SUN

CH022.tex

18/7/2007

17: 15

Page 549

Quality Evaluation

and Control of Potato

Chips and French Fries

Franco Pedreschi1 , Domingo Mery2 and Thierry Marique3

1 Universidad de Santiago de Chile, Departamento de Ciencia y

Tecnología de Alimentos, Av. Ecuador 3769, Santiago de Chile, Chile

2 Pontificia Universidad Católica de Chile, Departamento de Ciencia de

la Computación, Av. Vicuña Mackenna 4860 (143), Santiago de

Chile, Chile

3 Centre pour l’Agronomie et l’Agro-Industrie de la Province de Hainaut

(CARAH), 11 rue P. Pastur, 7800 Ath, Belgium

1 Introduction

Potato chips have been popular salty snacks for 150 years, and retail sales in the US

are worth about $6 billion/year, representing 33 percent of the total sales of this market

(Garayo and Moreira, 2002; Clark, 2003). In 2001 about 50 percent of the US potato

crop was processed to produce 11 300 million kg of processed potatoes, of which

21.6 percent were made into chips. The worldwide trade over recent years indicates

that about 7.4 × 107 kg of potato chips were exported, with a value of ∼$165 million

annually (Economic Research Service, 2004).

Frying in hot oil at temperatures between 160◦ and 180◦ C is characterized by very

high drying velocities, which are critical to improve not only the mechanical but also the

structural properties of the potato chips (Baumann and Escher, 1995). Potato chips are

thin slices whose moisture content decreases from around 80 percent to almost 2 percent

when they are fried. However, the drying in oil inevitably leads to a considerable oil

uptake of around 35 percent, most of which is located on the surface of the chip

(there is almost no penetration during frying) and adheres to the surface at the end

of frying. Therefore, a high proportion of oil penetrates into the food microstructure

during the post-frying cooling stage (Ufheil and Escher, 1996; Aguilera and Gloria,

2000; Bouchon et al., 2003).

In the potato chip industry, the quality of each batch of potato tubers must be tested

before processing, and of the various quality criteria the visual aspect, especially the

Computer vision technology for food quality evaluation

ISBN: 978-0-12-373642-0

Copyright © 2007, Elsevier Inc.

All rights reserved

22

SUN

CH022.tex

18/7/2007

17: 15

Page 550

550 Quality Evaluation and Control of Potato Chips and French Fries

color, is of great importance (Marique et al., 2005). Color of potato chips is the first

quality parameter evaluated by consumers, and is critical in the acceptance of the

product (Pedreschi et al., 2006). Consumers tend to associate color with flavor, safety,

storage time, nutrition, and level of satisfaction, due to the fact that color correlates

well with physical, chemical, and sensorial evaluations of food quality. The color of

potato chips changes during frying, as the components of potatoes are restructured.

Consequently, the surface color reflects not only the heterogeneous surface formed as

a result of frying but also the non-homogeneous oil distribution. Visual aspects, such

as surface color and appearance, can be studied using computer vision techniques in

order to determine the potato chip.

Acrylamide, which is formed in potatoes during frying and is highly related to the

color of potato chips, is suspected to have critical implications for human health, since it

has recently been found to be a carcinogen in rats (Mottram and Wedzicha, 2002; Rosen

and Hellenäs, 2002; Stadler et al., 2002; Pedreschi et al., 2005). Potato chip color is

affected by the Maillard reaction, which depends on the content of reducing sugars,

amino acids, or proteins at the surface. It is also affected by the frying temperature

and time (Márquez and Añón, 1986). Generally, potato tubers that contain more than

2 percent of reducing sugars are discarded for frying, since they generate too dark a

coloration. Research has demonstrated that 2.5–3 mg of reducing sugar per gram of

potatoes should be the maximum value accepted for potato chip preparation (Lisinska

and Leszczynski, 1989).

In European factories, some computer vision systems are used for the on-line evaluation of potato chips, allowing chips to be sorted according to defects such as black

spots or blisters (Marique et al., 2005). Some researchers have been also working on

a promising device that is able both to classify chips according to color and to predict acrylamide levels using neural networks (Marique et al., 2003, 2005), and some

are currently evaluating devices based on this system with the expectation that it will

be fully operational very soon. Apart from the neural network, there is another device

based on statistical pattern recognition for color classification of potato chips (Marique

et al., 2003; Pedreschi et al., 2004). Researchers in this topic are routinely providing

classical visual evaluation against a standard chart, and have conducted a good amount

of work to testify which criteria (overall appearance, heterogeneity, contrasted extremities, etc.) should be taken into account by the operator to evaluate the surface of potato

chips. In this chapter, the application of computer vision to study the quality attributes

of potato chips is summarized.

2 Computer vision

Computer vision (CV) is a novel technology for acquiring and analyzing an image in

order to obtain information or to control processes. Basically, a computer vision system

(CVS) consists of a video camera for image acquisition, illuminants with standard

settings, and computer software for image analysis (Papadakis et al., 2000; Brosnan and

Sun, 2004). Image processing and image analysis are at the core of CV, with numerous

SUN

CH022.tex

18/7/2007

17: 15

Page 551

Computer vision 551

B

G

R

I

Preprocessing

Image

acquisition

B

G

R

Red

features

R

Segmentation

S

color

images

camera

chip

gray

image

Green

features

G

Blue

features

B

L*a*b*

features

L

Classification

Intensity

features

I

binary

image

Geometric

features

γ

“class A”

