Ester Synthesis and Analysis

advertisement

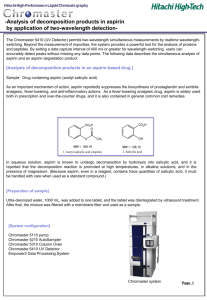

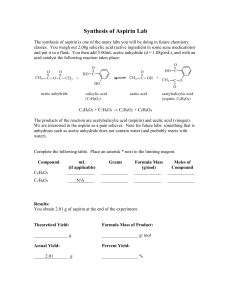

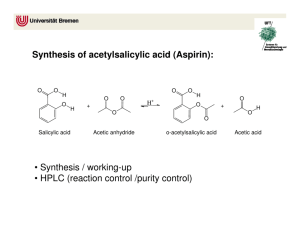

Ester Synthesis and Analysis: Aspirin and Oil of Wintergreen Christy Chan October 23, 2014 Thursday Evening Lab Section Partner: Deven Roberts INTRODUCTION The objectives of this experiment were to synthesize two organic esters, study the implications of reactions, which do not go to completion, and use chromatographic techniques to evaluate the purity of the products. A synthesis reaction is a reaction in which two or more reactants combine to form a single product. Esters, which have characteristically fruity odors, are synthesized by reacting an alcohol with an acid and is catalyzed by the addition of a strong acid and heat; this is also known as esterification. Carboxylic Acid + Alcohol heat à Ester + Water In this experiment, both methyl salicylate (oil of wintergreen) and acetylsalicylic acid (aspirin) were synthesized with the use of salicylic acid. As an alcohol, salicylic acid reacts with acetic anhydride to form acetylsalicylic acid, which is a white, powdery solid. As an acid, salicylic acid reacts with methyl alcohol (methanol) to form methyl salicylate, which is a colorless and fragrant oil. Salicylic acid Salicylic acid + + Acetic anhydride à Methanol à Acetylsalicylic acid Methyl salicylate + + Water Water Acetylsalicylic acid (aspirin) is commonly used in the treatment of different medical conditions such as pain, fever, and inflammatory diseases. Studies have also found that low doses of aspirin consumed immediately after a heart attack can help reduce the chance of another heart attack or of the death of cardiac tissue.1 However, the main side effects of aspirin include gastrointestinal ulcers, stomach bleeding, and ringing in the ears; therefore, it is not recommended that children under 16 years old consume aspirin for flu-like symptoms or viral illnesses.2 Methyl salicylate (oil of wintergreen) is naturally produced by many species of plants, most likely to serve as an anti-herbivore defense. For example, when a plant is infected with herbivorous insects, the production of oil of wintergreen attracts other insects that kill these herbivorous insects.3 Oil of wintergreen can also be used by plants as a pheromone to warn other plants of pathogens such as the tobacco mosaic virus.4 The final products of these syntheses were evaluated for purity with a chemical test for salicylic acid and the use of two chromatographic techniques – thin layer chromatography and highpressure liquid chromatography. In aspirin synthesis, the chemical test was conducted by the addition of an indicator (Fe3+), which changed color in the presence of salicylic acid. In thin layer chromatography, compounds in mixtures are separated between the stationary phase (the TLC plate) and the mobile phase (the solvent: a mixture of hexane and ethyl acetate) due to differing polarities. With this test, ratios of fronts of the experimental product are calculated and compared to controls to determine its purity. In high-pressure liquid chromatography, the compounds in the mixture placed into the chromatograph separate based on polarity as well. The retention times and peak areas of the different compounds in the mixture are compared to a standard, which was created by putting pure compounds into the chromatograph. The data obtained from a chromatography experiment are compared with controls to determine the presence of impurities, where in this experiment is the presence of salicylic acid. EXPERIMENTAL During week one, to make oil of wintergreen, a 0.50-g sample of salicylic acid was weighed out and transferred to a labeled test tube. Next, two mL of methanol was added to the test tube, along with 15 drops of concentrated sulfuric acid. The test tube was swirled continuously and then stopped with a cotton plug to prevent water from entering the reaction mixture. A boiling water bath was made by filling a 400-mL beaker with water, and adding several boiling stones. The test tube was added to the boiling water for 30 minutes. Next, two mL of cold distilled water was added to the test tube before it was stopped with a cork. The test tube was shaken to mix the contents. Using three mL of methylene chloride, the oil of wintergreen was extracted. The test tube was stopped with a cork and inverted several times. The cork was removed to relive pressure, and then placed back onto the test tube. The test tube was shaken for one minute, and then allowed to stand to let the layers separate. Using