vented, dome-shelter outer-cover blueprints

advertisement

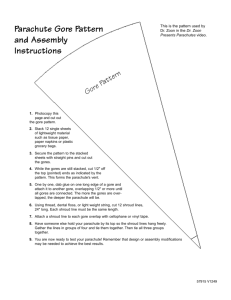

DOME OUTER-COVERING BLUEPRINTS WickerJungle . com Richard S. Currier, P. O. Box 35241, Albuquerque, NM 87176 or Richard S. Currier P. O. Box 2384, Taos, NM 87571 E-mail: mail@wickerjungle.com or the.gardenloft@yahoo.com Cell Phone: 575-224-9368 or 505-377-8789 Page 1 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Wicker Jungle presents the GARDEN-LOFT VENTED, DOME-SHELTER OUTER-COVER BLUEPRINTS – SMALL VERSION - ASM O R OR D E R TH E “ S KI N ” OR O U T ER - C OV ER I N G AT W E B S I T E : W WW.W I CKE RJ UNGL E .COM Richard Currier, Inventor N O TE : BE FO RE P RI N TI N G T HE S E BL U E P RI NT S : C L I C K F I L E - PA G E S E T U P O R C L I C K F O R M AT- PA G E A N D C H A N G E T H E P R I N T M AR G I N S T O H AL F I N C H O R . 5 0 B E C AU S E I C R E AT E D T H I S D O C U M E N T W I T H . 5 0 M AR G I N S . T H A N K YO U F O R YO U R S U P P O R T ! ! IMPLIED AND/OR BINDING CONTRACT: The buyer of these blueprints agrees not to copy, distribute, sell, or give away these blueprints without the express written permission of the inventor, Richard S.Currier. Buyer also agrees not to manufacture and/or sell any portion of this dome shelter system without the express written permission of the inventor. Buyer agrees that these blueprints are solely to be used on a personal level to make dome shelters for personal use. You may contact the seller to arrange a commission on sales of blueprints or sales of the outer covering. Page 2 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 3 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 4 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 5 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 6 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 7 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 8 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 9 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 10 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com This is the area that get sewn together or GLUED together. So, seam or glue should not go past inside line. It should be about 5 inches wide, so add FIVE inches to your pattern point marks. I do it AFTER pattern is marked and traced. Page 11 3 -1/4” WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com 138 ” 15 -1/2” 127 ” 18 -1/2” 120 ” Center Line Measure all points on ONE SIDE of material, then, fold on Center Line and trace other side so contours will match exactly ! If you are using a store bought TARP, do not cut off reinforced edge. Just leave it sauare.l Any othe material that is cut can be slightly rounded – but should then be reinforced on bottom. That goes for TOP of pattern as well. 26 -1/2” 102 ” 34 -3/4” 78 1/2 ” 40 -1/4” 58 3/8 ” 44 -1/4” 42 1/8 ” 48 -3/8” 21” 3 -1/2” This is an outer cover pattern for the new frame with base hoop members cut 23-1/8”. With this pattern, the user does NOT have to cut the vertical members at all. In other words, you simply use the 10' factory lengths of electrical conduit to make the dome framework! This outer cover pattern and the new frame blueprints provide about 25 additional square footage of floor space as well. See www.wickerjungle.com Page 12 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com 51” 51-1/2” NOTES about figuring conical sections. Page 13 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com NOTE: Conical section geometry is not intuitive. For instance, if you were to measure your finished frame to determine the cover dimensions – your cover would wind up WAY TOO SHORT ! Trust me, this is my “real world” experience. If you measure the frame to make the cover, you will make the cover SHORTER (vertically) than what the actual PVC finished frame measurements might suggest by rote measurements. So, GO WITH the measurements herein when making the cover, so that your outer cover will match the respective PVC framework blueprints. NOTE: Each of the 6 covering sections (gores) (used to make ONE outer covering) actually covers 5 of the 24 vertical PVC pipe vertical frame spines (not pictured), where 3 of the vertical spines are in the middle of each “gore,” and one vertical spine on the left and right side of each respective “gore” for a total of 5. A “gore” is the parachute industry term for one of the sections needed to make a parachute. So