National - Em

advertisement

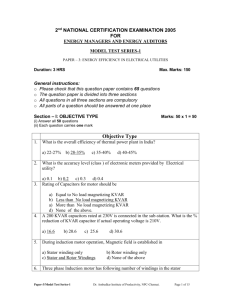

1 Model Question Paper - 2006 NATIONAL CERTIFICATION EXAMINATION FOR ENERGY MANAGERS AND ENERGY AUDITORS PAPER –3 : ENERGY EFFICIENCY IN ELECTRICAL UTILITIES Section – 1 : OBJECTIVE TYPE 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Power generating capacity in India, from coal based thermal power plants is about – b) 70% Power loss in a line is the product of a) Resistance and Square of the current Power factor is called as – of the angle between kW and kVA a) Cosine If the fundamental frequency of the power system is 50 Hz, 5th harmonic will have a frequency of -- Hz b) 250 MD recorder is recording --b) time-integrated demand over a predefined recording cycle For a synchronous speed of 1500 rpm, at a given mains frequency of 50 Hz, the motor will have the number of poles as --b) 4 Squirrel cage motors are normally --- efficient than Slip ring motors a) more Core losses in a motor accounts for --- of its total losses b) 20-25% For efficient overall operation in a Plant, it is desirable to have – a) High value of efficiency and high power factor Fixed losses in a motor consist of --a) Magnetic core loss, friction and Windage losses For every 250 mm Wc pressure drop increase across at the suction path due to choked filter etc., the compressor power consumption increases by about ---percent for the same output b) 2 The likely estimate on equivalent power wastage for a leakage from 7 bar compressed air system through 1.6 mm orifice size is ---kW c) 0.8 Vertical type reciprocating compressors are used in the capacity range of --cfm a) 50-150 1 2 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. The compression ratios for axial flow compressors are --b) higher The temperature at which moisture condenses is called as --b) Dew point The driving force for refrigeration in vapour absorption refrigeration plants is – b) mechanical energy In general, designed chill water temperature drop across the chillers is ---0 C a) 5 The compressor that has recently become practical in the Market is— compressor b) Scroll Screw compressor is also called as – compressor d) helical rotary The output of a reciprocating compressor is --a) nearly constant Specific ratio is used to define fans, blowers and compressors as per --c) ASME System curve of a fan depicts the relation between --a) air flow and pressure Axial flow fans are equipped with ---blades a) variable pitch Peak efficiency of a radial fan is --c) 69-75% The most efficient axial fan is of – type c) vane axial Frictional losses in a pumping system is proportional to – b) Q-2 The intersection point of the pump curve and the system curve is called --b) best efficiency point Increased suction lift from open wells, the delivery flow rate --b) decreases For large capacity of centrifugal pumps, design efficiencies are in the range of around --a) 85% Throttling the delivery valve of a pump results in increased --c) both (a) and (b) Natural draft cooling towers are mainly used in – b) Power stations Cooling capacity of cooling tower is --a) the heat rejected Which one of the following has the maximum effect on cooling tower performance? c) fill media This fill material is more energy efficient b) film fill Some of the components of cooling tower are: 2 3 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. c) both (a) and (b) Colour rending index is measured in the scale of --a) 1-100 Which of the following lighting source has the least life? a) incandescent The average rated life of CFL is – hr b) 10,000 This device aids initial voltage build-up for a Tube light a) Choke For better street lighting, ---type of lamp is recommended a) HPSV Power requirement of DG set is determined by: b) minimum load Designed power factor of a DG set is – b) 0.8 The radiator cooling temperature for DG sets should be in the range of – 0 C d) 80-90 High pressure gas injection is resorted to in the case of --b) slow speed dual-fuel engines Water-cooled DG sets are ---air- cooled DG sets in performance c) more efficient Hydrodynamic principle of speed control is used in --b) Fluid coupling MD controller is used to switch off ---loads, in logical sequence b) non-essential Identify the “odd one” out from the following: d) capacitor based sensor Eddy current Drive is used to --b) vary the output speed Amorphous core transformers are available at present up to –KVA capacity d) 1600 Section ii : SHORT DESCRIPTIVE QUESTIONS 10 X 5 =50 MARKS S-1 “One Unit saved in Industry is equal to Two Units generated in the Power