20 + 10 points - Department of Mechanical Engineering

advertisement

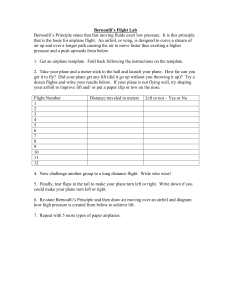

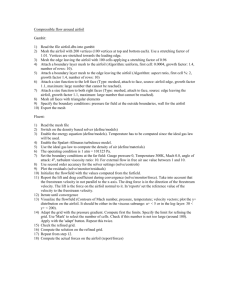

ME-410 MECHANICAL ENGINEERING SYSTEMS LABORATORY EXPERIMENT-6 CHARACTERISTICS OF AN AIRFOIL OBJECT The aim of this experiment is to obtain the pressure distribution around an airfoil, and to determine the lift, drag and pitching moment variations with different angles of attack. THEORY The drag force, FD is the component of force on the body acting parallel to the direction of motion. Most of the information about the drag force on the bodies is a result of huge number of experiments in the wind tunnels, water tunnels etc. on scaled models. These data can be interpreted in terms of the non-dimensional drag coefficient, CD, as CD = D 1 ρV 2 AP 2 AP = Maximum projected wing area (for other objects frontal area is used) ½ ρ V2 = Dynamic pressure in terms of free stream velocity V. If compressibility and free surface effects are neglected drag coefficient is a function of Reynolds number only. For a given configuration Reynolds number is Re = ρ ⋅V μ ⋅ t t = maximum thickness of the airfoil section The total drag force, FD is the sum of the friction drag and pressure drag. Fig 1 illustrates the two extremes. V FD = ∫τ wall plate−surface .dA τ wall Turbulent Wake Behind a Flat Plate Normal to the flow Wall Shear stress does not contribute to drag force only pressure (form) drag Flow over a flat plate parallel to the flow pressure gradient =0 Only friction drag Fig-1 Flow Over a Flat Plate at Different Orientations EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 1 CD = Drag coefficient In Fig. 2 Drag coefficients for a few selected objects are given. This experimental data is for single objects immersed in an unbounded fluid stream. Wind tunnel tests require corrections to simulate the condition of an unbounded flow. Fig.2 Drag coeffient for selected objects Fig.3 Drag coefficient on a streamlined strut as a function of thickness ratio, showing contribution of skin friction and pressure to total drag. By streamlining, the separated flow region can be reduced thus pressure drag decreases. However since surface area also increases so as the friction drag, in Fig. 3, there is an optimum streamline shape which gives minimum total drag. Lift force FL acts on an immersed body normal to the relative motion between fluid and the body. Fig. 4 illustrates the production of dynamic lift on a cambered airfoil at angle of attack (α=8.6o ) Chord, c Negative pressure on suction (upper) surface Positive pressure on pressure (lower) surface Stagnation point s Fig. 4 Streamlines and pressure distribution about a cambered airfoil, at angle of attack α=8.6o EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 2 The lift coefficient CL is defined as C F = L L 1 ρ .V 2 . A P 2 where AP is projected wing area and it is equal to chord times span (see Fig. 8) Lift Coefficient From Pressure Distribution: The lift coefficient may be calculated from the pressure distribution on the upper and lower surfaces such as shown in Fig. 4. Referring to Fig.5 and Fig.6, pressure coefficient CP, and the components of the resultant force, CZ and CX in respective directions are defined as follows, CZ = x C . d ( ) p ∫ c SURFACE CP = where p a − pi 1 ρ .V 2 2 CX = z C p .d ( ) c SURFACE ∫ Pa = Pressure on airfoil surface Pi = Inlet pressure(reference pressure) The ordinates of the highest and lowest points on the sections are z2 and z1 respectively. From geometry of the airfoil CL = CZ cosα – Cx sinα CD = CZ sinα + Cx cosα For numerical integration of CX and CZ please refer to APPENDIX P.dx P.ds P.dz ds Z CL X CZ O V α V α CX CD Fig 5&6 Normal Pressure Force on an Element of Airfoil surface and Coefficients of Aerodynamic Forces at Different Directions EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 