SUPPLY CHAIN MANAGEMENT (SCM) IN THE SPANISH

advertisement

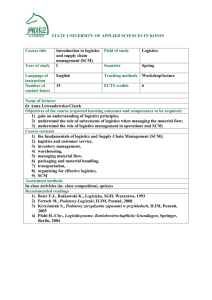

SUPPLY CHAIN MANAGEMENT (SCM) IN THE SPANISH GROCERY SECTOR CRISTINA GIMÉNEZ THOMSEN Escola Universitària del Maresme (Universitat Pompeu Fabra) Universitat de Barcelona cgimenez@eum.es ABSTRACT The aim of this paper is to explore the current state of Supply Chain Management (SCM) in the Spanish grocery sector and, in the case of a SCM approach, to establish what have been the main benefits achieved and the main barriers found. Firstly, a review of the Spanish grocery sector and SCM concept are presented. After this review, a multiple case study analysis based on interviews to important manufacturers and retailers is shown. And, finally based on the case study findings, some conclusions, limitations and further research needs of this study are pointed out. ACKNOWLEDGEMENTS The analysis presented in this paper is part of my MSc thesis at Cranfield University and, therefore, I would like to thank my supervisor at Cranfield University, Mark Barratt, for all his guidance and valuable advice throughout the thesis. I would also want to thank you my PhD thesis supervisor at Universitat de Barcelona, José Mª Castán, for all his valuable comments. Finally, I would also like to express my thanks to all manufacturers and retailers that have been open to participate in this study, as well as to Asociación Española de Codificación Comercial (AECOC). 1. INTRODUCTION The grocery sector in Spain, as it is happening in other countries around the world, is characterised by suffering important concentration movements and by having a very competitive environment. In this highly competitive environment companies need to look for competitive advantages that enable them to have a better customer service and/or a lower cost by eliminating existing inefficiencies. Many of these inefficiencies are due to the fact of not managing the supply chain as a whole. Each member of the chain tries to optimise its part of the supply chain without taking into account the effects of its actions in the rest of the supply chain members. The management of the supply chain is very important because today, it is not one firm competing against another firm; instead, it is a supply chain competing against another supply chain (Christopher, 1998, p16). What creates value for the end-user is not the last firm in the chain; instead, it is all the members in the chain who create value for the end user. Therefore, it is a key aspect to contemplate the chain as a whole and not each of its members individually. The management of the supply chain is “the management of upstream and downstream relationships in order to deliver superior customer value at less cost to the supply chain as a whole” (Christopher, 1998, p4). As Supply Chain Management (SCM) is based on the management of supply chain relationships it becomes evident that the management of supply chain relationships is a key aspect to achieve competitive advantage. 1 A company must strategically segment its relationships and establish closer relationships with key members of its supply chain in order to minimise inefficiencies by working all of them as one unit. These closer relationships are characterised as being longer-term relationships, the sharing of information and benefits, the collaboration and co-ordination of activities and planning, etc. (Gardner, Cooper & Noordewier, 1994; Spekman, Kamauff & Myhr, 1998; Macbeth & Ferguson, 1994). In the grocery sector, the concept of Efficient Consumer Response (ECR) has evolved. This concept is based upon an initiative of manufacturers and retailers working together in order to eliminate supply chain inefficiencies and create a higher value for the end customer. 2. THE SPANISH GROCERY SECTOR During the last twelve years the Spanish grocery sector has evolved and modernised considerably: There has been a growth in the implementation of new technologies and the development of new commercial formats, such as hypermarkets and supermarkets. The most important characteristics of the Spanish grocery retailing sector are: Market concentration, considerable presence of foreign capital, overcapacity, the increase of the modern commercial formats (hypermarkets and supermarkets) and the decrease in the traditional establishments’ market share. However, with respect to the modern commercial formats, it has to be pointed out that the hypermarkets segment is showing signs of exhaustion while the supermarkets segment is growing. Another important characteristic of the grocery sector is the long payment terms imposed by big retailers that have allowed them to have considerable financial benefits. With respect to manufacturers-retailers relationships, there have been developments of very big and important purchasing centres, which have increased the retailers’ power. Medium and small retailers use these centres in order to obtain their supplies with better commercial conditions and discounts. On the other hand, big grocery retailers do not use these purchasing centres because they have enough power to impose prices and other trade conditions. During recent years, despite the recognition of the need for increasing efficiency in the retailing sector, mainly through a higher co-operation and co-ordination between the different members in the channel, few actions have succeeded. This is mainly due to (1) the scarcity of a general culture of co-operation and (2) the existing