Spider Disc

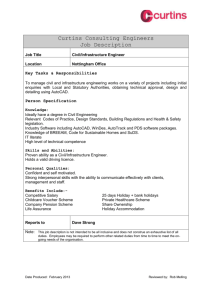

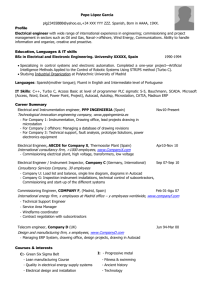

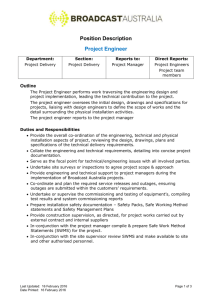

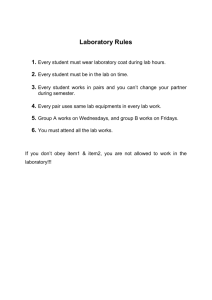

advertisement