3 Pitching moment M is the moment acting in the plane containing the lift and the drag. It is positive when it tends to increase incidence. The moment coefficient CM (with respect to 0.25c) is defined as CM = M 1 ρ V 2 A P .c 2 In order to complement the theory presented in this section references can be used, following keywords may guide you: 9 9 9 9 9 9 9 9 9 9 Effect of Flaps on Aerodynamic Characteristics of Airfoil Sections Laminar-Flow and Conventional Airfoil Sections Effect of Compressibility, on Drag and Lift Lift and Drag in Automotive Applications Designation of Airfoil Section Shapes Optimum Shapes for Low Drag Polar Plots (plots of CLand CD) Lift and Circulation Induced Drag Stall EXPERIMENTAL SET UP 300mm × 300mm Suction Wind Tunnel: For better understanding refer to Fig 7 Double Butterfly Valve Guided Vane Assembly Silencer 24 Tube Manometer Pitot Tube Total Tube Head Effuser Diffuser Model Holder Protective Screen Starter 20 way scanning box Fig 7 : 300mm × 300mm Suction Wind Tunnel The tunnel, of the open circuit type, is constructed mainly in aluminium, and supported by a tubular steel framework. The air enters the tunnel through a carefully shaped inlet, the entrance being covered by a protective screen. The working section is of perplex giving full visibility and the various models are supported from one of EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 4 the sidewalls or by means of the three component balance. At the upstream end of the working section there is a static tapping and a total head tube. While at the downstream end there is pitot static tube, which may be traversed over the full height of the working section (Fig 8). TOTAL HEAD TUBE PITOT STATIC TUBE STATIC TAPPING 305 mm FLOW DIRECTION 128 mm 283 mm PLANE 3 PLANE 2 MOUNTING MODEL AXIS PLANE 1 Fig. 8 Dimensions of the Test Section 152 mm UPPER SURFACE LOWER SURFACE After the working section a diffuser leads to the axial flow fan unit and the air velocity is controlled by means of a double butterfly valve on the fan outlet. The fan discharges by way of a silencer. Maximum air velocity is such that pressure differences of the order of 300mm water are developed and these may be read with suitable accuracy by the simple manometer provided. As an airfoil model NACA 0012 profile is used. In Fig 9 the locations of pressure tappings and dimensions of the model are given. z t =9 mm 148.5 mm NACA 0012 AIRFOIL PRESSURE TAPPINGS: ORDINATES ‘Z' UPPER SURFACE LOWER SURFACE 1.52 7.62 15.24 22.86 41.15 59.44 77.73 96.02 114.30 129.54 0.76 3.81 11.43 19.05 38.00 62.00 80.77 101.35 121.92 137.16 Fig 9 Pressure Tapping Locations of the Airfoil Model EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 5 LOAD CELLS AFT LOAD CABLE STRAIN GAUGE AMPLIFIERS TO DISPLAY UNIT MOUNTING PLATE LOAD CELLS CLEARANCE HOLE MODEL INCIDENCE CLAMP HOLDER MODEL MOUNTING BEAM CENTERING CLAMPS DISPLAY UNIT AIR FLOW IN Fig.10 Three Component Balance Three Component Balance : The balance is mounted on the side wall of the test section of the tunnel, and it will be used to measure lift and drag forces acting on the model. Referring to Fig 10 its main framework comprises a mounting plate, which is secured to the wind tunnel working section, and carries a triangular force plate. The force plate and mounting plate are connected by these supporting legs, disposed at the corners of the force plate. Each leg is attached to the force plate and mounting plate by spherical universal joints. The effect of this is to constrain the force plate to move in a plane parallel to the mounting plate, while leaving it free to rotate about a horizontal axis. The necessary three-degree of freedom is thus provided. The model support is free to rotate in the force plate for adjustment of the angle of incidence (attack) of the model while its position may be locked by means of an