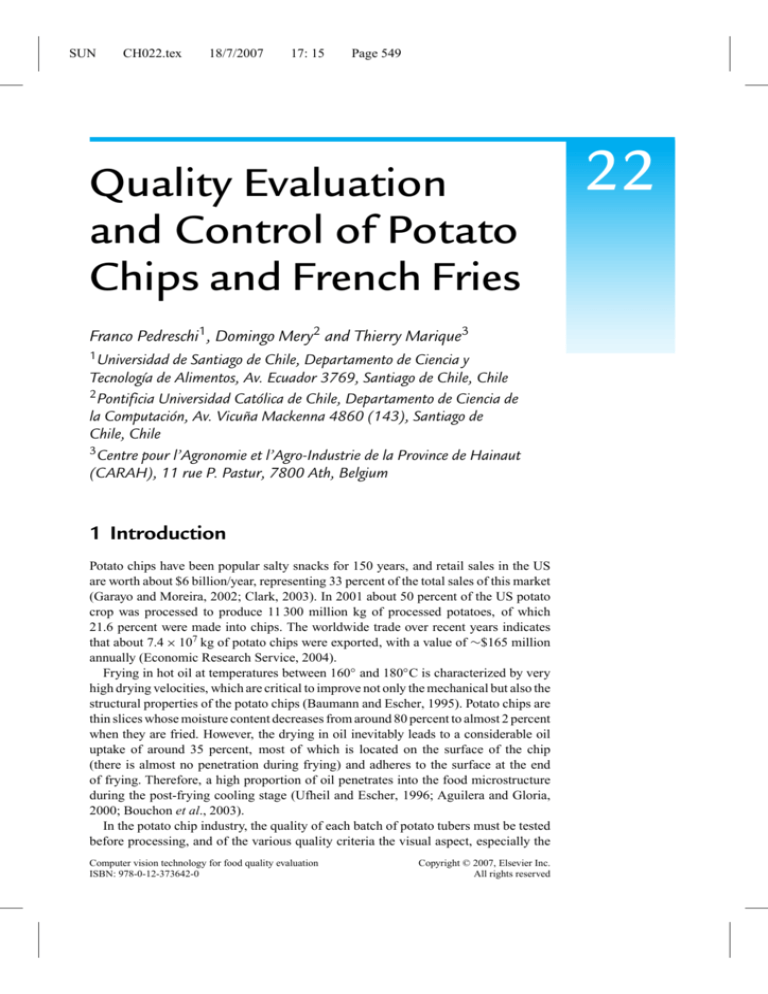

Figure 22.1 Schematic representation of the pattern-recognition process required for automatic

classification of potato chips. (Reprinted from Pedreschi et al., 2004©, by courtesy of the Institute of Food

Technologists.)

algorithms and methods being capable of objectively measuring and assessing the

appearance quality of agricultural products (Sun, 2004). Figure 22.1 shows a schematic

representation of a general CV pattern-recognition process required for the automatic

classification of potato chips, which involves the following four steps (Castleman,

1996; Mery et al., 2003): image acquisition, image pre-processing and segmentation,

feature extraction, and classification.

2.1 Image acquisition

A digital image of the potato chip is captured and stored in the computer. When acquiring images, it is important to consider the effect of illumination intensity and the

orientation of specimens relative to the illumination source, since the gray level of

the pixels is determined not only by the physical features of the surface but also by

these two parameters (Peleg, 1993; Chantler, 1995). Typically, a color digital camera

provides an image of which each pixel is associated with three digital values as red (R),

green (G), and blue (B). Figure 22.2 shows an image-acquisition system implemented

by Pedreschi et al. (2004) to measure the different quality attributes in potato chips.

This system is composed of:

1. A color digital camera with 4 megapixels of resolution (Power Shot A70, Canon,

Tokyo, Japan)

2. Four natural daylight 18-W fluorescent lights (60 cm in length) with a color

temperature of 6500 K (Philips, Natural Daylight, 18 W) and a color index (Ra)

close to 95 percent for proper illumination

3. A wooden box where the illuminating tubes and the camera are placed; the interior

walls of the box are painted black to minimize background light.

SUN

CH022.tex

18/7/2007

17: 15

Page 552

552 Quality Evaluation and Control of Potato Chips and French Fries

Lamps

Camera

Wooden box

Sample

Figure 22.2 Image-acquisition system developed to evaluate potato chip quality. (Reprinted from León

et al., 2006©, courtesy of Elsevier.)

2.2 Image pre-processing and segmentation

The digital images taken must be pre-processed to improve their quality before they are

analyzed. Using digital filtering, the noise in the image can be removed and the contrast

enhanced. Sometimes in this step the color image is converted to a gray-scale image,

called the intensity image (I). The intensity is used to divide the images into disjointed

regions with the purpose of separating the region of interest from the background.

This segmented image (S) is a binary image, where 0 (black) and 1 (white) indicate

background and object, respectively. In our case, such a region of interest corresponds

to the area where the potato chip is located for the test.

Segmentation is an essential step in computer vision, and the accuracy of this operation is critical in automatic pattern recognition for food image analysis. This is because

pattern recognition is based on the data subsequently extracted from the segmentation

process (Brosnan and Sun, 2004). Segmentation detects regions of interest inside the

image, or structural features of the object, and can be achieved by three different techniques: thresholding, edge-based, and region-based (Sonka et al., 1998; Sun, 2000)

segmentation. Mery and Pedreschi (2005) developed a robust algorithm implemented

in Matlab 6.1 software (The MathWorks, Inc., Natick, Mass., USA.) to segment potato

chips from the background. The segmentation has three steps:

1. Computation of a high-contrast gray-value image from an optimal linear

combination of the RGB components

2. Estimation of a global threshold using a statistical approach

3. A morphological operation in order to fill the possible holes presented in the

binary image (Figure 22.3).

2.3 Feature extraction

Image feature extraction is one of the most active research topics in computer vision (Du

and Sun, 2004). Following segmentation, feature extraction is concentrated principally

SUN

CH022.tex

18/7/2007

17: 15

Page 553

Computer vision 553

(a)

(b)

(c)

Figure 22.3 Potato images: (a) color image of a potato chip; (b) gray-scale image of (a); (c) segmented

image of (a). (Reprinted from Pedreschi et al., 2006©, by courtesy of Elsevier.)

around the measurement of the geometric properties (size and shape) and surface

characteristics of regions (color and texture) (Zheng et al., 2006). It is important to

know in advance which features provide relevant information for the classification. In

order to reduce the computational time required in the pattern-recognition process, it is

necessary to select the features that are relevant for the classification. For this reason,

feature selection must be performed in a training phase.

Features extracted from potato chip images by Pedreschi et al. (2004) are described

in Table 22.1, and are grouped into six types:

1.

2.

3.

4.

5.

6.

Geometric (γ)

Intensity (gray-scale image) (I)

Red component (R)

Green component (G)

Blue component (B)

Mean values of the L*a*b* components (L).

The details regarding now these features are calculated can be found in the references

cited in Table 22.1.

