Doc - School of Electrical and Computer Engineering at Georgia Tech

advertisement

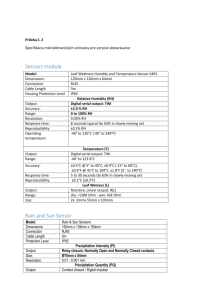

Battery Management System (BMS) for a Solar Powered Racer Revision 1 ECE 4007 Senior Design Project Section L01, Solar Jackets – Battery Management Team Project Advisor: Dr. Whit Smith Prepared by: Mark Slade Daniel Christopher Daniel Paul Martin Ali Bibonge Taverishima Tsegha Submitted December 12, 2011 Table of Contents Executive Summary.............................................................................................................4 1. Introduction......................................................................................................................5 1.1 Objective............................................................................................................5 1.2 Motivation..........................................................................................................5 2. Project Description and Goals..........................................................................................6 2.1 Description.........................................................................................................6 2.2 Goals...................................................................................................................7 3. Technical Specification....................................................................................................8 3.1 Physical Specifications.......................................................................................8 3.2 Lithium-Ion Battery Specifications....................................................................9 3.3 Microcontroller Specifications..........................................................................10 3.4 MOSFET Specifications....................................................................................11 3.5 LTC Specifications............................................................................................12 3.6 Temperature Sensor IC Specifications..............................................................12 3.7 Electromechanical Relay Specifications............................................................13 3.8 DC Fuse Specifications......................................................................................14 4. Design Approach and Details..........................................................................................14 4.1 Design Details....................................................................................................14 4.2 Microcontroller……..........................................................................................15 4.3 LTC Battery Monitoring IC…………...............................................................16 4.4 Temperature Sensor Implementation.................................................................16 4.5 Current Sensor Implementation.........................................................................16 2 4.6 Printed Circuit Board Design.………................................................................17 5. Schedule, Tasks, and Milestones......................................................................................18 6. Results and Acceptance testing.........................................................................................18 7. Marketing and Cost Analysis............................................................................................21 7.1 Marketing Analysis.............................................................................................21 7.2 Cost Analysis......................................................................................................22 8. Project Conclusions, Observations, and Future Work......................................................23 9. References.........................................................................................................................24 Appendix A...........................................................................................................................25 Appendix B...........................................................................................................................26 Appendix C...........................................................................................................................27 3 Executive Summary The Solar Jackets club at Georgia Tech is building a solar powered racer to compete in a 1200-1800 mile cross-country American Solar Challenge in summer 2012. The battery management system (BMS) project is a continuation of the design that began in January 2011 by the previous ECE 4007 senior design class. The BMS system proposed will be