we use it here, since this cover is essentially a parachute. There are 6 gores used to make your outer cover. Since there are 6 gores, as you might expect, it is easier to sew 3 pairs together FIRST. The join to pairs to make a 4 gore section. Then, add the last pair to the 4 pair section. When I sew two gores together, I call it a “butterfly.” So, you connect three butterflies together to make your outer cover. Of course, one of the “butterflies” will have a zipper on it. The vertical and horizontal “green dotted lines” in the blueprint above represent the lines that YOU NEED TO DRAW on the TARP (or other cover material) in order to properly make this “pattern.” You must have 3 straight horizontal lines and one straight vertical center-line on which to then measure OUTWARD from the center line in order to get your “marker points”, (see LARGE RED dots in drawing). Using the above measurements, straighten and smooth the TARP out on the ground, and THEN use a chalk-line and tape measure to mark and make the vertical (up & down) and horizontal (left and right) lines (seen as green dotted lines). Make sure that the TARP is straight and wrinkle free (as possible) before making marks. Then, lay weights on each corner and in the middle to keep the TARP stable, while measuring to make “marker points” and then to chalk-line the straight horizontal and vertical lines. You should probably start my making the VERTICAL MARK first – using a “chalkline.” A “chalk-line” can be purchased from any hardware store and is simply a device that has cotton string inside that absorbs chalk. You put powdered chalk inside the chamber, and the chalk comes with the chalk-line device usually. When you stretch the line out tightly (at the desired length) on each end, you THEN “pop” the actual chalk-line by pulling straight up and then letting it go abruptly – leaving a straight chalk imprint of the cotton line. Since, the line is chalk, it will eventually wear off. I use a “grease pencil” to make the more permanent “marker points” along the chalk lines. As seen below, you will make the “marker point” marks on both sides, but you will draw and cut only one side. You will then fold the pattern vertically in half lining up the cut side curvature as near as possible to the opposing “marker points.” Then, you will trace exactly the image of the already cut curvature side to the opposing side of the patter – thus making the two sides of the pattern EXACTLY symmetrical or a ‘mirror image.” Read the paragraph below for further details on how to do this – or if you don’t understand this explanation. NOTE: There are 6 of the above conical sections (gores) sewn together to make ONE cover, so you need to make a separate “pattern” out of TARP to then make the six conical sections (gores) that are Page 14 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com used to make one cover . A “gore” is a term for the pattern above, and the term is used in the parachute industry. The small red dots on the patter below represent the very outer edge “marker points” that YOU need to mark on the TARP for making a “pattern.” Mark BOTH sides by measuring OUTWARD from a vertical center line you make with something like a chalk-line. After making these “marker points,“ you would then connect these small red dots or “marker points” on JUST ONE SIDE leaving the “marker points” on the opposing side alone for later. Now, you connect the dots on JUST ONE SIDE by carefully hand-drawing the curvature or using a slightly curved edge surface as a guide. Use your best reckoning, gradual curved items around the house, and a “good eye” to make sure that the curvature flows smoothly and naturally with no waves. STEP BACK and look at how you connected the dots and see if it looks uniform, smooth, and flowing. YOU NEED TO PUT “marker points” on BOTH SIDES of the center line, but YOU ONLY NEED TO draw just ONE side (either the left or right side of the above pattern but not both) by connecting the “marker points” on just one side of an established vertical center line. and THEN cut the marked curvature on just the one side by following the line that you made when you connect the “marker points” on just one side. NOW YOU ARE READY to fold over the one cut side in half lining up the bottom and making sure the “center line” is being creased. Make sure the new cut contour line lines up as closely as possible with the “marker points” on the opposing side. SMOOTH OUT ALL WRINKLES IN THE TARP AND MAKE SURE IT IS LAYING NATURAL AND FLAT, and add some weights (books, flower pots) around the perimeter to keep the TARP from moving before you cut the pattern the second time. Double check that the “marker points” on the opposing side are lined up with the curvature of the side you just cut. If they line up, you are ready to CAREFULLY trace the second side by following the curvature of the already cut side with a MAGIC MARKER. As you trace the curvature of the already cut side, your MAGIC MARKER should be passing through the “marker points;” however, what is most important is to trace the already cut side EXACTLY. AGAIN, while tracing, make sure the ALREADY cut side matches (as closely as possible) with your pre-drawn “marker points” on the opposing side of your new pattern. This redundant process insures PERFECT SYMMETRY, since the ALREADY cut side SHOULD now has an exact mirror image of itself if you followed these instructions. Adding weights on top of the TARP as you work will keep the pattern from moving while you CAREFULLY TRACE the curvature of the side you just cut onto the opposing side to make a mirror image. To repeat, you fold the pattern vertically in half, trace the ALREADY cut side of the pattern from the one side you just cut, line up the “marker points” on the opposing side with the cut contoured side, and CAREFULLY trace and cut the second side. Match up the cut side with the opposing “marker points” as close as possible. By “folding” and then tracing in this manner, you maintain PERFECT SYMMETRY of the curves on BOTH SIDES of the pattern and the edges are equi-distant on both sides of the established vertical center line on the pattern. AGAIN, by cutting one side and then folding the pattern vertically in half to trace the other side from the side you just cut, you will get a “mirror image” of the side you just cut – necessary to make a symmetrical pattern. If you mistakenly attempt to try to measure from the vertical center line to mark and cut both sides independently using two sets of “marker points” – YOU WILL HAVE A TERRIBLE MESS AND WILL RUIN YOUR PATTERN AND MAKE REDUCE LIKELIHOOD OF SUCCESSFULLY MAKING THE COVER. This is because when trying to connect the “gores” to sew together or heat seal, nothing will “match up.” However, all curves will MOSTLY match up (assuming that you DO NOT allow your pattern to slip when making it or when using it to trace the 6 gores) if you make a “perfect symmetry” pattern as described here !! Page 15 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com So, mark and cut ONE SIDE of the pattern, then fold in half on the vertical line and then TRACE the other side in order to achieve perfect symmetry. Now, that your PERFECTLY SYMMETRICAL “pattern” is made, you are ready to trace as many “gores” as you desire; however, you only need 6 “gores” to make ONE YURT COVER. Also, when placing the gore pattern on top of stock TARP material to trace your 6 gores, you need to WEIGHT DOWN the pattern on top to keep it from slipping in order to carefully trace the pattern onto each gore. Since the pattern you carefully made into a mirror image of itself and because it is symmetrical, you can just lay it down on top of stock TARP material, and you can then trace both sides directly onto each gore – using weights and insuring that the pattern does not slip when tracing both sides. Now, you can cut BOTH SIDES using your newly made “pattern” as a guide to trace and cut. Leave the “pattern” laying on top of TARP stock as you cut – even if I have marked it to gauge if the “pattern” has slipped while cutting and by keeping my eye on the “pattern” and “marked lines” at all times to see if they are still aligned accurately. NOTE TO SEAMSTRESS: You need grommets on the top and bottom. If you cut the “gores” from STOCK TARP, you can simply leave the grommets on the long bottom edge. Since the narrow top is raw with no factory re-enforcment because you just cut the tarp, you can add extra reinforcement to the narrow top by sewing some of the scrap double-thickness edging (where the grommets are) from your tarp. All grommets should be evenly spaced (if possible) on the bottom, since the grommets may be used to tether rope and used as a parachute. So, when you cut TARP material from a STOCK roll, you need to figure it, so that grommets can be