2.4 Classification

The extracted features of each region are analyzed and assigned to one of the defined

classes. A classifier is designed following supervised training. Simple classifiers can

be implemented by comparing the measured features with threshold values. However,

it is also possible to use more sophisticated classification techniques, such as statistical

and geometric analyses, neural networks, and fuzzy logic (Castleman, 1996; Jain et al.,

2000; Mery et al., 2003). For example, in statistical pattern recognition, classification

is performed using the concept of similarity – i.e. patterns that are similar are assigned

to the same class (Jain et al., 2000). In other words, a sample is classified as class “i”

if its features are located within the decision boundaries of class “I”. Furthermore, a

decision-tree classifier can be implemented to search for the feature that can separate

one class from the other classes with the most confidence (Safavian and Landgebe,

1991).

SUN

CH022.tex

18/7/2007

17: 15

Page 554

554 Quality Evaluation and Control of Potato Chips and French Fries

Table 22.1 Extracted features from images of potato.

Type

Feature

Description

Reference

γ

γ

γ

γ

γ

γ

γ

γ

γ

γ

(ī, j̄)

h, w, A, L, R

φ1 . . . φ7

|DF 0 |. . .|DF 7 |

FM1 . . . FM4

FZ 1 . . . FZ3

(ae , be )

ae /be

α (i 0 , j 0 )

Gd

Center of gravity

Height, width, area, roundness, and perimeter

Hu’s moments

Fourier descriptors

Flusser and Suk invariant moments

Gupta and Srinath invariant moments

Major and minor axis of fitted ellipse

Ratio of major to minor axis of fitted ellipse

Orientation and center of the fitted ellipse

Danielsson form factor

Castleman, 1996

Castleman, 1996

Sonka et al., 1998

Zahn and Roskies, 1971

Sonka et al., 1998

Sonka et al., 1998

Fitzgibbon et al., 1999

Fitzgibbon et al., 1999

Fitzgibbon et al., 1999

Danielsson, 1978

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

I, R, G, B

G

C

D

K1 . . . K3

Kσ

K

Q

Q

σQ

Q

Q̄

F 1 . . . F15

φ1 . . . φ7

σg2

Tx d

Castleman, 1996

Mery and Filbert, 2002

Mery and Filbert, 2002

Kamm, 1998

Mery and Filbert, 2002

Mery and Filbert, 2002

Mery, 2003

Mery, 2003

Mery, 2003

Mery, 2003

Mery, 2003

Mery, 2003

Sonka et al., 1998

Mery and Filbert 2002

Haralick et al., 1973

I, R, G, B

KL, DFT, DCT

Mean gray value

Mean gradient in the boundary

Mean second derivative

Radiographic contrasts

Deviation contrast

Contrast based on CLPa at 0◦ and 90◦

Difference between maximum and minimum of BCLP1

ln(Q + 1)

Standard deviation of BCLPa

Q normalized with average of the extreme of BCLP1

Mean of BCLPa

First components of DFT of BCLPa

Hu moments with gray value information

Local variance

Mean (M) and range () of 14 texture featuresb

with d = 1, 2, 3, 4, 5

64 first components of the KL, DFT,

and DCT transforma

L

L∗ a∗ b∗

Color components of the region

Hunt, 1991;

Papadakis et al., 2000

Castleman, 1996

Reprinted from Pedreschi et al., ©2004, by courtesy of the Institute of Food Technologists.

γ, geometric features; I, intensity features; R, red component features; G, green component features;

B, blue component features, L, L∗ a∗ b∗ features.

a

CLP: Crossing line profile, gray function value along a line that crosses the region at its center of gravity.

The term BCLP refers to the best CLP – in other words, the CLP that represents the best homogeneity

at its extremes (Mery, 2003).

b

The following features are extracted based on a co-occurrence matrix of the whole image of the potato

chips: second angular moment, contrast, correlation, sum of squares, inverse difference moment, mean

sum, variance of the sum, entropy of the sum, variance of the difference, entropy of the difference, two

measures of correlation information, and maximum correlation coefficient, for a distance of d pixels.

c

The transformation takes a re-sized window of 32 × 32 pixels which includes the middle of the potato chips.

3 Applications

3.1 Sorting of potato chips

Recently, the different features of color, size, shape, and texture have been combined for

their applications in the food industry, because in this way they increase the performance

of the methods proposed. These features can be applied with various kinds of food,

SUN

CH022.tex

18/7/2007

17: 15

Page 555

Applications 555

L*: 58.743568

a*: 8.0011638

b*: 26.339806

L*: 38.099905

a*: 13.974827

b*: 19.029009

Figure 22.4 The color of a complete potato chip and a small circular browned region of it in L*a*b*

units. (Reprinted from Pedreschi et al., 2006©, courtesy of Elsevier.)

such as in fried potatoes for the detection and segmentation of surface defects, the

prediction and characterization of chemical and physical properties, and the evaluation

and determination of sensorial characteristics (Pedreschi et al., 2004).

3.1.1 Color

The color of potato chips is an extremely important quality attribute and a fundamental

criterion for the potato-processing industry, since it is strictly related to consumer

perception, the Maillard reaction, and acrylamide formation (Scanlon et al., 1994;

Mottram and Wedzicha, 2002; Stadler et al., 2002; Pedreschi et al., 2006). These

reasons make extremely important to have methods for measuring the color of potato

chips properly (Pedreschi et al., 2005; León et al., 2006).

In image analysis for food products, color is an influential attribute and powerful

descriptor that often implies object extraction and identification, and that can be used to

quantify the color distribution of non-homogeneous samples (Brosnan and Sun, 2004).

The color of fried potatoes is usually measured usually in the unit of L∗ a∗ b∗ , using either

a colorimeter or specific image-acquisition and processing systems. Parameter L∗ is

the luminance or lightness component, which ranges from 0 to 100, and parameters

a∗ (from green to red) and b∗ (from blue to yellow) are the two chromatic components,

which range from –120 to 120 (Papadakis et al., 2000). In the L∗ a∗ b∗ space the color

perception is uniform, which means that the Euclidean distance between two colors

corresponds approximately to the color differences perceived by the human eyes (Hunt,

1991). More recently, potato-chip color has been measured with computer vision techniques (Scanlon et al., 1994; Segnini et al., 1999; Marique et al., 2003; Pedreschi et al.,

2004). Computer vision (CV) is used to measure the color of potato chips objectively,

as it provides some obvious advantages over a conventional colorimeter – namely, the

possibility of simultaneously analyzing the whole surface and the details of the chip,

and quantifying characteristics such as brown spots and other appearance defects on

the surface (Figure 22.4).

