specification 05720 - Peachtree Protective Covers

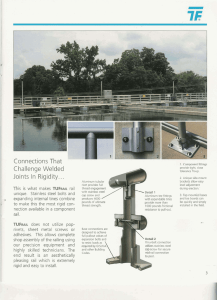

advertisement

SPECIFICATION 05720 PART 1 - GENERAL 1.01 Related Documents A. Drawings and general provisions of Contract, including General and Supplementary Conditions and Division-I Specification Sections, shall apply to work specified in this Section. 1.02 General Description of Work A. Work in this section shall include design, fabrication and installation of extruded aluminum handrails and railings. All work shall be in complete accordance with the drawings and this specification. 1.03 A. B. C. D. E. References Specifications for Aluminum Structures, Sixth Edition, 1994. ASCE 7-98, Minimum Design Loads for Buildings and Other Structures, December 1995. 1999 Standard Building Code American Architectural Manufacturers Association (AAMA) American Society for Testing and Materials (ASTM) 1.04 A. B. C. D. Related Sections Concrete Work Masonry Work Miscellaneous Metals Sealants Section 03300 Section 04200 Section 05500 Section 07900 1.05 Submittals A. Product Data: Submit manufacturer's product information, specifications and installation instructions for building components and accessories. B. Shop Drawings: Submit complete shop drawings including all necessary plan dimensions, elevations and details. General Contractor shall verify all dimensions and provide elevations at each post, and finish floor before releasing to manufacturer for fabrication. C. Certification: Submit design calculations signed by a Registered Professional Engineer, licensed in the project state. Design calculations shall state that the handrail system design complies with the requirements of ASCE 7-98, the stability criteria of applicable building code, and all other governing criteria. 1.06 Quality Assurance A. Handrail system shall be wholly produced by a recognized manufacturer experienced in the design and fabrication of extruded aluminum handrails. Components shall be assembled in shop to greatest extent possible to minimize field assembly. Handrail system, including material and workmanship, shall be warranted from defects for a period of one year from substantial completion of installation. PART 2 - PRODUCT 2.01 Manufacturers A. Contract documents are based on products manufactured by: Peachtree Protective Covers, Inc., 1477 Rosedale Drive, Hiram, GA 30141 770/439-2120, fax 770/439-2122 800/341-3325, ppc@peachtreecovers.com, http://www.peachtreecovers.com Poma Corporation 9040 Belvedere Rd. West Palm, FL 33411 561/790-5799 B. Other manufacturers will be considered for substitution only when the following conditions are met: Other manufacturers must qualify to bid not less than 10 days prior to bid closing date. Complete details, including sizes of all members and structural calculations showing loads applied in accordance with the specification must be submitted to the architect for review. 2.02 Structural Design Criteria A. Top Rail of Handrail System: Capable of withstanding the following loads applied as indicated: 1. 2. 3. B. C. Single concentrated load of 200 lbf applied in any direction at any point along the top. Uniform load of 50lb/ft applied in any direction at the top. These loads need not be assumed to act concurrently. Intermediate Rails (all those except the handrail): Capable of withstanding the following loads: 1. Uniform load of 50lb on an area not to exceed 1 ft2 including openings and space between rails. Thermal Movements: Expansion joints shall be included to accommodate temperature changes of 120 deg F to prevent buckling, opening of joints, overstressing of components, failure of connections, and other detrimental effects. 2.03 Materials A. B. C. D. Aluminum Members: All sections shall be extruded aluminum 6063 alloy, heat treated to T-6 temper. Fasteners: Fasteners shall be aluminum, 18-8 stainless steel or 300 series stainless steel. Protective Coating: Aluminum posts embedded in concrete shall be protected by clear acrylic. Grout and Anchoring Cement: Exterior Use Anchoring Cement. 7000 p.s.i. compressive strength after 28 days. Mix 5 parts anchoring cement with 1 part water for a pourable mixture. 2.04 Components All components to be sized to meet the structural design criteria indicated in section 2.02. A. Posts: Posts shall be 1/8" minimum radius-cornered tubular extrusion of size shown on drawings. B. Handrails: Handrails shall have a circular cross section with a diameter of 1 1/4" to 2", or a noncircular cross section with a perimeter dimension of at least 4", but not greater than 6 1/4" with the largest cross section dimension not exceeding 2 1/4". Edges shall have a minimum radius of 1/8". C. Pickets: Pickets shall be of size shown on drawings. Edges shall have a minimum radius of 1/8". 2.05 Fabrication A. Fabricate handrails and railings to comply with the requirements indicated for design, dimensions, member sizes and spacing, finish, details, and anchorage, but not less than those required to support structural loads. B. Assemble handrails and railings in the shop to the greatest extent possible to minimize field assembly. C. Fabricate handrails and railings for connecting members by welding. 2.06 Factory Finishing A. Finish shall be selected by architect. 1. For factory baked enamel finish, specify AAMA 603.8, standard or custom color 2. For flouropolymer (Kynar) finish, specify AAMA 605.2, two or three coat 3. For clear anodized finish, specify AA-M-10 C-22 A-31 (AAMA 607.1) 4. For bronze or black anodized finish, specify AA-M-10 C-22 A-44 (AAMA 606.1) 5. Powder coat finishes include Tiger Drylac, Dupont and Mortan PART 3 - EXECUTION 3.01 Preparation A. Erection shall be performed after all concrete, masonry, and roofing work in the vicinity is complete and cleaned. 3.02 Installation A. Post sleeves or anchor bolts (if required) shall be furnished by Peachtree Protective Covers, Inc. and installed by the General Contractor. A. Anchor post in concrete by forming or core-drilling holes 4" deep and at least 1" larger than the size of post being set. C. Aluminum posts embedded in concrete shall be protected by clear acrylic. D. Set handrails and railings accurately in location, alignment, and elevation and free of rack. E. Install handrails and railings in accordance with shop drawings and specification guidelines. System shall be plumb, square, level and anchored securely in correct alignment with adjacent work. 3.03 Cleaning A. All handrails and railing systems shall be cleaned promptly after installation with plain water containing a mild detergent or distillate. 3.04 Protection A. Materials shall be delivered to the job site by PPC transporters in good condition and properly protected against damage to finished surfaces. B. Material shall be stored in a location and in a manner to avoid damage. C. Extreme care shall be taken to protect materials during and after installation.