A Proposed Systems Engineering Diagnostic Method

advertisement

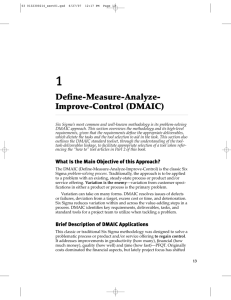

47th AIAA Aerospace Sciences Meeting Including The New Horizons Forum and Aerospace Exposition 5 - 8 January 2009, Orlando, Florida AIAA 2009-1006 A Proposed Systems Engineering Diagnostic Method John C. Hsu* The Boeing Company, Long Beach, California, 90846 S. Raghunathan† M. Price+ Queens University, Belfast BT95AH, Northern Ireland R. Curran# Delft University, Delft, The Netherlands I. Introduction The systems engineering was revitalized in the middle of 1990s. Increased participation using systems engineering processes and practices during the system development and demonstration phase is seen as key to implementing this new approach. Engineering and critical thinking is increasingly important in these revitalization efforts in resource management, skills management, and supplier management. The industry and government revitalization efforts including publishing systems engineering processes, methods and templates to guide people to implement systems engineering. In 2003 and 2004, Department of Defense (DoD) issued a number of policies that placed renewed emphasis on the application of rigorous Systems Engineering (SE), stating that it is essential to the Department’s ability to meet the challenge of developing and maintaining needed capability, noting that this is especially true as systems become more complex in a family-of-systems, systems-of-systems, and net-centric warfare context. In these complex systems, SE provides the integration/technical processes to define and balance performance, cost, schedule, and risk. Under Secretary of Defense (USD) stated in 2004, “We will select only contractors regardless of acquisition category who apply a robust systems engineering approach.” Michael W. Wynne, Acting USD for Acquisition, Technology and Logistics (AT&L), and Mark D. Schaeffer, Principal Deputy, Defense Systems and Director, Systems Engineering, Office of the USD AT&L (Ref. 1), called for the revitalization of systems engineering across the Department of Defense. A systems engineering plan is key to the revitalization of systems engineering in the business systems environment. The documented technical management approach within the business systems engineering process addresses the risks and concerns surrounding business systems programs and provides the tailored approach to effectively manage, design, test, and deploy critical business systems solutions. An important element in revitalization has been the acquisition management education program (Ref. 1). Leadership skills are also essential to developing successful systems engineering and acquisition management professionals. The Acquisition Leadership Development Program (ALDP) began in January 2004 for Acquisition Directorate systems engineers and program managers who demonstrated leadership potential. The SE revitalization campaign leads extensive educational training in learning SE (Ref. 2) for customers, contractors and universities. The contractors and customers work together to implement SE using acquired SE knowledge and processes. The systems engineering implementation is more challenge than understanding the system engineering process. The implementation of systems engineering requires a flawless interface between team members working toward a common system thinking to correctly execute systems engineering process. But the program cost overrun, schedule slippage and even failures were still high after more than 10 years of systems engineering revitalization efforts although it was gradually improved. The reason for slow pace of improvement is * Senior Staff, Systems Engineering, Advanced Systems, Integrated Defense Systems, The Boeing Company, MC C076-0228, 3855 Lakewood Blvd, Long Beach, CA, 90846, Adjunct Professor of California State University at Long Beach, Royal Academy Visiting Professor in Systems Engineering, Queens University, Belfast, Northern Ireland, and Associate Fellow. † Retired Professor and Bombardier Chair in Aeronautical Engineering, Queens University, Belfast BT95AH, Northern Ireland, and Associate Fellow. + Professor of Aeronautical Engineering, Queens University, Belfast BT95AH, Northern Ireland, Member. # Professor and Chair of Aerospace Management & Operations, Aerospace Engineering, Delft University of Technology, The Netherlands, and Senior Member. 