SUN

CH022.tex

18/7/2007

17: 15

Page 556

556 Quality Evaluation and Control of Potato Chips and French Fries

R

G

B

Preprocessing

Segmentation

binary image

Image

formation

Fluorescent lamps

Camera

Color conversion

procedure

L*a*b* values

Figure 22.5 Schematic representation of a computer vision system used to covert color images from RGB

to L*a*b* space. (Reprinted from Pedreschi et al., 2006©, by courtesy of Elsevier.)

3.1.1.1 Color models

The use of CV for the color assessment of potato chips requires an absolute color

calibration technique based on a common interchange format of color data and the

knowledge of which features can be best correlated to the product quality. With a digital

camera it is possible to register the color of any pixel of the image of the object using

three color sensors per pixel, which depend on the color model being used (Forsyth and

Ponce, 2003). The most frequently used color model is the RGB model, in which each

sensor captures the intensity of the light in the red (R), green (G) and blue (B) spectra

respectively. There have been two trends recently in the application of image color

for food quality evaluation: one is to carry out a point analysis, encompassing a small

group of pixels for the purpose of detecting small characteristics of the object; the other

is to carry out a global analysis of the object under the study of the color histogram in

order to analyze its homogeneity (Brosnan and Sun, 2004; Du and Sun, 2004).

Pedreschi et al. (2006) recently designed and implemented a CV system to measure

representatively and precisely the color of highly heterogeneous food materials, such

as potato chips, in L∗ a∗ b∗ units from RGB images (Figure 22.5). Since RGB digital

cameras obtain information in pixels, León et al. (2006) developed a computational

color conversion procedure that allows the obtaining of digital images in L∗ a∗ b∗ color

units from the RGB images by testing five models: linear, quadratic, gamma, direct,

and neural network. After the evaluation of the performance of the models, the neural

network model was found to perform the best, with an error of only 0.96 percent. The

network architecture is shown in Figure 22.6.

Finally, in order to show the capability of the proposed method, León et al. (2006)

compared the color of a potato chip measured by this approach with that obtained by a

Hunter Lab colorimeter. The colorimeter measurement was obtained by averaging 12

measurements (at 12 different places on the surface of the chip), whereas the measurement using the digital color image was estimated by averaging all pixels of the surface

image. Measurement from the colorimeter was used as the standard measurement.

SUN

CH022.tex

18/7/2007

17: 15

Page 557

Applications 557

ˆ*

L

R

aˆ *

bˆ *

G

B

Figure 22.6 Architecture of the neural network used to estimate L∗ a∗ b∗ values from RGB images.

(Reprinted from León et al., 2006©, by courtesy of Elsevier.)

Instrument

Hunter lab

Digital image

(a)

(b)

L*

61.7

66.9

a*

1.7

1.3

b*

26.6

27.3

(c)

Figure 22.7 Estimatation of L∗ a∗ b∗ values of a potato chip: (a) RGB image; (b) segmented image by the

method proposed by Mery and Pedreschi (2005); (c) color measured in L∗ a∗ b∗ space using a commercial

colorimeter and the approach of León et al. (2006). (Reprinted from León et al., 2006©, by courtesy of

Elsevier.)

The results are summarized in Figure 22.7, and the error of the CV system was only

1.8 percent.

3.1.1.2 Classification techniques

A pattern-recognition approach was used for the classification of potato chips processed

under six different conditions, and good classification results were obtained (Pedreschi

et al., 2004). Pedreschi et al. (2004) implemented an approach to classifying potato

chips using pattern recognition from color images where more than 1500 features

were extracted from each of the 60 potato images tested. The feature selection was

carried out based on the Sequential Forward Selection (SFS) method (Jain et al., 2000).

Finally, 11 features were selected according to their classification attributes. Although

samples were highly heterogeneous, classification of the potato chips using a simple

classifier and just a few features was able to obtain a very good performance (accuracy

≥ 90 percent) in all cases. These authors showed that pattern-recognition techniques

could easily and successfully be applied to classify highly heterogeneous materials

such as fried potato chips processed under different conditions, as well as other food

products.

Marique et al. (2003) used an artificial neuronal network to classify fried potato

chips. In this approach, gray-level features of the apex, the center and the base of each

potato chip were obtained from a color image in order to determine the quality class

SUN

CH022.tex

18/7/2007

17: 15

Page 558

558 Quality Evaluation and Control of Potato Chips and French Fries

Acrylamide content (µm/kg)

2000

R2 0.9569

1600

1200

800

400

0

10

Acrylamide content 113.77a* 1062.23

5

0

a*

5

10

Figure 22.8 Acrylamide content vs color parameter a∗ of controlled and blanched potato chips (moisture

content of ∼1.8%, wet basis) fried at 120, 150, and 180◦ C. (Reprinted from Pedreschi et al., 2005©, by

courtesy of Elsevier.)

to which each chip belonged. Using a relatively small number of samples, the authors

obtained good agreement with human inspectors, yielding a classification performance

of around 90 percent.

3.1.1.3 Color and frying temperature

Color has been extensively used for evaluation of the effect of different temperatures

on the quality of fried potato chips. The kinetics of color changes in potato slices during frying at four temperatures were investigated using the CV system implemented by

Pedreschi et al. (2006). Furthermore, Pedreschi et al. (2005) found a good linear correlation (r 2 = 0.9569) between the acrylamide content of potato chips (moisture content

∼1.8 percent on a wet basis) and their color represented by the redness component a∗ in

the range of the temperatures studied. The redness component a∗ is an indicator of nonenzymatic browning; the lower a∗ value, the paler the potato chip (Figure 22.8). As the

frying temperature increased from 120◦ to 180◦ C, the resultant chips became redder

and darker as a result of non-enzymatic browning reactions that are highly dependent

on oil temperature. Blanching reduced the a∗ value of potato chips due to the leaching out of reducing sugars previous to frying, thus inhibiting non-enzymatic browning

reactions and leading to lighter and less-red chips. Figure 22.9 shows how the potato

chips increased in redness and became darker as the frying temperature increased from

120◦ to 180◦ C. At the same frying temperature, blanching pre-treatment led to paler

potato chips after frying.

