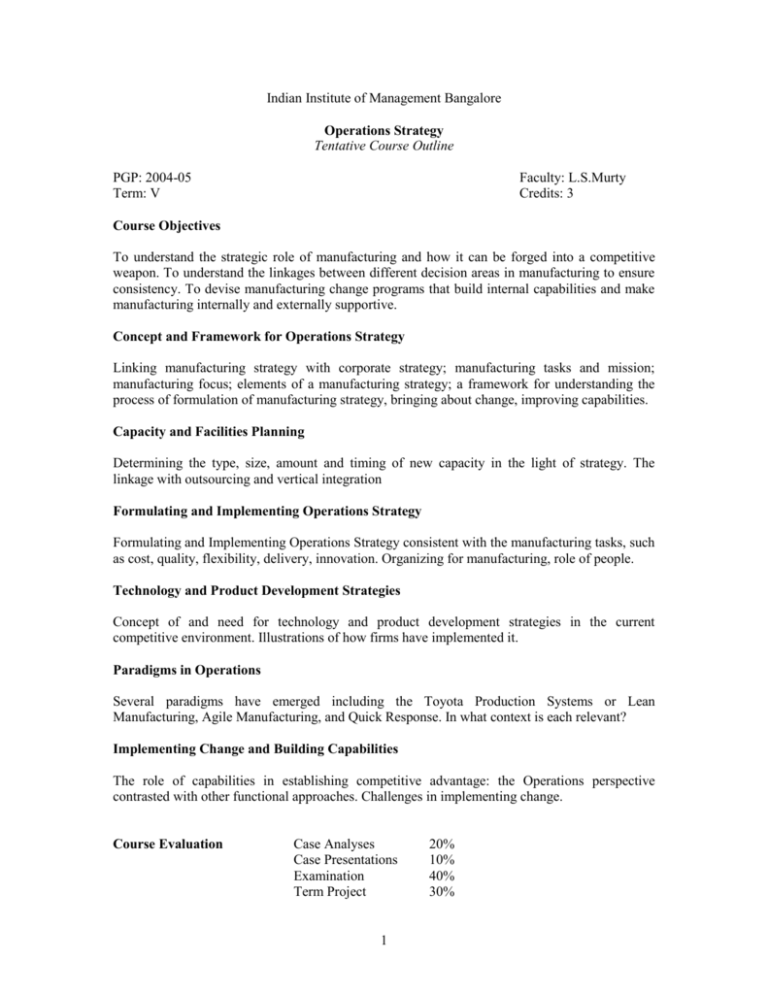

OS - Spidi - Indian Institute of Management Bangalore

advertisement

Indian Institute of Management Bangalore Operations Strategy Tentative Course Outline PGP: 2004-05 Term: V Faculty: L.S.Murty Credits: 3 Course Objectives To understand the strategic role of manufacturing and how it can be forged into a competitive weapon. To understand the linkages between different decision areas in manufacturing to ensure consistency. To devise manufacturing change programs that build internal capabilities and make manufacturing internally and externally supportive. Concept and Framework for Operations Strategy Linking manufacturing strategy with corporate strategy; manufacturing tasks and mission; manufacturing focus; elements of a manufacturing strategy; a framework for understanding the process of formulation of manufacturing strategy, bringing about change, improving capabilities. Capacity and Facilities Planning Determining the type, size, amount and timing of new capacity in the light of strategy. The linkage with outsourcing and vertical integration Formulating and Implementing Operations Strategy Formulating and Implementing Operations Strategy consistent with the manufacturing tasks, such as cost, quality, flexibility, delivery, innovation. Organizing for manufacturing, role of people. Technology and Product Development Strategies Concept of and need for technology and product development strategies in the current competitive environment. Illustrations of how firms have implemented it. Paradigms in Operations Several paradigms have emerged including the Toyota Production Systems or Lean Manufacturing, Agile Manufacturing, and Quick Response. In what context is each relevant? Implementing Change and Building Capabilities The role of capabilities in establishing competitive advantage: the Operations perspective contrasted with other functional approaches. Challenges in implementing change. Course Evaluation Case Analyses Case Presentations Examination Term Project 1 20% 10% 40% 30% MODULE 1. Introduction 1. Case: Blitz Company Read: Manufacturing – Missing Link in corporate strategy, HBR March April 1969 2. Read: 1. Focused Factory, HBR, May June 1974 2. Competing through Manufacturing, HBR Jan Feb 1985 3. Case: American Connector Company (A) MODULE 2. Capacity and Facilities Planning 4. Case: YETI Consultants Read: Chapters 3 and 4, Restoring our Competitive Edge 5. Case: Applichem (A) Read: Chapters 3 and 4, Restoring our Competitive Edge Look beyond the obvious in plant location 6. Case: Indalex Ltd. Read: Chapters 3 and 4, Restoring our Competitive Edge MODULE 3. Formulating and Implementing Operations Strategy 7. Case: Madras Refineries Limited 8. Case: Just in Time at Eicher Tractors People make it happen MODULE 4. Technology and Product Development Strategies 9. Case: Plus Development Corporation (A) Read: Rigid Disk Drives – An Industry Note 10. Case: Eli Lilly and Company: Drug Development Strategy (A) Read: Regaining the lead in manufacturing 11. Case: BMW: The 7-Series Project (A) Read: The Dynamic Aspect of Product Development Capabilities Another look at how Toyota integrates product development A second look at Japanese product development MODULE 5. Paradigms in Manufacturing 12. Read: 1. The Rise of Lean Production (from Machine that Changed the World) 2. Running the Factory (from Machine that Changed the World) 3. Total Framework of the Toyota Production System 4. Fast, global, and entrepreneurial supply chain management, Hong Kong style 13. Continuation of previous session 2 14. Case: Chaparral Steel Read: Agile Manufacturing: To be distributed What strategy can do for technology 15. Case: Sport Obermeyer Ltd. Read: Making supply meet demand in an uncertain world MODULE 6. Implementing Change and Building Capabilities 16. Case: Infosys Ltd. (to be distributed) Read: Growth Models for Top Indian Software Firms 17. Case: The Rogers Corporation 18. Case: Eli Lilly and Company – The Flexible Facility Decision 19. Case: Copeland Corporation: Evolution of a Manufacturing Strategy (A) 20. Course Review Read: Beyond World Class: The new manufacturing strategy What is Strategy? Reading Materials Kit The reading materials come to you in two kits – one is spiral bound and consists of the articles; and the other is a set of cases. This packaging is chosen for your reading convenience. References Dynamic Manufacturing by R.Hayes, S.Wheelwright and K.Clark Managing Quality by D.Garvin Manufacturing in the Corporate Strategy by Wickham Skinner Manufacturing Strategy – Process and Content by Christopher A Voss Manufacturing: the Formidable Competitive Weapon by Wickham Skinner Measures for Manufacturing Excellence by Robert Kaplan Restoring our Competitive Edge: Competing through Manufacturing by R.Hayes and S.Wheelwright The Uneasy Alliance: Managing the Productivity –Technology Dilemma by K.Clark, R.Hayes and C.Lorenz. 3