Station”Justify this Statement. The generated power from the Power station is transmitted and distributed to consumers. Though the T & D losses are said to be around 17% in India and hence efficiency being 87%, all these losses may not constitute technical losses as, un-metered consumption and pilferage are also accounted in this loss. Before the generated power reaches Industry, it passes thro’ transformers having 95% efficiency and in Industry the motor efficiency is about 90%. Another 30% is lost in mechanical system that includes coupling/driving system and driven equipments like pumps, valves etc. Thus the overall efficiency becomes 0.83 x 0.95 x 0.9 x 0.70 = 0.50 i.e. 50% efficiency. 3 4 Hence, one unit saved in the Industry is equal to two units generated in the Power station. S-2 What is an energy-efficient motor? An energy-efficient motor is the one in which, design improvements are incorporated to increase operating efficiency over motors of standard design. These improvements are in reducing motor losses, use of lower-loss silicon-steel, a longer core, thicker wires to reduce resistance, thinner laminations, smaller air gap between stator and rotor, copper instead of aluminium bars in the rotor, superior bearings and a smaller fan. As per the stipulations of BIS, energy-efficient motors are designed to operate with out loss in efficiency at loads between 75% and 100% of rated capacity. S-3 What are the major compressed air system components? Compressed air system consists of the major components as stated below: Intake Air Filters, preventing dust entering compressor Inter-stage Coolers, reducing the temperature of air before it enters the next stage to reduce the work of compression and increase efficiency After Coolers, removing moisture in the air by reducing the temperature in a watercooled heat exchanger Air-dryers, removing the remaining traces of moisture Moisture Drain Traps, used for the removal of moisture in the compressed air Receivers, provided to store and smoothen the pulsating air output. S-4 What are the several heat transfer loops in a refrigeration system? The several heat transfer loops in a refrigeration system are: Indoor air loop: indoor air is driven in the leftmost loop by the supply air fan through a cooling coil, where it transfers its heat to chilled water. The cool air then cools the building Chilled water loop: It is driven by the chilled water pump and water returns from the cooling coil to the chiller’s evaporator to be re-cooled Refrigerant loop: Using a phase-change refrigerant, the chiller’s compressor pumps heat from the chilled water to the condenser water Condenser water loop: Water absorbs heat from the chiller’s condenser and the condenser water pump sends it to the cooling tower Cooling tower loop: The cooling tower’s fan drives air across an open flow of the hot condenser water, transferring the heat to the outdoors. S-5 What are the design and selection criteria in respect of fan? Accurate determination of air-flow and required outlet pressure are most important in the proper selection of fan type and size. The required air flow depends on the process requirements, normally determined from heat transfer rates or combustion air or flue gas quantity to be handled. System pressure requirement is to be computed, though it is difficult. Pressure drop across the length, bends, contractions and expansions in the ducting system, pressure drop across filters, drop in branch lines etc. A very conservative approach is adopted allocating large safety margins, resulting in over-sizing of fans, operating at flow rates much below their design values and consequently of poor efficiency. 4 5 S-6 What are the affinity laws relating to a rotodynamic pump performance? The equations relating to rotodynamic pump performance of flow, head, and power absorbed, to speed are known as “Affinity Laws”. They are: 1. Q is proportional to N 2. H is proportional to N2 3. P is proportional to N3 Where, Q = Flow rate H = Head P = Power absorbed N = Rotating speed In other words, Flow is proportional to speed Head is proportional to the square of speed Power is proportional to the cube of speed S-7 What is meant by Cycles of concentration and how is it related to cooling tower Blow down? Cycles of Concentration (COC) is the ratio of dissolved solids in circulating water to the dissolved solids in make up water. Blow down losses depend up on Cycles of concentration and evaporation losses and is related as: Blow down = Evaporation loss / (COC – 1) S-9 What is ‘lamp efficacy’? How savings in Industrial