Analysis of Thermal Cycles ME302

advertisement

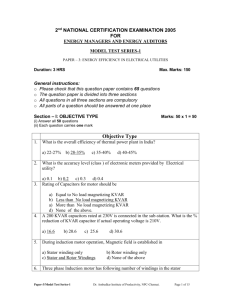

Analysis of Thermal Cycles MEC3002 Laboratory Experiments M Farrugia 14/11/2005 Air Compressor, Single Stage Object: To carry out various tests on a single stage, water cooled, air compressor at constant speed. The changes in the following list of parameters is to be studied when the delivery pressure is varied 1. Volumetric efficiency 2. Difference between adiabatic and actual temperatures 3. Heat rejected in the cooling water 4. The value of the polytropic index of expansion, n 5. Motor power, motor efficiency Apparatus: Compressor Broom and Wade Type N3 Ser No 1/790447 Bore 4in, Stroke 4in, clearance volume 1.573in3 Max Speed 720 rev/min Free air delivered 14ft3/min Max pressure 200psig Dynamometer Swinging field type, motor No 28517/1 Rated power output 7.5hp @ 720 rev/min Length of brake arm 12.605in WN hp Formula, 1 hp = 746 W 5000 W is the weight on spring balance in lbs N is the rpm of the motor Intake Air Box Size 30in x 20in x 24in Orifice diameter 0.8115in Coefficient of discharge 0.60 h460 t Q 25.9d 2 Formula B d is the orifice diameter in feet h is the head of water across the orifice in feet B is the barometric pressure in inches of Mercury t is the ambient temperature in F ft3/s 1 Cooling water flow meter Number R183 Orifice size No0, Capacity 0-40gall/hr Formula, Q 9.23H 0.512 Q in gall/hr H is the head of water in inches Air Receiver Broom and Wade No Y 22264/1 Size: 60in long x 24in diameter Max working pressure 205psig Test pressure 308psig Safety valve, Broom and Wade, set to 205psig Additional instruments Tachometer 0 - 1000rpm Cooling water thermometers Inlet and Delivery air thermometers Procedure Run the compressor as close to a fixed speed as possible by adjusting the voltage control. A speed between 300 and 600 rpm is suggested. The amount of cooling water is adjusted so that the level in the measuring level is higher than half the maximum. By adjusting the amount of air discharged from the air vessel, the delivery pressure is varied between 0 bar and maximum 10bar. Record the readings listed in the reading table, allowing enough time for the parameters to settle. Theory From the area under the pv diagram for a single stage reciprocating compressor it can be shown that the indicated power required, i.p., is given by n T2 T1 i. p. mR n 1 n 1 p2 n n 1 1 i. p. or mRT p1 n 1 where n is the polytropic index of expansion and compression m is the mass induced per unit time R is the specific gas constant (287 J/kgK for air) T1 is the absolute temp at the end of the induction stroke T2 is the absolute temp at the end of the compression process p1 is the pressure at the induction stroke, the free air pressure p2 is the pressure of the receiver 2 From the second equation for i.p., it is noted that the power required to drive the compressor increases with higher pressure ratios. The mass flow rate can be calculate by p m . Q Q RT The volumetric efficiency v is defined as the volume of air delivered measured at the free air pressure and temperature, divided by the swept volume of the cylinder. The adiabatic exit temperature would be the temperature if no heat was lost from the air being compressed to the surroundings. T2 adiabatic p T1 2 p1 1 The heat lost to the cooling water = m water . Cwater . Twater Watts m is the cooling water flow rate in kg/s where C is the specific heat capacity of water, 4200 J/kgK Twater is the temperature rise of the cooling water n 1 p n T n 1 p2 T Since 2 2 then ln 2 ln T1 n p1 T1 p1 Hence this equation can be used to find a value for the polytropic index of compression n, by plotting ln[T2/T1] against ln[p2/p1]. Results Calculate and put down in table form for each delivery pressure. the free air flow rate, and its uncertainty. the volumetric efficiency, and its uncertainty. the cooling power dissipated in the cooling water the adiabatic exit temperature the motor electrical power (I V) the shaft power (measured by the dynamometer) the motor efficiency In the calculations of uncertainty, limit your analysis to uncertainties due to parameters measured during the experiment, i.e. assume all constants and given data (e.g. bore and stoke) to be known accurately. Plot curves for volumetric efficiency and shaft power against delivery pressure. Also plot the actual exit temperature (T2) and the adiabatic exit temperature on the same sheet versus the delivery pressure. Plot ln[T2/T1] against ln[p2/p1] and obtain a value for n. Conclusions Draw your own conclusions on the experiment and results obtained. 3 Readings 0 Ambient temperature: Atmospheric pressure: Delivery Pressure bar Motor Voltage Volts C cmHg Current Amps Rotational Speed rpm Dynamo meter Load lbs Air Head H2O Air Temp Air Temp mm in 0C out 0C Cooling water Head Temp in 0 cm C Temp out 0 C 4