a Pasteur pipet, the lower layer (methylene chloride layer) was drawn up and transferred to a clean and dry test tube. The extraction was repeated and the second layer of methylene chloride was placed in the same test tube as the first layer. The methylene chloride layers were dried by the addition of a small amount of solid anhydrous sodium sulfate. Next the layer was decanted, leaving the sodium sulfate behind, into a clean and dry sample vial that was previously labeled and weighed. The vial was stopped loosely with a cotton plug and stored so that the methylene chloride evaporates. To make aspirin, a 0.50-g sample of salicylic acid was weighed out and transferred to a labeled test tube. Approximately 25 drops was acetic anhydride was added to the test tube, followed by two drops of concentrated phosphoric acid. The test tube was stopped loosely with a cotton plug to prevent water from entering the reaction mixture. It was then placed in the water bath for ten minutes before it was removed. While the mixture is still hot, two mL of cold distilled water was added. Another three mL of cold distilled water was added and swirled. The test tube was placed in an ice-water bath for five to ten minutes to allow for maximum crystallization of the product. At the same time, 15 to 20 mL of distilled water is cooled to be used for the transfer and washing of the crystals later. A side-arm flask and Büchner funnel was set up for vacuum filtration. The contents of the test tube were carefully poured into the Büchner funnel and a rubber policeman was used to scrape the solid into the tunnel. Small amounts of cold distilled water were used to aid in the transfer of the solid. The solid was carefully transferred to a clean and dry sample vial that was previously labeled and weighed. The vial was stopped loosely with a cotton plug and stored for drying. During week two, to determine percent yield, sample vials that were stored the previous week were obtained and the cotton plugs were removed. The vials were weighed and the masses of the products were determined by calculating the difference in weight of the vial before and after product was added. Using theoretical yields, the percent yield for each compound was calculated. To conduct a chemical test for salicylic acid, in a test tube, a small amount of aspirin was dissolved in two mL of a 50:50 mixture of ethanol and water. This was repeated in a second test tube with a small amount of salicylic acid starting material, and in a third test tube with a small amount of pure acetylsalicylic acid. Next, ten drops of one molar iron chloride solution was added to each test tube. The test tubes were compared to determine if the aspirin product contained any salicylic acid. To conduct thin layer chromatography, three test tubes were prepared (one with four drops of experimental wintergreen, one with four drops of pure methyl salicylate, one with a small amount of salicylic acid). Next, two mL of methanol was added to each test tube and swirled gently to dissolve the sample. The TLC chamber was prepared by placing five mL of the TLC solvent (50% hexane and 50% ethyl acetate) in a clean and dry 250-mL beaker. A piece of folded filter paper was placed in the beaker and pushed against one side. The top of the beaker was covered with aluminum foil and the mixture was swirled to saturate the beaker with its vapors. Next, three evenly spaced spots were lightly made with a pencil on the TLC plate. Using a different spotter for each substance, the samples were spotted onto the plate. The solvents evaporated and then the TLC plate was placed on the opposite side of the filter paper in the beaker. The beaker was covered. The TLC plate was removed when the solvent front was almost at the top of the plate. When the TLC plate was thoroughly dried, it was placed under a UV lamp and glowing shapes that appeared on the plate were traced lightly with a pencil. The color of the spots, distance the spots traveled and the total distance the solvent front traveled were recorded. The ratios of fronts were calculated for each spot on the TLC plate. To conduct high-pressure liquid chromatography, a few grains of experimental aspirin were dissolved in five to ten mL of methanol in a sample vial. This solution was injected onto the chromatograph with the help of the professor. The resulting chromatogram was compared to that of the standard sample provide by the professor. The retention times and areas for aspirin and salicylic acid peaks were recorded. Using known concentrations and measured areas from the standard