spaced fairly evenly across the bottom. You would like to be able to deliver the frame or supplies by dropping it from an airplane to refugees, disaster victims, earthquake victims, or flood victims, etc. – using the cover as a parachute if necessary. Making the cover an alternative parachute adds to the marketability, since the shelter is ALREADY a dome or perfect hemisphere. CUT THE 6 OUTER-COVERING VENT RE-ENFORCEMENT STRIPS TO A LENGTH OF 18,” AND LEAVE OR PUT THE ONE GROMMET DIRECTLY IN THE MIDDLE OF THE STRIP. WHEN ATTACHING, CENTER THE RE-ENFORCEMENT STRIP GROMMET AT THE TOP OF THE “GORE,” AND LEAVE 1.5” FREE OR LOOSE AT EACH END OF THE STRIP IN ORDER TO “FINISH” VERTICAL SEAMS BY WRAPPING THE 1.5” LOOSE END AROUND THE HEM AND SEWING IT FLAT DOWN. SO, YOU WILL SEW 7.5” TO EACH SIDE OF THE CENTER GROMMET FOR THE TOP VENT RE-ENFORCEMENT STRIP AND STOP – LEAVING THE REST TO HANG FREE FOR LATER “FINISHING.” EXPLANATION: Remember, the narrow top area of each “gore” that ultimately makes the 72” vent hole cover circumference needs to be re-enforced FIRST before then joining the “gores”. You need to cut the reinforcement strip to be sewn at the VENT about 1.5” longer (on each side) than the EFFECTIVE top width and then add back the hem width on each side plus a 1.5 inch overlap on each side on which to “finish” the TOP VENT sewing. This makes the re-enforcement VENT strips 18” (18 inches (total TOP VENT gore measurement) – 3” sewing overlap hem allowance left side – 3” sewing overlap hem allowance right side + 1.5” hem coverage left side + 1.5” hem coverage right side) + 1.5” hem finish wrap around (left side) + 1.5” hem finish wrap around (right side). You should cut the VENT reinforcement strips and sew them on, so that you have ONE grommet in exactly the TOP Page 16 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com MIDDLE of each “gore,” and you should: BE SURE AND LEAVE 1.5” inches of the TOP VENT re-enforcement strip loose or unsewn on each side to be used to wrap over and “finish” the TOP VENT seam. This outer covering VENT grommet will come in handy for securing the cover to the PVC frame. When you sew all the gores together at the top, you will find that one side of the “overlapping” reinforcement strips will have to be cut flush and the other side will be folded over and sewn flat to create the “finished” and “strong” top VENT seam. So, it is important to remember that of the 18” width seen on the “gore” pattern plans above, there is 6” that is used to fold over and sew the hem – which leaves an effective top width of 12 inches (18 inches – 3” overlap left side – 3” overlap right side). So, the effective width is 12” for each of the six gores to make the actual circumference of the VENT HOLE at 6 gores x 12” = 72” circumference. When I made the prototype cover, I simply used scissors to trim off the reinforced edges of scrap TARP, and then I RE-SEWED or re-attached the approximately 1 foot of grommet laden scrap TARP edging back onto the top of each “gore” – putting one grommeted scrap at the top center of each gore – with the grommet hole in the center. Then, when sewn together, you have a strong border at the top to keep the wind from tearing the TARP material at a very vulnerable location – especially if used as a parachute. Each “gore” should be slightly rounded (if possible) at top, so that the finished product will “fit” and will look round looking up and out of the shelter, but it is not absolutely necessary – since the cover will make itself round. So, to make the VENT re-enforcement strips, cut some scrap factory grommeted edging off of the TARP, and measure to the left and right of ONE GROMMET by 7.5 inches – to achieve the 15” re-enforcement strip to use around vent and to make the ZIPPER TIE DOWN if zipper fails and also to keep the zipper from coming open during free-fall as a parachute. Page 17 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 18 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 19 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 20 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 21 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 22 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com the GARDEN-LOFT parachute calculations C A LC U LA TIO N Sfora94"radiusD O M EO U TER -C O VER IN GA LSOU SEDA SAPA R A C H U TE 49.2183 192.7716 94.00 188.00 7.83 15.67 3.14 sq. feet sq. feet