rec7_MPS_and_MRP_q(çözümlü)

advertisement

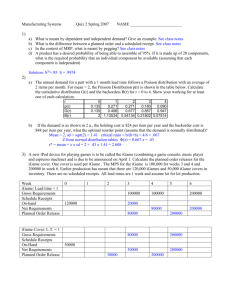

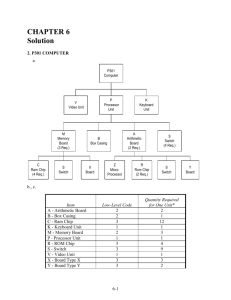

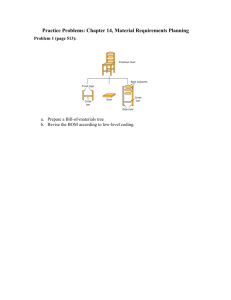

MS 401, Spring 09-10 Recitation #7 MPS and MRP Question 1. The MPS planer at Murphy Motors uses MPS time-phased records for planning end item production. The planner is currently working on a schedule for P24, one of the Murphy’s topselling motors. The planner uses a production lot size of 70 and a safety stock of 5 for the P24 motor. Period 1 2 3 4 5 6 7 8 Forecast 30 30 30 40 40 40 45 45 Orders 13 8 4 Available 60 30 70 30 60 20 45 70 ATP 39 1 40 70 70 70 70 70 70 70 MPS On hand = 20 a) Complete the MPS time-phased record for product P24. b) Can Murphy accept the following orders? Update the MPS time-phased record for accepted orders. New customer orders: 40 units, customer order number 4704 due in week 4. 30 units, customer order number 4709 due in week 6. 30 units, customer order number 4747 due in week 2. 25 units, customer order number 4747 due in week 3. Question 2: The Spencer Optics Company produces an inexpensive line of sunglasses. The company is interested in using material requirements planning to schedule its operations for one particular popular model. The forecast for this model is 100 orders per week for the next 10 weeks. Spencer has customer orders of 110 units, 80 units, 50 units, and 20 units in weeks 1, 2, 3, and 4 respectively. The sunglasses are assembled in batches of 300. Presently, three production batches are scheduled: one in week 2, one in week 5, and one in week 8. Complete the following time-phased record. WEEKS 5 6 100 100 7 100 8 100 9 100 10 100 230 30 230 130 30 Forecast 1 100 2 100 3 100 4 100 Orders 110 80 50 20 30 230 130 30 30 150 300 300 300 300 300 Available ATP MPS 140 130 Question 3. (a) Generate the relevant Bill of Material (BOM) diagrams using the following information: A and B are final products One unit of A requires one unit of C and one unit of D One unit of D requires two units of E and one unit of F One unit of B requires one unit of C and two units of F (b) Generate the MRP output for items A, B, D and F, using the BOMs you identified in part (a), and the following demand and inventory data. Use the MRP record tables provided in the following page. Week 1 2 3 4 5 6 7 8 9 10 Demand (A) 21 25 75 30 35 80 75 19 22 25 Demand (B) 0 0 10 15 15 15 25 25 30 30 Item Amount on Hand Scheduled Receipts Arrival on week Lead Time (Weeks) Lot Sizing Rule Safety Stock A 60 70 3 2 Lot-for-lot 5 B 30 0 N/A 3 Lot-for-lot 0 D 50 0 N/A 1 Multiple of 30 0 F 30 100 100 1 3 1 Multiple of 50 20 Item A, LT=2 now Gross Requirements 1 2 3 4 5 6 7 8 9 10 21 25 75 30 35 80 75 19 22 25 5 5 Scheduled Receipts Projected Avl. Balance 70 60 39 14 9 5 5 5 5 5 26 35 80 75 19 22 25 1 2 3 4 5 6 7 8 9 10 0 0 10 15 15 15 25 25 30 30 30 30 20 5 0 0 0 0 0 0 10 15 25 25 30 30 Planned Order Releases Item B, LT=3 now Gross Requirements Scheduled Receipts Projected Avl. Balance Planned Order Releases 30 Item D, LT=1 now 1 2 3 4 5 6 7 8 0 26 35 80 75 19 22 25 50 24 19 29 14 25 3 30 90 60 30 1 2 3 4 5 6 Gross Requirements 0 50 120 110 80 Scheduled Receipts 100 60 50 100 50 Gross Requirements 9 10 8 8 8 7 8 9 10 60 90 0 0 0 20 60 20 20 20 20 100 50 Scheduled Receipts Projected Avl. Balance 50 Planned Order Releases Item F, LT=1 Projected Avl. Balance now 30 Planned Order Releases 130 30 100 80 Question 4. Suppose you are an IE in a company that makes stools. You have collected the following data related to the production process: Part Name Components Lot Sizing Rule Planned Lead Time Part Name Components Lot Sizing Rule Planned Lead Time Part Name Components Lot Sizing Rule Planned Lead Time Part Name Components Lot Sizing Rule Planned Lead Time Part Name Components Lot Sizing Rule Planned Lead Time Stool (end item) 1 Base, 1 Seat, and 2 Bolts Period Order Quantity 1 week Base 3 Legs, 3 Bolts Lot for lot 2 weeks Seat None Lot for lot 1 week Leg None Lot for lot 2 weeks Bolt None Lot for lot 1 week Suppose that ordering cost is $10 per order and holding cost is $0.28 per unit per week. a) Draw a bill of diagram for the end item “Stool”. Show LLCs (Low level codes) and other necessary details. b) Complete the following MRP tables for stool, base, legs and bolts. This row indicates when a planned order release will be received (that is, “leadtime” periods after a planned order release) Stool (LT = 1) Gross Requirements Scheduled Receipts Projected Ending Inv Net requirements Planned order receipts Planned order releases Base (LT = 2) Gross Requirements Scheduled Receipts Projected Ending Inv. Net requirements Planned order receipts Planned order releases Leg (LT = 2) Gross Requirements Scheduled Receipts Projected Ending Inv. Net requirements Planned order receipts Planned order releases Bolt (LT = 1) Gross Requirements Scheduled Receipts Projected Ending Inv. Net requirements Planned order receipts Planned order releases 0 1 10 2 20 3 15 4 20 5 15 6 40 30 20 0 0 0 0 0 0 35 20 15 35 0 0 0 0 55 40 15 55 0 0 0 10 10 10 0 1 0 40 60 2 35 3 0 4 55 5 0 6 10 7 0 25 25 0 30 30 10 0 0 0 10 10 0 0 0 0 20 7 10 0 30 0 0 1 0 2 90 4 30 5 0 6 0 7 0 20 20 0 70 70 10 3 0 20 20 0 10 10 0 0 0 0 1 0 3 0 4 140 5 0 6 20 7 0 40 40 2 160 100 0 20 20 0 0 140 140 0 0 20 20 70 20 140 20 c) Determine the holding and ordering costs for each week only for the stool. Compare your findings with the ones that you would incur if L4L rule was used instead of the Period Order Quantity rule.