Heinz Leuenberger_Green Chemistry

advertisement

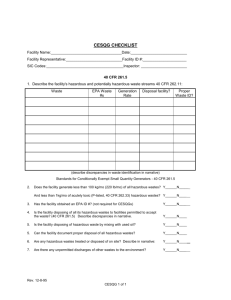

Green Chemistry and Hazardous Waste Heinz Leuenberger Director, Environmental Management Branch UNIDO THE CHALLENGE Business as usual is no longer an option Provide more value with fewer negative consequences Improve economic and ecological efficiency; do more with less Decouple Growth from Natural Resource Consumption and Negative Environmental Impacts Resource decoupling Human well-being Economic activity (GDP) Resource use Time Environmental impact Impact decoupling Source: International Resource Panel Decoupling Natural Resource Use and Environmental Impacts from Economic Growth, UNEP, 2011 THE GREEN INDUSTRY INITIATIVE Processes Benefits Economic Social Environmental More Innovation and Growth; Increased Resilience… More Employment, Rising Incomes and Empowerment… More Efficient Resource Use; Less Waste and Pollution… Increase resource productivity Bring down production costs Foster technology development and innovation Improve competitiveness Open up new markets Develop new businesses Create new jobs and make existing jobs more secure Reduce poverty Develop new skills and capacity Improve occupational health and safety conditions Safeguard health and safety of communities Lower risks to consumers Reduce environmental pollution Counteract resource depletion Prevent degradation of ecosystems Mitigate climate change Combat water scarcity HAZARDOUS WASTE • 200 million people at risk from toxic pollution in 49 low and middle income countries • Top 10 industrial sources: Lead-acid battery recycling, Lead smelting, Mining and ore processing, Tannery operations, Industrial/municipal dump sites, Industrial estates, Artisanal gold mining, Product manufacturing, Chemical manufacturing, Dye industry Source: Green Cross Switzerland & Blacksmith Institute, 2013 • • • • • • • • • • • EXAMPLES OF HAZARDOUS WASTE Wastes from the production of many chemicals Chlorinated hydrocarbons Compressed gas cylinders and spray cans Expired paints, dyes and solvents Infectious hospital waste Mercury and mercury compounds Pesticides, herbicides and insecticides Spent chemical solutions Used batteries Waste oil from cars/ machine maintenance Waste containing PCBs 5 HAZARDOUS WASTES FROM SELECTED INDUSTRIES Chemical Strong acids and bases, reactive and ignitable wastes, discarded commercial chemical products Cleaning & Heavy metal dusts & sludge, ignitable wastes, solvents, strong Cosmetic acids and bases Food and Beverages Animal waste (not always hazardous), cleaning wastes, CFCs (refrigerants) Furniture & Wood Ignitable wastes, spent solvents, paint wastes Leather & Textiles Tanning liquor and effluent, treatment containing, chromium, dyestuffs and pigments containing dangerous substances Metals Paint wastes containing heavy metals, strong acids and bases, cyanide wastes, sludge containing heavy metals Paper and Printing Ignitable and corrosive wastes, Ink wastes, including solvents and metals, photography waste with heavy metals solutions HAZARDOUS WASTE MANAGEMENT PREVENTION FIRST! • Hazardous waste management should prioritize reducing or eliminating the generation of hazardous waste in the first instance. Resource Efficient and Cleaner Production (RECP): – Increases the resource productivity in production processes – Promotes greater occupational safety by reducing the exposure of workers to hazardous materials – Helps avoid spills and accidental releases of hazardous waste – Reduces costs of treatment and disposal of hazardous materials GREEN CHEMISTRY … Going One Step Further – “Design and application of chemical products and processes to reduce or to eliminate the use and generation of hazardous substances.” • From 12 Principles of Green Chemistry by Paul Anastas and John C. Warner “Pharmaceutical plants typically generate 25 to 100 kilograms of waste per kilogram of product” Source: Nature 469, 18-20 (2011) | doi:10.1038/469018a GREEN CHEMISTRY IN ACTION Example: Supercritical CO2 • Above its critical temperature (304.25 K) and critical pressure (72.9 atm or 7.39 MPa), CO2 adopts properties midway between a gas and a liquid • Uses Industrial and domestic solvent replacement Production of silica, carbon and metal-based aerogels. Supercritical fluid extraction - is fast and offers selectivity through varying pressure and temperature Decaffeination of coffee beans Extraction of essential oils GREEN CHEMISTRY IN ACTION Example: Hydrogen Peroxide to Propylene Oxide (HPPO) • Innovative process for production of P0 Industrial success story • PO is top 30 chemical intermediate – used in variety of applications • Traditional process uses organic peroxides and produces organic byproducts, requiring disposal or recycling • New process uses hydrogen peroxide and produces water as byproduct • High selectivity and efficiency » 25% lower capital expenditure – no waste treatment facility required » 70-80 reduction of waste water » 35% reduction of energy – Developed and commercialized by Dow-BASF » First commercial plant in 2008 in Belgium » Second commercial plant in 2011 in Thailand 2010 Winner Presidential Green Chemistry Award GREEN CHEMISTRY IN ACTION Example: New Reactions - Catalysis Catalysts increase reaction yield and specificity and reduce its energy requirement and waste generation • Nano-technology provides new possibility to design and construct effective catalysts For example: Fisher Tops synthesis of liquid fuels from synthesis gas produced from biomass • Bio-catalysis is based on use of enzymes to catalyse reactions For example: cellulase enzymes to break down woody biomass as source for bio-ethanol production RESOURCE EFFICIENT AND CLEANER PRODUCTION (RECP) RECP accelerates the application of preventive environmental strategies to processes, products and services to increase efficiency and reduce risks to humans and the environment. RECP addresses the three sustainability dimensions individually and synergistically: 1.Production Efficiency: 2.Environmental 3.Human optimization of the productive use of natural resources; management: minimization of wastes and emissions; and Development: minimization of risks to people and communities. Global Network of Resource Efficienct and Cleaner Production Centres (RECPnet) Key Services: 1.Technical Assistance and In-plant Assessments 2.Training 3.Information Dissemination and Awareness Creation 4.Policy Advice 5.Technology and Investment Promotion WAY FORWARD - CHALLENGES Change in mindsets needed first Achieving technical feasibility Subsidies and perverse incentives3 Technology lock-in Many plants/equipment etc. may be in use 20-30+ years FUTURE ACTIVITIES AT UNIDO Pilot Project Formulation Based on provision of technical assistance to industries via CPCs Involve business organizations, private sector, research and academia Identify high-impact sectors Examples: Bio plastics, Enzymes in textile, Organic solvents based on bio waste Capacity Building Train CPC staff in Green Chemistry principles Launch training courses on Green Chemistry approaches in industry Stimulate further innovation and research Roll-Out of Capacity Building Activities Select pilot countries with active RECP centers Replicate training program at national and regional level Thank You Heinz Leuenberger Director, Environmental Management Branch UNIDO www.unido.org/greenindustry www.greenindustryplatform.org