inches inches feet feet constant = = = = = = = Parachute(outer-covering) C ircum ferenceinfeet. A reaof parachutecircum ferenceithR adiusbelow , alsoFloorSpaceof D om e. R adiusof D O M Eininches. D iam eterof D O M Eininches. R adiusof D O M Einfeet insteadof inches. D iam eterof D O M Einfeet insteadof inches. Pi =3.14159265358979 reaof aSPH ER E=4*Pi *(radiussquared). sq. feet = S=SurfaceA reaof H EM ISH ER E: inSQ U A R EFEET(above/ 2) sq. feet = S=SurfaceA eof aH EM ISPH ER E=(SPH ER E(4*PI *R adiuscubed) / 3) dividedby2) cu. feet = Volum irD ensity=.00237sl/ft^3(cubed?) or4000ft aboveseais.00211sl/ft^3(cubed?) sl/ft^3 = p=rho=A rho=M assperunit volum eof Earth'satm osphere. A irdensity&pressuredecreaseat higheraltitudes. eight of theparachute+load, inpoundsorN ew tons(m etric). 65.00 lbs. = W=w D=parachutedragcoefficient w hichisapprox. .75foraparachutew ithout holesorslits. 0.75 coeffic. = C VER TIC A LD ESC EN TR A TE escent Velocityinft/second V=SquareR oot ( 2*W )/(rho*C*S) 14.60 feet/sec. = V="Vertical D D=parachutedragcoefficient w hichisapprox. .75foraparachutew ithout holesorslits. 9.95 m iles/hour = C S="Total SurfaceA rea"of fabricusedtobuildparachuteplustheareaof slitsorholes. Thisdefinition(S) issuchthat w henventsarecut inthefabric, thevalueof Srem ains theSA M E, but thevalueof C D(coefficent of drag) becom esSM A LLER . http://w w w .aeroconsystem s.com /chutes/drag_calculator.htm d D=D ragof Parachute. 4.45 drag/sqft = D=1/2*p*V^2*S*C d=ProperparachuteSIZIN G ,w hichgivesdragpersquarefoot. 0.011550 drag/sqft = D=1/2*p*V^2*C PluginaparachuteA R EAtim estheresult toget correct parachute(SIZE.) D =D rag; C d=C oefficient of D rag(approx. .8to1.0); p(orrho)=A irD ensity; V=Velocity, S=surfaceareaof parachute 771.09 385.54 1,006.70 0.002110 http://www.aeroconsystems.com/chutes/drag_calculator.htm Here is the equation for calculating the drag of a parachute: D = 1/2 * p * V^2 * S * Cd Where: D=Drag; Cd=Coefficient of Drag (approx. .8 to 1.0); p(or rho)=Air Density; V= Velocity, S = surface area of parachute Alternatively you can determine the proper parachute sizing by using this formula: D = 1/2 * p * V^2 * Cd which gives drag per square foot. Plug in a parachute area times the result to get the correct parachute. Air density http://en.wikipedia.org/wiki/Density_of_air Page 23 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Calculating the descent rate of a round parachute By Dr. Jean Potvin Parks College Parachute Research Group How to calculate the descent speed of a round parachute: For most of its trajectory, the descent speed (velocity or V) of a round parachute has a near-constant value which can be computed from: /---------------/ / V = 2 W -------------rho C S / \ / \/ This formula is a consequence of the fact that during its descent, the parachute's own drag is balanced by the combined weight of the parachute and its load. The parameters appearing in the formula are as follows: CD = parachute drag coefficient which is approx 0.75 for a parachute without holes or slits cut in the fabric; same value in both Metric and English unit systems rho = air density near sea level its value is given by 0.00237 sl/ft^3 (English units) and 1.225 Kg/m^3 (Metric) near 4000 ft or 1219 m above sea level its value is 0.00211 sl/ft^3 (English units) and approx. 1.07 Kg/m^3 (Metric) W = weight of the parachute + load, in pounds (English) or Newtons (Metric) V = vertical descent velocity, here expressed in ft/sec (English) or m/sec (Metric) S is the total surface area of the fabric used to build the parachute, plus the areas of the holes and vents cut in the fabric if present. The units of S are in square feet (English) or square meters (Metric). This definition is such that when vents are cut in the fabric, the value of S remains the same but the value of CD becomes smaller. Nominal diameter versus constructed diameter Note that the parachute will be characterized by what parachute engineers called nominal diameter (or D), a number computed from this formula: /-------/ / D = 2 / \ / S -----3.1416 \/ Engineers also use the notion of constructed diameter, a number that is calculated from the measurement of the canopy's actual radius when holding it up by the apex. Here the radius is the distance between the apex and the canopy skirt (or "hem", where the suspension lines are attached). The constructed diameter is then twice the value of