relationships characterised as being adversarial (Múgica, 1999, p48). Also, the co-operation and coordination efforts contrast with two prevailing industry views (Múgica, 1999, p48): (1) “The dominance of the production perspective: The main concern of each company in the channel is in its particular goods or services and not in the final consumer service that creates the whole channel” and (2) “incompatibility of information systems and differences in the logistics standards; the information and materials flows are broken up and interrupted as many times as companies exist in the channel.” However, at the end of 1995, the executive Committee of ECR Spain was created. ECR Spain is a non profit organisation whose mission is to promote solutions based on collaboration among agents involved in satisfying demand (Efficient Replenishment) and generating demand (Efficient Store Assortments, Efficient Promotions and Efficient Product Launches). Within the ECR Spain forum some ECR pilots have been implemented (CRP, supply chain reengineering, unitary loads, etc.). The results of these pilots have been satisfactory in terms of improved service and reduced total costs. And, with respect to manufacturers-retailers relationships it has to be said that the pilot schemes proved to be a landmark in the establishment of alliances between manufacturers and retailers because they have demonstrated the viability of the solutions tested. 2 3. SUPPLY CHAIN MANAGEMENT 3.1. Supply Chain Management Logistics have existed since the first wars created the need to move enormous quantities of people and supplies to equip them. However, logistics first appeared in the academic literature in the early 1900s (Kent & Flint, 1997). And, it has evolved in techniques and in concept. Logistics is defined today as: “The process of strategically managing the procurement, movement and storage of materials, parts and finished inventory (and the related information flows) through the organisation and its marketing channels in such a way that current and future profitability are maximised through the costeffective fulfilment of orders” (Christopher, 1998, p4). The main characteristics of each one of the different stages of the logistics’ concept evolution are: • 1950’s – early 1970’s: Logistics was defined as a distribution function, where controlling finished goods, transportation and warehousing was the companies’ mission (Bowersox & Daugherty, 1987, p47). • Mid 1970’s - 1980’s: “The 1980s saw a major growth in the logistics area, with the recognition of the potential savings from integrating the management of the various components of logistics throughout the organisation as a whole” (Bowersox, 1987, p233). “The traditional structure for manufacturing firms is to have three separate segments within the material flow system. The first segment is the procurement loop and extends from source of raw material to production site. The second segment extends from production site to the end of the production line. The third segment or loop extends to the end of the production line to the consumer or user of the finished product. Traditionally, these three segments have been treated as separate in both a managerial and organisational design sense ... The restructuring that is well underway in many firms is aimed at co-ordinating these three segments of the materials flow system” (La Londe, 1983, p4). • Late 1980’s - 1990’s: “In the last ten years the term supply chain management has risen to prominence … And it has been defined as an integrative philosophy to manage the total flow of a channel from earliest supplier of raw materials to the ultimate customer, and beyond, including the disposal process” (Cooper, Ellram, Gardner & Hanks, 1997, p68). This evolution in the logistics concept is shown in figure 1. Nowadays there are companies at these different stages. There are firms that are still considering logistics as a distribution function; others that have already internally integrated and therefore, Procurement, Manufacturing and Distribution are co-ordinated. Finally, there are other companies that have adopted the SCM approach and have internally and externally integrated. These later companies have integrated key business processes from end user through original suppliers to provide products, services and information that add value for customers and stakeholders ( Lambert, Cooper & Pagh, 1998). “The supply chain is the network of organisations that are involved, through upstream and downstream linkages, in the different processes and activities that produce value in the form of products and services in the hands of the ultimate consumer” (Christopher, 1998, p15). And, therefore, SCM is “the management of upstream and downstream relationships with suppliers and customers to deliver superior customer value at less cost to the supply chain as a whole” (Christopher, 1998, p4). 