3.1.2 Texture

Computer analysis of the surface texture of foods is of interest, because it affects the

processing of many food products. For instance, there is a known dependence between

the oil uptake and the surface properties of fried potatoes (Pedreschi et al., 2000;

Bouchon, 2002). Visual textures are generally formed by the interaction of light with

a rough surface, such as that of fried potatoes. Scale-sensitive fractal analysis has

been applied directly over topographical data sets (heights as a function of position) to

SUN

CH022.tex

18/7/2007

17: 15

Page 559

Applications 559

(a)

(b)

(c)

(d)

(e)

(f)

Figure 22.9 Images of potato chips (moisture content of ∼1.8%, wet basis): (a) control fried at 120◦ C;

(b) control fried at 150◦ C; (c) control fried at 180◦ C; (d) blanched fried at 120◦ C; (e) blanched fried at

150◦ C; and (f) blanched fried at 180◦ C. Controls are unblanched slices. Blanching treatment was in hot

water at 85◦ C for 3.5 min. (Reprinted from Pedreschi et al., 2005©, by courtesy of Elsevier.)

quantify the important changes in the surface texture of potatoes during frying, such

as the area-scale fractal complexity (Asfc) and the smooth-rough crossover (SRC).

Another way to perform fractal analysis or to quantify the textural properties of a

surface is by using the information contained in images (brightness as a function of

position), with the advantage that the topography of the sample is not necessarily

correlated with the texture of its surface image (Rubnov and Saguy, 1997; Quevedo

et al., 2002).

Texture has been used in the quality inspection of potato chips. First, textural features

are acquired from images taken of the surfaces of a set of potato chip samples by using

video cameras. An identical set of samples of potato chips is used to obtain the quality

attributes of the samples, using sensory panellists or instruments. Afterwards, learning

models (e.g. statistical learning, fuzzy logic, and neural networks) can be set up to

correlate the texture features to the potato chip quality. Based on the information

obtained from the learning models, the qualities of different categories of potato chips

can be predicted by using their texture features from the images (Pedreschi et al., 2004).

Different problems involving appearance are associated with frying potato pieces

(either slices or strips). One is the presence of defects such as black dots and necrosis.

Searching for such defects involves on-line screening and eventual rejection of every

defective chip (Marique et al., 2003). Another is the development of dark coloration

because of the Maillard reaction between reducing sugars and amino groups (Márquez

and Añón, 1986). This must be assessed at the laboratory for every sample in the potato

batch intended for processing, because tubers that look perfectly healthy can develop

intensive and heterogeneous browning or dark tips, which lead to consumer rejection.

Defective batches are refused, to the disadvantage of the producer.

SUN

CH022.tex

18/7/2007

17: 15

Page 560

560 Quality Evaluation and Control of Potato Chips and French Fries

3.2 Browning evaluation

Evaluation of browning of samples taken from the frying lines must also be performed

frequently at the laboratory, to police the process. The synthesis of acrylamide during frying increases brownness, due to the reaction of asparagine and reducing sugars

(Pedreschi et al., 2005). As this reaction pathway is clearly correlated with the Maillard

reaction (Mottram and Wedzicha, 2002; Stadler et al., 2002; Pedreschi et al., 2005), it

has been proposed by several authors that quick and easy measurement of browning can

be performed using image analysis rather than painstaking chromatographic methods

(Pedreschi et al., 2005). Acrylamide is suspected to be a molecule with significant

toxicological effects – carcinogenic, neurotoxic, and mutagenic (Rosen and Hellenäs,

2002).

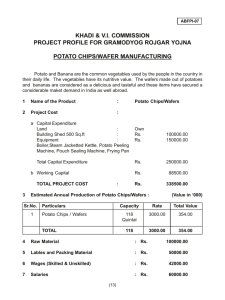

3.2.1 Using artificial neural networks (ANN) by CARAH (Centre pour

l’Agronomie et l’Agro-industrie de la Province de Hainaut, Belgium)

To estimate the darkening of French fries during frying, a simple frying assay is performed for 3 minutes at 180◦ C on 20 French fries obtained from the central part of

20 different potatoes. Each of the French fries is then assigned a category by visual

examination under standard white light (Marique et al., 2003). The assessors build

their evaluation with the help of a standard reference card (Figure 22.10), determined

from both the overall darkening of individual French fries, and the contrast between the

extremities (apex and base) and the center of the fries. Heterogeneous dark coloration

is also penalized.

There are, of course, problems associated with this subjective procedure. In particular, estimations may vary with the assessor. Even for a given assessor, sample

variability can influence results, since narrow distributions tend to be spread over the

scale. It is thus of great interest to develop a model that allows reproducible estimation

of the color category of French fries (Marique et al., 2003).

Artificial neural networks (ANNs) can attain very good performance when used to

predict values for complex non-linear systems (Mittal and Zhang, 2000; Wilkinson and

PF 00

Figure 22.10

PF 0

PF 1

PF 2

PF 3

A reading card of French fries for browning categories.

PF 4

PF 5

SUN

CH022.tex

18/7/2007

17: 15

Page 561

Applications 561

Yuksel, 1997). Moreover, they are endowed with a broad capacity for generalization,

so that they can give useful information for cases that are not part of their training

set (Schalkoff, 1997; Wilkinson and Yuksel, 1997; Marique and Wérenne, 2001; Yang

et al., 2002). They appear to be the logical choice for achieving successful prediction

of the darkening index for fried potatoes.

Marique and colleagues (2003) used image analysis to extract gray-level intensities

from an image data bank gathered from the routine frying assays of 12 different mealy

potato cultivars (Annabelle, Bintje, Cantate, Charmante, Cyclone, Daisy, Farmer, Innovator, Lady Olympia, Liseta, Markies, Victoria). Three values were computed for

individual French fries, corresponding to the mean gray values at the apex, center, and

base of the specimen, respectively. The ANN is a feed-forward network consisting of

three inputs, a hidden layer of four neurons with sigmoid transfer functions and bias

(Figure 22.11), and an output layer presenting a single linear neuron with bias that is

issued to the estimated value of the color category (from 0 to 4).