sector can be achieved by using high efficiency lamps? Lamp efficiency is the ratio of light output in lumens to power input to lamps in watts. High efficacy gas discharge lamps which are suitable for different types of applications, offer appreciable scope for energy conservation. In Industrial sector, instead of HPMV lamps of 250 W low efficacy, if changed to HPSV lamps of 150 W, there will be a saving of 100W in power saving will be 37%. For GLS lamps of 13 W existing, 9W CFL lamps, if used saves 31% power. S-9 Briefly explain two important factors, to decide the type of DG set. The two most important factors to decide the type of DG set are: power and speed of the engine. The power requirement is determined by the maximum load. The engine power rating should be 10-20% more than the power demand by the end use. Speed of the engine should be such of a value that the fuel efficiency at that speed is the greatest. The DG sets should be run at this rated speed to avoid poor efficiency and to prevent build up of engine deposits due to incomplete combustion, leading to higher maintenance costs. S-10 Why Amorphous core transformers are preferred over conventional transformers? 5 6 Amorphous core transformers provide excellent opportunities to conserve energy, due to low core loss. The reduction in energy loss over the conventional transformers is roughly around 70%. Amorphous core transformers are of less weight and hence easier to handle. Section-iii: LONG DESCRIPTIVE QUESTIONS Marks: 5 x 10 =50 L-1. The maximum demand approved by a utility is 5500 kVA and tariff provides for minimum billing demand of 80% of approved. Review of past 12 months records of bills reveals that the monthly maximum demand recorded is around 4200 kVA. Will there be any benefits in surrendering part of contract demand? If so what is the kVA that you recommend for surrendering? Give the costs savings by surrendering demand, if unit rate for kVA is Rs. 200. ANS: The maximum demand approved by a utility is 5500 kVA and tariff provides for minimum billing demand of 80% of approved. Review of past 12 months records of bills reveals that the monthly maximum demand recorded is around 4200 kVA. Will there be any benefits in surrendering part of contract demand? If so what is the kVA that you recommend for surrendering? Give the costs savings by surrendering demand, if unit rate for kVA demand is Rs 200. Approved maximum demand : 5500 kVA Minimum billing demand (MBD) : 4400 kVA Maximum demand recorded : 4200 kVA The approved maximum demand is selected such a way that the gap between MD recorded and minimum billing demand are narrowed down. A different scenario is to be created. Contract demand 5500 5400 5300 5200 (Minimum Billing Demand) 80% of contract demand 4400 4320 4240 Monthly demand recorded 4200 4200 4200 4200 4116 From above, it would be advantage to surrender ‘300 kVA’ demand and set new approved demand at 5200 kVA. The actual savings possible is calculated below: New contract (approved) demand :5200 kVA New minimum billing demand :4160kVA) Existing MD recorded :4200kVA Present billing demand :4200 (since recorded kVA is more than MBD) 6 7 Original minimum billing demand : 4400kVA (Before surrendering demand) Reduction demand value taken for billing: 200 kVA Savings in demand charges/month Rs 200 * 200kVA Rs40,000 L-2. What are the factors to be considered while selecting a motor? Explain in detail ANS: A. Torque Requirement The primary consideration defining the motor choice for any particular application is the torque required by the load. The relationship between the maximum torque generated by the motor (break-down torque) and the torque requirements for start-up (locked rotor torque) and during acceleration periods is very important. The thermal loading on the motor is determined by the duty/load cycle. One important consideration with totally enclosed fan cooled (TEFC) motors is that the cooling may be insufficient when the motor is operated at speeds lower than its rated speed. B. Sizing to Variable Load Industrial motors frequently operate under varying load conditions due to process requirements. A common practice in cases where such variable loads are found is to select a motor based on the highest anticipated load. In many instances, an alternative approach is typically less costly, more efficient and provides equally satisfactory operation. With this approach, the optimum rating for the motor is selected on the basis of the load duration curve for the particular application. Thus, rather than selecting a motor of high