergo time dependent plastic straining when loaded. This phenomenon is known as creep; it can occur at stress levels less than the yield strength! The extension of an involved component may eventually produce a troublesome loss of dimensional tolerance or even ultimately lead to catastrophic rupture. Turbine blade creep due to the inhospitable temperatures of a jet engine is an often cited example. High pressure boilers and steam lines, nuclear reactor fuel cladding, ceramic refractory brick in furnaces are components and systems that are also susceptible to creep effects. Creep tests are performed on round tensile-like specimens that are stressed by fixed suspended loads while being heated by furnaces which coaxially surround them. The typical response obtained in a creep test is shown in Fig.6.14, where the specimen elongation or strain is recorded as a function of time. There is an initial elastic extension or strain the instant load is applied. Then a viscous-like plastic straining ensues in which the creep strain rate (dε /dt) decreases with time. This primary creep period then merges with the secondary creep stage where the strain rate is fairly constant. Alternately known as steady state creep, this region of minimum creep normally occupies most of the test lifetime. Finally the strain rate increases rapidly in the tertiary creep stage leading to rupture of the specimen. Figure 6.14. Schematic of creep. Bottom: elongation as a function of time. Top: strain rate as a function of time. Engineers perform two types of tests. The first aims to determine the steady state creep rate over a suitable matrix of stress and temperature. These tests are performed at the same stress but at different temperatures, as well as at the same temperature but different stresses, as shown in Fig.6.15. Specimens are usually not brought to failure in such tests; accurately predicting their extension is of interest here. The second, known as the creep rupture test, is conducted at higher stress and temperature levels in order to accelerate failure. Such test information can either be used to estimate short term life (e.g., turbine blades in military aircraft), or be extrapolated to lower service temperatures and stresses (e.g., turbine blades in utility power plants) to predict long term life. Figure 6. 15. Creep strain versus time in a 0.5 wt% o, 0.23 wt% steel. (A) Constant stress, variable temperature. (B) Constant temperature, variable stress. From A.J. Kennedy, Processes of Creep and Fatigue in Metals. Wiley, New York (1963) 6.5.1. Steady State Creep. Much engineering design is conducted on the basis of steady state creep data. Since the creep strain rate is accelerated by both temperature and stress, a useful phenomenological equation that succinctly summarizes the data of Fig.6.15 and reflects the role of these variables is ε = A σmexp - Ec / kT. (6.4) A and m are constants; the exponential term is the Boltzmann factor that reflects the thermally activated nature of creep. Ec is the creep activation energy; it is close to the activation energy for bulk diffusion. m, a constant, typically ranges in value from 1-5. EX. 6.2 Determine Ec and m for the data shown in Fig.6-14. ANS. The steady state strain rate is the slope of the strain-time response. Limiting the calculation to only the maximum and minimum slopes for the superimposed lines, the following results are tabulated: Test Temperature (C) Stress (psi) 1. 670 (= 943K) 9000 Strain Rate (h -1) (2.5-0.28) X10-3/ (370-0) = 6X10-6 2. 3. 4. 615 (= 888K) 645 (= 918K) 645 (= 918K) 9000 11200 6700 (0.56-0.2) X10-3/ (400-0) = 9X10-7 (1.5-0.6) X10-3/ (200-0) = 4.5X10-6 (0.5-0.25) X10-3/ (400-0) =6.25X10-7 To determine Ec, data from tests 1 and 2 are utilized. From Eq.7-29, ε (1) / ε (3) = (exp -Ec / kT1) / (exp -Ec / kT3) or Ec = k T1T2 / (T1 - T2) ln [ε(1) / ε(2)]. Substituting, Ec = 8.31 J/mol-K (943X888 / 55) Xln [6X10-6 / 9X10 -7] = 240 kJ / mol. Similarly, using test data 3 and 4, ε(3) / ε(4) = (σ3/σ4)m / ε(4)) and m = ln (ε(3) / ln (σ3/σ4). After substitution m = ln (4.5X10-6/6.25X10-7) / ln (11200 / 6700) = 1.01. Knowing Ec and m enables ε to be evaluated at any other temperature and stress level. 6.5.2. Creep Rupture Creep or stress rupture test data are normally plotted as the stress versus rupture time (tR) on a log-log plot as shown in Fig.6.16. Each data point represents one test at a specific temperature and stress level. Given sufficient testing at different temperatures, a complete profile of the material response is obtained. Figure 6.16. Creep - rupture data of Incoloy 800, an iron-based alloy containing 30 wt% Ni and 19 wt% Cr. Source: Huntington Alloys Inc. Several mechanisms have been identified for creep, depending on the stress level and temperature. At stresses below the yield stress σy and at high temperature, diffusion of atoms or vacancies dominate. Observations of creep failure often reveal the dominant role grain boundaries play in the phenomenon. By diffusion of atoms in the grain boundaries, the grains slide past each other. For this reason, modern jet engine turbine blades are grown as single crystals by a method of directional solidification. Stainless steels and superalloys containing nickel and cobalt are notoriously creep resistant. Recapitulation. 