District Cabling Specifications

advertisement

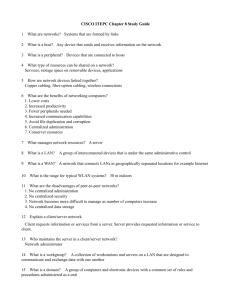

NETWORK INFRASTRUCTURE STRUCTURED CABLING SYSTEM SPECIFICATION STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION Table of Contents 1. Introduction ........................................................................................................................ 4 1.1. 1.2. 1.3. 1.4. 2. Purpose ............................................................................................................................................................ 4 Applicable Standards & Codes ....................................................................................................................... 4 Contractor Qualifications ................................................................................................................................ 5 Product Guarantee and Warranty .................................................................................................................... 5 Scope Of Project / Scope Of Work .................................................................................... 7 2.1. 2.2. 2.3. 2.4. 2.5. 2.6. 2.7. 2.8. 2.9. 3. Horizontal Cabling .......................................................................................................................................... 7 Backbone-Fiber ............................................................................................................................................... 8 J-hooks ............................................................................................................................................................ 8 Rack Hardware ................................................................................................................................................ 8 Cable Tray ....................................................................................................................................................... 8 Fire-stopping systems ...................................................................................................................................... 9 UPS ................................................................................................................................................................. 9 Poke-thru ......................................................................................................................................................... 9 Grounding ....................................................................................................................................................... 9 Telecommunication Network System Requirements ...................................................... 9 3.1. 3.2. 3.3. 4. Description ...................................................................................................................................................... 9 Supported applications .................................................................................................................................. 10 Additional requirements ................................................................................................................................ 11 Work Area Outlets ........................................................................................................... 11 4.1. 4.2. 4.3. Category 6 Copper Modules .......................................................................................................................... 11 Patch Cords ................................................................................................................................................... 12 Faceplates ...................................................................................................................................................... 12 4.3.1. 4.3.2. 4.3.3. 4.3.4. 5. Designer Series Face / Wall Plate .......................................................................................................................... 12 Modular Office Furniture Face Plates .................................................................................................................. 12 Surface Mount Plates ............................................................................................................................................. 13 Wall Phone Faceplates ........................................................................................................................................... 13 Horizontal Cabling Subsystem ........................................................................................ 13 5.1. 5.1.1. 5.1.2. 5.1.3. 6. Copper UTP Cable ........................................................................................................................................ 14 Cable Testing Criteria ............................................................................................................................... 14 Color Codes .............................................................................................................................................. 14 Cable Jacket Print ..................................................................................................................................... 14 Telecommunications Room .............................................................................................. 15 6.1. Cable Termination Hardware ........................................................................................................................ 15 6.1.1. 6.1.2. 6.1.3. 6.2. Cable Management ........................................................................................................................................ 