incidence clamp. The force plate may be locked in position by two centering clamps, and these should always be tightened when the balance is not in use, or when changing models. The forces acting on the force plate are transmitted by flexible cables to strain gauge load cells, which measure respectively the aft, and fore lift forces and the drag force. The drag cable which lines horizontally, acts on a line through the center of the model support, while the two lift cables act vertically through points disposed equidistant from the center of the model support and in the same horizontal plane with the support. The sum of the forces on the fore and aft lift tapes thus gives the lift on the model, while the difference when multiplied by 0.127 gives the pitching moment in Newton-meters. A drag balance spring acts on the force plate to apply preload to the drag load cell. The output from each load cell is taken to a strain gauge amplifier carried on the mounting plate and hence via a flexible cable to a display unit comprising a set of EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 6 three electronic voltmeters, showing the output from the respective load cell circuits (Fig 10 Lower right) Computer Control With the Wind Tunnel: The software COMPEND W which runs on a PC is interfaced with threecomponent balance, the 20 way scanning valve which constraints also the pressure transducers and single axis traverse mechanism. When the equipment interface for computer control and data acquisition, COMPEND W is used with the wind tunnel, it is possible to present experimental results rapidly and clearly on the video display unit, with copies available for analysis from the printer. Each data point recorded by COMPEND W is the mean of several separate readings taken over a specified time period. Hence high frequency fluctuations can be averaged. Setting up the system and running COMPEND will be demonstrated by your lab assistant during experiment. 20 Way Scanning Valve: The 20 way scanning valve provides a method of performing 20 pressure measurements in sequence automatically. Tubes are connected to 20 solenoid valves on a common manifold. These valves are appeared in turn to allow the pressure to act on a sensitive differential pressure transducer with a full scale range of 500mm H2O. The opening of the valves can be manually stepped using the up and down buttons, automatically stepped at a present time interval or controlled by COMPEND W when scanning valve is set to PULSE mode. Thus data from any pressure port on the airfoil model can be obtained by selecting the pressure port number. The two additional pressure transducers (PRESSURE 2 [P2] and PRESSURE 3 [P3]), have a full scale range of 700mm H2O. These transducers are used too measure dynamic pressure at the inlet and exit of the test section. Thus connected to total and static tubes differentially at these locations (see Fig 8). TEST PROCEDURE 1. Read Fluid Mechanics Laboratory Rules and Regulations before starting which is posted in technicians’ room. 2. Check whether the centering clamps are tight, set the airfoil support at zero incidence and tighten the incidence clamp. 3. Switch on the mains supply in the force display unit. It is desirable to allow a warm up time of fifteen minutes for the load cells before taking any readings. During this time record atmospheric pressure and temperature. 4. Release the centering clamps. Record zero readings of aft lift, fore lift and drag. 5. Start the electric motor, which drives the wind tunnel. Set the tunnel speed using the butterfly valve. Record inlet dynamic pressure as a difference of inlet static and total pressure manometer readings. Use this value to calculate wind velocity. 