chromatogram and the measured areas from the experimental chromatogram, the concentrates of aspirin and salicylic acid in the sample were calculated. These concentrations were then used to calculate the fraction of aspirin in the sample. This fraction was then used to adjust the percent yield of the aspirin synthesis. RESULTS Table 1: Raw Data and Calculated Data of Oil of Wintergreen and Aspirin Compounds Oil of wintergreen (C8H8O3) Aspirin (C9H8O4) Salicylic Acid Mass (g) Sample Vial Mass (g) Vial and Product Mass (g) Product Mass (g) Theoretical Yield (g) Percent Yield (%) 0.4999 12.9981 13.4524 0.4543 0.5507 82.50 0.5135 13.1250 13.5224 0.3974 0.6698 59.33 Sample Calculations of Oil of Wintergreen Theoretical Yield of Oil of Wintergreen = 0.4999 g C7H6O3 x 1 mol C7H6O3 / 138.122 g C7H6O3 x 1 mol C8H8O3 / 1 mol C7H6O3 x 152.149 g C8H8O3 / 1 mol C8H8O3 = 0.5507 g C8H8O3 Percent Yield of Oil of Wintergreen = Experimental yield / Theoretical yield x 100 = 0.4543 g / 0.5507 g x 100 = 82.50% Observations About the Physical Appearance of the Products Oil of Wintergreen: clear, liquid, oil bubbles, peppermint and minty scent Aspirin: white, wet, powder paste Observations of the Iron Chloride Chemical Test for Salicylic Acid Performed on Aspirin Aspirin with 50:50 mixture of ethanol and water + iron chloride: solution turned dark purple Salicylic acid + iron chloride: solution turned golden Pure acetylsalicylic acid + iron chloride: solution turned golden Table 2: Thin Layer Chromatography Data and Observations Sample Dsolv (cm) Dspot (cm) Rf 3.72 0.8176 0.63 0.1385 Oil of wintergreen 4.55 Salicylic acid 4.55 0.67 0.1473 Pure oil of wintergreen 4.55 3.30 0.7253 Color Spot was dark purple Spot was light purple Upper spots were violet Lower spots were light purple Spot was dark purple Sample Calculation of Rf Rf (Spot B) = Distance traveled by the compound / Distance traveled by the solvent front = 0.67 cm / 4.55 cm = 0.1473 Solvent front A: Sample of oil of wintergreen B: Salicylic Acid C: Pure oil of wintergreen Table 3: High-Pressure Liquid Chromatography Data on Aspirin Peak Identity Aspirin Salicylic Acid Retention Time (min) 7.50 9.15 Peak Area (mAU) 1489386 201040 Concentration (mg/mL) 0.0965 0.00603 Sample Calculation of Adjusted Yield of Aspirin Concentration of Aspirin = Aspirin standard x Peak area of experimental aspirin / Peak area of standard aspirin = 2.27 mg/mL x 1489386 mAU / 35039045 mAU = 0.0965 mg/mL Concentration of Salicylic Acid = Salicylic acid standard x Peak area of experimental salicylic acid / Peak area of standard salicylic acid = 1.51 mg/mL x 201040 mAU / 50308147 mAU = 0.00603 mg/mL Adjusted Yield of Aspirin = Concentration of aspirin / (Concentration of aspirin + Concentration of salicylic acid) x Percent yield of aspirin = 0.0965 mg/mL / (0.0965 mg/mL + 0.00603 mg/mL) x 59.33% = 55.84% Aspirin Salicylic acid Figure 1: Experimental High Pressure Liquid Chromatography Data on Aspirin Figure 2: Standard High Pressure Liquid Chromatography Calibration Data on Aspirin DISCUSSION In order to study the implications of reactions that do not go to completion, two organic esters were synthesized, and chromatographic techniques were used to evaluate the purity of the products. First, the percent yields of aspirin and oil of wintergreen were calculated to determine how much of the theoretical yields were produced. While a 100% yield is strived for, it is not possible even with the best technique because the product could have been lost in certain areas of the procedure. Also, in esterification reactions, no matter how much time is allowed, some of the reactants remain. For example, in the synthesis of oil of wintergreen, when drawing up the methylene chloride layer with the Pasteur pipet, it was very likely that not all of the methylene chloride was transferred to the test tube. Next, when the methylene chloride was dried with anhydrous sodium sulfate and then decanted, it was possible that not all of the liquid was transferred and that some anhydrous sodium sulfate was transferred as well. Also, in the synthesis of aspirin, when filtering the solution, which contained acetic anhydride, concentrated phosphoric acid, and distilled water, the aspirin solid may not all have been transferred to the Büchner funnel, or the filtration may have allowed some solid to filter through, losing the product. Previous years demonstrate the percent yield to fall between 40-70%; in this experiment, the oil of wintergreen had a 82.50% yield and the aspirin had a 59.33% yield (Table 1). However, the percent yield calculated was not an