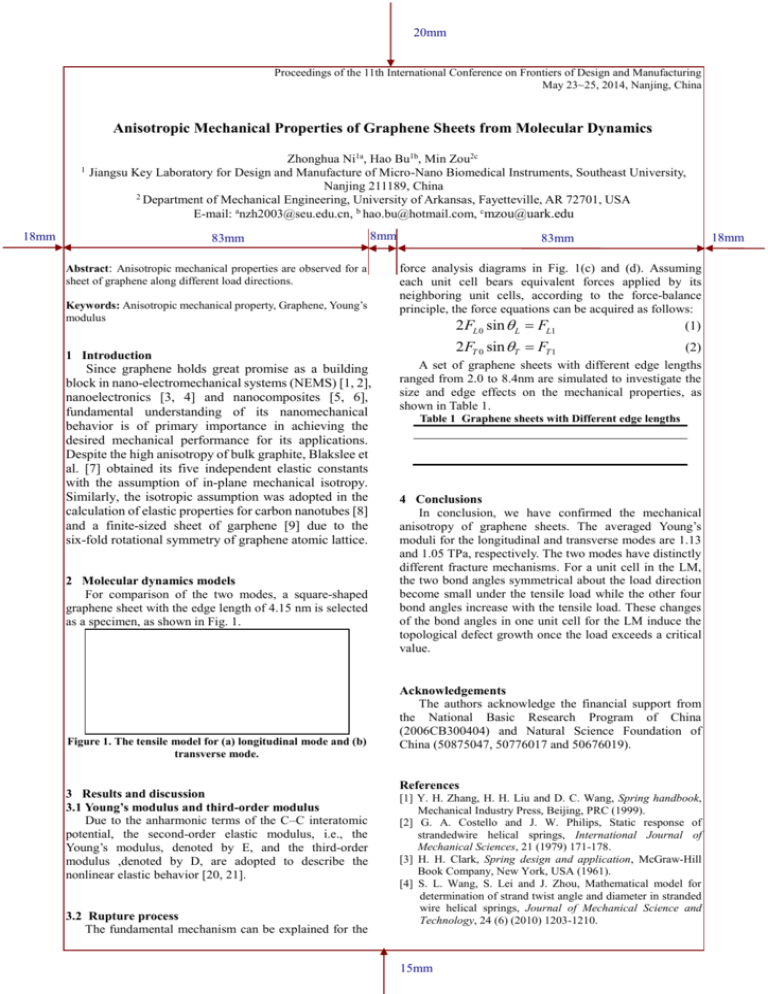

2 Molecular dynamics models

advertisement

20mm Proceedings of the 11th International Conference on Frontiers of Design and Manufacturing May 23~25, 2014, Nanjing, China Anisotropic Mechanical Properties of Graphene Sheets from Molecular Dynamics 1 Zhonghua Ni1a, Hao Bu1b, Min Zou2c Jiangsu Key Laboratory for Design and Manufacture of Micro-Nano Biomedical Instruments, Southeast University, Nanjing 211189, China 2 Department of Mechanical Engineering, University of Arkansas, Fayetteville, AR 72701, USA E-mail: anzh2003@seu.edu.cn, b hao.bu@hotmail.com, cmzou@uark.edu 18mm 83mm 8mm Abstract: Anisotropic mechanical properties are observed for a sheet of graphene along different load directions. Keywords: Anisotropic mechanical property, Graphene, Young’s modulus 1 Introduction Since graphene holds great promise as a building block in nano-electromechanical systems (NEMS) [1, 2], nanoelectronics [3, 4] and nanocomposites [5, 6], fundamental understanding of its nanomechanical behavior is of primary importance in achieving the desired mechanical performance for its applications. Despite the high anisotropy of bulk graphite, Blakslee et al. [7] obtained its five independent elastic constants with the assumption of in-plane mechanical isotropy. Similarly, the isotropic assumption was adopted in the calculation of elastic properties for carbon nanotubes [8] and a finite-sized sheet of garphene [9] due to the six-fold rotational symmetry of graphene atomic lattice. 2 Molecular dynamics models For comparison of the two modes, a square-shaped graphene sheet with the edge length of 4.15 nm is selected as a specimen, as shown in Fig. 1. Figure 1. The tensile model for (a) longitudinal mode and (b) transverse mode. 3 Results and discussion 3.1 Young’s modulus and third-order modulus Due to the anharmonic terms of the C–C interatomic potential, the second-order elastic modulus, i.e., the Young’s modulus, denoted by E, and the third-order modulus ,denoted by D, are adopted to describe the nonlinear elastic behavior [20, 21]. 3.2 Rupture process The fundamental mechanism can be explained for the 18mm 83mm force analysis diagrams in Fig. 1(c) and (d). Assuming each unit cell bears equivalent forces applied by its neighboring unit cells, according to the force-balance principle, the force equations can be acquired as follows: 2 FL 0 sin L FL1 (1) 2FT 0 sin T FT 1 (2) A set of graphene sheets with different edge lengths ranged from 2.0 to 8.4nm are simulated to investigate the size and edge effects on the mechanical properties, as shown in Table 1. Table 1 Graphene sheets with Different edge lengths 4 Conclusions In conclusion, we have confirmed the mechanical anisotropy of graphene sheets. The averaged Young’s moduli for the longitudinal and transverse modes are 1.13 and 1.05 TPa, respectively. The two modes have distinctly different fracture mechanisms. For a unit cell in the LM, the two bond angles symmetrical about the load direction become small under the tensile load while the other four bond angles increase with the tensile load. These changes of the bond angles in one unit cell for the LM induce the topological defect growth once the load exceeds a critical value. Acknowledgements The authors acknowledge the financial support from the National Basic Research Program of China (2006CB300404) and Natural Science Foundation of China (50875047, 50776017 and 50676019). References [1] Y. H. Zhang, H. H. Liu and D. C. Wang, Spring handbook, Mechanical Industry Press, Beijing, PRC (1999). [2] G. A. Costello and J. W. Philips, Static response of strandedwire helical springs, International Journal of Mechanical Sciences, 21 (1979) 171-178. [3] H. H. Clark, Spring design and application, McGraw-Hill Book Company, New York, USA (1961). [4] S. L. Wang, S. Lei and J. Zhou, Mathematical model for determination of strand twist angle and diameter in stranded wire helical springs, Journal of Mechanical Science and Technology, 24 (6) (2010) 1203-1210. 15mm