1 American Institute of Aeronautics and Astronautics Copyright © 2009 by John C Hsu. Published by the American Institute of Aeronautics and Astronautics, Inc., with permission. not correctly implementing the systems engineering process. The SE implementation problems will be discussed in the next section. II. Implementation Issues SE knowledge and processes is not a rocket science and not hard to Inad equate derivation o f detailed requirements learn. But the Inad equate SE review of analysis assumptions for quality implementation of SE is a Collabo ration to assure solutions meeting their requirements team effort requiring Design integration problems contractors, subcontractors Ineffective identification and management of risks and acquirers to seamlessly Inad equate SE oversight of suppliers work together. Every team Lack definition of RAAs for key SE lead ership roles member has to execute to Poor requirements decomposition the common SE process and Over reliance o n specs and ICDs versus understanding of products method correctly. This is a Inadequate peer review big challenge that may be Poor (loo se) req uirements harder than finding solutions Perception that "test comes later" for rocket science. Poor subcontract Statement of Work Analyses of a sampling There is an inconsistent application/understanding of Systems Engineering of major acquisition programs show a definite Poor requirements up front linkage between escalating Lack of System Architects costs and the ineffective Lack of recognized authority as “over-arching” integration function application of systems Mismatch between subcontractor requirements and requirements development engineering. United States process Government Accountability Program management and IPT leads unaware of impo rtance of Requirements Office (GAO) (Ref. 3) found Management problems related to quality Risk Management Process Ownership and Execution Responsib ility are separate have resulted in major Supplier Risk Management process not properly executed o r estimated in the impacts to the 11 DOD proposal process weapon systems GAO Integrated flowdown of pro cess and requirements to Suppliers reviewed—billions in cost Lack of train ing of key Program personnel overruns, years-long delays, Inconsistent product documentation results in integrity and traceability issues and decreased capabilities Understand Customer needs for the warfighter. GAO’s PM’s/IPT leaders don’t have SE experience analysis of 11 DOD weapon SE should be an “arch” functio n integrating function for programs systems illustrates those defense contractors’ poor Table 1. Tabulation of Systems Engineering Implementation Issues practices for systems engineering activities as well as manufacturing and supplier quality problems contributed to these outcomes. DOD faces its own set of challenges—setting achievable requirements for systems development and providing effective oversight during the development process. DoD Project Management Institute cited the top 10 reasons projects fail A few of them are: changing requirements, inadequate specification, poor architectural design, etc. The most frequent SE implementation issues were listed in Table 1. There are many challenges to overcome the implementation issues. To quote from Einstein, “Insanity is doing the same thing over and over again and expecting different results”. The SE implementation.issues will have to be overcome. List of challenges is shown in Table 2. Most frequent Systems Engineering Implementation Issues III. Performance Measurements 2 American Institute of Aeronautics and Astronautics No process is complete without tracking progress and measuring (Ref. 1) the extent to which objectives have been achieved. The Systems 1. How can we highlight complexity and risk in early requirements engineering-specific balanced scorecard development and the budgeting process? metrics address such areas as posting 2. What are the best SE indicators and metrics and what is their mandatory artifacts, sharing best program effect? practices, conducting independent 3. How do we incorporate technology improvement into SE and SE technical assessments, and meeting planning? schedules. These and other related 4. What kind of contracting strategies are most “friendly” to help metrics to be reported on a quarterly foster SE? basis. 