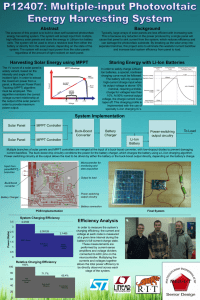

Microcontroller Detail View

advertisement

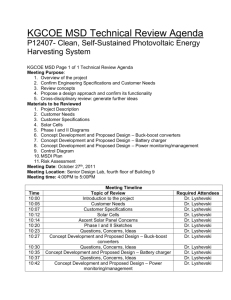

KGCOE MSD TECHNICAL REVIEW P12407- Clean, Self-Sustained Photovoltaic Energy Harvesting System Josh Stephenson Mike Grolling Thomas Praderio PROJECT OBJECTIVE Utilize and properly manage energy from multiple sources to drive a load or charge a battery with high efficiency for portable applications CUSTOMER REQUIREMENTS • Design will include safety and component failure • Ability to manage inputs from multiple power sources • Investigate and benchmark technologies, components and modules • System will integrate power management and load distribution. • Establish highly efficient energy conversion parameters and design • System must manage energy source variability • Provide data acquisition points for future team's display design • System must be portable • System must include instructions for set-up and use PROJECT SPECIFICATIONS • Ability to generate ~5W of power • Voltage stabilization for battery charging (~15V ±0.05V) • Output voltage of 10V • Full solar delivery, provide a max output current of 0.5A • Energy Storage is ~5 A-h • Multiple solar panels • Benchmark given component's specifications • Calculate, design, measure each function • List DAQ points • Efficiencies for each function PHASE 1: PRELIMINARY DESIGN • Incorporates single energy source (INITIAL) FINAL DESIGN FINAL DESIGN MAXIMUM POWER POINT TRACKING (MPPT) SPV1020 MPPT IC STANDARD BBC CONFIGURATION STANDARD BATTERY CHARGER CONFIGURATION STANDARD POWER MANAGEMENT CONFIGURATION LITHIUM-ION BATTERIES RISK MANAGEMENT ID Risk Item Effect Cause Likelihood Severity Importance Poor project planning 2 5 10 Unreliable vendor 2 3 6 Poor choice of technology Poor pairing of solar cells with DC/DC Conv. 1 3 3 2 5 9 Buck Boost converter reverse currents will Poor isolation of incapable of blocking reverse drastically lower energy sources bias conditions efficiency and may compromise operation or damage solar cells Internal electronics produce Electronics overheat; Poor choice of too much heat inefficient electronics or casing; unrealistic goals Internal electronics do not Redesign/ project Low margins of safety/ produce acceptable signals goals not met high-risk technology 1 7 8 2 2 4 Choose low power electronics 2 3 6 Work with electronics that are acceptable 1 Team runs out of time 2 Parts arrive late 3 Prototype draws too much Poor battery life power Photovoltaic produce Very low efficiency insufficient/minimum voltage and power generation 4 5 6 7 Project doesn't get finished Schedule is delayed Action to Minimize Risk Good plan Constant communication with Vendor Choose low power electronics Examine energy curves for different solar cells Place diode across each solar cell to dissipate reverse emf RISK MANAGEMENT ID Risk Item 8 Requirements change during the project Teammates do not do assigned work 9 10 Teammates do not arrive prepared 11 Inability to contact the customer or guide 12 Getting wrong information from customer 13 Arguments between teammates 14 Microcontroller not fast enough to manage power Effect Cause Project will not be able Redesign required to change in time Team will need to do Laziness/ not enough the work for the time teammate Team will be delayed Laziness/ not enough and work will be time postponed May miss vital Poor Communication information and requirements Lead to solving an issue Poor Communication that doesn't exist Will hurt team morale Poor Communication and cause conflict between members Power management Poor part selection will be ineffective Likelihood Severity Importance 1 5 5 1 3 6 2 2 4 2 2 4 2 3 6 2 2 4 2 2 5 15 Fractional gain op-amps use too Battery life will much power decrease Bad amplifier design 2 6 5 16 Microcontroller code does execute properly Poor coding 4 7 8 Power management will be ineffective Action to Minimize Risk Verify deliverables with customer Ask for help with needed Assign tasks that have a high likelihood of being completed Keep constant info flow with the customer and guide Set up meeting s and communicate often Have group focused and group leader aware Microcontroller selected with appropriate speed Select appropriately high-ohm feedback resistors and lowleakage op-amps Code will be thoroughly tested and debugged CHALLENGES • Winter in Rochester– Forced to rely on artificial light • Batteries used during experimentation were 12 years old and • did not hold charge very long • Flexible PV panels did not supply enough power • Buck/Boost did not maintain required voltage while charging • Learning curve on PCB layout software • Scheduling with PCB ordering during the Chinese New Year • Working with BGA footprint CHALLENGES CONTINUED • Express PCB or Eagle CAD? • Proprietary vs. open standards • Licensing and version issues • Finding vendor footprints • Finding LGA footprints for the buck-boost • Board house selection • Price, capabilities, scheduling (Chinese new year) • Final decisions: • Eagle 5.7 for schematic and board layout • MyRo PCB for fabrication MICROCONTROLLER MSP430 DETAIL VIEW FRACTIONAL GAIN AMPLIFIER FOR VOLTAGE SENSING 𝐴1 = − 𝑅𝑓𝑏 9.1 𝑀Ω =− = −1 𝑅𝑖𝑛 9.1 𝑀Ω 𝑅𝑓𝑏 750 𝑘Ω 𝐴2 = − =− = −0.0824 𝑉/𝑉 𝑅𝑖𝑛 9.1 𝑀Ω 𝐴𝑡𝑜𝑡𝑎𝑙 = 𝐴1 ∗ 𝐴2 = −1 ∗ −0.0824 = 0.0824 𝑉/𝑉 Both op amps are powered with a 3V button-cell CR2032 CURRENT SHUNT MONITOR INA193 PCB LAYOUT RESULTS Power at Each Stage 3.5 3.28 Power (Watts) 3 2.35 2.5 2.15 2 1.5 1 0.5 0 MPPT Output Buck-Boost Output Battery Charging Power RESULTS CONTINUED Power at Each Stage Vs. Time 6 5 Power (Watts) 4 MPPT output 3 BB output Battery 2 1 0 0 5 10 15 Time (Minutes) 20 25 30 FUTURE CONSIDERATIONS • Troubleshoot analysis on PCB • Added display for real-time data capture • New batteries QUESTIONS?