This document is under review as revision to an API Standard; it is under consideration within an API technical committee but has not received all approvals required

for publication. This document shall not be reproduced or circulated or quoted, in whole or in part, outside of API committee activities except with the approval of the

Chairman of the committee having jurisdiction and staff of the API Standards Dept. Copyright API. All rights reserved.

650-2021

Title: Eliminate Reference to EGW in 5.1.3.6.1(b)

Date:

Dec 31, 2014

0

Revision:

Handled By:

Doug Miller

Chicago Bridge and Iron Company

14105 S. Route 59

Plainfield, IL 60544-8984

Telephone: 815-439-6522

Fax: 815-439-6560

Email: dmiller@cbi.com

__________________________________________________________________________________________

Purpose:

Eliminate a pointless exception and cross-reference.

Source:

D. Miller Dec. 31, 2014 email to B. Roberts as prompted by a user editorial cross reference

correction notification.

Impact:

Cleanup of the API 650 document.

Discussion:

A user pointed out that in 12th ed, paragraph 5.1.3.6.1 b, reference to “7.2.3.4” should actually be to

“7.2.3.5”. That is a correct observation as verified by checking the cross referencing arrangements back

in the 11th edition. This cross referencing update was missed when 7.2.3.3 was inserted.

However, I note that the connection between 5.1.3.6.1 b and “7.2.3.5” actually does not make sense.

That's because 5.1.3.6.1 only addresses bottom, roof and shell to bottom welds. 7.2.3.5 addresses only

circ and vert welds in the shell. Given the scope of 5.1.3.6.1, there is no reason to bring up 7.2.3.5 as an

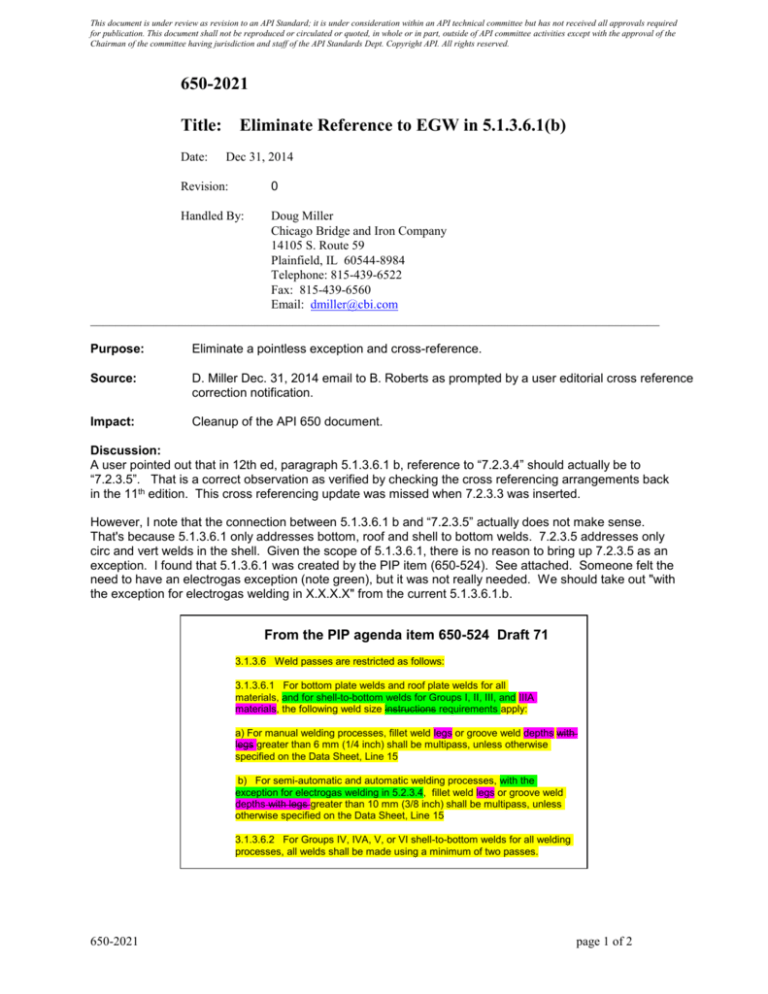

exception. I found that 5.1.3.6.1 was created by the PIP item (650-524). See attached. Someone felt the

need to have an electrogas exception (note green), but it was not really needed. We should take out "with

the exception for electrogas welding in X.X.X.X" from the current 5.1.3.6.1.b.