5. What new SE process areas will simplify SE implementation? Capability Maturity Model 6. How can we best leverage the development of Modeling and Integration (CMMI) is a tool to Simulation tools? determine the risk associated with 7. What domain specific studies can help implement SE? suppliers’ systems engineering 8. No significant domain training or mentoring to make new, processes. This method helps Defense multidisciplinary Systems Engineers. Contractor Management Agency 9. We need more qualified systems engineers. (DCMA) engineers to identify and 10. How to contain program complexity and program control? prioritize the most critical supplier 11. How to overcome cultural inhibitors? processes; to evaluate those processes 12. Where does sustainment fit in? The old adage of “build Now – objectively relative to industry’s best Fix Later.” practices as defined in the CMMI; to identify suppliers’ process strengths and Table 2. Challenges in Implementing Systems Engineering weaknesses and the impact on product and program performance; and to assess program and product risk along with other measures, such as earned value and technical performance measurements, and also predict future program outcomes. The standard CMMI measurement techniques focus on the application of systems engineering processes and the repeatability assessing consistency of processes, but did not address the effectiveness of the process application. Design reviews were often used to assess systems engineering implementation within a program and across interrelated with customer, partner and subcontractor. Verify compliance in both areas from an end-to-end global information grid perspective. Technical assessments are being conducted for each program/project to identify best practices and recommended areas for improvement. Peer reviews were being used to focus on requirements incompliance and design deficiencies. Systems engineering artifacts (Ref. 1) were required to be posted on the intranet for review across the program. This practice improves efficiency by allowing managers and engineers to review and re-use relevant data and methodologies. It can also lower risks by ensuring cross-program consistency and preventing repetition of past mistakes. Performance-based Earned Value concepts have been applied to measure systems engineering effectiveness (Ref. 4). Focusing on SE work products provides a basis for ensuring that the closed-loop operation of the SE management function provides measurements of the work products, not just the process. In some cases “Lessons Learned” was attempted to be used to correct the SE performance. The lessons learned were recorded and stored in database but seldom used and referenced, i.e., lessons were never learned only recorded. Knowledge Management was developed to capture the good SE processes, methods and examples of practices. However, not many engineers will read the information and data in the Knowledge Management database, or the database may not be complete enough. Many large corporations conducted independent reviews of critical programs and projects. It helped correct the design problems or technical deficiencies but the SE implementation findings were faded away as time passed. It has the same symptom as “Lessons Learned”. Challenges in Implementing Systems Engineering 3 American Institute of Aeronautics and Astronautics Metrics of Systems Engineering 1. Requirements a. Requirements Volatility b. Requirements Concurrence c. Requirements Verification d. Requirements Allocation e. Requirements Traceability f. Requirements Controlled g. Interface Requirements h. Requirements Scheduled Completion i. Cost to Complete Requirements j. System Trouble Reports 2. Technical Performance Measurement a. Critical Parameters (CP) Identified b. Validity of CP c. Monitoring Frequency of CP 3. Trade Studies a. Trade Study Criteria b. Spantime of Trade Study c. Trade Study Scheduled Completion d. Cost to Complete Trade Study 4. Verification a. Verification Plan b. System Requirements Verification c. Verification Scheduled Completion 5. Risk, Opportunity and Issue Management a. Risk Identified b. Risk Management Plan c. Risk Burndown Rate d. Monitoring Risks e. Percentage of Risks Completed Prior SRR f. Opportunity Identified and Assessed g. Issue volatility 6. Configuration Management a. On-Time Data Delivery b. Change Analysis Cycle Time c. Configuration Identification & Status Accounting 7. IMP/IMS a. Change IMP Progress 8. Interface Management a. Interface Control Documents 9. System Integration a. System Integration Plan Some organizations believed that SE performance could be improved by tailoring SE process, especially, for small projects. In the Value Stream Mapping it was agreed that the SE process was more closely followed on large projects. This raises the question: How do you do SE on small projects? How do you define "small"? What do you do and under what conditions? It was suggested to improve consistency of SE training and process applications. It may imply to train engineers on how to apply the process. But is this at the heart of SE performance? Engineers were trained but how to measure. Metrics have been defined to measure SE performance for a project/program in