OS,DT - Spidi - Indian Institute of Management Bangalore

advertisement

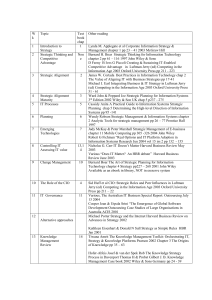

Indian Institute of Management Bangalore Operations Strategy 2010-11: PGP II, Term VI Faculty: Devanath Tirupati Office: D Block, II Floor (D 205) Phone: X3103, e-mail: devanath@iimb.ernet.in Course Objective: The primary objective of the course is to develop awareness of the strategic role of operations in an organization. Besides providing exposure to elements of operations strategy, the intent is to bring out the linkages with other functional areas and the corporate strategy. The role of strategic fit, focus and flexibility in aligning the organization’s resources and prioritizing projects / activities will be discussed. We will also explore issues related to coordination within the firm and in the supply chain. Pedagogy: The course is predominantly case based, supplemented by lectures as appropriate. Class discussions will involve presentations by participants (in groups). In addition, each group will work on a project / term paper and submit a report and make a presentation at the end of the term. Much of the learning happens both during your preparation and discussion in class involving mutual exchange of ideas. Hence, attendance and participation in all sessions is expected. In case you are unable to attend class, an advance intimation by e-mail will be appreciated. Group work: Participants will work in groups of five or six for case analyses and project reports and presentations. In addition to project report / term paper, each group is required to submit three case reports and make one case presentation (on a case different from the written reports). The case reports are due on the day the case is scheduled for discussion, prior to the start of class. The case reports should be about five pages in length, plus any supporting exhibits and analyses. (The report should flow smoothly, with lead questions answered implicitly and not have explicit answers to the questions. The lead questions should be considered as starting point and you should feel free to consider other relevant issues.) Guidelines for project topics will be handed out later in the term. Course Grade: The course grade will be based on the following components: Case reports (3) and presentation (1): Project / Term Paper (Report and presentation): End term examination: 35% 30% 35% Course Schedule and Session Plan Module / Topic Session No. Introduction: Concept 1 of Operations Strategy 2 Date Case 14/12/10 American Connector Company (A) (Revisited) 1,2, 3, 4 & 5 Opthalmic Consultants of Boston and Dr. Bradford J. Shingleton 15/12/10 Reading(s) Elements of OS: Vertical Integration & 3 & 4 Sourcing Strategy 20/12/10 21/12/10 Elements of OS: Capacity & Facilities 27/12/10 28/12/10 Applichem (A) (Revisited) 3/1/11 4/1/11 Eli Lilly and Company: Manufacturing 8 Process Technology Strategy Sensormatics Electronics Corporation 6 Indalex Ltd. 5&6 7&8 7, 18 Call Center Design for Lion Financial Services** Developing capabilities: 9 & 10 Innovation & Product Development 11 & 12 10/1/11 11/1/11 BMW Project 7 Series 9 17/1/11 18/1/11 Nucleon Inc.** 10 Developing capabilities: 13 Quality, Productvity, Innovation & Flexibility 14 31/1/11 Lucas-TVS Limited: A Journey towards Manufacturing Excellence 11, 12, 13** 1/2/11 Chapparal Steel: Rapid product and Process development 15 2/2/11 Cyclone Grinder, Part I & II Building competitive 16 advantage through operations 17 7/2/11 National Bicycle Industries 14 8/2/11 Benetton (A) 15 Project Presentations 14/2/11 15/2/11 18 & 19 Course Wrap-up & Emerging Scenarios* 20 Reading List: 17/2/11 16, 17 1. W. Skinner, “Manufacturing: Missing Link in Corporate Strategy,” HBR, May-June 1969. 2. “Operations Strategy: Origins and New Directions,” Chapter 2, Operations, Strategy and Technology: Pursuing the Competitive Edge, R. H. Hayes, G. Pisano, D. Upton, and S. C. Wheelwright, Wiley, 2005. 3. R. H. Hayes and S. C. Wheelwright, “Link Manufacturing Process and Product Life Cycles,” HBR, Jan. – Feb. 1979. 4. W. Skinner, “The Focused Factory,” HBR, May – June, 1974. 5. S. C. Wheelwright and R. H. Hayes, “Competing Through Manufacturing,” HBR, Jan. – Feb. 1985. 6. “Vertical Integration and Sourcing,” Chapter 9, Restoring Our Competitive Edge: Competing Through Manufacturing, R. H. Hayes and S. C. Wheelwright, Wiley, 1984. 7. “Facilities Strategy,” Chapter 4, Restoring Our Competitive Edge: Competing Through Manufacturing, R. H. Hayes and S. C. Wheelwright, Wiley, 1984. 8. D. M. Upton, “Impacts of Flexibility on Strategic Choices,” CMR, 36, 2, 1994. 9. “Creating an Edge Through Superior Project Management,” Chapter 8, Operations, Strategy and Technology: Pursuing the Competitive Edge, R. H. Hayes, G. Pisano, D. Upton, and S. C. Wheelwright, Wiley, 2005. 10. “Creating an Edge Through New Process Development,” Chapter 7, Operations, Strategy and Technology: Pursuing the Competitive Edge, R. H. Hayes, G. Pisano, D. Upton, and S. C. Wheelwright, Wiley, 2005. 11. “Applying the Toyota Way in your Organization,” Chapters 21, 22, The Toyota Way, Liker, TataMcGraw Hill, 2004. 12. A. Bartmess and K. Cerny, “Building a Competitive Advantage Through a Global Network of Capabilities,” CMR, 35, 3, 1993. 13. J, H. Fleming, C. Coffman, and J. K. Harter, “Manage Your Human Sigma,” HBR, March – April, 1994. 14. “The Four Faces of Mass Customization,” HBR, 15. M. L. Fisher, “What is the Right Supply Chain for Your Product,” HBR, 16. C. M. Christensen, “The Past and Future of Competitive Advantage,” MIT SMR, 42, 2, 2001. 17. R. H. Hayes and G. Pisano, “Beyond World Class: The New Manufacturing Strategy,” HBR, 1994. 18. “Implementing Facilities Planning Process,” Chapter 5, Restoring Our Competitive Edge: Competing Through Manufacturing, R. H. Hayes and S. C. Wheelwright, Wiley, 1984. Other References: 1. R. H. Hayes, G. Pisano, D. Upton, and S. C. Wheelwright, Operations, Strategy and Technology: Pursuing the Competitive Edge, Wiley, 2005. 2. R. H. Hayes and S. C. Wheelwright, Restoring Our Competitive Edge: Competing Through Manufacturing, Wiley, 1984. 3. T. Hill and A. Hill, Manufacturing Operations Strategy: Text and Cases, Palgrave Macmillan, 2009. 4. D. A. Garvin, Operations Strategy: Text and Cases, Prentice-Hall, 1992. 5. C. A. Voss, Manufacturing Strategy: Process and Content, Chapman and Hall, 1992. Lead Questions for American Connector Company (ACC): 1. How serious is the threat of DJC to American Connector Company? 2. How big are the cost differences between DJC’s plant and ACC’s Sunnyvale plant? Consider both DJC’s performance in Kawasaki and its potential in the United States. 3. What accounts for these differences? How much of the differences is inherent in the way each of the companies compete? How much is due strictly to differences in the efficiency of operations? 4. What should ACC’s management at Sunnyvale plant do?