16 6.2.1. 6.2.2. 6.2.3. 6.2.4. 7. Modular Patch Panels ............................................................................................................................................ 15 Fiber Termination Enclosure ................................................................................................................................ 15 Fiber Connectors .................................................................................................................................................... 16 7’ Rack System ....................................................................................................................................................... 16 Vertical Cable Management .................................................................................................................................. 17 Horizontal Cable Management ............................................................................................................................. 17 Cable Runway and Associated Accessories .......................................................................................................... 18 Backbone Cabling System................................................................................................ 18 7.1. 7.2. 7.3. Copper Backbone .......................................................................................................................................... 18 Fiber Backbone ............................................................................................................................................. 19 Fiber Cable .................................................................................................................................................... 19 7.3.1. 7.3.2. 7.4. 7.5. 7.6. 7.7. 8. 9. 10. 11. 12. 12.1. Performance - ......................................................................................................................................................... 19 Fiber Cable Specifications ..................................................................................................................................... 20 Fiber Termination Hardware ......................................................................................................................... 22 LC Connectors............................................................................................................................................... 22 Fiber Optic Adapter Panels ........................................................................................................................... 22 Fiber Optic Patch Cords ................................................................................................................................ 22 Grounding ......................................................................................................................... 23 Additional Documentation ............................................................................................... 23 Labeling ............................................................................................................................. 23 Testing Data ...................................................................................................................... 24 Drawings............................................................................................................................ 25 Rack Layout-Typical-Telecommunications Room ................................................................................... 25 STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION 1. Introduction 1.1. Purpose The purpose of this document is to provide documentation to cabling professionals interested in providing their Tuloso-Midway I.S.D. a standard specification applicable to commercial building structured cabling applications. No substitutions accepted. The documentation includes • Product specifications • Minimum product performance • Structured cabling design considerations • Installation guidelines Tuloso-Midway I.S.D. intends to acquire a complete telecommunications distribution system for its new facility. Tuloso-Midway I.S.D. here within requests proposals for the installation, testing, and acceptance of the telecommunications distribution system described in the attached specifications and drawings by interested persons (hereinafter known as “The Vendor”). The Vendor shall be responsible for all parts, labor, and all other associated apparatus necessary to completely install, test, and turnover for acceptance to Tuloso-Midway I.S.D. the telecommunications distribution system detailed herein. 1.2. Applicable Standards & Codes All work shall conform to the latest edition of the National Electrical Code, the Building Code, and all state & local codes and ordinances, as applicable. ANSI/TIA/EIA-568-B.1 and addenda ”Commercial Building Telecommunications Cabling Standard - Part 1: General Requirements” ANSI/TIA/EIA-568-B.2 and addenda ”Commercial Building Telecommunications Cabling Standard - Part 2: Balanced Twisted-Pair” ANSI/TIA/EIA-568-B.3 and addenda ”Commercial Building Telecommunications Cabling Standard - Part 3: Optical Fiber Cabling and Components Standard” ANSI/TIA/EIA-569-A and addenda ” Commercial Building Standard for Telecommunications Pathways and Spaces” ANSI/TIA/EIA-606 and addenda ” Administration Standard for the Telecommunications Infrastructure of Commercial Buildings” ANSI/TIA/EIA-607 and addenda ” Commercial Building Grounding and Bonding Requirements for Telecommunications” ANSI/TIA/EIA-526-7 ”Measurement of Optical