designed to monitor, regulate, and maintain the solar powered lithium-ion (Li-ion) rechargeable batteries that power the Solar Jacket’s racer. The racer will be powered by three battery packs connected in parallel containing 30 Li-ion cells each. The battery packs will supply the 96 V required for the motor and a 12 V bus to power all peripheral equipment such as microcontrollers. During the race, it is required that an active method of circuitry protection be utilized to continually monitor and regulate the over-voltage, under-voltage, over-current, and over-temperature of the Li-ion battery cells. Communication with other systems in the racer will be achieved via a RS-485 network being designed by another Solar Jackets team. 4 1. Introduction The Solar Jackets team at Georgia Tech is building a solar powered racer to compete in the 2012 American Solar Challenge. This was the second semester of working on a battery management system (BMS) continuing from where the spring 2011 team stopped. The current Solar Jackets battery management system (BMS) team had a $410 budget from Georgia Tech to develop and build a custom BMS, a subsystem of the solar power system in the racer. 1.1 Objective The spring 2011 BMS group left a semi-functional battery management system that could measure individual cell voltages in a controlled environment. This semi-functional BMS could also communicate via the RS-485 network and determine whether to turn on or off each battery pack. The main objective this semester was to get the current and temperature monitoring components of the BMS functional as well as potentially polishing the voltage monitoring aspect of the BMS [1]. The RS-485 communication protocol will be designed and managed by another Solar Jackets design group; the BMS will only provide the data acquired from the battery packs. 1.2 Motivation The Solar Jackets want to have a fully functional car before summer 2012. A working BMS prototype must be produced and integrated along with the other subsystems before the Solar Jackets can race. There are a total of 90 lithium-ion (Li-ion) cells in the car and safety is critical. These Li-ion cells are capable of exploding if the temperature exceeds 85 °C and will be damaged if the voltage drops below a certain threshold (2.20 V). A BMS system is necessary to ensure that the batteries are maintained within the desired operating conditions for temperature, current, and voltage. Without a battery management system, the driver would need to repeatedly check on the battery’s health himself which would quickly become tedious and dangerous [1]. A 5 custom design BMS will produce a more cost effective means for monitoring and managing the batteries for the Solar Jackets. It will also allow the Solar Jackets to better understand how to deal with rare problems such as large currents and other various characteristics that are expected from the system. 2. Project Description and Goals 2.1 BMS Description The BMS was designed to provide measurements of the voltage of individual batteries in each pack, the current flowing in or out of the battery pack, and the temperature of the battery pack. Predetermined zones were selected in order to provide safe operating conditions for the batteries. The three zones are shown in Table 1. The green zone indicates a safe operating zone, the yellow zone indicates a warning zone, and the red zone indicates a dangerous zone. If any red zone thresholds are exceeded, the lithium ion batteries will be electrically isolated from the 96 V bus as required in the American Solar Challenge regulations. The battery packs will consist of 30 3.2 V lithium ion cells connected in series to produce 96 V. 6 Table 1. BMS predefined thresholds Green Yellow Red Zone Zone Zone Temperature < 40 C 40 C - 45 C > 45 C Discharge Current < 40 A 40 A - 60 A > 60 A Charge Current < 16 A 16 A - 18 A > 18 A Voltage (module) 103 V - 105 V > 105 V 85 V - 103 V Voltage 3.3 V - 3.6 V > 3.6 V 2.3 V - 2.6 V < 2.3 V 2.6 V - 3.3 V (Li-ion cell) A printed circuit board (PCB) was designed and is ready to be milled. It contains components for measuring the voltage of each cell, the current at the connection of each battery pack, and the temperature at various locations in the battery pack. The measurements obtained from the sensors will be read by a Microchip PIC24 microcontroller. Continuous monitoring of the sensors from the microcontroller will allow for system stability and allow for the capability of disconnecting the battery pack if necessary. The microcontroller will be connected to the car’s computer system to report its status and receive commands to connect and disconnect the pack. 2.2 Goals Program microcontroller to read sensor data and