industry. The typical metrics were listed in Table 3. Some of the metrics are hard to measure and some are not clearly defined. It is not the purpose of this paper to defend and justify these metrics but simply list a few of them to show one way of measuring the SE performance. Is there a better way to measure and capture the corrective actions for systems engineering implementation problems? The answer may be in the following sections. IV. Why Need a More Effective Diagnostic Method? How do we measure the systems engineering implementation deficiencies correctly? Quantity is easy to measure but measuring quality and technical content is a challenge. Number of drawings released and number of line codes completed are meaningless if quality is not measured. Quantity is a direct measure and quality is a derived measure. Efficiency is another measurement. These measurements cannot be assessed before the completion of a program. Large corporations conducted many systems engineering independent assessments. Unfortunately, it is still not effectively correcting the implementation problems. The new diagnostic method proposes to assess and analyze a program/project after the failure or poor-performance based on the evidence and fact. This is a more reliable method than prediction and audit on an on-going program/project based on interviews with workers. Heinz Stoewer, the then president of INCOSE (International Council on Systems Engineering) 2003, made a speech in which he asserted that we needed to spend less time on the process and more time on the product. What does it mean? Is it possible to do a process well and have a faulty product? Is it possible to have a good product with Table 3. List of Systems Engineering Metrics faulty processes? Certainly in the systems engineering world, process is as important as product. No one would argue that a good product could be derived from a bad process. Process effectiveness will affect the cost and availability of the product. Of course, a good and sound process can produce a bad product if not accomplished well. It can be concluded that product is critically dependent on process. On the other hand, the improvement of processes will be based on the outcome of products. Therefore, the SE performance measurement should be focused on the product not the process. You would often hear the question of “How accurate the drawings and how the software work correctly meeting customer demands.” This is an example that the 4 American Institute of Aeronautics and Astronautics product performance is the final measurement. Most of the current measurements as discussed in the above sections were focused on process execution or on a portion of product since the program/project being audited was not completed. V. Proposed Systems Engineering Diagnostic Method Define ... CTX Tree (Process Tree) The proposed SE diagnostic method will be focused on measuring the final products. Successful Change or improvement begins with results (Ref. 5). The results from the product measurement will be used to improve process. Six Sigma methodology (Ref. 6) and (Ref. 7) was invented to measure and eliminate manufacturing product defects. It is commonly known and has been used for more than ten years. There are two Six Sigma sub-methodologies: DMAIC and DMADV. The Six Sigma DMAIC process (define, measure, analyze, improve, control) is an improvement system for existing processes falling below specification and looking for incremental improvement. The Six Sigma DMADV process (define, measure, analyze, design, verify) is an improvement system used to develop new processes or products at Six Sigma quality levels. Since the purpose of this paper is to improve the SE implementation and process, DMAIC will be adopted. Six Sigma DMAIC shall be applied under the following conditions assuming the SE process has been implemented: Stakeholders Level of Commitment Engineer Specialty Quality Systems Verification Manufacturing • Customers expressed concern that Engineer Engineer Engineer Engineer Engineer product defects were causing Compliant O O O O O O frequent failures in the field. Enthusiastic Support X • A program or a project failed to Help it work X Hesitant X X deliver. • A program or a project had serious Indifferent X cost overrun and schedule slippage Uncooperative Opposed X especially near the end of design life Hostile cycle. X = Was Level of Com mitme nt • There were many redesigns or O = Level of Com mitme nt Neces sary for Succe ss reworks associated with a program or project. Most of the time this Figure 1. Identification of Stakeholders condition is closely related to the above condition. A Six