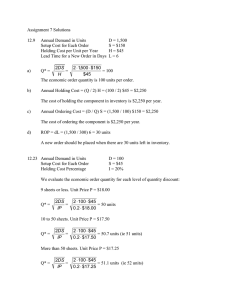

sol6

advertisement

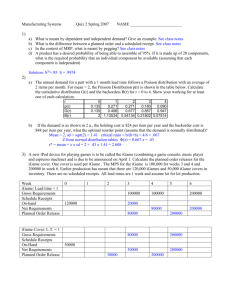

CHAPTER 6 Solution 2. P301 COMPUTER a. P301 Computer P Processor Unit V Video Unit M Memory Board (3 Req.) C Ram Chip (4 Req.) S Switch A Arithmetic Board (2 Req.) B Box Casing X Board K Keyboard Unit Z MicroProcessor S Switch (4 Req.) R Rom Chip (2 Req.) S Switch b., c. Item A - Arithmetic Board B - Box Casing C - Ram Chip K - Keyboard Unit M - Memory Board P - Processor Unit R - ROM Chip S - Switch V - Video Unit X - Board Type X Y - Board Type Y Low-Level Code 2 2 3 1 2 1 3 3 1 3 3 6-1 Quantity Required for One Unit* 2 1 12 1 3 1 4 9 1 3 2 Y Board Z - Microprocessor 3 *Assuming no inventory for any item 2 6. MULTI-LEVEL ITEM EXAMPLE A B (2 Req.) C C Part: A Week Gross Requirements Scheduled Receipts Projected Available Balance Planned Order Release Q = 20, LT = 1, SS = 0 21 1 5 2 15 3 18 4 8 5 12 6 22 16 1 20 3 20 15 3 20 1 1 2 40 3 40 4 5 40 6 32 52 40 12 12 40 12 12 12 1 40 2 20 3 60 4 5 20 6 30 10 60 10 10 20 10 10 Part: B Week Gross Requirements Scheduled Receipts Projected Available Balance Planned Order Release Q = 40, LT = 2, SS = 0 20 Part: C Week Gross Requirements Scheduled Receipts Projected Available Balance Planned Order Release Q = LFL, LT = 1, SS =10 70 6-2 7. TRACI’S TOMAHAWK Product Structures A G (2 required) C F D G H Part A Week Gross Requirement Scheduled Receipt Projected Available Balance Planned Order Release Lead Time = 1, Q = L4L, SS = 0 10 1 5 5 10 2 3 3 10 4 15 5 15 7 3 0 15 0 15 0 1 10 2 20 15 0 15 3 25 4 15 5 5 0 5 0 0 2 21 3 35 4 30 5 24 40 29 20 19 19 Part F Week Gross Requirement Scheduled Receipt Projected Available Balance Planned Order Release Lead Time = 2, Q = L4L, SS = 0 15 5 25 Part G Week Gross Requirement Scheduled Receipt Projected Available Balance 30 Planned Order Release Lead Time = 1, Q = multiples of 20, SS = 10 1 25 20 25 20 An order for 20 units must be planned for Part G in period 1 so that safety stock is maintained in period 3. 6-3 8. Ajax Manufacturing A X B Y G H Y (2 Req.) Z a. Part: G Period Gross Requirements Scheduled Receipts Projected Available Balance Planned Order Release Q = LFL, LT = 1, SS = 0 0 1 8 10 2 6 2 8 3 8 4 8 5 8 6 8 7 8 0 8 0 8 0 8 0 8 0 8 0 1 32 10 45 27 2 36 3 36 4 36 5 36 6 36 7 36 9 36 0 36 0 36 0 36 0 0 1 32 10 45 36 2 36 3 36 4 36 5 36 6 36 7 36 10 36 10 36 10 36 10 36 10 10 Part: Y Period Gross Requirements Scheduled Receipts Projected Available Balance Planned Order Release Q = LFL, LT = 2, SS = 0 67 b. Part: Y Period Gross Requirements Scheduled Receipts Projected Available Balance Planned Order Release Q = LFL, LT = 2, SS = 10 67 1 There will be a past due order of 1 that must be expedited and then the first order would increase to 36. The other option would be to order 37 in period 1 which would resolve the safety stock problem in period 3 instead of period 2. 6-4 9. PRODUCT A Item A B C D Inventory 10 40 60 60 Limit of A's by Item a b c 10 10 10 20 40 40 30 30 25 60 40 60 Start 10 40 30 60 The table above provides the basis for answering the three parts of the question. There are two difficulties that students are likely to have with this problem. The first is that you must add the restriction caused by A itself plus the minimum from B, C, or D. The second is they will forget that it takes 2 Cs to make an A. The answers are: a. 30 units of A (10 A’s in inventory + 20 A’s can be built) b. 40 units of A (10 A’s in inventory + 30 A’s can be built) c. 37 units of A (10 A’s in inventory + 27 A’s can be built) 13. Toaster Week Gross Requirements Scheduled Receipts Projected Available Balance Planned Order Release Q = 50, LT = 2, SS = 5 10 1 20 50 40 50 2 20 3 35 4 25 5 35 6 35 7 35 8 35 20 35 50 10 50 25 40 50 5 20 Toaster Week 2 3 4 5 6 7 8 9 Gross Requirements 20 35 25 35 35 35 35 40 Scheduled Receipts 50 Projected Available Balance 57* 37 52 27 42 7 22 37 47 Planned Order Release 50 50 50 50 Q = 50, LT = 2, SS = 5 *57 = 10 (Previous) + 45 (Receipt) + 7 (Adjustment) - 5 (Disbursement) **To get the required on-hand inventory at the beginning of week 2 need to release an order for 50 at the beginning of week 1. 6-5