File

advertisement

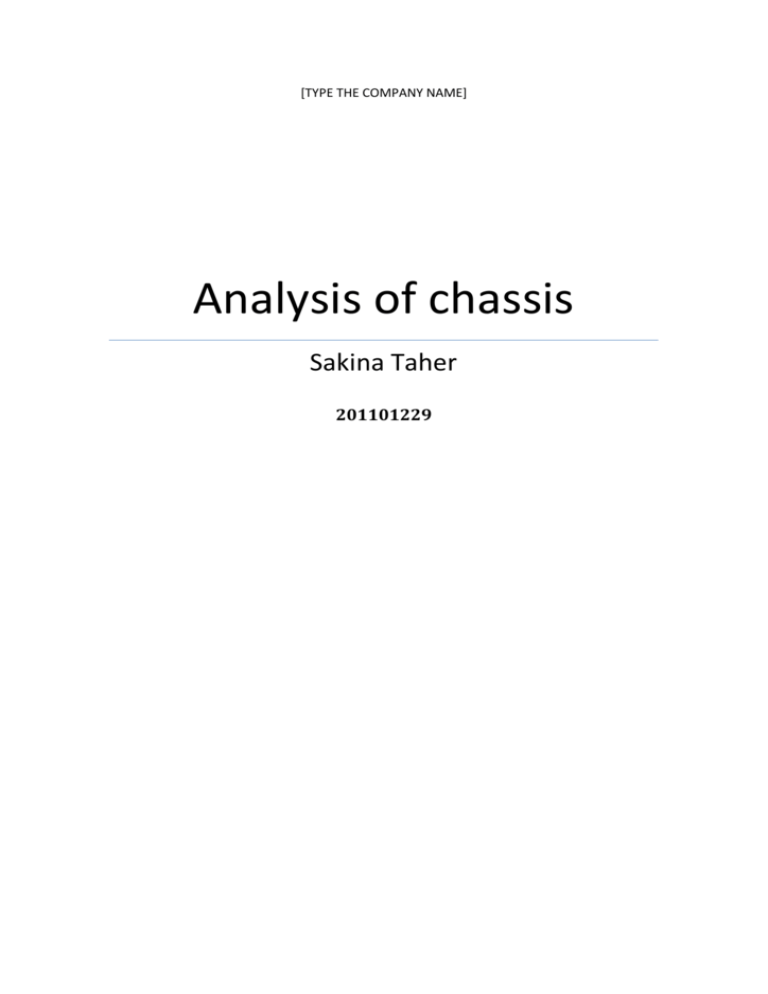

[TYPE THE COMPANY NAME] Analysis of chassis Sakina Taher 201101229 Summary of forces Mass(kg) 1 Weight(N) Size Height (mm) (mm) 150 Engine Transmission Radiator 210 50 2060.1 700 600 10 2 Battery 24 235.4 240 200 3 Wheels and tires 80 784.8/2=392.4 550 550 4 Chassis 45 441.5 3100 280 5 Passengers 140 1373.4 1530 600 6 Fuel tank 35 343.4 800 270 Total mass 534 5238.5 20% additional mass for seat, electrical system 106.8 1047.7 Total mass+ 20% additional mass for seat, electrical system 640.8 6286.2 Chassis +20% additional mass for seat, electrical system 151.8 1489.2 Table 1 Summary od forces. Tube properties Size of the tubes used 25x25 mm Thickness = 2 mm 20x20 mm Thickness = 2 mm Outer diameter =50 mm Inner diameter = 46 Outer diameter =38 mm s = 33 mm Inner diameter Mechanical properties of the tube (mild steel low carbonmm AISI 1020) Failure modes Failure modes are the physial processes that has an effect or combined effects to produce failure (defects in design, process, quality, or part application). Some of theses failures will be discussed in this section. Fracture Separation of a body into pieces due to stress, at temperatures below the melting point. First crack forms and then it propagates in the body, depends on the ability of the material to undergo plastic deformation before the fracture (Failure, 2014). Ductile fracture: Extensive plastic deformation before cracking The crack is stable and it can resist more extension if the applied stress is not increased. Brittle fracture: Little plastic deformation The crack is not stable and it propagates rapidly Ductile material: extensive plastic deformation and energy absorption before fracture. Brittle material: little plastic deformation and low energy absorption before fracture (Failure, 2014). Figure 1 Brittle Vs Ductile