6. Press ‘Hold Display’ button on the display unit. Record the readings of the digital voltmeter. EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 7 7. By 4° increments, increase the angle of attack and make a series of measurements of lift and drag up to 20° of attack. The angles may be set by releasing the incidence clamp, rotating the model support to the desired angle and retightening the clamp. THE CENTERING CLAMP MUST BE LOCKED BEFORE RELEASING THE INCIDENCE CLAMP OR HANDLING THE FORCE PLATE IN ANY WAY OTHERWISE THERE IS A RISK OF DAMAGING THE LOAD CELLS. Due to blockage of the airfoil at high angles of attack, tunnel velocity may change, make the experiment at fixed tunnel speed by regulating with the butterfly valve. Pressure distribution on the airfoil 8. Set the airfoil to an angle of attack selected by your lab assistant 9. Record pressure from [P1] cell on the COMPEND main screen at the displayed scanning positions. The scanning will continue manually until the pressure at all twenty points on the airfoil have been measured and recorded. 10. Record the dynamic pressure for the calculation of free stream velocity from PRESSURE 3 cell on the COMPEND main screen. CALCULATIONS 1. Free stream velocity V= 2 ρ air .ΔPi .g .ρ water where ΔPi is the upstream dynamic pressure in mH2O. 2. Drag, lift forces and pitching moment at each angle of attack FD = D FL = (A+F) M = 0.127 (F-A) where A, F and D are obtained after correcting the readings by zero readings as follows A = AOFF – AON F = FOFF - FON D = DON - DOFF (Lift force from aft load cell in Newtons) (Lift force from fore load cell in Newtons) (Drag force from drag load cell in Newtons) 3. Calculate CL, CD and CM using force balance readings directly. 4. Tabulate FD, FL, M, CL, CD and CM with respect to angle of attack. EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 8 5. Calculate pressure coefficients; where P − Pi CP = a 1 .ρ air .V 2 2 Pa : Static pressure on the surface of the airfoil in Pa. Pi : Inlet static pressure V : free stream velocity and complete Table 1 in Appendix. 6. After obtaining the pressure distribution around the airfoil, using Table 1 and the expressions given in Theory and Appendix, calculate lift and drag coefficients. COMPARE them with the ones you measured directly from the balance. GRAPHS Draw the following curves on graph paper a) On the same graph plot CL, CD and CM vs. the angle of incidence. Label the curve with the Reynolds number of the flow. b) Plot CP vs. x/c along the chord direction at the selected angle of attack. EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 9 UNCERTAINTY ANALYSIS 1.INTRODUCTION As the second part of the experiment, you will perform an uncertainty analysis for the wind tunnel experiment. The term uncertainty is used for refer to a ‘ possible value that an error may have ‘. It is necessary to make distinction between single sample and multiple sample uncertainty analysis. The distinction hinges on whether or not a ‘ large’ or ‘small’ number of independent data points are taken at each test point and on how the data are handled. 2. THEORY 2.1. Describing a variable Consider a variable Xi which has a known uncertainty δXi. The form of representation of this variable and its uncertainty is xi = x mean (measured ) ± δxi Which should be interpreted as x mean 1 n = .∑ xi n i =1 • The best estimate of xi is x mean , where • There is an uncertainty in Xi that may be as large as δXi . The value of δXi can be taken as 2σ for a single sample analysis or as nσ where n is the coefficient that can be taken from Z-distribution table for a desired confidence level. σ is the standard deviation of the data set, given as σ =( n 0 ,5 ) .σ f n −1 where σf is the deviation for a finite number of measurements, given as σf = 1 n .∑ ( xi − xmean ) 2 n i =1 2.2 The Root Sum Square (RSS) The uncertainty of a result may depend on the uncertainties of the individual measured quantities and on how these quantities are combined. In general if a result Q is a function of more than one variable Xi, then the expected value Qmean will be calculated through the expected values of the affecting, Ximean, and will have an overall uncertainty, δq = [( dq dq .