Power Loss of Installed Single-Mode Fiber Cable Plant” STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION ANSI/TIA/EIA-526-14A ”Optical Power Loss Measurements of Installed Multimode Fiber Cable Plant” IEC/TR3 61000-5-2 - Ed. 1.0 and amendments “Electromagnetic compatibility (EMC) - Part 5: Installation and mitigation guidelines Section 2: Earthing and cabling” ISO/IEC 11801:2000 Ed1.2 and amendments ” Information technology - Generic cabling for Tuloso-Midway I.S.D. premises” CENELEC EN 50173:2000 and amendments ” Information Technology - Generic cabling systems” shall be adhered to during all installation activities. Methodologies outlined in the latest edition of the BICSI Telecommunications Distribution Methods Manual shall also be used during all installation activities. Should conflicts exist with the foregoing, the authority having jurisdiction for enforcement will have responsibility for making interpretation 1.3. Contractor Qualifications The Contractor shall be fully capable of installing cabling of low voltage infrastructure to support applications such as, but not limited to data, voice and imaging network systems. The Contractor shall at a minimum possess the following qualifications: Possess those licenses/permits required to perform telecommunications installations in the specified jurisdiction. Personnel trained and certified to design and install Systimax Products Provide proof of current Systimax Certified Installer Certification. Provide proof of current RCDD Certification. Provide references of the type of installation provide in this specification. Personnel trained in the Systimax Certified Installer course and be competent in Termination, Splicing, Testing, Trouble Shooting Fiber and Copper Products Personnel knowledgeable in local, state, province and national codes, and regulations. All work shall comply with the latest revision of the codes or regulations. When conflict exists between local or national codes or regulations, the most stringent codes or regulations shall be followed. Be in business a minimum of five (5) years. Must have personnel fluent in the use of Computer Aided Design and possess and operate CAD software using .DWG or .DXF format and Microsoft Visio. Must possess current liability insurance certificates. 1.4. Product Guarantee and Warranty STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION All CommScope Systimax non-consumable products have a 20-year guarantee. In order to qualify for the guarantee, the structured cabling system must be installed per the following: 1. Meet all TIA/EIA commercial building wiring standards 2. Use CommScope Systimax products purchased from CommScope Systimax Authorized Distributors 3. Products must be installed per Systimax instructions and Systimax Certified Installer training. Note: All Networks shall be installed per applicable standards and manufacturer's guidelines. Materials and workmanship hereinafter specified and furnished shall be fully guaranteed by The Vendor for Twenty years from transfer of title against any defects. The Vendor shall correct defects that may occur as the result of faulty materials or workmanship within Twenty Years after installation and acceptance by Tuloso-Midway I.S.D., at no additional cost to Tuloso-Midway I.S.D.. The Vendor shall promptly, at no cost to Tuloso-Midway I.S.D., correct or re-perform (including modifications or additions as necessary) any nonconforming or defective work within Twenty Years after completion of the project of which the work is a part. The period of The Vendor’s warranty(ies) for any items herein are not exclusive remedies, and Tuloso-Midway I.S.D. has recourse to any warranties of additional scope given by The Vendor to Tuloso-Midway I.S.D. and all other remedies available at law or in equity. The Vendor’s warranties shall commence with acceptance of the work in full. If The Vendor procures equipment or materials under the Contract, The Vendor shall obtain for the benefit of Tuloso-Midway I.S.D. equipment and materials warranties against defects in materials and workmanship to the extent such warranties are reasonably obtainable. The Vendor shall pass along to Tuloso-Midway I.S.D. any additional warranties offered by the manufacturers, at no additional costs to Tuloso-Midway I.S.D., should said warranties extend beyond the 20 year period specified herein. This warranty shall in no manner cover equipment that has been damaged or rendered unserviceable due to negligence, misuse, acts of vandalism, or tampering by Tuloso-Midway I.S.D. or anyone other than employees or agents of The Vendor. The Vendor’s obligation under its warranty is limited to the cost of repair of the warranted item or replacement thereof, at The Vendor’s option. Insurance covering said equipment from damage or loss is to be borne by The Vendor until full acceptance of equipment and services. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION 2. Scope Of Project / Scope Of Work 2.1. Horizontal Cabling The Horizontal Structured Cabling System shall consist of Category 6 cables placed from the Telecommunications Room to the outlets as shown on drawings. All Category 6 outlets will terminate in the Telecommunications Room on 48-port Category 6 patch panels. Wire management shall be used to provide cable management above, below and to each side of the patch panel. Cabling for horizontal cabling shall be routed through J-hooks placed above ceiling and below floor as needed to accomplish proper cable routing to work areas. J-hooks and all cable pathways they create shall follow building lines and allow access to cabling from hallway and open area locations and not be placed over other end user offices. J-hooks should follow all building lines. Outlet types are as follows: Flush Wall mount 2, 4, or 6 port outlet mounted on wall in device box at the work-area. Modular Furniture outlet 4-port outlet mounted in furniture at the work-area with cable access from floor below with cable routing through poke-thru. Surface Mount outlet 2-port outlet mounted at the work-area with cable access from ceiling area. Flush wall mount Phone 1-port outlet mounted on wall at the work-area in device box with studs for mounting phone Flush mount Wireless Access Point 1-port outlet mounted on wall in device box at the work-area. Flush floor mount poke-thru for Conference Room 2, 3, or 4-port outlet mounted in floor with cable access from floor below routing through and terminated in floor poke-thru. Frame provided for attaching information outlets Contractor will provide all materials to place and terminate all outlet types. Category 6 modules will be color coded for ease of identification. Blue icons for CCTV and Black icons for Data/Voice, Orange icons for WAP. Patch cords to complete work (CCTV/VOIVE & DATA/WAP) area patching shall be provided & installed by the contractor. One (1) CAT 6 work area patch cord, 10 feet in length and in same color shall be provided for each outlet. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION Patch cords to complete closet patching shall be provided & installed by the contractor. One (1) CAT 6 patch cord, 10 feet in length and same in color shall be provided for each outlet. 2.2. Backbone-Fiber The Backbone Fiber Riser System shall consist of fiber cables with 12 (twelve) 50 um Multimode interlocking armor cable placed from the telecommunications room to telecommunications room. All fiber terminations will terminate with LC connectors. Fiber will be terminated and routed through rack mount fiber panels. 2 duplex 7’ LC patch cords will be provided for each closet. 2.3. J-hooks The cabling from the Telecommunications Rooms will be routed to their respective outlets utilizing J-Hooks above ceiling and below floor. Cables will be bundled in groups of less than 50 and placed no more than 5’ apart following the pathway from Telecommunications Room to work area outlet. J-hooks and all mounting hardware as well as any placement of these devices are the responsibility of the contractor. Only Velcro should be used. No tie-wraps allowed. 2.4. Rack Hardware Rack Hardware will be utilized in the Telecommunications Room on each floor and the Equipment Room Main Cross-Connect facility to house terminated Category 6 patch panels, fiber termination hardware, network switch equipment. Additionally, a UPS system shall be installed in racks in the Telecommunications Rooms and the Equipment Room. All Rack hardware will be secured to the floor with appropriate hardware and overhead by cable tray. All racks will be 7 feet in height and 19 inches wide with 3-inch channels. Vertical cable management will be utilized between each rack and at the end of each rack to manage vertical patch cables (in front) and horizontal cable runs (in back). 3.65” vertical managers will be used at the end of each rack to provide cable management vertically. 8” vertical cable managers will be used between racks to provide cable management vertically. Horizontal wire management shall be provided so there will be wire management above and below each copper patch panel. All rack hardware shall be grounded to an approved building ground. 2.5. Cable Tray Cable tray shall be placed inside the Telecommunications Rooms and Equipment Room to provide a pathway into the room and routing the cables to the rack mounted termination hardware. Cable tray will be 12” wide and mounted to walls and racks as STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION shown on drawings. Tray shall be mounted above racks and doors to allow a natural cable drop from the tray to the rack. All cable trays shall be grounded to an approved building ground. 2.6. Fire-stopping systems Suitable fire-stopping shall be used to prevent the spread of smoke and fire through out the building. Contractor will be responsible for installing fire-stopping system for every wall or floor penetration as required by code. 2.7. UPS An Uninterruptible Power System shall be placed into each Telecommunications Room to provide conditioned power and back-up in case of power failure. UPS shall be mounted in the bottom of the rack housing the network equipment. APC Smart-UPS X 1500VA Rack/Tower LCD 120V with Network Card SMX1500RM2UNC. 2 post mount kit – AP9625. No substitutions. 2.8. Poke-thru Poke-thru devices will be provided for the Flush floor mount poke-thru for Conference Rooms. These devices will include poke-thru device and frames to allow an outlet to be placed into them. Poke-thru devices will be provided for access into modular furniture. These devices will offer a 2” pathway to route cables into modular furniture. Contractor will be responsible for any additional protection required to route cables into modular furniture. 