that radius. The values of the nominal diameter and the constructed diameter will be the same only when the parachute is built out of a flat circle of fabric. Alternate designs Most parachutes used in aerospace today are not based on flat circles but rather on shallow cones, Page 24 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com bulged hemispheres or other non-flat surfaces. It turns out that these designs optimize the value of the drag coefficient CD for pretty much the same amount of fabric as that of flat canopies. But these parachutes are much more complicated to build and moreover the constructed diameter and the nominal diameter are not equal. Parachute stability and venting Usually parachutes will swing wildly because of the air spilling from alternating sides of the canopy. This swinging can be reduced by cutting a hole at the parachute's apex, or altogether eliminated by cutting a large number of holes all over the canopy. But remember that adding vents will increase the descent speed. In the case of apex venting, the area of the apex hole should be about 1 to 10 percent of the parachute's flat surface area, depending of the desired trade-off between a slower descent speed and improved stability. Remember, the larger the hole, the faster the descent speed, since the value of the drag coefficient CD will decrease in the process. Examples of designs that improve stability besides apex venting are shown in an article by Dr. C. W. Peterson in Physics Today, August 1993. The magazine Physics Today can be found at university and college libraries. Making an experimental/toy parachute Constructing an experimental round parachute is very simple: just cut a piece of fabric in the shape of a circle. The fabric type can be cut from a plastic garbage bag, but such a chute won't last very long and will puncture easily. Using the nylon fabric of tents will yield a more durable product. Real parachutes use a reinforced version of that nylon. For detailed info about parachute design and rigging: 1.D. Poynter, The Parachute Manual-Vols 1&2, Para Publishing, Santa Barbara, CA 2.T.W. Knacke, Parachute Recovery Systems Design Manual, Para Publishing, Santa Barbara, CA Page 25 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 26 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com You should make your “rainfly” like this. Notice that there is a half-inch rainfly over the #10 YKK double pull plastic zipper. THEN, there is an additional “rainfly” that is about 1-1/2” - that is what my finger is touching in the picture. Notice that the larger “rainfly” has grommets. How is that done? I simply cut off the outer edging from the tarpaulin and save it to use for this purpose. Why the grommets you ask? Because you can tie it shut in the even of a gail force winds, hurricane, etc. - to keep the zipper from blowing open. Good idea, huh. It works. Also, if you were going to use the outer cover as a utility parachute to deliver to disaster relief, you would tie the grommets shut to allow the outer-cover/parachute to descend without the zipper coming open. Page 27 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com The picture below shows how I used the “edging” off a green tarpaulin to re-enforce the top VENT portion of the outer cover. There are six sections that make an outer cover, so use must cut and sew six pieces of edging. I choose edging that has a grommet and intentionally put the grommet in the MIDDLE to use as a utility grommet for such things as fastening the top of the cover to the top of the frame. Good idea, huh? Notice that I sewed an X in each corner AND put 3 horizontal stitchings to make sure it does not come undone or rip in a violent storm or if used as a utility parachute to deliver itself and other goods to disaster relief. Below is the FINISHED OUTER-COVER. It looks like only a pattern doesn't it? That is because the other sections are properly folded beneath the zippered section. It is not easy to fold and layer it, but it gets easier the more you do it. Once you get the outer cover to look like the picture below, you simply fold it like a sheet. In fact, you can see the fold lines where I folded it and then re-opened it for this picture at my storage unit. Page 28 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com Page 29 WickerJungle.com 575-224-9368 or 505-377-8789, the.gardenloft@yahoo.com or mail@wickerjungle.com