The ANN was trained with a Lenvenberg–Marquardt algorithm (Schalkoff, 1997)

and the output values were compared to the corresponding color categories estimated

by human operators, who assigned each of the French fries to a color category ranging from 0 (very pale) to 4 (very dark). The Lenvenberg–Marquardt algorithm gave

fast convergence, as is usually the case for small networks. Figure 22.12 shows how

the assessor assigns a particular color value to individual French fries. The different

color categories are distributed throughout the gray-value scale, and there is partial

overlapping. This comes from the fact that when a particular specimen stands exactly

Hidden

1

Apex

Hidden

2

Center

Output

Color

class

Hidden

3

Base

Hidden

4

Figure 22.11 Structure of a two-layer feed-forward artificial neural network with three inputs, four hidden

neurons with bias, and one output neuron with bias. (Reprinted from Marique et al., 2003©, courtesy of

Institute of Food Technologists).

SUN

CH022.tex

18/7/2007

17: 15

Page 562

562 Quality Evaluation and Control of Potato Chips and French Fries

300

300

250

250

200

200

150

150

100

Center

100

50

50

0

Apex

0

Figure 22.12 Mean gray values of the center and apex of French fries. The color code indicates the class of

color: very pale gray, 0; pale gray, 1; mid-gray, 2; dark gray, 3; black, 4. The ellipsoids contain the two

sub-populations of class 1: dark gray, globally darker fries; pale gray, paler fries with contrasted dark ends.

(Reprinted from Marique et al., 2003©, courtesy of Institute of Food Technologists).

between two categories, the assessor will select one at random and either undervalue

or overvalue it, which hence leads to the overlapping.

French fries are assigned to category 0 if they appear both very pale (gray levels over

150) or rather paler at the extremities than in the center. A specimen will be assigned

to category 1 for one of the following two reasons: it appears paler in the center but

has contrasting dark ends (global appearance), or it appears dark in the center with

paler ends. Category 1 is thus clearly split in two subpopulations (see ellipsoids in

Figure 22.12) flanking both sides of category 0. Categories 2, 3, and 4 then progressively regroup darker French fries, which are generally pale in the center with more

or less contrasted dark ends. Thus, it is only for the two lower color categories that

the assessor will overvalue a specimen possessing dark contrasted extremities. For

higher color categories, estimations are based mostly on the global (center) appearance

of French fries, where dark contrasted ends are considered to be “normal” (Marique

et al., 2003).

The trained ANN was used to generate a complete set of predictions for the different

possible combinations of gray levels of the center and the apex of the French fries. This

is illustrated in Figure 22.13, where computation was performed using equal gray values

for both the base and the apex of the fries. The ANN showed a good performance, with

correlation coefficients of 0.972 for the training data and 0.899 for the validation data.

The network displays complex and continuous behavior for the low color categories 0, 1,

and 2, but operates a discrete classification between categories 3 and 4. This could be a

SUN

CH022.tex

18/7/2007

17: 15

Page 563

Applications 563

4

3.5

3

2.5

2

6

1.5

Color class

4

0

2

1

0.5

0

100

2

0

0

0.5

200

100

1

200

300

300

Center

Apex

Figure 22.13 Response of the artificial neural network: color class categories are described as a function

of all possible combinations of gray levels of the center and the apex of French fries. (Reprinted from

Marique et al., 2003©, by courtesy of Institute of Food Technologists).

consequence of both the greatest number of data points for high color categories, and the

more complex behavior of the assessor for low color categories (Marique et al., 2003).

A more complete simulation is shown in Figure 22.14, illustrating the discrete color

categories (the values predicted from the ANN are approximated by the nearest integer)

obtained for all the possible combinations of gray levels of the three regions of the

fries. Again, more complex behavior is observed for the lower color categories. The

intermediate categories 2, 3, and 4 also extend between two “wings,” being either

globally paler with dark ends or globally darker with pale ends. Color classification

varies most with the apex and center gray values (Marique et al., 2003).

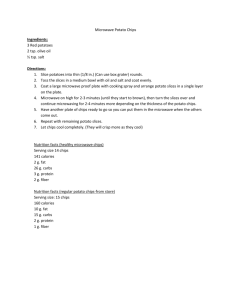

3.2.2 Using other methods (Walloon Agricultural Research Center, Belgium)

This research center, affiliated to the GemblouxAgricultural University in Belgium, has

developed a home-made system for the quality evaluation of French fries (Figure 22.15).

In the system, 20 French fries are cooked and arranged on a tray with a reference tongue

(Figure 22.16). The reference tongue is directly extracted from the USDA reference

card in order to represent the seven reference colors on each sample. For each image,

a tray contains 20 French fries and a reference tongue. The tray is then placed in the

box and an image is taken.

Image analysis is performed using Image Pro Plus software 6 (Media Cybernetics,

USA). The program checks the number of references, which are represented by the

seven colored squares arranged on each tray, and offers a manual correction in cases

SUN

CH022.tex

18/7/2007

17: 15

Page 564

300

300

250

250

200

200

Apex

Apex

564 Quality Evaluation and Control of Potato Chips and French Fries

150

100

50

50

300

250

200

(a)

150 100

Center

50

200 400

Base

0

300

250

200

200

100

50

50

250

200

(c)

150 100

Center

50

300

200 300

0 100

Base

300

200

Apex

200

100

50

50

200

150 100

Center

50

200 300

0 100

Base

200

150 100

Center

50

4

0

300

(f)

200 300

0 100

Base

150

100

250

250

300

250

300

200 300

0 100

Base

2

(d)

250

0

50

0

3

150

150 100

Center

150

100

300

200

300

250

150

250

(b)

1

0

Apex

0

Apex

Apex

300

(e)

150

100

0

0

250

200

150 100

Center

50

200 300

0 100

Base

Figure 22.14 Discrete color categories obtained from all the possible combinations of gray levels for the

three regions of the French fries: (a) general presentation; (b)–(f) partial views of each color category,

from 0 (b) to 4 (f). (Reprinted from Marique et al., 2003©, by courtesy of Institute of Food Technologists).

where this number is different from seven. The references are then scanned. The French

fries are also scanned and counted. Once this has been done, macro sequences successively comply in a few seconds (via sending data to Excel) to compare the colors of the

French fries with the reference tongue in order to determine the color parameters. For

this comparison, RGB images are first converted into gray-scale and their luminous

intensity is then estimated. These stages are repeated until there is automatic generation

of a detailed written (containing photographs of the sample, the date, color parameters

etc.) and archived report.

