Issue 4/2013 - Delivered.

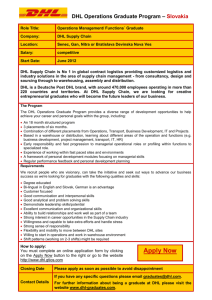

advertisement