Sigma team is formed to perform the Six Sigma DMAIC as follows: 1. Define Define the problems, scope and (external and internal) customer. a. Study the “as-was” process map (AWPM) taken by the program/project team. The top-level process map should show the SE tasks/steps utilized by the program/project team. The next level should show the steps taken under each utilized SE task. For example, under the Requirements Task, how the requirements were developed, from The CT Matrix Structure customer requirements CTY Tree (Product Tree) or other source, or no source, etc.? Another example, how the ... risk(s) was assessed and mitigated, or no Process mitigation plan? Was Input the risk real or formality? What was the quality of risk assessment, understandable or ambiguity? If CT Tree necessary, the next 5 Figure 2. The Critical To (CT) Mat rix 5 American Institute of Aeronautics and Astronautics lower level map could be generated to show the sub-steps taken under each step of a SE task. The AWPM can reveal any missing SE tasks not utilized by the s PM er program/project team. ld o AW eh ak b. Identify stakeholders early to t S ix atr M develop communication plan based T C 5 1 on level of commitment required. CONTROL DEFINE An example was shown in Figure 1. It showed the “Was Level” of identified stakeholders and the 2 4 MEASURE IMPROVE “Level of Commitment Necessary 3 for Success”. Each identified ANALYZE stakeholder can be further identified, for example, engineer has electrical, mechanical, etc. and Figure 3. DMAIC - Define specialty engineer has reliability, maintainability, etc. c. "Critical To" (CT) matrix links systems engineering process (columns of the matrix) or CTX tree and product (rows) or CTY tree as shown in Figure 2. All critical characteristics, Y, of products were driven by factors, X, of processes from the results. Understanding and controlling the causative factors, X, is Process/Product Failure Modes and Effects Analysis (PFMEA) Process/Product Failure Modes and Effects Analysis (FMEA) Process or Product Name: Prepared by: Responsible: FMEA DateOri ( g) ______________ (Rev) _____________ Process Step/Part Numb er Potent ial Failure Mode Potent ial Failure Effect s S E V Po tential Causes O C C Current Cont rols Page ____ of ____ D R E T P N A ct ions . Resp Reco mmended Act ions Taken S O D R E V C C E P N T Table 4. Process/Product Failure Modes and Effects Analysis the real key to high quality with no product defect. It is mathematically expressed as Y = f(X). “Define” step with the key documents is shown in Figure 3. 2. Measure Measure the process to determine current performance; quantifying the problem. The purpose is to narrow range of potential causes and establish a baseline capability level. a. Once the AWPM is completed, the team that put it together will analyze it. A checklist of things to Be On the LookOut (BOLO) will be provided for analyzing the process. The team will study “Why did the defect Y happen?” and “What was the X contributing the defect Y?” The study is no more than considering the process activities and flow by looking at each process step for bottlenecks, sources of 6 American Institute of Aeronautics and Astronautics delay, errors being fixed instead of prevented (rework), role ambiguity, duplications, unnecessary steps and cycle time, authority ambiguity, decisions needed or not, possibly eliminating the step(s) or doing in less time, or trying to prevent and value-added vs. non-value-added steps (from the customer's point of view). b. Build a Data Collection Plan. Clearly define the goals and objectives of the data collection. 5 1 Reach understanding and CONTROL DEFINE agreement on operational definitions and methodology for Da t a the data collection plan. Ensure 2 Sam 4 plin MEASURE IMPROVE data collection (and measurement) g PFM repeatability, reproducibility, 3 EA ANALYZE BO accuracy, and stability. Follow LO C ap through with the data collection a bil it y process and the results. c. Perform Process/Product Failure Figure 4. DMAIC - Measure Modes and Effects Analysis (PFMEA) which is shown in Table 4. Determine and rank potential causes (X’s) and their possible effect on the product problem (Y). “Measure” step with key documents is shown in Figure 4. 