SUN

CH022.tex

18/7/2007

17: 15

Page 565

Applications 565

Figure 22.15 Device for quality evaluation of French fries (Gembloux Agricultural University in Belgium).

Figure 22.16 Tray ready for image analysis with 20 French fries and 7 colored squares.

In order to compare the image analysis method with sensory analysis (visual comparison), a series of 100 samples is first analyzed using both methods. The correlation

of the results between the two methods is 0.951, which is a very good result compared

with the weak repeatability of the reference method (Figure 22.17).

3.2.3 Browning-sorting and acrylamide estimation using ANN by CARAH

Determination of the acrylamide concentration nowadays appears to be necessary since

very high concentrations of this potentially toxic molecule are detected in amylaceous

SUN

CH022.tex

18/7/2007

17: 15

Page 566

566 Quality Evaluation and Control of Potato Chips and French Fries

6.00

Judge index 0.7491(Image analysis index) 0.6221

R 0.9510

5.00

Judge index

4.00

3.00

2.00

1.00

0.00

0.00

Figure 22.17

1.00

2.00

3.00

4.00

Image analysis index

5.00

6.00

Correlation between the visual measurements and those by image analysis.

Figure 22.18 Artificial neural network imaging system for the determination of color class and acrylamide

concentration in French fries.

fried foodstuffs (Rosen and Hellenäs, 2002). However, standard procedures for acrylamide determination involve slow and expensive methods of chromatography and mass

spectroscopy, and thus cannot be used for routine analysis. It was therefore a logical step

to develop alternative techniques based on image analysis of the browning of French

fries to measure the acrylamide concentration. It was known that there would be good

correlation between non-enzymatic browning development and acrylamide formation,

since several studies had reported a strong linear relationship between browning and

SUN

CH022.tex

18/7/2007

17: 15

Page 567

References 567

acrylamide accumulation in fries (Mottram and Wedzicha, 2002; Stadler et al., 2002;

Pedreschi et al., 2005).

CARAH and a Belgian industrial partner, Rovi-Tech s.a. (Presles, Belgium), have

developed a high-speed imaging system incorporated with ANN. Snapshots of every

one of the French fries tested are taken and then results for both color category and

acrylamide concentration are obtained (Figure 22.18). The system is intended to analyze

incoming potato batches of pre-fried French fries for quality control in food distribution.

The heart of the system is Rovi-Tech’s ILB-25 (Image Learning Box), a very efficient

ANN that allows easy and powerful correlations of complex visual data analysis.

4 Conclusions

Both gray-scale and color images of potato chips are useful for extracting image features

for an appropriate classification. The most relevant features for potato-chip classification are either texture or color from L∗ a∗ b∗ space. Potato chips can be properly

classified to obtain very good values, despite their high heterogeneity. The automatic

classification methodology proposed for potato chips has a wide range of potential uses.

The computer vision system described in this chapter allows determination of the

color of potato slices in L∗ a∗ b∗ color space that is transformed from the RGB space

in an easy, precise, and objective way. To achieve this, image pre-processing and

segmentation is performed. The computer vision system allows easy measurement of

color not only over the entire potato chip surface, but also at small, specific regions of

interest.

Five models that can measure the color in potato chips using the color of each pixel

on the target surface, which cannot be accessed with conventional colorimeters, have

been built. The best results were achieved by the quadratic and neural network models,

both with small errors of close to 1 percent.

For both control and blanched potato chips, acrylamide formation decreases dramatically as the frying temperature decreases from 180◦ to 120◦ C. There is a linear

correlation between non-enzymatic potato-chip browning quantified by computer

vision and the corresponding acrylamide values.

Acknowledgments

The authors acknowledge financial support from the FONDECYT Project N◦ 1030411.

References

Aguilera JM, Gloria H (2000) Oil absorption during frying of frozen par-fried potatoes.

Journal of Food Science, 65, 476–479.

SUN

CH022.tex

18/7/2007

17: 15

Page 568

568 Quality Evaluation and Control of Potato Chips and French Fries

Baumann B, Escher E (1995) Mass and heat transfer during deep fat frying of potato

slices. I. Rate of drying and oil uptake. Lebensmittel Wissenschaft und Technologie,

28, 395–403.

Bouchon P (2002) Modeling oil uptake during frying. PhD Thesis, Reading University,

England.

Bouchon P, Aguilera JM, Pyle DL (2003) Structure oil-absorption relationships during

deep-fat frying. Journal of Food Science, 68, 2711–2716.

Brosnan T, Sun D-W (2004) Improving quality inspection of food products by computer

vision – a review. Journal of Food Engineering, 61, 3–16.

Castleman K (1996) Digital Image Processing. Englewood Cliffs: Prentice Hall, p. 667.

Chantler M (1995) Why illuminant direction is fundamental to texture analysis. IEE

Procedures Visual Image Signal Process, 142, 199–206.

Clark JP (2003) Happy birthday, potato chip! And other snack developments. Food

Technology, 57(5), 89–92.

Danielsson PY (1978) A new shape factor. Computing Graph Image Processing, 7,

292–299.

Du C-J, Sun D-W (2004) Recent developments in the applications of image processing

techniques for food quality evaluation. Trends in Food Science & Technology, 15,

230–249.

Economic Research Service (ERS) of the US Department of Agriculture (2004) Briefing

room potatoes. Available at http://www.ers.usda.gov./briefing/potatoes/.

Fitzgibbon A, Pilu M, Fisher R (1999) Direct least square fitting ellipses. IEEE

Transactions on Pattern Analysis, 21(5), 476–480.

Forsyth D, Ponce J (2003) Computer Vision: A Modern Approach. Englewood Cliffs:

Prentice Hall.

Garayo J, Moreira R (2002) Vacuum frying of potato chips. Journal of Food Engineering,

55, 181–191.

Haralick RM, Shanmugan K, Dinstein L (1973) Textural features for image classification.

IEEE Transactions on Systems, Man, and Cybernetics, 3, 610–621.

Hunt RWG (1991) Measuring Color, 2nd edn. Chichester: Ellis Horwood, Ltd, p. 313.

Jain AK, Duin RPW, Mao J (2000) Statistical pattern recognition: a review. IEEE

Transactions Pattern Analysis Machines Intelligence, 22, 4–37.