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) Ductile fracture occurs after extensive plastic deformation. It occurs by the formation and coalescence of voids and shearing. Brittle fracture occurs by the propagation of cracks that usually nucleate at the surface. Toughness is the resistance to fracture. The units of fracture toughness are MPa√m or ksi√in. 1 ksi√in = 1.1 MPa√m. Cracks, indentations and sharp interior corners constitute stress concentrators that lead to crack propagation. The toughness of ceramics is well defined, the fracture stress is not because of the presence of cracks of unknown length. Fatigue is the failure of materials that is due to repeated, cyclic application of a stress. Fatigue failure can occur at stresses below the yield stress. Steels and some materials exhibit a fatigue limit. This is a stress below which fatigue does not occur. Fatigue resistance can be increased by avoiding stress concentrators in design, polishing the surfaces and introducing compressive residual stresses. Creep is the slow plastic deformation due to diffusion of atoms at high temperatures (T > ½ melting temperature). Creep occurs at stresses below the yield stress. Note the difference: plastic deformation is not dependent on time; modern manufacturing exploits the fact that metals can be shaped very rapidly. Creep is a viscous-like deformation and the stress governs the rate of deformation. In gas turbines of jet engines, creep is avoided by fabricating the turbine blades as single crystals. Problems and questions. 6.1 What is the difference between a. stress intensity and critical stress intensity b. strength and toughness c. cracks in metals and cracks in ceramics d. transverse - rupture strength and tensile strength? 6.2. Draw a stone bridge and a steel (railroad) bridge and explain the difference of their shapes in terms of their materials properties. 6.3. A plate of steel has a yield stress of 1000 MPa. The plate fractured when the tensile stress reached 800 MPa and it was therefore hypothesized that a surface crack was present. If the fracture toughness for this steel is 60 MPa-m1/2, approximately what crack size is suggested? 6.4. Big Bird Helicopter Company requires a stainless steel that is tough enough for use in the Tropics (120F) as well as the Arctic (-60F). They peruse this book and find the data of Fig.6.15. At the designed use stress, the component can tolerate a surface flaw of 0.080in at 120F. Manufacturing inspection equipment can only detect flaws that are larger than 0.050in. Will a fracture unsafe situation arise at -60F for the same loading? Figure 6.15. Fracture toughness and yield strength as a function of testing temperature. From Metals Handbook. American Society of Metals. Metals Park, OH 6.5 A steel cylinder containing CO2 gas pressurized to 1500 psi (10 MPa) is being transported by truck when someone fires a bullet that pierces it making a 1cm hole. a. Explain the conditions that might cause the steel to fracture violently with fragments flying off at high velocity. b. Similarly, explain the conditions that would cause the cylinder to release the gas relatively harmlessly. 6.6 Steady state creep testing of electrical solder wire yielded the indicated strain rates under the test conditions given. Test Temperature (C) 1 2 3 22.5 22.5 46 Stress (MPa) Strain Rate (sec -1) 6.99 9.07 6.99 From these limited data determine the creep activation energy (Ec) and stress exponent, m. 2.50X10-5 6.92X10-5 2.74X10-4 6.7 Incoloy 800 tubes are selected for use in a pressurized chemical reactor. If they are designed to withstand wall stresses of 2000 psi at a temperature of 900C predict how long they will survive. 6.8 Suppose the fatigue behavior of a steel is characterized by a two line response when plotted on an S- logN plot, namely 1. S(MPa) = 1000 - 100 logN ; between N = 0 to N = 106 stress cycles, 2. S(MPa) = 400 ; for N >106 stress cycles. a. Sketch the S - logN plot. b. What is the value of the endurance limit? c. How many stress cycles will the steel probably sustain prior to failure at a stress of 460 MPa? d. Elimination of surface scratches and grooves changed the endurance limit to 480 MPa. (Assume plot 1 is not altered). How many stress cycles will the steel probably sustain prior to failure at a stress of 470 MPa? How many stress cycles will the steel probably sustain prior to failure at a stress slightly above 480 MPa? 6.9. Assume the same stress develops in WC and Al2O3 tool bits during identical machining processes. Since crack formation is a cause of tool bit failure what is the ratio of the critical flaw dimensions in Al2 O3 that can be tolerated relative to WC? 6.10 The fracture toughness of a given steel is 60 MPa-m1/2 and its yield strength is given by σy(MPa) = 1400 - 4T where T is the temperature in degrees Kelvin. Surface cracks measuring 0.001m are detected. Under these conditions determine the temperature at which there may be a ductile-brittle transition in this steel. 6.11 The quenched and aged Ti-6Al-4V alloy used in the Atlas missile has yield points of 229 ksi at -320F, 165 ksi at -70 F and 120 ksi at 70F. Suppose small cracks 0.02 inch long were discovered on cryogenic storage containers made from this alloy whose fracture toughness is 50 ksi-in1/2. Estimate the ductile to brittle fracture transition temperature of this alloy. Would it be safe to expose these containers to liquid nitrogen temperatures (77K)? Assume the fracture toughness is independent of temperature. 6.12 An aluminum aircraft alloy was tested under cyclic loading with ∆σ = 250 MPa and fatigue failure occurred at 2X105 cycles. If failure occurred in 107 cycles when ∆σ = 190 MPa, estimate how many stress cycles can be sustained when ∆σ = 155 MPa.