2.9. Grounding Contractor shall provide a ground bar at each termination location (Telecommunications Rooms and Equipment Room). Contractor shall provide a #6 AWG stranded copper wire cable between ground bars located at each TR and ER to the building main service ground point. This ground conductor shall be utilized for grounding termination equipment, equipment rack and cable tray. 3. Telecommunication Network System Requirements 3.1. Description The Structured Cabling System shall consist of any one or all of the following structured cabling elements or subsystems: Work area Horizontal cabling Telecommunications room (or horizontal cross connect) Backbone cabling STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION 3.2. Equipment room Entrance facility All cable support structure Supported applications The Structured Cabling System shall be capable of supporting and/or integrating the following: Analogue and digital voice applications Data applications Local area network services Wide area network services Video /Imaging services Low voltage devices for building controls The applications that shall be supported include, but are not limited to: Data Communications Token Ring (IEEE 802.5) Ethernet (10 Base-T, 100 Base-T, 1000 Base-T) 100 Base VG Any LAN ATM (155 Mbps, 622 Mbps) Fiber Distributed Data Interface (FDDI) Twisted Pair-Physical Medium Dependant (TP-PMD) IBM System 3X IBM AS/400 AppleTalk Arcnet ISDN CDDI Any other application designed to run on a generic structured cabling system designed and installed to TIA or ISO structured cabling standards. Data Processing Mainframe access client server, enterprise server, messaging systems and electronic mail, client database, etc. Voice Applications Digital and analogue PABXs and key systems Video Analogue video, digital video, and video conferencing Building Services Heating, ventilation, and air conditioning (HVAC) monitoring and control Lighting Motion sensors Public address and paging systems Security Other low voltage devices Multiple Services The structured cabling system shall also support backward and forward migration of applications with minimal disruption to existing services or personnel, allowing for quick moves, adds, and changes. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION 3.3. Additional requirements 4. Categorized copper product shall be used in conjunction with an equivalent or higher Category cable as verified by ETL or TSV. All structured cabling products shall be installed according to any applicable instructions. All networks and other applications shall be installed per applicable standards and manufacturers’ guidelines and transmitted over the appropriate minimum Category copper cable or fiber cable for which it was intended to operate on. All applicable local, state, national, and federal electrical and fire safety standards shall be adhered to during and after installation. Work Area Outlets The Work Area shall consist of the connectivity equipment used to connect the horizontal cabling subsystem and the equipment in the work area. The connectivity equipment shall include the following options: 4.1. Category 6 Copper Modules All category 6 information outlets designed for termination of 4-pair balanced twistedpair category 6 copper cables must possess the following characteristics at the minimum: Be able to be a gravity feed (45 degree angled) as well as flush mount utilizing the same jack. Have 110 style insulation displacement connectors with quadrant pair isolation and a pyramid wire entry system. Termination is accomplished with a single conductor impact tool. Be backwards compatible to allow lower performing categories of cables or connecting hardware to operate to their full capacity. Have rear protective strain relief caps rear entry, which will be installed onto cable after termination. Support industry standards for T568A or T568B wiring options (568B wiring scheme applicable to this project) on each individual outlet. Be side-stackable for high-density solutions. Provide color-coded and labeled VOICE, DATA or Blank, Snap-In icons for circuit identification. Be constructed of high impact, flame-retardant thermoplastic. Verified to ETL TSV performance in a channel Color Scheme: Blue is CCTV, Black is Voice/Data & Orange is WAP. CommScope GigaSPEED 700206XXX Outlets shall be Blue (758), orange (683), and Black (667) STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION 4.2. Patch Cords All category 6 Patch (Work-area & Telecommunication Room) Cords shall use 4-pair balanced twisted-pair category 6 23 AWG stranded twisted pair copper cable and be available in both Booted and Non Booted options. The cords must be available in Blue, Orange & Black in 10FT length. Blue is CCTV, Black is Voice/Data & Orange is WAP. CommScope CPC3313-0XXXXX (Blue – 2F010, Orange – 6F010, & Black – 1F010) 4.3. Faceplates 4.3.1. Designer Series Face / Wall Plate Designer series faceplates shall be available in single gang design in (electric ivory) and available in (2, 4 or 6) port openings. They shall feature openings on both sides to allow easy identifications of the ports and accept Systimax information outlets. They shall come equipped with mounting screws, label covers, and label cards. Any unused ports will be filled with blanks. CommScope – M12L-246 108168477 (2-port outlet) CommScope - M14L-246 108168550 (4-port outlet) CommScope – M16L-246 108168592 (6-port outlet) CommScope Blanks –M20AP-246 107067860 4.3.2. Modular Office Furniture Face Plates Modular office furniture faceplates shall be (electric ivory) consisting of openings on both sides to allow easy identifications of the ports and accept Systimax information outlets. They shall be coordinated with the STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION manufacturer of the modular furniture to fit the appropriate opens. Any unused ports will be filled with blanks. CommScope Modular Furniture 4-port Faceplate –M14CE-246 108216144 CommScope Blanks –M20AP-246 107067860 4.3.3. Surface Mount Plates Surface mount faceplates shall consist of 2 port openings, and accept Systimax information outlets faceplates shall be (electric ivory) consisting of openings on both sides to allow easy identifications of the ports and accept Systimax information outlets. They shall be coordinated with the manufacturer of the modular furniture to fit the appropriate opens. Any unused ports will be filled with blanks. CommScope Surface Mount box – M202SMB-246 – 760057356 4.3.4. Wall Phone Faceplates Wall Phone Outlets shall have a single port and be equipped with mounting studs for attachment of wall phone and accept Systimax information outlets. CommScope Wall Phone Outlet– M10LW-262 108258450 5. Horizontal Cabling Subsystem The horizontal cabling system is the portion of the telecommunications cabling system that extends from the work area telecommunications outlet/connector to the horizontal cross-connect in the TC. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION • • Horizontal cabling is installed in a star topology (home run) Bridged taps and splices are not permitted as part of the copper horizontal cabling. 5.1. Copper UTP Cable • Maximum cable length is 90 meter Category 6 Systimax 71E series GigiSPEED XL UTP Cable (BLUE 700208093) These requirements are for cables of four unshielded twisted pairs of 23 AWG bare copper, thermoplastic insulated solid conductors enclosed by a thermoplastic jacket. The finished cable shall exceed the requirements of ANSI/TIA/EIA-568-B.2-1 Category 6 . All cable shall conform to the requirements for communications circuits defined by the National Electrical Code (Article 800) and the Canadian Building Code. All cable shall be listed with an OSHA approved laboratory and carry labeling of either CMP or CMR which ever is appropriate for the installation environment. The cable manufacturer shall be ISO 9001 registered. 5.1.1. Cable Testing Criteria Tested to 400 MHz Maximum Delay Skew < or = 25 ns Positive PowerSum ACR > or = 310 MHz PSUM ELFEXT & ELFEXT =1dB over 6 standard Capacitance Unbalance of 58.2 pF Max @ 23 degrees Celsius. PSUM NEXT & NEXT =or > 3dB over category 6 5.1.2. Color Codes The color code shall be as follows: Pair 1 Pair 2 Pair 3 Pair 4 Blue-White/with extruded Blue stripe on White single Orange-White/with extruded Orange stripe on White single Green-White/with extruded Green stripe on White single Brown-White/with extruded Brown stripe on White single 5.1.3. Cable Jacket Print The cable jacket shall be printed with a minimum of the following information: Manufacturer, Manufacturer’s part number, cable type, listing file number, number of pairs, listing type (i.e. CMP), and sequential footage markings starting at 1000 ending at 0. Web-Trak cable test report identification number. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION Category 6 Systimax 2071E series GigiSPEED XL UTP Cable (BLUE 700208093) 6. Telecommunications Room The telecommunications room (TR) includes those products that connect the networking equipment to the horizontal and backbone cabling subsystems. These products include termination hardware (connectors and patch cords), racks, cable management products and cable routing products. 6.1. Cable Termination Hardware Each horizontal or backbone cabling run will be terminated using appropriate connectors or connecting blocks depending upon the cable type. Matching patch cords will be used to perform cross-connect activities or to connect into the networking/voice hardware. 6.1.1. Modular Patch Panels CommScope M2000-48 2U CAT 6 is a 2U 48 Port Patch Panel. CommScope M2000-48 2U - 760049940 6.1.2. Fiber Termination Enclosure All fiber optic rack mount enclosures shall be CommScope. All adapter panels shall be CommScope for both Single-mode and Multi-mode applications. All rack mount enclosures shall be CommScope G2 Fixed Modular Cassette style enclosures. Blanks panels must be inserted into unused slots. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION CommScope Enclosure 760032094 CommScope Adapter Panel w/6 Ganged Beige SC adapters 760109397 CommScope SC Multiport Shuttered Adapter, Aqua - 700207012 CommScope Blank Panel PNL-BK-BLANK-6-PACK 760147751 6.1.3. Fiber Connectors All fiber optic connectors shall be CommScope. Connector type shall be CommScope SC connectors for both Single-mode and Multi-mode applications. CommScope 760007070 6.2. Cable Management The Cable Management System shall be used to provide a neat and efficient means for routing and protecting fiber and copper cables and patch cords on telecommunication racks and enclosures. The system shall be a complete cable management system comprised of vertical and horizontal cable managers to manage cables on both the front and rear of the rack. The system shall protect network investment by maintaining system performance, controlling cable bend radius and providing cable strain relief. 6.2.1. 7’ Rack System 2 Post Rack The CommScope 2-Post rack will be Black, 7FT x 19IN and will be EIA-310E Compliant, UL Listed, Certification- Information Technology and Communications Equipment. The CommScope 2-Post rack will be 7’H x 19”W with 12-24 Tapped Rails. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION CommScope RK3-45A 760082479 6.2.2. Vertical Cable Management VCM Kit The CommScope Vertical Cable Management Kit will be provided for both sides of 2-post rack and will provided as detailed. 8” width x 84”, SingleSided with doors, with spools, black. CommScope VCM-SS-84-8B 760089433 6.2.3. Horizontal Cable Management HTK Kit The CommScope Horizontal Trough Kit (2RU, 19IN single sided) will be provided for both sides of 2-post rack and will provided as detailed. 