Kamm KF (1998) Grundlagen der Röntgenabbildung. In: Moderne Bildgebung: Physik,

Gerätetechnik, Bildbearbeitung und -kommunikation, Strahlenschutz, Qualitätskontrolle (Ewwen K ed.). Stuttgart: Georg Thieme Verlag, pp. 45–61.

León K, Mery D, Pedreschi F, León J (2006) Color measurements in L∗ a∗ b∗ units from

RGB digital images. Food Research International, 39(10), 1084–1091.

Lisinska G, Leszczynski W (1989) Potato Science and Technology. London: Elsevier

Applied Science.

Marique T, Wérenne J (2001) A general artificial neural network for the modeling of culture

kinetics of different CHO strains. Cytotechnology, 36, 55–60.

Marique T, Kharoubi P, Bauffe P, Ducatillon C (2003) Modelling of fried potato chips

color classification using image analysis and artificial neural network. Journal of

Food Science, 68, 2263–2266.

SUN

CH022.tex

18/7/2007

17: 15

Page 569

References 569

Marique T, Pennincx S, Kharoubi A (2005) Image segmentation and bruise identification

on potatoes using a Kohonen’s self-organizing map. Journal of Food Science, 70,

415–417.

Márquez G, Añón MC (1986) Influence of reducing sugars and amino acids in the color

development of fried potatoes. Journal of Food Science, 51, 157–160.

Mery D (2003) Crossing line profile: a new approach to detecting defects in aluminium

castings. Proceedings of the Scandinavian Conference on Image Analysis (SCIA 2003)

(Bigun J, Gustavsson T, eds). Lecture Notes in Computer Science, 2749, 725–732.

Mery D, Filbert D (2002) Classification of potential defects in automated inspection

of aluminium castings using statistical pattern tecognition. In Proceedings of the

8th European Conference on Non-Destructive Testing (ECNDT 2002), June 17–21,

Barcelona, p. 14.

Mery D, Pedreschi, F (2005) Segmentation of color food images using a robust algorithm.

Journal of Food Engineering, 66, 353–360.

Mery D, da Silva R, Caloba LP, Rebolledo JMA (2003) Pattern recognition in the automatic

inspection of aluminium castings. Insight, 45, 475–483.

Mittal GS, Zang J (2000) Use of artificial neural network to predict temperature, moisture,

and fat in slab-shaped foods with edible coatings during deep-fat frying. Journal of

Food Science, 65, 978–983.

Mottram DS, Wedzicha BL (2002) Acrylamide is formed in the Maillard reaction. Nature,

419, 448–449.

Papadakis SE, Abdul-Malek S, Kamdem RE, Yam KL (2000) A versatile and inexpensive

technique for measuring color of foods. Food Technology, 54(12), 48–51.

Pedreschi F, Aguilera JM, Brown CA (2000) Characterization of food surfaces

using scale-sensitive fractal analysis. Journal of Food Process Engineering, 23,

127–143.

Pedreschi F, Mery D, Mendoza F, Aguilera JM (2004) Classification of potato chips using

pattern recognition. Journal of Food Science, 69, 264–270.

Pedreschi F, Moyano PC, Kaack K, Granby K (2005) Color changes and acrylamide

formation in fried potato slices. Food Research International, 38, 1–9.

Pedreschi F, León J, Mery D, Moyano P (2006) Implementation of a computer vision system

to measure the color of potato chips. Food Research International, in press.

Peleg M (1993) Fractals and foods. Critical Review Food Science & Nutrition, 33, 149–165.

Quevedo R, López C, Aguilera JM, Cadoche L (2002) Description of food surfaces

and microstructural changes using fractal image textura analysis. Journal of Food

Engineering, 53, 361–371.

Rosen J, Hellenäs KE (2002) Analysis of acrylamide in cooked foods by liquid chromatography tandem mass spectrometry. Analyst, 127, 880–882.

Rubnov M, Saguy IS (1997) Fractal analysis and crust water diffusivity of a restructured

potato product during deep-fat frying. Journal of Food Science, 62, 135–137, 154.

Safavian S, Landgrebe D (1991) A survey of decision tree classifier methodology. IEEE

Transactions on Systems, Man, and Cybernetics, 21(3), 660–674.

Scanlon MG, Roller R, Mazza G, Pritchard MK (1994) Computerized video image analysis

to quantify color of potato chips. American Potato Journal, 71, 717–733.

SUN

CH022.tex

18/7/2007

17: 15

Page 570

570 Quality Evaluation and Control of Potato Chips and French Fries

Segnini S, Dejmek P, Öste R (1999) A low cost video technique for color measurement of

potato chips. Lebensmittel Wissenschaft und Technologie, 32, 216–222.

Schalkoff RJ (1997) Artificial Neural Networks. New York: McGraw-Hill, p. 448.

Sonka M, Hlavac V, Boyle R (1998) Image Processing, Analysis and Machine Vision, 2nd

edn. Pacific Grove: PWS Publishing.

Stadler RH, Blank I, Varga N, Robert F, Hau J, Guy A, Robert P, Riediker MC (2002)

Acrylamide from Maillard reaction products. Nature, 419, 449–450.

Sun D-W (2000) Inspecting pizza topping percentage and distribution by a computer vision

method. Journal of Food Engineering, 44, 245–249.

Sun D-W (2004) Computer vision – an objective, rapid and non-contact quality evaluation

tool for the industry. Journal of Food Engineering, 61, 1–2.

Ufheil G, Escher F (1996) Dynamics of oil uptake during deep-fat frying of potato slices.

Lebensmittel Wissenschaft und Technologie, 29, 640–644.

Wilkinson C,Yuksel D (1997) Using artificial neural networks to develop prediction models

for sensory-instrumental relationships: an overview. Quality Preferences, 8, 439–445.

Yang CC, Prasher SO, Landry J, Ramaswamy HS (2002) Development of neural networks

for weed recognition in corn fields. Transactions of the ASAE, 45, 859–864.

Zahn C, Roskies R (1971) Fourier descriptors for plane closed curves. IEEE Transactions

on Computing, 21, 269–281.

Zheng C, Sun D-W, Zheng L (2006) Recent developments and applications of image features for food quality evaluation and inspection – a review. Trends in Food Science

and Technology, 17(12), 642–655.