3. Analyze The purpose is to evaluate data/information for trends, patterns, causal relationships and "root causes". a. A pareto chart is used to graphically summarize and display the relative usage of systems engineering tasks that has been applied by a program/project. An example s t s i s n si nt ys al me die aly me n is shown in Figure 5. This u e n e t A S ag lA ag ts an de na an en chart shows which systems a o M r i M T ct e em sk un uir Ri fac engineering task was used more F r q e t Re In than other tasks or can also shows the ignorance or Figure 5. Pareto Chart for Systems Engineering Implementation omission of which systems engineering tasks(s). b. When utilizing a team approach to problem solving, there are often many opinions as to the problem's root cause. One way to capture these different ideas and stimulate the team's brainstorming on root causes is the cause and effect diagram, commonly called a fishbone. The fishbone will help to visually display the many potential causes for a specific problem or effect. It is particularly useful in a group setting and for situations in which little quantitative data is available for analysis. c. 5 Whys Analysis is a problem solving technique that allows you to get at the root cause of a problem fairly quickly. The 5 Whys can be used individually or as a part of the fishbone cause and effect diagram. Application of the strategy involves taking any problem and asking "Why - what caused this problem?" By repeatedly asking the question "Why" (five is a good rule), it is possible to peel away the layers of symptoms to identify the root cause of a problem. Although this technique is called "5 Whys," you may find that you will need to ask the question fewer or more times than five before you find the issue related to a problem. An example of “Not Implementing Systems Engineering” problem was shown in Figure 6. There could be many fishbone diagrams for analyzing different problems. “Analyze” step with key documents is shown in Figure 7. 4. Improve 7 American Institute of Aeronautics and Astronautics s es oc is P r a ly s An a D at ly sis An a Fishbone Caus es & Effect Pa r C h e to a 5 W rt hy s The purpose is to develop, implement and evaluate solutions targeted at identified root causes. Improve the process by eliminating defects. a. A brainstorming session is a tool for No Management Support Lack of Teamwork generating as many Why ? Why? ideas or solutions Why? Why? as possible to a Why? Why? Why? Why? Not problem or issue. It Why? Why? Implementing is not a tool for Systems determining the Why? Engineering Why ? Why ? best solution to a Why? Why ? Why? problem or issue. Why ? Why? Why ? Why? Before beginning any effective brainstorming Cultural Barrier Not Understanding Customer session, ground rules must be set. Figure 6 . Fishbone Cause and Effect Diagram The typical groundrules are: no dumb ideas, no criticizing other people’s ideas, building on other people’s ideas, quality over quantity, etc.. b. Pugh matrix can help determine 5 1 which items or potential solutions CONTROL DEFINE are more important or 'better' than others. It is necessarily to be done 2 4 after you capture the CT matrix. MEASURE IMPROVE The Push matrix is a scoring matrix 3 ANALYZE used for solution selection, in which options are assigned scores relative to criteria. The selection is made based on the consolidated scores. An example is shown in Figure 7. DMAIC - Analyze Table 5. If the criteria is the same as in the existing solution, a “S” is given, if Key Criteria Solution 1 Solution 2 Solution 3 it is better a “+” is given Organizational + + and if it is worse a “-” is Compatibility Customer + given. The sum of the Satis faction sames, pluses, and minuses Support S + are consolidated. The “+”s geographical distribution indicate the strengths and Scalable to S S S the “-”s indicate the size of weaknesses. A solution, progra m Sum of 1 3 0 which has more strength, is Positive s selected. In this example, Sum of 1 0 3 Solution 2, which had more Negatives strength, was selected. Sum of Sames 2 1 1 c. Develop the Systems Table 5. Push De cision Matrix Engineering Implementation Improvement Plan (SEIIP) based on the results in “Analyze” step and the recommendation from Pugh matrix. Use the AWPM to develop the new “to be” process map (TBPM) by referring to CT matrix in 8 American Institute of Aeronautics and Astronautics Control Plan iz ed dard s St an esse Pro c ito r Mo n ning ai Tr “Define”, BOLO list and the data collected in “Measure” step. The Plan shall be thorough and robust to correct all the identified deficiencies. “Improve” step with key documents is shown in Figure 8. 