3 Figure 1. Logistics evolution: From distribution logistics to supply chain CUSTOMER SERVICE MATERIALS FLOW STAGE I: DISTRIBUTION LOGISTICS Purchasing Materials control Production Sales Distribution STAGE II: INTERNAL INTEGRATION OF MATERIALS FLOWS ! INTEGRATED LOGISTICS OR INTRA-FIRM LOGISTICS Materials Manufacturing Management Management Distribution STAGE III: EXTERNAL INTEGRATION ! SUPPLY CHAIN Internal Suppliers Supply Customers Chain Adapted from STEVENS, G.C. (1989): “Integrating the Supply Chain”, International Journal of Physical Distribution and Materials Management, vol. 19, no. 8, 3-8. Until recently SCM has been viewed as not different from the contemporary understanding of logistics management (as defined by the Council of Logistics Management in 1986): “from point of origin” to “point of consumption”. The members of The Global Supply Chain Forum redefined SCM in 1998 as: “The integration of key business processes from end user through original suppliers which provides products, services, and information that add value for customers and other stakeholders” (Lambert, Cooper & Pagh, 1998, p1). And, the CLM announced in 1998 a modified definition of logistics: “Logistics is that part of the supply chain process that plans, implements, and controls the efficient, effective flow and storage of goods, services, and related information from the point-oforigin to the point-of-consumption in order to meet customers’ requirements” (CLM, 1998i). 3.2. Why to adopt Supply Chain Management? There are some main motivators or drivers that have led firms to adopt SCM; but there have also been some facilitators that have contributed to its implementation and development. The drivers: “Houlihan (1985) and Jones and Riley (1985) stated that the objective of SCM is to lower the total amount of resources required to provide the necessary level of customer service to a specific segment” (Cooper, Lambert, & Pagh, 1997, p3). “Other writers have indicated other objectives supportive of this overall goal, including synchronising the requirements of the customer with the flow of materials from suppliers (Stevens, 1989), reducing inventory investment in the chain, increasing customer service, building competitive advantage for the supply chain (Cooper,1993; Cooper & Ellram, 1993), and value (La Londe, 1997; Langley & Holcomb, 1992 )” (Cooper, Lambert, & Pagh, 1997, p3). The enablers: Information systems and technology developments have played an important role in facilitating an efficient management of the supply chain. Information technology is a key enabler to the development of an integrated supply chain. “Leading organisations have long recognised that the key to success in SCM is the information system” (Christopher, 1998, p271). Information systems allow to link the customer directly to the supplier, enabling the supplier to react, sometimes in real-time, to changes in the 4 market. Some new technological tools that have been implemented to manage the supply chain are data standards, bar codes and information networking capabilities. 3.3. Supply chain relationships SCM is more than the management of upstream and downstream relationships along the supply chain; however, the performance of the supply chain is considerably based on this management of relationships. With respect to these relationships, it has to be pointed out that firms very often strategically segment them and establish different type of relationships with their supply chain members (Kraljic,1983; Dyer, Cho & Chu, 1998). These relationships between organisations range from arm’s length relationships to vertical integration. Each one of these two extreme approaches has its advantages and disadvantages. Partnerships appear as the type of relationship that can lead a company to benefit from both the advantages of the arm’s length relationship and vertical integration and, moreover minimise the problems related to these types of relationship (arm’s length and vertical integration). As pointed out before, companies strategically segment their relationships with their supply chain members and, with some they establish a more arm’s length type/style of relationship and with others a more partnership type. Also, within the more partnership type/style of relationship there can be different degrees of partnership: There is one type of partnership where firms only co-ordinate activities and planning on a limited basis and, on the other hand, there is another type of partnership where there is such a significant level of operational integration that each firm sees the other as an extension of its firm. In the grocery sector there is a new relationship framework between manufacturers and grocery retailers. This relationship framework is based on a joint and co-ordinated work . This new philosophy is called Efficient Consumer Response (ECR) and its aim is to eliminate inefficiencies, generate economies, benefit both parties in the relationship (winwin) and offer higher value to customers. Apart from these main objectives, which are important drivers for implementing ECR practices, there can also be structural factors that contribute to the spread of the ECR practices, such as higher competition due to concentration and the entry of hard discounters, decrease in interest rates, etc. 4. METHODOLOGY The research question to be answered by this study is: To determine the extent of SCM development in the Spanish grocery sector. A multiple case study analysis has been used to answer this question. The process followed to design and implement the case study methodology has been adopted from Yin (1994). In order to increase the reliability of the case study analysis, it was decided to create an interview protocol and a case study database. Also, other sources of evidence such as newspapers clippings and other articles have been used to corroborate and amplify evidence from other sources. With respect to “how to link the data to the research questions”, a chain of evidence has been established in order to allow any external observer to follow the derivation of any