determine state of battery system Monitor individual cell voltages, temperature, charge/discharge current 7 Satisfy cooling requirements Implement safety shut off system Send/receive data and commands with computer 3. Technical Specifications 3.1 Battery Pack Specifications Three independently monitored battery packs all work together to power the solar vehicle. The specifications are listed in Table 2 [2]. The choice of batteries was chosen by the Solar Jackets officials. The battery packs will output at 96V for the motor and also supply the 12 V power used by the all other electronics in the vehicle. Additionally, size constraints will play a critical role and are also listed in Table 2 [2]. The BMS is designed to keep the batteries within the manufacturer's operational specifications [2] and will shutdown operation whenever safe limits are exceeded. 8 Table 2. Pack Specifications 3.2 Battery Make Headway Headquarters H-38120S Battery cells per pack 30 Number of packs 4 Motor output voltage 96 V Peripheral output voltage 12 V Microcontroller PIC24HJ64GP502 Communication Protocol RS 485 Maximum mass 10 kg Maximum width 20 inches Maximum length 22 inches Maximum height 8 inches Lithium-Ion Battery Specifications The Headway 38120S Li-ion batteries were selected by the Solar Jackets officials. The specifications can be seen in Table 3 [2]. 9 Table 3. Headway 38120S(10AH) No. 1 2 3 4 5 6 7 8 9 10 11 12 13 3.3 Item Normal capacity Normal Voltage Inter Impedance Maximum Charge Current Maximum Charge Voltage Maximum Continuous Discharge Current Maximum Peak Pulse Discharge Current Discharge Stop Voltage Dimension Diameter Height Weight Work temperature Charge Discharge Store temperature In one month In six month Cycle Life 1500 cycles 1C 100% DOD Specification 10000mAh 3.2V <6mΩ 2C(20A) 3.65±0.05V 10C(100A) 15C(150A) 2.0V 38±1mm 122 ±1mm (132±1mm) Approx. 330g 0~45°C -20~60°C -20~45°C -20~35°C 2000 cycles 1C 80% DOD Microcontroller Specifications PIC microcontrollers will be used to monitor the batteries and relay such information to the rest of the vehicle. Each individual microcontroller will have a unique hardware identity used to communicate among the RS-485 bus, programmed with jumper on the primary board. Each monitoring PIC microcontroller operates in slave mode and waits for a ping before sending its response. Table 4 shows the specs on the PIC microcontroller chosen [3]. 10 Table 4. Microcontroller Specifications 3.4 Microcontroller PIC24HJ64GP502 Architecture 16-bit CPU Speed (MIPS) 16 Memory Type Flash Program Memory (KB) 16 RAM Bytes 1,536 Temp Range (C) -40 to 125 Operating Voltage 1.8 to 3.6 I/O Pins 24 Internal Oscillator 8 MHz, 32 kHz Timers 3 x 16-bit Current Sensor IC Specifications An ACS758KCB-150B-PSS-T integrated-circuit will be used as the current sensor. We chose this current sensor because we inherited some of them from the previous BMS group. It is bidirectional meaning it can read current from either direction. A bidirectional current sensor is necessary because we want to be able to measure charge current and discharge current. The current sensor outputs half the input voltage plus or minus 13.3 mV per ampere. The specifications for the current sensor IC are shown in Table 5 [4]. Table 5. Current sensor specifications Part Number ACS758KCB-150B-PSS-T Primarily Sampled Current(A) 150 Sensitivity Sens(mV/A) 13.3 Current Directionality Bidirectional 11 3.5 LTC Specifications The LTC IC will interface between the PIC microcontroller and the battery cells. It will be used to measure/balancing voltages and measuring current. The specifications for the LTC IC are shown in Table 6 [5]. Table 6. LTC Specifications Total Supply Voltage (V+ to V–) Input Voltage (Relative to V–) C1 C12 Cn Sn CSBO, SCKO, SDOI All other pins Voltage Between Inputs Cn to Cn-1 Sn to Cn-1 C12 to C8 C8 to C4 C4 to V– Operating Temperature Range Specified Temperature Range Junction Temperature Storage Temperature Range 3.6 60V –0.3V to 9V V+ – 0.6V to V+ + 0.3V –0.3V to min (9 • n, 60V) –0.3V to min (9 • n, 60V) V+ – 0.6V to V+ + 0.3V –0.3V to 7V –0.3V to 9V –0.3V to 9V –0.3V to 25V –0.3V to 25V –0.3V to 25V –40°C to 85°C –40°C to 85°C 150°C –65°C to 150°C Temperature Sensor IC Specifications An LM35D integrated-circuit will be used as the temperature sensor. We favored it because its output voltage is linearly proportional to the temperature in Celsius. The LM35 thus has an advantage over linear temperature sensors calibrated in Kelvin, as the user is not required to subtract a large constant voltage from its output to obtain convenient Centigrade scaling. The 12 LM35 does not require any external calibration or trimming to provide typical accuracies of ±1⁄4°C at room temperature