c356c29e76f11967481d64271ab79310-1

PRIVATE & CONFIDENTIAL PLEASE

Mahesh M U

Aiswarya,

CharipparambuP O

Kadakkal,

Kollami,.

Kerala,India.

E-Mail: mu.mahesh1987@gmail.com

Phone No : 0096897839608 ( Oman )

00918281613928( India )

“Suitable post in QC Inspector for welding & piping”

Dear Sir / Madam,

I am working as QA/QC INSPECTOR , currently based in Oman, with around – 6 years in fabrication industry as a QA/QC inspector -at Middle East & India.

I enclosed herewith my updated Curriculum Vitae for your consideration, which briefly outlined my

6 years of multi-tasking experience to date.

Self Assessment: Am a fast learner with a stomach and passion to excel in whatever I do, adapts well to new technology / ambience, articulate ideas down the line, strict on deadlines, a go-getter, innate qualities of dedication, commitment, perseverance, integrity, team leader – lead upfront with excellent man management skills.

Career Objectives / Ambition: Build a formidable closely knit team that would make the company proud. Articulate Company’s vision statement down the line. Take up higher / challenging responsibilities and climb the corporate ladder.

From what has been said above and outlined in the pages that follow, I am confident as much as you would be that I would most definitely blend well with the line of business and work culture of your esteemed organization.

Please be assured that you would be looking at the best both in content and quality.

Yours sincerely,

MAHESH M U

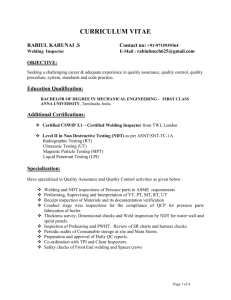

Curriculum Vitae

(Page 1 of 3)

Personal:

INDIAN

Date of birth: 23/05/1987

Language: English, Hindi, Tamil

& Malayalam

Driving licence: Indian & Oman .

Indian Contact details:

Passport No: G9659698

Valid up to 04-08-2018

Mahesh M U

Address in India:

Aiswarya

Charipparambu P O

Kadakka

Kollam,Kerala

India e-mail: mu.mahesh1987@gmail.com

TECHNICAL

COURSE&

EDUCATION

Diploma.

ASNT LEVEL-II

AWS - Certified Welding Inspector (CWI)

TWI - CSWIP 3.1

IRCA approved LEAD AUDITOR, ISO 9001

EXPIREINCE : 6 YEARS

.

PROFILE: Duties & Responsibilities in (QA/QC)

Coordinate all QA/QC activities with QC Manager

Conduct the all QC inspection and Testing

Monitor the all quality related activities on the Project

Prepare the punch list

Conduct the Mechanical Completion inspection with client

Conducting Welder Performance Qualification tests

Conducting procedure qualification record

Carrying out dimension and visual inspection in accordance with

drawings and specification

Maintaining Fit-up progress report

Maintaining Welding progress report

Monitoring welder performance (% of Repairs)

Performing field inspection for ongoing welding and finished elements at site

Looking after all types of destructive and Non Destructive testing

Knowledge on Radiography film Interpretation

QC line check, joint status &NDT attachments

Coordinating NDT crew

Preparing weld history, joint type & joint details for Pipe line

Spool release and spool movement

Experience in welding process GTAW, SMAW,GMAW,SAW.

Knowledge about Standards ASME Sec II ,ASME Sec V, Sec VIII, Sec

IX , API 1104, ASME 31.1, ASME 31.3, API 650,AWS D 1.1.

Duties & Responsibilities

Daily checking fit-ups and Maintaining Fit-up progress report

03.11.2012 to Till Date

Company :

–

ENGINEERING

BHAWAN

COMPANY

MUSCAT, OMAN .

Coordinate all QA/QC activities with QC Manager

Preparing weld history, joint type & joint details for Pipe line

Maintaining Repair Register

Conduct the all QC inspection and Testing

Project : Sur Independent

Power Project

Client: DAEWOO Engineering

& Construction

Position: QC INSPECTOR

WELDING & PIPING

27.05.2012 to 02.11.2012

Project : Sohar 2 Independent

Power Plant

Monitor the all quality related activities on the Project

Prepare the punch list

Witness for torquing.

Coordinating NDT crew

PWHT Inspection

Conduct the Mechanical Completion inspection with client

Radiography film Interpretation

Test package preparation

Witnessing of Hydro and Pneumatic Test

Maintaining Fit-up progress report

Client: The Consortium of

GS Engineering &

Construction and Siemens

Position: QC INSPECTOR

WELDING & PIPING

17.05.2011 to 30.012012

Company

: AHMEDMANSOOR

AL’A’ ALI – BAHRAIN

,

Spool release and spool movement

Preparation & Review of the final QC dossier/Inspection records and handing over to plant team.QC document control- Maintain procedure &

Method statements document No

Duties & Responsibilities

Conducting Welder Performance Qualification tests

Welding consumable inspection (welding electrodes)

Carrying out dimension and visual inspection in accordance with drawings and specification

Project : Water Transmission facility for Bahrain financial

Harbour,Lulu island & Al

Daily checking fit-ups and Maintaining Fit-up progress report

Maintaining Welding progress report

Looking after all types of destructive and Non Destructive testing

futtaim

Client:Projects Directorate,

Electricity and Water

Authority, Bahrain.

Position: QA/QC INSPECTOR

MECHANICAL

07.01.2010 to 31-03-2011

Company : SUNIL HI-TECH

Engineers Ltd

Radiography film Interpretation

Preparation of hydro test package.

Witness for hydro test & pneumatic

Preparation of inspection report

Released joints for coating after all inspection

Witness all the golden joint cutting, ndt and welding

Material inspection for valves and flanged tie in.

Witness for torquing.

Project permanent material inspection

Mechanical line check preparing punch with piping supervisor.

Preparation & Review of the final QC dossier/Inspection records and handing over to plant team.QC document control- Maintain procedure &

Method statements document No

Duties & Responsibilities

Conducting Welder Performance Qualification tests

Involved in WPS/PQR and construction procedure preparation

Welding consumable inspection (welding electrodes)

Carrying out dimension and visual inspection in accordance with drawings

Position : QC INSPECTOR

MECHENICAL and specification

Daily checking fit-ups and Maintaining Fit-up progress report

Maintaining Welding progress report

Monitoring welder performance (% of Repairs)

Looking after all types of destructive and Non Destructive testing

Radiography film Interpretation

Witness for hydro test.

Spool release shop to painting after all inspection

Finalizing and follow-up with procurement for vendor final documentation package.

Vendor QCP.

ITP evaluation and approval.

Fabrication, spool release shop to painting after all inspection

Storage and handling of welding consumables.

Duties & Responsibilities

03.01.2008 to10.12.2009

Maintain welding database- input daily welding reports to system

Maintaining Fit-up progress report

Company: SEAM INDUSTRIES PVT

LTD

Welder Performance Qualification tests

Field welding inspection

NDT Coordination

Maintaining Repair Register

Position: QC INSPECTOR

Coating Clearance /lowering clearance

Welder percentages charts

Supervisor of on shop fabrication, planning, procurement of materials

Conducting Welder Performance Qualification tests

Daily checking fit-ups and Maintaining Fit-up progress report

Carrying out dimension and visual inspection in accordance with drawings and specification

Preparation of inspection report

DEC LA RAT IO N

I hereby decl are t h at al l t he i nform ati on f urni shed above i s t r ue t o t he best of m y knowl e dge and bel i ef .

MAHESH M U