evidence from initial research question to ultimate case study conclusions. Due to the time constraints it has not been possible to cover all the various facets of this supply chain in the context of this study. The focus of this paper is primarily on the manufacturer-retailer relationship, not considering any other type of relationship within the grocery supply chain. When focusing on manufacturer-retailer relationship, the most appropriate method would be to analyse particular relationships. However, in view of the time constraints relating to data collection (i.e. approaching a retailer for an interview, carrying out the interview, and then asking to interview ones of the retailer’s suppliers), such an approach 5 has not been possible. As an alternative, the data collection method has been redesigned. Interviews have been undertaken with non-specific relationships between retailers and manufacturers, thereby facilitating data collection within the constraints of this study. The consequences of such an approach is discussed in the analysis and presentation of results. The units of analysis chosen are manufacturers and retailers from the Spanish grocery sector. For the research, interviews with fifteen companies (nine manufacturers and six retailers) were conducted. Manufacturers are leading companies or among the leaders in different product categories and retailers have been selected from the top-12 Spanish retailers (retailers interviewed had a market share of 18% in 1997, while the top-10 companies had a market share of 45%). Among both samples there were companies participating in the ECR forum and pilots and companies that were not. Initially, ten manufacturers and ten retailers were contacted to ask if they wanted to participate in the study; one manufacturer and four retailers declined. A structured guide was used to initiate the interview through the meetings, which typically lasted one to two hours. The meetings were generally held with the logistics directors or supply chain directors of manufacturers and retailers. Purchasing directors of some retailers were also interviewed in order to achieve more in depth information about supply chain relationships. Interviews with key accounts managers in manufacturers companies were more difficult to establish, but in some cases it was possible to interview a customer service manager. All interviews were (subject to the permission of the interviewed person) tape recorded (there were very few cases were the interview could not be recorded). 5. CASE STUDY ANALYSIS 5.1. Introduction The aim of the research question is to determine at which stage of supply chain integration are each one of the companies, taking into account Stevens’ (1989) classification (see figure 1). In order to determine if a company was internally integrated some factors needed to be present. The most important one is the integration of the following functions: Purchasing, Manufacturing and Distribution. If for example, Manufacturing was not linked to actual Sales or/and Purchasing to Manufacturing or Sales, then, the firm was considered not to be internally integrated. Finally, in some cases the organisational structure has also helped to determine if the company was internally integrated or not. For example, a fact showing internal integration in some companies was the existence of a “Customer Service” department responsible for the following process: Order ! Commercial conditions ! Logistics ! Invoices ! Payment On the other hand, in order to determine if a company was externally integrated, either upstream or downstream, the variables analysed were: (1) what it understands for SCM and what is the firm doing with respect to it; (2) its participation in ECR pilots and (3) its interfaces with other supply chain members. If the definition of SCM was right and the firm was implementing it at least with some supply chain members, then the firm was considered to be externally integrated. There were some cases in which the person interviewed knew the SCM concept but the firm was not really externally integrated but initiating this integration process through its participation for example in some CRP pilots. In these later cases firms were said to be at the beginnings of external integration. 6 5.2. Manufacturers’ perspective The findings from the case studies are: Four of the nine companies interviewed have adopted SCM (internal and external integration of its logistics, at least with some supply chain members); two other companies have achieved the internal integration stage and are in the initials of the external integration; one company shows signals of being internally integrated but not taking action with respect to the external integration and, finally, the last two companies are not internally integrated yet. Companies that are not fully externally integrated and/or not internally integrated know, however, the benefits that SCM can bring to them. Some have not achieved the internal integration stage basically due to internal reticence (reticence at some levels of their organisations). Others have not externally integrated yet or are at their first steps because they have preferred to prepare internally first. Concluding, it is suggested that manufacturers are making efforts to achieve the SCM stage in the near future, but first some are internally restructuring their organisations. When asked about the benefits that SCM can bring, most of them agreed in the general objectives of stocks