8” width x 84”, Single-Sided with doors, with spools, black. CommScope HTK-19-SS-2U 760072959 STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION 6.2.4. Cable Runway and Associated Accessories The 12” Ladder Rack in a Telecommunications Room / Equipment Room shall be placed to allow easy access into the room and formed. Rack shall route cables from room entrance to their termination location. Rack shall use a stand off bracket to allow cables to be routed above racks and flow easily into vertical managers. Straight Sections, Flat, Inside and Outside Radius Sections, and all accessories (mounting & butt splice kit, retaining post, stringer & rung drop outs, protective end caps, junction splice, retaining post, runway to rack mount) shall be provided for complete install. All CommScope 76008XXX series. Ladder rack shall be grounded to ground bar located in the termination location. CommScope 760085605 CommScope 76008XXXX (Accessories) 7. Backbone Cabling System The Backbone Cable Subsystem in a building is the part of the premises distribution system that provides connection between equipment rooms, telecommunication rooms, and telecommunications service entrance facilities. A backbone subsystem provides either intra-building connections between floors in multi-story buildings or inter-building connections in campus-like environments. 7.1. Copper Backbone The type of backbone copper cable shall be unshielded twisted pair (UTP), 4-pair Category 6 cable as previously specified in this document. Each Telecommunications Room shall have six (6) Category 6 cables terminated on a patch panel located in the Telecommunications Room and located in the rack housing the network equipment. The cables shall terminate on the other end in the Main Cross-Connect in the Equipment Room. Color of Backbone copper cables shall be Blue. Terminations in the Telecommunications Room shall be on a 24-port Category 6 patch panel. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION Terminations in the Equipment Room shall be on a 48-port Category 6 patch panel. Category 6 Systimax 71E series GigiSPEED XL UTP Cable (BLUE 700208093) CommScope 360-IPR-1100-E-GS3-2U-28 760152579 7.2. Fiber Backbone The type of fiber cable used shall be CommScope Indoor/Outdoor Plenum Distribution Cable, interlocking aluminum armored with plenum jacket, 12 Strand single unit. Termination enclosure will be located at the top of the rack housing the network equipment in the Telecommunications Room. A single fiber jumper trough shall be provided directly below the fiber termination enclosure for fiber patch cord management. 7.3. Fiber Cable 7.3.1. Performance Fiber Optic Backbone Cable shall be rated OFNP or OFNR per the installation environment as defined by the NEC and local authority having jurisdiction. a) Fiber construction shall be multi-mode with a core/cladding size of 50/125 microns. Contractor shall purchase and install the appropriate CommScope fan out and breakout materials where dictated by the application and choice of fiber optic cable type. The maximum attenuation of the cable shall be 3.0 dB/km at 850nm and 1.0 dB/km at 1300nm. The cable shall be capable of supporting 10 Gigabit Ethernet to 300 meters. b) See Multimode Fiber Specifications section for detailed specifications. Fiber Optic Cable size shall be 12 strandsMM, and termination shall be as per the backbone diagram, or TULOSO-MIDWAY I.S.D. requirements. All Fiber Optical Cable shall be constructed to the requirements listed in Fiber Cable Specifications. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION All fiber links shall be tested for attenuation using a power meter and light source. The allowable attenuation for any link shall be calculated using the following formula: Total allowable loss in dB = Number of connector sets X 0.5 + Number of Splices X .09 + loss for cable. All testing shall be accomplished according to Section 11 of ANSI/TIA/EIA568-B.1 1. Fiber Optic Backbone Cable shall be rated OFNP or OFNR per the installation environment as defined by the NEC and local authority having jurisdiction. a) Multi Mode Fiber construction shall be multi-mode with a core/cladding size of 50/125 microns. Contractor shall purchase and install the appropriate CommScope fan out and breakout materials where dictated by the application and choice of fiber optic cable type. The maximum attenuation of the cable shall be 3.0 dB/km at 850nm and 1.0 dB/km at 1300nm. The cable shall be capable of supporting 10 Gigabit Ethernet to 300 meters. 2. Fiber Optic Cable size shall be 12 strand multimode, and termination shall be as per the riser diagram, or TULOSO-MIDWAY I.S.D. requirements. All Fiber Optical Cable shall be constructed to the requirements listed in Fiber Cable Specifications. 3. All fiber links shall be tested for attenuation using a power meter and light source. The allowable attenuation for any link shall be calculated using the following formula: Total allowable loss in dB = Number of connector sets X 0.5 + Number of Splices X .09 + loss for cable. All testing shall be accomplished according to Section 11 of ANSI/TIA/EIA568-B.1 7.3.2. Fiber Cable Specifications This optical fiber backbone cable shall be suitable for installation in building riser systems, in conduit, in cable tray and/or in J-hooks. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION CommScope Systimax P-012-0Z-5L-FSUBK 760134890 1. Optical fiber cable shall be encased in an interlocking armor with an overall plenum rated jacket. a. Optical fiber cable shall carry an OFCP (Optical Fiber Conductive Plenum) or OFCR (Optical Fiber Conductive Riser) rating, depending on installation environment. b. Outer Sheath: The outer sheath shall be marked with the manufacturer’s name, date of manufacture, fiber type, listing (OFCP or OFCR), manufacturer’s identification number, and sequential length markings every two feet. 2. Temperature Range: Storage: -40ºC to +70ºC (no irreversible change in attenuation). Operating: -20ºC to +70ºC. 3. Humidity Range: 0% to 100%. 