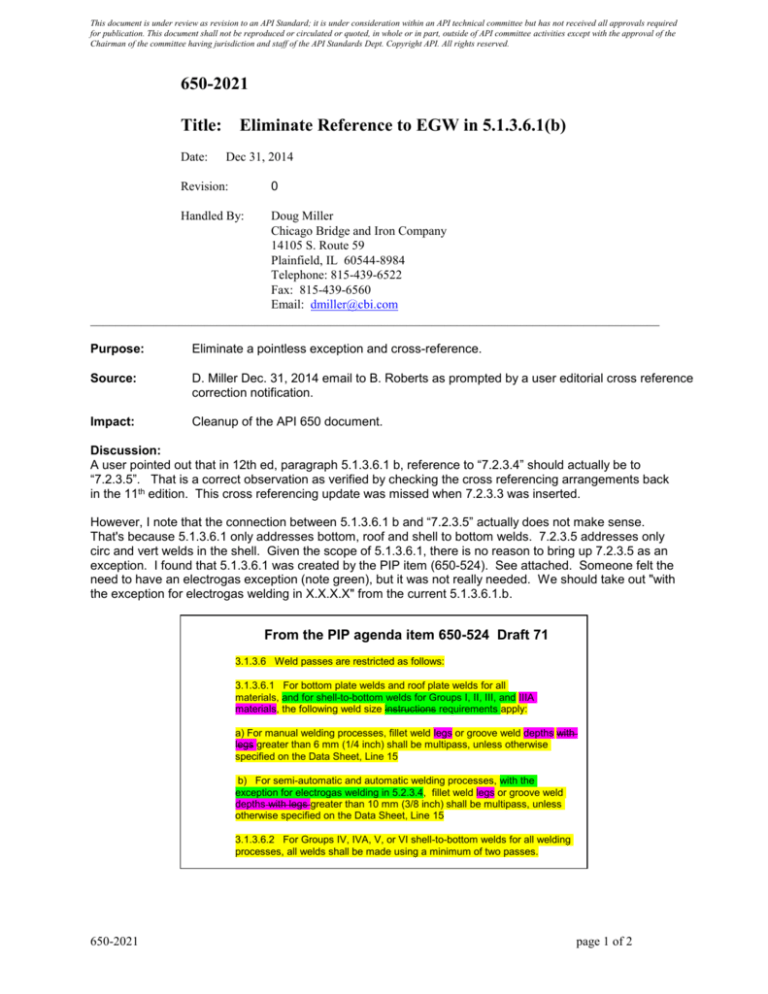

From the PIP agenda item 650-524 Draft 71

3.1.3.6 Weld passes are restricted as follows:

3.1.3.6.1 For bottom plate welds and roof plate welds for all

materials, and for shell-to-bottom welds for Groups I, II, III, and IIIA

materials, the following weld size instructions requirements apply:

a) For manual welding processes, fillet weld legs or groove weld depths with

legs greater than 6 mm (1/4 inch) shall be multipass, unless otherwise

specified on the Data Sheet, Line 15

b) For semi-automatic and automatic welding processes, with the

exception for electrogas welding in 5.2.3.4, fillet weld legs or groove weld

depths with legs greater than 10 mm (3/8 inch) shall be multipass, unless

otherwise specified on the Data Sheet, Line 15

3.1.3.6.2 For Groups IV, IVA, V, or VI shell-to-bottom welds for all welding

processes, all welds shall be made using a minimum of two passes.

650-2021

page 1 of 2

This document is under review as revision to an API Standard; it is under consideration within an API technical committee but has not received all approvals required

for publication. This document shall not be reproduced or circulated or quoted, in whole or in part, outside of API committee activities except with the approval of the

Chairman of the committee having jurisdiction and staff of the API Standards Dept. Copyright API. All rights reserved.

Proposed Changes:

The red deletion is the only change to API 650 proposed in this agenda item.

5.1.3.6.1

For bottom plate welds and roof plate welds for all materials, and for shell-tobottom welds for Groups I, II, III, and IIIA materials, the following weld size requirements

apply:

a) For manual welding processes, fillet weld legs or groove weld depths greater than 6 mm

(1/4 in.) shall be multipass, unless otherwise specified on the Data Sheet, Line 15.

b) For semi-automatic, machine, and automatic welding processes, with the exception for

electro-gas welding in 7.2.3.4, fillet weld legs or groove weld depths greater than 10 mm

(3/8 in.) shall be multipass, unless otherwise specified on the Data Sheet, Line 15.

Below quotation of sections 7.2.3.4 and 7.2.3.5 is provide simply for reference. Note that I'm sure that the

current 7.2.3.5 is addressing Electro-gas welding even though it does not say that directly.

7.2.3.4

The reverse side of double-welded butt joints shall be thoroughly cleaned in a

manner that will leave the exposed surface satisfactory for fusion of the weld metal to be

added, prior to the application of the first bead to the second side. This cleaning may be

done by chipping; grinding; melting out; or where the back of the initial bead is smooth and

free from crevices that might entrap slag, another method that, upon field inspection, is

acceptable to the Purchaser.

7.2.3.5 For circumferential and vertical joints in tank shell courses constructed of material

more than 40 mm (11/2 in.) thick (based on the thickness of the thicker plate at the joint),

multipass weld procedures are required, with no pass over 19 mm (3/4 in.) thick permitted.

650-2021

page 2 of 2