and ±3⁄4°C over a full −55 to +150 °C temperature range. Its low output impedance, linear output, and precise inherent calibration make interfacing to readout or control circuitry easy. It is used with a single power supply in this BMS design. As it draws only 60 μA from its supply, it has very low self-heating which is extremely important in proper temperature sensing. Table 7 shows the specifications for the LM35DT temperature sensor [6]. Table 7. LM35DT Specifications Manufacturer Range Supply voltage accuracy National Semiconductor -55°C ~ 150°C 4 V ~ 30 V ±0.6°C 3.7 Electromechanical Relay Specifications The Kilovac EV200AAANA is our electromechanical relay of choice. It is a reliable and safe option for disconnecting and reconnecting the battery packs. The specifications for the EV200 electromechanical relay are shown in Table 8 [7]. Table 7. EV200 Specifications Hold Power 1.7W Contacts Rating 500+ Amps Rated Operating Voltage 12-900 VDC Max Inrush Current 3.8A 13 3.8 DC Fuse Specifications The Copper Bussman FRN-R-70 is our fuse of choice due to its included heavy duty fuse holder and large ampere rating at high voltages. This DC fuse’s specifications are shown in Table 9 [8]. Table 9. FRN-R-70 Fuse Specifications Max AC Voltage 250 Max DC Voltage 125 Amperage Rating 70 Fuse Class Class RK5 Time Delay Yes Fuse Length 5.88” Fuse Width 1.06” 4. Design Approach and Details 4.1 Design Details The BMS was implemented using a PCB per battery pack. On the PCB, the LTCs, microcontroller, RS-485 chip, and low current relay were the main components. There are three LTC ICs used to measure and monitor the 30 Li-ion cells. Connections to these cells, the temperature sensors, current sensor, electromechanical relay and all external input points is accomplished via a 40-pin header interface. A protective fly-back diode circuit was implemented to protect the microcontroller from voltage spikes or transients that could result from the main power bus. The low current relay drives a high current, high voltage relay to connect or disconnect the pack from the main bus. A systems overview can be seen in Figure 1. A RS485 IC 14 was implemented to allow communication with the rest of the car’s systems. Prior to the completion of the design, there were uncertainties surrounding the use of MOSFET; therefore, auxiliary output pins were added to allow for future implementation. MOSFETs can not be used for this design, hence these pins can be used for any other functions. 4.2 Microcontroller The microcontroller used on the PCB is a PIC24HJ64GP502. This microcontroller was selected to match the microcontroller already in use by the rest of the car’s systems. For testing convenience, the microcontroller’s slot on the PCB is detachable. This also allows the microcontroller to be programmed away from the car. A sensor connection diagram is shown in Appendix C. Figure 1. Hardware systems overview of the BMS. 15 4.3 LTC Battery Monitoring IC The voltage monitoring component of the BMS was designed to utilized three LTC6802 Multi-cell Battery Stack Monitors. Each LTC chip monitors the voltages of 10 cells in the battery pack. The chips were designed to be daisy-chained with the capability to measure cell voltages up to 1000 V. The LTC chips communicate with the microcontroller using a standard serial peripheral interface (SPI). Although the design is complete and incorporated into the PCB, the SPI programming needs to be completed. 4.4 Temperature Sensors Implementation The temperature sensor was implemented using an LM35 precision temperature IC. The LM35 was chosen because its output is linearly proportional to the temperature in degree Celsius and has a sensitivity of up to 0.1 °C. The LM35 outputs a voltage level corresponding to 10mV/°C. The sensor is shown in Figure 2 and has a turn on voltage range of 3V to 5V DC. Figure 2. LM35 IC temperature sensor. 4.5 Current Sensor Implementation Current sensing was implemented using the ACS758 IC from Allegro. The IC is a bidirectional current sensor that can measure up to 150A with linear output. When a turn on 16 voltage of 5V DC is applied to the ACS758, it outputs 13.3mV per 1A change in the line current. The current sensor output, VIOUT, has a default output voltage equal to half the input voltage, VCC. When current is applied to the IC, the VIOUT either increases in the positive direction indicating charge voltage or decreases in the case of discharge voltage. This feature was key in the design because the Li-ion cells have a different maximum charge current (20A) and a different maximum discharge current (100A). The schematic of the current sensor is shown in Figure 3. Figure 3. Current sensor IC schematic. 