δ x1 ) 2 + ( .δ x 2 ) 2 + ......] 0.5 dx1 dx 2 EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 10 The partial derivatives of q with respect to Xi ‘s are the sensitivity coefficients for the result q with respect to measurement Xi. When several independent variables are used in the function of q, the individual terms are combined by RSS method. Then, Q = Qmean ± δq 2.3. Single Sample Analysis Unlike a multiple sample experiment, in which the variable error in a set of measurements can be determined from variance of the set itself, simple sample experiments require an auxiliary experiment in order to estimate the variable component of the uncertainty. This usually takes the form of a set of independent observations of the process at a representative test condition over a representative interval of time. The principal difficulty here is finding σ, the standard deviation of the population from a smaller than infinite set of observations. σ is different from the standard deviation of the set of observations made in the auxiliary experiments, but can be estimated from it, as given above. In single sample uncertainty analysis, each measurement is assigned three uncertainty value, its zeroth, first, and Nth order uncertainties. • The zeroth order uncertainty of a measurement is the RSS combination of all the fixed and random uncertainty components introduced by the measuring system. • The first order uncertainty of a measurement describes the scatter that would be expected in a set of observation using the given apparatus and instrumentation system, while the observed process is running. The first order uncertainty includes all effects of process unsteadiness as well as the variable error effects from the measuring system. The first order uncertainty interval must be measured in an auxiliary experiment. • The Nth order uncertainty of a result is a measure of its overall uncertainty, accounting for all sources of fixed and variable errors. This is the value that should be reported as the overall uncertainty. The Nth order uncertainty is calculated as the RSS combination of the first order uncertainty δXi,1, and the fixed errors from every source. 3. PROCEDURE Make a simple sample analysis by performing an auxiliary experiment at a certain airfoil position (with fixed incidence and fixed tunnel speed). a) Take the necessary data after disturbing the system and returning back to the fixed operating point. You can disturb the system in various ways like playing with the butterfly valve, angle of attack or their combination, but make sure that you take the disturbance back so that you are at fixed operating point again, just then you can take your readings. b) Referring to the above terminology and to the lecture notes, make an uncertainty analysis for the following terms and report their Nth order uncertainty; • Inlet Dynamic Pressure Readings both for manometer and transducer(ΔPi ) • Display unit readings (A,F,D) EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 11 Assume that all the fixed error on the display unit readings are corrected by subtracting zero values at the specific angle of attack. Also assume that there is no fixed error on Δh (inlet dynamic pressure manometer). c) Find out the uncertainty for Re, CL , CD by performing RSS method. d) Use inlet dynamic pressure manometer to find the fixed error of the inlet pressure transducer. DISCUSSION & CONCLUSION Discuss what have you observed during the experiment, NOT WHAT YOU DONE. Also discuss the results 9 Do you think they are reasonable? Why or why not? 9 Compare the behaviour of curves and relate them to each other etc…. Write about the shortcomings of the experiment and your recommendations. Note that the originality of the discussions is for your benefit. Remember what is graded is the degree to which you can correctly comment on the experiment and the results. REFERENCES 1. Moffat, R. J. ; “Describing the Uncertainties in Experimental Results”; Experimental Thermal and Fluid Science no:1 pp.3-17 ;1988. 