4. Single Unit Cables: a. b. 5. Maximum Tensile Strength (2 fibers). During Installation: 1001 Newton (225 lb. force) (no irreversible change in attenuation). Long Term: 300 N (67 lb. force). Maximum Tensile Strength (≥4 fibers): During Installation: 1335 Newton (300 lb. force) (no irreversible change in attenuation). Long Term: 400 N (90-lb. force). Multiple Unit Cables: a. Maximum Tensile Strength (24 fibers). During Installation: 2670 Newton (600 lb. force) (no irreversible change in attenuation). Long Term: 180 N (801 lb. force). STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION b. c. 6. 7.4. Maximum Tensile Strength (36 fibers 48): During Installation: 3560 Newton (800 lb. force) (no irreversible change in attenuation). Long Term: 1068 N (240-lb. force). Maximum Tensile Strength (≥60 fibers): During Installation: 4450 Newton (1000 lb. force) (no irreversible change in attenuation). Long Term: 1335 N (300-lb. force). Bending Radius: During Installation: 20 times cable diameter. No Load: 10 times cable diameter. Fiber Termination Hardware All Fiber Optic termination Hardware shall be CommScope. Termination hardware in the Equipment Room shall be a rack mount fiber enclosure, fixed, SYSTIMAX G2 2U Fixed Modular Cassette Shelf and require the use of fiber adapter modules. 7.5. ST Connectors All Fiber Optic Connectors shall be CommScope. They shall be available in ST style connectors. They shall be terminated with anaerobic style kits. CommScope 7600070 P-012-0Z-5L-FSUBK 760134890 P-012-0Z-5L-FSUBK 76013489070 7.6. Fiber Optic Adapter Panels Systimax Fiber Optic modular adapters shall support high-speed networks and applications designed for implementation on multimode (both 62.5/125 and 50/125 m) glass fiber cabling. All outlets shall utilize interchangeable and individual connector modules that mount side by side to facilitate quick and easy moves, adds, and changes. The fiber optic modular adapters shall be available with adapters for SC duplex outlets. 7.7. Fiber Optic Patch Cords All fiber optic patch cords shall be available in ST connector type. Cords shall be available in multiple jumper lengths. CommScope’s fiber optic jumpers connect the patch panel/shelf to the equipment bay. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION CommScope FEXLCLC42-MXMXXX Multimode (50UM) 8. Grounding Contractor shall provide a ground bar at each termination location (Telecommunications Rooms and Equipment Room). Contractor shall provide a #6 AWG stranded copper wire cable between ground bars located at each TR and ER to the building main service ground point. This ground conductor shall be utilized for equipment, termination, equipment rack, cable tray and computer equipment grounding. All grounding and bonding shall meet the National Electrical Code (NEC) as well as local codes, which specify additional grounding and/or bonding requirements. Bonding and Grounding Communication bonding and grounding shall be in accordance with the NEC and NFPA. Horizontal cables shall be grounded in compliance with ANSI/NFPA 70 and local requirements and practices. Horizontal equipment includes cross connect frames, patch panels and racks, active telecommunication equipment and test apparatus and equipment. When required by local code, provide a Telecommunications Bonding Backbone utilizing a #6-AWG or larger bonding conductor that provides direct bonding between equipment rooms and telecommunications closets. This is part of the grounding and bonding infrastructure (part of the telecommunications pathways and spaces in the building structure), and is independent of equipment or cable. 9. Additional Documentation Installer shall provide asbuilt drawings to Tuloso-Midway I.S.D. with full documentation as it relates to TIA/EIA 606-A or latest recognized standard. The drawings shall be submitted to Tuloso-Midway I.S.D. no later than 45 days after completion of work. Tuloso-Midway I.S.D. will not process payment until said documentation is received. 10. Labeling The Contractor shall be responsible for printed labels for all cables and cords, distribution frames, and outlet locations, according to Tuloso-Midway I.S.D. specifications at the time of delivery. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION 11. Testing Data All Test Data will be submitted to Tuloso-Midway I.S.D. in Hard Copy in a labeled binder and also in electronic version approved by the manufacturer. If Specific Software is needed for viewing or managing documentation, it is the responsibility of the Installer to provide software at no additional cost if requested by Tuloso-Midway I.S.D.. STRUCTURED CABLING SYSTEM TECHNICAL SPECIFICATION 12. Drawings 12.1. Rack Layout-Typical-Telecommunications Room CAT6 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 CAT6 CAT6 1 2 3 4 5 6 7 8 23 24 17 18 22 16 21 15 20 14 19 13 23 24 17 18 22 16 21 15 20 13 14 19 12 47 48 41 42 46 40 45 37 38 43 36 39 44 35 9 10 11 12 9 10 11 33 34 CAT6 1 25 2 26 3 27 4 28 5 29 6 7 30 31 8 32 CAT6 1 2 3 4 5 7 9 11 13 14 15 17 18 19 12 16 21 10 20 23 8 22 24 6 25 26 27 28 29 31 33 35 37 38 39 41 42 43 36 40 45 34 44 47 32 46 48 30 CAT6 1 2 3 4 5 7 9 11 13 14 15 17 18 19 12 16 21 10 20 23 8 22 24 6 25 26 27 28 29 31 33 35 37 38 39 41 42 43 36 40 45 34 44 47 32 46 48 30 23 24 13 14 17 19 12 15 20 11 16 21 10 18 22 9 47 48 37 38 41 43 36 39 44 35 40 45 34 42 46 33 CAT6 1 25 2 26 3 27 4 28 5 29 6 30 7 31 8 32 CAT6 1 2 3 4 5 7 9 11 13 14 15 17 18 19 12 16 21 10 20 23 8 22 24 6 25 26 27 28 29 31 33 35 37 38 39 41 42 43 36 40 45 34 44 47 32 46 48 30 This is representative of what can be built (as it has templates for UPS, Power strip, switch, angled and flat panels, cable management, modular and fiber panels.