4.6 Printed Circuit Board Design The PCB was designed using DesignSpark to allow quick replacement of any component. The microcontroller, the external oscillator, and the RS485 IC were placed on sockets to allow easy programming and replacement. All unused inputs to the microcontroller were connected to auxiliary pins on a header that could be reprogrammed for additional BMS features. All sensor inputs are designed to be easily connected to one of the pins on the 40 pin header. Due to the high density of pins connecting to each LTC, a thin trace profile was selected. The PCB layout and 3D model are shown in Appendix A. 17 5. Schedule, Tasks, and Milestones The Battery Management Systems’ schedule for this initiative required more days than previously realized. Upon receipt of the Li-ion batteries and other essential parts of the design, assembly of the initial prototype and programming of the PIC24 began. Issues involving communication between the LTC and PIC24 presented a substantial amount of time debugging code. The technical faults with the PCB milling machine hindered production of the final PCB. However, testing was able to continue with the prototype. The programming tasks lasted until the final week, while the circuitry with the battery pack and other components only took a few weeks to setup. Circuit assembly was delayed three weeks by lack of funding from the Solar Jackets in purchasing the electromechanical relay. Table 10 shows a summary schedule of the BMS project. A more detailed project schedule can be found in Appendix B. Table 10. Summary of the BMS Project Task Name Purchase Parts Test Parts and Batteries Design PCB Program PIC24 PIC Debugged Final Presentation Final Demonstration 6. Duration Start End 68 days 48 days 20 days 83 days 83 days 1 days 1 days 9/29/2011 10/24/2011 11/14/2011 9/19/2011 9/19/2011 12/6/2011 12/11/2011 11/6/2011 12/10/2011 12/2/2011 12/10/2011 12/10/2011 12/6/2011 12/11/2011 Results and Acceptance Testing The final demonstration and delivery were at the end of the Fall 2011 semester, and included a working system that monitored temperature and current; however, the voltage 18 monitoring aspect of the system was not functional. The outputs of the sensors were monitored with the PIC24 and displayed on a LCD. If one of these sensor outputs were in the red zone as previously defined, the relay would disconnect the battery pack from the 96V bus. Testing of the BMS can be seen in Figure 4. To indicate that the relay was closed, a light bulb was connected in series with the system. A lit light bulb indicated a closed and active circuit. Figure 4. BMS testing of temperature sensors and current sensor. 19 The temperature sensors were tested using a heat gun to raise their temperature and the temperature for each sensor was displayed on the LCD. Not all temperature sensor outputs were displayed on the LCD at once because the screen was not large enough. Instead a pushbutton was implemented to cycle through each sensor output, including the output from the current sensor. Temperature thresholds were defined for the red zone, yellow zone, and green zone. These zones were indicated by three LEDs on the breadboard. One LED would be illuminated at a time which would depend on the temperature zone of the temperature sensor that read the highest temperature. If any of the sensors reached the red zone, the relay would disconnect the battery pack from the 96V bus. When the temperature drops down to the yellow zone, the relay would reconnect the battery pack. The current sensor function worked in a slightly different way than the temperature sensor function. When the red zone was reached with the current sensor, the relay would disconnect the battery pack from the 96V bus and not automatically reconnect. Reconnecting the battery pack to the 96V bus would have to be done manually. A resistor load bank was used to alter the amount of current through the sensor and to ensure that the current sensor worked for various currents. This is shown in Figure 5. 20 Figure 5. BMS testing of current sensor. 7. Marketing and Cost Analysis 7.1 Marketing Analysis While other battery management systems are commercially available, the constraints and the power efficiency used in our system are not currently available on the market [1]. Interpretation of this design will succeed previous iterations and will incorporate features that will enhance the functionality of the device. The nature of the vehicle requires that each management system be able to operate with a current of 60A. However, most systems can handle only a maximum of 15 cells per pack. This constraint would require two BMS boards to be used per pack. An implementation like this would reference all the control signals against a 48 V ground for the upper half of the battery packs [1]. This result would not meet the ASC standards. The systems that meet the required 96 V for the motor will fail to have the required current 21 capacity [8]. Most available commercial systems do not have the capability to manage battery packs in a parallel system. These systems manage the cells during charging in an attempt to equalize the charges on each cell, which can result in the packs having different voltages from one another [1]. Even if systems are used in parallel, they are not cost friendly to consumers in the market. 