tm 55-203 technical manual maintenance of railway car

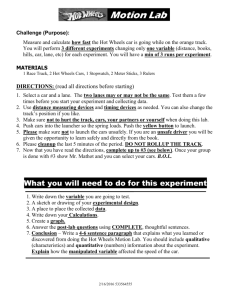

advertisement