and costs reductions and service improvements. Also, some of them recognised that a very important benefit that SCM and specially ECR has brought was to create collaboration between manufacturers and retailers. With respect to the improvements in stock levels and costs, it has to be said that manufacturers state that they have not seen these benefits in the CRP projects in which they have been involved, basically due to a lack of critical mass. However, all agree that improvements in service levels have been considerably. Finally with respect to the main barriers to implement SCM, most of the companies pointed out: Distrust on the other party because of being afraid that the savings will go only to the other party, lack of culture of sharing information, internal resistant at some levels of the organisation and incompatibility of information systems. 5.3. Retailers’ perspective With respect to which degree of integration retailers have, the findings from the case studies are: Three of the six companies interviewed have adopted the SCM approach being internally and externally integrated. Two are not internally integrated and neither externally integrated and one shows some signals of internal integration, but it is not fully internally integrated and it is neither externally integrated. Companies that are not internally and neither externally integrated state that the reasons are: (1) “First we have to consolidate the merger we suffered some little time ago” and (2) “Now we have to take advantage of the expansion phase; in the future the trend will be towards ECR and SCM”. And, with respect to the company that shows some signals of internal integration but not any about external integration there is not enough information in the case to determine what’s the main reason for not externally integrateii. When asked about the main benefits that SCM can bring to a company most of the retailers pointed out: Cost and stock reductions, service improvements and higher competitivity. Few of them also added the following benefits: Simplification of operations and higher productivity at the stores and, to allow win-win relationships. Finally, with respect to the main barriers, retailers were not coincident in stating the same barriers; nearly all of them stated different barriers: The need of a know-how, the need of a minimum size, the history and habits, the company culture, a lack of trust on the other party, the commercial relationship and the departmental barriers within a firm. 7 5.4. Conclusions There are major differences in the SCM development among retailers than compared to manufacturers. Four of the nine manufacturers had adopted the SCM view, two were in the initials of the external integration and one was internally integrated despite it was not taking any action with respect the external integration. On the other hand, with respect to retailers, three of the six companies interviewed had adopted the SCM approach being internally and externally integrated and, from the rest only one company showed some signals of internal integration. From the interviews it was deduced that the three retailers that have the SCM approach are the ones more advanced in these topics, and within the first twelve retailers there is only another firm (that has not accepted to participate in the study) that has adopted the SCM approach. It has to be said that among the top-10 retailers that represented 45.5% of total sales in 1997, there are three retailers (approximately 18% of market share in 1997) that are very advanced in SCM, while there are others that have adopted this approach lately and are not so advanced (13.5% of market share in 1997) and others that have not adopted this SCM view yet (7.8% of market share in 1997)iii. Among manufacturers interviewed there is less difference in the degree of SCM development, but it has to be said that most of the manufacturers in the sample are leaders or between the leaders in their respective categories. Probably, if smaller manufacturers had been interviewed they would have not shown the same level of SCM development. Despite generalisation can not be done as the sample sizes are not big enough, the findings of these case studies suggest that main manufacturers could be, in general terms, more prepared to adopt SCM than main retailers in the Spanish grocery sector, despite there are some important retailers (threefour) that are very advanced in this development. The concept of SCM was well understood by most of the firms, among retailers and manufacturers. And, regarding the benefits that SCM can bring to a firm, the general objectives of cost and stock reductions and service improvements were stated by most of the companies. Retailers added the benefits of simplification of operations and higher productivity at the stores (no need of having a warehouse at each store). And finally, with respect to the main barriers to implementing SCM there were differences between manufacturers and retailers. Manufacturers highlighted distrust on the other party because of being afraid that the savings will go only to the other party and a lack of culture of sharing information as the main barriers; while for retailers the main barriers were different for each one of the companies. Only one retailer mentioned lack of trust on the other party. These findings suggest that manufacturers see more barriers with respect to aspects related to the other party: (1) “Distrust” because they are afraid of retailers owning all the savings due to a CRP project and (2) “lack of culture of sharing information” because there are still some retailers that have reticence to share some information about stock levels. 