7.2 Cost Analysis The BMS for the Solar Jackets’ solar vehicle will cost an estimated $599.89 for purchasing equipment. Table 11 gives a full listing of the parts used to make the BMS. Table 11. Equipment Cost Product Description Quantity Unit Price Amount Purchased Price BMS IC chip LTC6802 PIC24F16KA102 microcontroller 3 $13.86 $41.58 $0.00 1 $2.70 $2.70 $0.00 External Oscillator 1 $2.13 $2.13 $0.00 Fuse /Fuse Holder 1 $34.00 $34.00 $0.00 Current sensor 1 $7.00 $7.00 $0.00 RS 485 transceiver 1 $6.30 $6.30 $0.00 Copper Bus Bar 1 $7.94 $7.94 $0.00 Copper Set Screw Lugs 8 $1.83 $14.64 $0.00 Gate driver 1 $1.36 $1.36 $0.00 DC/DC converter 1 $4.22 $4.22 $0.00 Voltage differential amplifier 1 $2.45 $2.45 $0.00 Connector 1 $4.58 $4.58 $0.00 PCB, low-current board 1 $350 $350.00 $0.00 PCB, high current board 1 $100 $100.00 $0.00 47 $0.01 $0.47 $0.00 9 $0.01 $0.09 $0.00 Capacitors 11 $0.03 $0.33 $0.00 Op-Amps 1 $0.50 $0.50 $0.00 Pin headers 4 $0.20 $0.80 $0.00 20 $0.94 $18.80 $0.00 Resistors Diodes LM35DT Total Cost $599.89 22 The original budget for the project was $400, but late additions such as the fuse and fuse holder were added to the design which increased our initial cost. Also, some of the parts for our design were obtained for free through the Senior Design lab. 8. Project Conclusions, Observations, and Future Work The proposed goal was to have a fully operable and functional BMS by December 9th, 2011. The BMS system although not fully assembled or operational, is able to provide 75% of the proposed functions. It is able to electrically isolate the lithium ion cells from the 96 V bus to provide the active level of protection as required by the American Solar Challenge regulations. The BMS actively monitors the ambient temperature of the battery module and provides control dependent on the predetermined thresholds. Current draw through the system is also monitored, if and when the current draw exceeds the predetermined threshold, the system disconnects the lithium ion cells and requires a physical reset when the conditions are safe again. The voltage monitoring feature was not successfully implemented; this was due to difficulty in interfacing the LTC6802 with the PIC24 via SPI. It is recommended that the Solar Jackets have a new BMS team to complete the mounting of the circuit components on the completed PCB design. Although the LTC is currently not functioning, it has been incorporated on the PCB and is ready for programming in the future. Someone with SPI programming experience will be best suited for the job. Other recommended future work include fabrication, RS-485 programming, and installation of the electromechanical relay and DC fuse in the battery box. 23 9. References [1] J. Durham, N. Murdaugh, D. Trawick, “Battery Monitoring System for a Solar Powered Racer”, May, 2011. [Online]. Available: http://www.ece.gatech.edu/academic/courses/ece4007/11spring/ECE4007L01/ws4/deliverables.h tml [Accessed Sep. 18, 2011]. [2] All Battery, “Detailed description of LiFePO4 38120S battery,” stores.headwayheadquarters.com, 2011. [Online]. Available: http://stores.headway-headquarters.com/-strse1/Headway,-batteries,-EV,-solar/Detail.bok. [Accessed Feb. 4th, 2011]. [3] Micorchip, “PIC24HJ64GP502,” 2011. [Online]. Available: http://www.microchip.com/wwwproducts/Devices.aspx?dDocName=en539800 [Accessed Sept. 15, 2011]. [4] Allegro, “ACS758KCB-150B-PSS-T,” 2011. [Online]. Available: http://www.allegromicro.com/en/Products/Part_Numbers/0758/0758.pdf [Accessed Sept. 15, 2011]. [5] Linear Technology, “Multicell Battery Stack Monitor” LTC 68002 datasheet, 2007. [6] National Semiconductor, “Precision Centigrade Temperature Sensors” LM35 datasheet, 2000. [7] “2012 American Solar Challenge – General Regulations,” September. 2010. [Online]. Available: http://americansolarchallenge.org/tech/tech-center-2012/regulations/. [Accessed Sept. 5th, 2011]. [8] Zero Emissions Vehicles Australia, “TS90 Fail Safe Battery Management System” zeva.com.au, 2011. [Online]. Available: http://zeva.com.au/store/datasheets/TS90_BMS.pdf [Accessed Feb 14, 2011]. 24 Appendix A PCB models 25 Appendix B 26 Appendix C 27