rather than selecting a motor of high rating that would operate at full capacity for only a short period, a motor would be selected with a rating slightly lower than the peak anticipated load and would operate at overload for a short period of time. Since operating within the thermal capacity of the motor insulation is of greatest concern in a motor operating at higher than its rated load, the motor rating is selected as that which would result in the same temperature rise under continuous full-load operation as the weighted average temperature rise over the actual operating cycle. L-3. List out different basic capacity control methods for the fans and blowers Different basic capacity (volume) control methods adopted in fans and blowers are as follows: 1. Changing the rotational speed is the most efficient. If the volume requirement is constant, it can be achieved by selecting appropriate pulley sizes. If the volume varies with the process, adjustable-speed drives can be used. 2. Changing the blade angle is a method used with some vane-axial fans. 7 8 3. Restricting the air flow is accomplished with dampers or valves which close off the air flow at the inlet or outlet. Inlet vanes, which swirl the air entering the centrifugal fan or blower, are more efficient than dampers or butterfly valves. 4. Venting the high-pressure air, or recirculating it to the inlet, is often used with positive-displacement blowers. It is sometimes used with fan systems, but is the least efficient method as there is no reduction in the air being moved. L-4. Explain the methodology of refrigeration plant energy audit. ANS: The cooling effect produced is quantified as tons of refrigeration. 1 ton of refrigeration = 3024 kCal/hr heat rejected. The specific power consumption kW/TR is a useful indicator of the performance of refrigeration system. By measuring refrigeration duty performed in TR and the Kilo Watt inputs measured, kW/TR is used as a reference energy performance indicator. The refrigeration TR is assessed as TR = Q Cp (Ti – To) / 3024 Where Q is mass flow rate of coolant in kg/hr Cp is coolant specific heat in kCal /kg deg C Ti is inlet, temperature of coolant to evaporator (chiller) in 0C To is outlet temperature of coolant from evaporator (chiller) in 0C. The above TR is also called as chiller tonnage. In a centralized chilled water system, apart from the compressor unit, power is also consumed by the chilled water (secondary) coolant pump as well condenser water (for heat rejection to cooling tower) pump and cooling tower fan in the cooling tower fan. Effectively, the overall energy consumption would be towards ; Compressor kW Chilled water pump kW Condenser water pump kW Cooling tower fan kW, for induced / forced draft towers The specific power consumption for certain TR output would therefore have to include : Compressor kW/TR Chilled water pump kW/TR Condenser water pump kW/TR 8 9 Cooling tower fan kW/TR and overall kW/TR as a sum of the above. In case of air conditioning units, the air flow at the Fan Coil Units (FCU) or the Air Handling Units (AHU) can be measured with an anemometer. Dry bulb and wet bulb temperatures are measured at the inlet and outlet of AHU or the FCU and the refrigeration load in TR is assessed as: TR Q ρ h in h out 3024 Where Q is the air flow in CMH is density of air kg/m3 h in is enthalpy of inlet air kCal/kg h out is enthalpy of outlet air kCal/kg Use of handy psychometric charts can help to calculate h in and hout from dry bulb, wet bulb temperature values which are, in-turn measured, during trials,by a whirling psychrometer. L-5. Describe the step by step methodology of lighting system audit in a plant? ANS: Improvement option in lighting at any facility would involve following step by step approach: a. Step-1: Inventorise the lighting system elements with respect to device rating, population & use profile. b. Step-2: Measure and document lux levels at various plan locations at working place, at day time and night times w.r.t lamps ON or OFF during the said period. c. Step-3: Use a portable load analyzer to measure and document the voltage and power consumption profile at various lighting load distribution panels d. Step-4: Compare the measured lux values with standard values and identify locations of under-lit and over-lit areas e. Step-5: Analysis of failure rates of lamps, ballasts and actual life expectancy levels from the past data. f. Step-6: Based on above careful assessment has to be carried out along with energy saving potential, investment required and payback calculations. 9