Variations in coffee processing and their impact on quality and

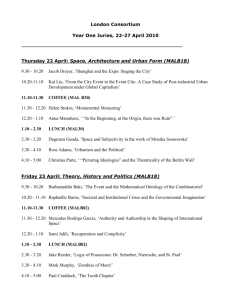

advertisement