Figure 7

advertisement

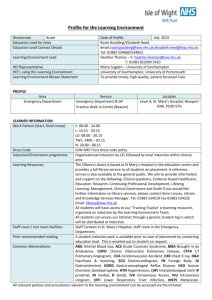

Figure 7.2 outlines how informational, standard & critical IOW limits/targets might interact with different levels of communications (notifications, alerts & alarms) for controlling elevating temperatures on furnace tubes. Several high temperature damage mechanisms are possible in furnace tubes. In general, long term creep life and corrosion from temperature dependant damage mechanisms are the primary concerns. However, when operating at temperatures significantly higher than the design, failure can occur rapidly due to overpressure from the significant loss in material strength, i.e. short-term overheat and stress rupture. For example, furnace tubes that normally operate at 900 °F (482 °C) and have an API 530 design temperature of 950 °F (510 °C) would have an increasingly shortened service life if operated beyond this design temperature. Using the principals from Figure 7.2, a more specific example of how IOWs may be employed to establish furnace tube temperature limits to avoid premature rupture or unplanned replacement of the tubes is presented below; Informational IOWs – Inspection, Corrosion and Process Engineering personnel (SME’s) would be responsible for tracking and trending furnace tube temperatures operating below the design temperature, <950 °F (510 °C). Limits or target operating ranges may be set and/or notifications sent to inform the SME if the temperatures exceed a normal operating range of 900 °F (482 °C). Standard IOW Limit - The initial standard limit for furnace tubes is frequently set at the API 530 design metal temperature (100,000 hour design life). This standard limit may be adjusted based on an engineering analysis from detailed knowledge of the time dependent damage mechanisms (creep and corrosion), and the estimated remaining life. For this example the standard limit is set at 950 °F (510 °C). An alert (or an alarm) is used to notify SME’s and Operations when this temperature is exceeded. Operators would be directed to adjust furnace controls to get the tube temperature back to below 950 °F (510 °C) within a preset amount of time. Critical IOW Limit – The critical limit set at a temperature prior to the point when failure is imminent due to loss of strength with some amount of safety factor. For this example, a critical temperature limit of 1025 °F (552 °C) was selected. An alarm point is set for the board operator that alarms when this temperature is exceeded and the operator is directed to take immediate actions to regain control or even shut down the furnace to avoid failure. This example shows how there may be more than one IOW limit for the same process parameter (in this case furnace tube temperature), for tracking/trending or to gain control prior to reaching a critical IOW limit. In addition, there may be more than one predefined response, depending upon the degree of exceedance of the process parameter limit. In this example, all three levels of IOWs were set to show a progression of failure risk and commensurate communication and response activity initiating with the SME’s, then Operations and ultimately the Board Operator to correct the increasing temperature. Imminent Failure IOW Potential Issue Example Response to Exceedances Typical Range for Critical IOW’s, Based on Short Term Failure Short term overheating and stress rupture due to loss of tensile strength Alarm is set for the Board Operator whom responds immediately with predetermined actions to gain control of the operation or shut down the furnace Typical Range for Standard IOW’s, Based on Remaining Life Assessment Temperature range for operation where some damage mechanisms may begin to shorten the equipment life, such as creep, sulfidation, oxidation, carburization, etc. Alarms and/or Alerts are set for Operations which may or may not have a predetermined action and timing to implement. Otherwise the situation may be reviewed with SME’s and a plan developed to bring the operation back into control and/or adjust the inspection plan and conduct remaining life calculations as appropriate Typical Range for Long term reliability of equipment out to the design life. Typically the SME would be responsible for tracking and trending this information and adjusting the inspection and test plans, as necessary The SME (e.g. Corrosion / Materials Eng.) is typically responsible for tracking the furnace tube temperatures and recommending inspection and testing activities such as routine IR examinations, tube strapping, UT measurements, etc. Informational IOW’s Based on Design Life Figure 7.2 Example of how IOW’s might be set for furnace tube temperatures