MRP Problems: Material Requirements Planning Exercises

advertisement

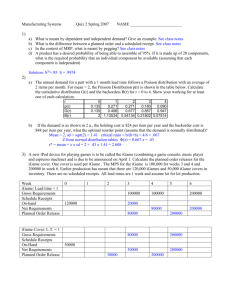

Class Problems: Chapter 14, Material Requirements Planning Problem 1: The Hunicut and Hallock Corporation makes two versions of the same basic file cabinet, the TOL (Top-of-the-line) five drawer file cabinet and the HQ (High-quality) five drawer filing cabinet. The TOL and HQ use one unit each of the same cabinet frame and locking mechanism (A). The drawer assemblies are different (5 units of B for each TOL and 5 units of F for each HQ). Both drawer assemblies B and F use one unit of the same drawer frame assembly (C) for each drawer assembly. Further, the drawer assembly B for the TOL cabinet uses one sliding assembly (D) that requires eight bearings (E), and the drawer assembly F for the HQ cabinet uses one sliding assembly (G) and each G requires only four of the same bearings (E). Develop a material structure tree for the TOL and the HQ file cabinets. Problem 2: Determine the overall lead time for the two end products TOL and HQ. Item Lead time TOL HQ A B C D E F G 1 1 2 1 3 2 2 1 1 Problem 3: Suppose that the production of 100 TOL and 300 HQ file cabinets is planned. Further suppose that the following inventories are available. Determine the low-level code and calculate the net requirements for all the component items. Item A B C D E F G Item Available 200 300 120 300 1500 150 1000 Gross requirement Available Net requirement Problem 4: Develop a net material requirements plan for the TOL and HQ file cabinets. Available Lead time Item Scheduled Receipts A B C D E F G Week #1 = 200 None Week #1 =600, Week #2 = 600 Week #1 = 200 Week #1 = 3000, Week #2 =3000 Week #1 =800 Week #1 = 500 Master production schedule Week: MPS for TOL MPS for HQ Item Week: 1 50 100 2 40 200 250 800 100 3000 150 0 2 1 3 1 2 2 1 3 40 200 4 200 2 3 4 2 3 4 5 60 6 60 200 7 8 80 300 5 6 7 8 5 6 7 8 LT = 1 Gross requirement Scheduled receipts Projected on-hand Net Requirement Planned receipts Planned order releases Item Week: Gross requirement Scheduled receipts Projected on-hand Net Requirement Planned receipts Planned order releases LT = 1 Item Week: LT = 1 2 3 4 5 6 7 8 2 3 4 5 6 7 8 2 3 4 5 6 7 8 Gross requirement Scheduled receipts Projected on-hand Net Requirement Planned receipts Planned order releases Item Week: LT = 1 Gross requirement Scheduled receipts Projected on-hand Net Requirement Planned receipts Planned order releases Item Week: Gross requirement Scheduled receipts Projected on-hand Net Requirement Planned receipts Planned order releases LT = 1 Item Week: LT = 1 2 3 4 5 6 7 8 2 3 4 5 6 7 8 Gross requirement Scheduled receipts Projected on-hand Net Requirement Planned receipts Planned order releases Item Week: Gross requirement Scheduled receipts Projected on-hand Net Requirement Planned receipts Planned order releases LT = 1 Problem 5: For item B, the setup cost is $250 per setup and the inventory carrying cost is $0.90 per unit per week. Determine the lot sizes and total cost for this item under (i) Lotfor-Lot, (ii) EOQ, and (iii) POQ methods. Let lead time be 1 week. (i) Lot-for-lot Item LT = Week: 1 2 3 4 5 6 7 8 Gross requirement 250 200 200 250 300 300 0 400 Scheduled receipts 150 0 0 0 0 0 0 0 Projected on-hand Net Requirement Planned receipts Planned order releases 100 (ii) EOQ Item LT = Week: 1 2 3 4 5 6 7 8 Gross requirement 250 200 200 250 300 300 0 400 Scheduled receipts 150 0 0 0 0 0 0 0 Projected on-hand 100 Net Requirement Planned receipts Planned order releases (iii) POQ Item LT = Week: 1 2 3 4 5 6 7 8 Gross requirement 250 200 200 250 300 300 0 400 Scheduled receipts 150 0 0 0 0 0 0 0 Projected on-hand 100 Net Requirement Planned receipts Planned order releases