5. Control The purpose is to make sure that the problem stays fixed and new methods can be further 5 1 CONTROL DEFINE improved over time. It is how to control future S oluti ons process performance. TBPM a. Develop a Control Plan to sustain the 2 4 Brainstorming MEASURE IMPROVE improvements. Identify the process Docum ents owners who will track the execution of 3 at rix M h ANALYZE Pug g n the SEIIP. The variation from the i er ne gi n improved process will be tracked and the En t io P lan e ta e m en nt s t em m e cause should be identified. Tools and y S pl ve I m pro charts are needed to assist the monitoring Im Figure 8. DMAIC - Improve of variations. Measure the key inputs and outputs on an ongoing basis. There is "common cause" variation. For example, people tend to work silo not participating in the teamwork as often as it should be, or tendency to forget the customer requirements especially there were changes, etc.. In most processes, reducing common cause variation saves money. When the “common cause” cannot be reduced, it is time to perform another DMAIC to correct the causes. b. Perform cost of quality. Calculate Co Qu st o f the cost savings if the process cycle alit Key L ear y 5 1 nin g time is reduced; the re-design is CONTROL DEFINE reduced or eliminated or the rework is reduced or eliminated. 2 4 This is a measurement of the MEASURE IMPROVE degree of success of DMAIC or the 3 ANALYZE failure of DMAIC. If it creates savings, the ROI should be captured for justification and future reference. Figure 9. DMAIC - Control c. The new process map and associated procedures should be published and distributed. Training may be required for the new process and procedures. Transfer ownership and knowledge to new process owner and project team tasked with the responsibilities if it is necessary. At this step, it is the project closure. Capture knowledge gained from this DMAIC project. What is the key learning? Communicate to rest of organization for knowledge sharing and transfer. Archive in knowledge management repositories for future projects. “Control” step with key documents is shown in Figure 9. VI. Conclusion The systems engineering revitalization was started more than ten years ago. There are still issues with system engineering implementation. Large corporations and government organizations conducted independent design reviews for design deficiencies caused by incorrect systems engineering implementation. When the independent design review was completed, the program/project design problems associated with systems engineering execution might be corrected but the comments from the review team were not captured for future improvements on other programs/projects. When the program/project was assessed by the Best Practice Systems Engineering Independent Assessment Team, it was based on the interviews with workers and observation of the partial results for an on-going program/project. The findings from the assessment were not totally accurate and definitely not based on final products. Final products are the ultimate indicators of the degree of success of processes implementation. A good 9 American Institute of Aeronautics and Astronautics product will not need to be diagnosed, like a healthy person does not need to see a doctor. Six Sigma DMAIC process will be used to measure and evaluate the defects of imperfect (quality) product(s). After thorough study, evaluation and analysis using the DMAIC methodology, a SEIIP is generated. The systems engineering execution will be monitored and controlled. If the variation from the improved process cannot be corrected, another DMAIC may need to be performed. The DMAIC methodology presented in this paper is not in enough details since it has not been applied to a poor performed program/project yet. The readers will have to explore and navigate through the recommended path to apply on a real case. Acknowledgments The authors gratefully acknowledge the funding from the Royal Academy of Engineering UK for the work reported in this paper. References 1 Defense AT&L, “Revitalizing Systems Engineering”, May-June 2005. Hsu, J. C., Raghunathan S. and Curran, R., “Effective Learning in Systems Engineering”, Aerospace Science Meeting, American Institute of Aerospace and Astronautics, Reno, Nevada, 2008. 3 Government Accounting Office, “Increased Focus on Requirements and Oversight Needed to Improve DOD’s Acquisition Environment and Weapon System Quality”, GAO-08-294, February 2008 4 Carson, Ronald S., “Using Performance-Based Earned Value for Measuring Systems Engineering Effectiveness”, INCOSE International Symposium, Netherlands, 2008. 5 Schaffar, Robert H. and Thomson, Harvey A., “Successful Change Programs Begin with Results,” HBR, Jan-Feb 1992. 6 Rath & Strong, “Six Sigma Pocket Guide,” Rath & Strong Management Consultants, Lexington, MA, 2001. 7 Harry, Mikel, J. and Schroeder, Richard, “Six Sigma, The Breakthrough Management Strategy Revolutionizing The World's Top Corporations”, Doubleday, December 1999. 2 10 American Institute of Aeronautics and Astronautics