6. LIMITATIONS AND FURTHER RESEARCH 6.1. Limitations One on the main limitations of this study is that it has not considered other important members of the grocery supply chain such as TPL, manufacturers’ suppliers, etc. The analysis has focused only on the manufacturer-retailer relationships. Another important limitation of this study is that the unit of analysis should have been the dyadic relationship between a retailer and a manufacturer (i.e. a specific relationship), and not relationships in general between manufacturers on one hand and the retailers on the other. Future research on supply chain relationships must have a dyadic 8 relationship between a retailer and a manufacturer (i.e. a specific relationship) as the minimum unit of analysis. The small sample sizes have also impeded generalisation of some findings. The fact of involving only a single executive from some organisations is another limitation, as logistics managers, for example, may find supply chain relationships more collaborative than commercial managers or key accounts managers do. Finally, the fact of having based the case studies on personal interviews all limitations related to this tool should be added, such as subjectivity. The mentioned limitations have been due to the time constraints for data collection. However, despite these limitations the findings of this study contribute to its exploratory aim: To determine the degree of SCM in the Spanish grocery sector. 6.2. Further research Some lines of further research are: (1) To include more supply chain members in the study in order to determine the type of approach that the Spanish grocery sector has adopted. Is it a dyadic approach or is it basically driven by retailers? Or by manufacturers? (2) It has been seen that some companies are adopting a process orientation. In this area, further research should try to identify the key business processes and what are the relationships between them. What are the relationships between processes of different supply chain members? Can the Spanish grocery sector be mapped as a group of processes rather than a group of companies? 7. BIBLIOGRAPHY AND REFERENCES ALIMARKET (1998): “Informe Anual de Distribución: 1998”, Alimarket. BOWERSOX, D.J. & DAUGHERTY, P.J. (1987): “Emerging patterns of logistical organization”, Journal of Business Logistics, vol.8, no.1, 46-59. BOWERSOX, D.J. (1987): “Logistics strategic planning for the 1990’s”, Council of Logistics Management Fall Conference Proceedings, vol.1. COOPER, M.; ELLRAM, L.; GARDNER, J. & HANKS, A. (1997): “Meshing Multiple Alliances”, Journal of Business Logistics, vol.18, no.1, 67-89. COOPER, M.; LAMBERT, D. & PAGH, J. (1997): “Supply Chain Management: More than a new name for logistics”, The International Journal of Logistics Management, vol.8, no.1; 1-13. CHRISTOPHER, M. (1998): Logistics and Supply Chain Management: Strategies for reducing cost and improving service, Financial Times Pitman Publishing, London. DYER, J.; CHO, D. & CHU, W. (1998): “Strategic supplier segmentation: The next best practice in supply chain management”, California Management Review, vol.40,no.2, 57-78. GARDNER, J.; COOPER, M.; NOORDEWIER, T. (1994): “Understanding shipper-carrier and shipper-warehouser relationships: Partnerships revisited”, Journal of Business Logistics, vol.15, no.2, 121-143. GIMÉNEZ THOMSEN, C. (1999): Supply Chain Relationships in the Spanish Grocery Sector, Cranfield University, MSc Thesis. KENT, J.L. JR. & FLINT, D.J. (1997): “Perspectives on the evolution of logistics thought”, Journal of Business Logistics, vol.18, no.2, 15-29. KRALJIC, P. (1983): “Purchasing must become supply management”, Harvard Business Review, vol.61, 109-117. LA LONDE, B. (1983): “A reconfiguration of logistics systems in the 80s: Strategies and challenges”, Journal of Business Logistics, vol.4, no.1, 1-11. 9 LAMBERT, D.M.; COOPER, M.C. & PAGH, J.D. (1998): “Supply Chain Management: Implementation issues and research opportunities”, The International Journal of Logistics Management, vol.9, no.2, 1-19. MACBETH, D. & FERGUSON, N. (1994): Alianzas con los proveedores, Ed. Folio S.A., Barcelona. MÚGICA, J.M. (1999): “Cambios en los canales de distribución en Europa: Tecnología de la información, sistemas integrados y cadenas de suministro”, Distribución y Consumo, no.43, 48-56. SPEKMAN, R.E., KAMAUFF, J.W. & MYHR, N. (1998): “An empirical investigation into supply chain management”, Supply Chain Management, vol.3, no.2, 53-67. STEVENS, G.C. (1989): “Integrating the supply chain”, International Journal of Physical Distribution and Materials Management, vol.19, no.8, 3-8. YIN, R.K. (1994): Case study research: Design and methods, Sage Publications, USA. i CLM (1998): Annual Business Meeting; Anaheim, CA. Cited in LAMBERT, D.M.; COOPER, M.C. & PAGH, J.D. (1998): “Supply Chain Management: Implementation Issues and Research Opportunities”, The International Journal of Logistics Management; Vol.9, no.2, 3. ii The person interviewed did not know about the ECR project and stated that another person in the company was responsible for this kind of projects. iii There is 8.5% of the market share of this top-10 companies that belongs to companies for which the development of SCM has not been able to be identified due to a lack of information. 10