accurate reflection of purity because there may have been a low percent yield, but the product could possibly contain only the ester synthesized. A chemical test was conducted to determine the purity of the aspirin qualitatively. The indicator, Fe3+, turns violet when reacting with salicylic acid. A positive control was created by reacting iron chloride with salicylic acid forming the violet color, and a negative control was created by reacting iron chloride with pure acetylsalicylic acid forming a golden color. The experimental aspirin was reacted with the iron chloride and its color was compared with the controls to determine which compounds were present in the experimental product. With the chemical test, the experimental product, when reacted with iron chloride, formed a golden color, identical to that of the negative control. This suggested that the experimental product contained aspirin, and possibly minute traces of salicylic acid. A thin layer chromatography test was conducted to determine the purity of the oil of wintergreen qualitatively. The TLC plate (a plastic plate covered with silica gel), which acts as the stationary phase, was spotted with three different compounds dissolved in methanol – the experimental oil of wintergreen, salicylic acid, and pure methyl salicylate, and then placed in a solvent (a mixture of hexane and ethyl acetate), which acts as the mobile phase. When the solvent moved pass the spots on the TLC plate through capillary action, molecules of the spotted materials separated between the stationary phase and the mobile phase because of their differing polarities. Each compound was characterized by its ratio of fronts, which is the distance that the compound traveled divided by the distance traveled by the solvent front. The spot B was salicylic acid and the spot C was pure oil of wintergreen, so these two spots served as controls for comparison with spot A, which was the experimental oil of wintergreen. In this experiment, the Rf of salicylic acid was 0.1473 and the Rf of pure oil of wintergreen was 0.7253 (Table 2). The Rf values of the two spots found in the experimental oil of wintergreen were relatively similar to that of the controls (0.1385 and 0.8176), suggesting that the oil of wintergreen was not really pure due to the presence of salicylic acid in the final product. A high-pressure liquid chromatography was conducted to determine the purity of aspirin. The chromatograph is made up of a pump that pushes a solvent (the mobile phase) through a small column (the stationary phase), which contains very small polymer beads that attract different molecules based on their polarity. Different compounds pass through the column at different rates, allowing for the separation of different compounds in a sample. Experimental aspirin was dissolved in methanol and injected onto the chromatograph and the resulting chromatogram was compared to that of the standard chromatogram, which showed the retention times and peak areas of pure aspirin and pure salicylic acid. By comparing the experimental retention time and peak area to that of the standard, purity can be determined. For example, the experimental peak area of aspirin was 148936 mAU and the experimental peak area of salicylic acid was 201040 mAU, while the standard peak area for aspirin was 35039045 mAU and the standard peak area for salicylic acid was 50308147 mAU; this indicated that the level of salicylic acid in the experimental product was relatively low (Table 3). With these data, the percent yield was adjusted to factor in purity of the aspirin. The experimental product had a 55.84% adjusted yield, suggesting that the aspirin was not as pure as indicated with the chemical test of salicylic acid. This may be due to fact that there may be salicylic acid in the product, but not even to trigger a violet purple in the test. CONCLUSION The syntheses of oil of wintergreen and aspirin were successful, but the products were not pure. REFERENCES 1. Julian, D.G.; Chamberlain, D.A.; Pocock, S.J. A comparison of aspirin and anticoagulation following thrombolysis for myocardial infarction (the AFTER study): a multicentre unblinded randomised clinical trial. BMJ 1996; 313:1429 2. Macdonald, S. Aspirin use to be banned in under 16 year olds. BMJ 2002; 325:988 3. James, D.G.; Price, T.S. Field-Testing of Methyl Salicylate for Recruitment and Retention of Beneficial Insects in Grapes and Hops. Journal of Chemical Ecology 2004; 30:8 4. Shulaev, V.; Silverman, P.; Raskin, I. Airborne signalling by methyl salicylate in plant pathogen resistance. Nature 1997; 385:6618