2. Moffat, R. J. ; “Using Uncertainty Analysis in the Planning of the Experiments”; Journal of Fluid Engineering Vol. 107 pp. 173-182 ; 1985 3. Moffat, R. J. ; “Contributions to the Theory of Single Sample Uncertainty Analysis”; Journal of Fluid Engineering Vol. 104 pp. 250-260 ; 1982 4. Abernety, R. B. ; Benedict, R. P. ; Dowdell, R.B. ; “ASME Measurement Uncertainty”; Journal of Fluid Engineering Vol. 107 pp. 161-164 ; 1985 5. Dauherty, Robert L. ; “ Fluid Mechanics with Engineering Applications”;1985 6. Fox, Robert W. ; “ Introduction to Fluid Mechanics ”;1985 7. ME-483 Experimental Techniques in Fluid Mechanics Lecture Notes by O. Cahit Eralp, 2002 8. Lecture notes by Orhan Kural EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 12 APPENDIX NUMERICAL INTEGRATION OF CX AND CZ C =152 mm Cz Cp18 20 X 20 FLOW 4 21 2 19 Direction 17 0 5 CCW Cp19 17 Cp3 5 C P21 = Assume C ij = Define CZ = − C X = 1 c 1 c C P20 + C P19 C Pi + C PJ Cp 3 1 C P1 + C P2 2 Cp ij= Pressure coefficients acting on the airfoil panel between pressure tapping positions i and j 2 C Pij . Δ x for For _ all all panels panels (going ( going _ CCW) CCW ) ∑ 1 3 C P0 = 2 ∑ Cp 0 2 Z 18 C P ij for _ all For all panels panels (going_CCW) ( going CCW ) .Δ z EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL Δ x = x j − xi Δ z = z j − zi 13 FORMAT OF THE LAB. REPORT SHORT EXPERIMENT Â Â Â Â Â OBJECTIVE ( 1 page long at most ) SAMPLE CALCULATIONS GRAPHS (On graph paper with acceptable format) CONCLUSION INDIVIDUAL PERFORMANCE 5 30 15 20 10 QUIZ 20 TOTAL 100 LONG EXPERIMENT Â Â Â Â Â Â Â Â Â ABSTRACT & OBJECTIVE NOMENCLATURE & REFERENCES INTRODUCTION THEORY EXPERIMENTAL PROCEDURE SAMPLE CALCULATIONS GRAPHS DISCUSSION & CONCLUSION INDIVIDUAL PERFORMANCE 5 5 5 5 5 50 20 25 10 QUIZ 20 TOTAL 150 You are expected to bring the following materials. Â Â Â CALCULATOR FLUID MECHANICS TEXT BOOKS ME-410 LECTURE NOTES NO OTHER MATERIAL WILL BE ALLOWED FOR USE IN SHORT EXPERIMENTS. EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL 14 ME - 410 CHARACTERISTICS OF AN AIRFOIL DATA SHEET NAME: STUDENT NO: AMBIENT CONDITIONS Temperature ( Co ) Pressure ( mmHg ) LAB DATE: LAB GROUP: SUPERVISOR SIGN: ΔPi, Inlet Dynamic Pressure (mm H2O) [P3] = Alpha (α) Data # 1 2 3 4 5 6 7 8 9 10 A, Aft Load Cell [N] Degree AOFF AON D, Drag load Cell [N] F, Fore Load Cell [N] FOFF FON DOFF DON UNCERTAINITY ANALYSIS ( AUXILARY TEST DATA SHEET ) Sample # 1 2 3 4 5 6 7 8 9 10 Δpi [ P3] mm H2O Aft (A) [N] Fore (F) [N] EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL Drag (D) [N] Δpi [ manometer] mm H2O 15 PRESSURE DISTRIBUTION OVER THE AIRFOIL LOWER SURFACE No Pa (mm H2O) Pa-Pi (mm H2O) UPPER SURFACE No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Pa (mm H2O) ANGLE OF ATTACK ( o) Pa-Pi (mm H2O) (mm H2O) INLET STATIC PRESSURE (Pi) INLET DYNAMIC PRESSURE (ΔPi) TABLE-1 No 21 19 17 15 13 11 9 7 5 3 1 0 2 4 6 8 10 12 14 16 18 20 CP x(mm) 152.00 129.54 114.30 96.02 77.73 59.44 41.15 22.86 15.24 7.62 1.52 0.00 0.76 3.81 11.43 19.05 38.00 62.00 80.77 101.35 121.92 137.16 z(mm) 0.00 3.08 4.77 6.53 7.94 8.87 9.09 8.13 7.12 5.41 2.59 0.00 1.86 3.98 6.39 7.69 9.03 8.77 7.73 6.05 3.95 2.16 Cpij EXPERIMENT 6 CHARACTERISTICS OF AN AIRFOIL dxij dzij -22.46 3.08 -15.24 1.69 -18.28 1.76 -18.29 1.41 -18.29 0.93 -18.29 0.22 -18.29 -0.96 -7.62 -1.01 -7.62 -1.71 -6.10 -2.82 -1.52 -2.59 0.76 1.86 3.05 2.12 7.62 2.41 7.62 1.30 18.95 1.34 24.00 -0.26 18.77 -1.04 20.58 -1.68 20.57 -2.10 15.24 -1.79 14.84 -2.16 SUM= Cpij*dxij Cpij*dzij 16