TUFRAIL, Aluminum Component Handrails

advertisement

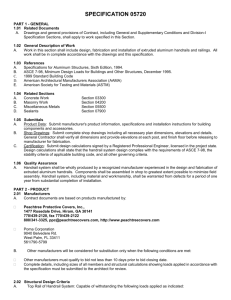

Connections l hat Challenge Welded Joints In Rigidity... , This is what makes TUFRAILrail unique. Stainless steel bolts and expanding internal tines combine to make this the most rigid connection available in a component cail. provide'tight, close tolerance fit-up. 4 / Aluminum tubular rivet ~rovidesfull threab engagement with stainless steel cap screw and produces 4000 pounds of ultimate thread strength. 2 . Unique sidemount brackets allow easy level adiustment during erection: 1 I Detail 1 Aluminum tee fittings with expandable tines provide more than 1000 pounds frictional resistance to pull-out. TUFRAILdoes not utilize pop- rivets, sheet metal screws or adhesives. This allows complete shop assembly of the railing using our precision equipment and highly skilled technicians. The end result is an aesthetically pleasing rail which is extremely rigid and easy to install. Base connections are designed to achieve full pullout values of expansion bolts and to resist loads as and other Building Codes. - \ Detail 2 Thru-bolt connection utilizes stainless steel cap screw for secure mid-rail connection to post. L 3. TOPmounted bases and toe boards can be quickly and simply installed in the field. TUFRAIL, Aluminum Component Handrails Designed to meet the load requirements of the International Building Code for Public-Access. Typical Guardrail Typical Guardrail with Offset Handrail at Stairs s a MAX, SAQNG i COMmM(S YAY BE T(IPYOUNTEDm rn YOUKlED TOCONCRETEOR MTSM-1.50 2 PC.Side-Mt. Bracket - ~ Y O U l T l D ~ #TBF-3.4 Base Flange -TBYOMT~CO(CRETE- #TBF-3.2 Base Flange -T(IPYOU(TTOCMlCRETECURB- See pages 12 thru 14 for typical details International Building Code Design Specifications for Public-Access 1. Guardrails and Handrails shall be the product of a company normally engaged in the manufacture of pipe railing. Railings shall be shop assembled in lengths not to exceed 24 feet for field erection. ' 2. The handrail shall be made of pipes joined together with component fittings. Samples of all components, bases, toeboard and pipe must be submitted for approval at the request of the engineer. Components that are pop-riveted or glued at the joints will not be acceptable. All components must be mechanically fastened with stainless steel hardware. Handrail and components shall be TUFRAIL, as manufactured by Thompson Fabricating, LLC, Birmingham, AL or an approved equal. 3. Railings shall be 151" Schedule 40 aluminum pipe alloy 6105-T5, ASTM-B429 or ASTM-6-221. Posts shall be 1IX" Schedule 80 aluminum pipe of the same alloy. Post spacing shall be a maximum of 6'-0". I I 1 I I 1; 4. Guardrails and Handrails shall be designed to withstand a 2001b concentrated load applied in any direction and at any point on the top rail. Guardrails and Handrails shall also be designed to withstand a uniform load of 50 Iblft applied horizontally to the top rail. Uniform loads are not to be applied simultaneously with the concentrated loads. 5. Pickets and intermediate railings shall be provided such that a 4-inch diameter g, CAD D lesign Draw~ngs tions are avai sphere cannot pass through any opening up to a height of 34 inches. From a height of 34 inches to 42 inches above the adjacent walking surface, a sphere 8 inches in diameter shall not pass. The triangular openings formed by the riser, tread and bottom rail at the open side of a stairway shall be of a maximum size such that a sphere of 6 inches in diameter cannot pass through the opening. system and provide physical tests from a laboratory to confirm compliance. 10. Concrete anchors shall be stainless steel type 303 or 304 wedge anchors and shall be furnished by the handrail manufacturer. The anchor design shall include the appropriate reduction factors for spacing and edge distances in accordance with the manufacturers published data. 6. Pickets and intermediate railings shall 11. Toeboard shall conform to OSHA be designed to withstand a horizontally standards. Toeboard shall be a miniapplied normal load of 501b on an area mum of 4 " high and shall be an not to exceed one square foot including extrusion that attaches to the posts with clamps that will allow for expansion and openings and spaces between rails. contraction between posts. Toeboards 7. The manufacturer shall submit calcu- shall be set !4" above the walking lations for approval at the request of the surface. Toeboards shall be provided on Engineer. Testing of base castings or handrails as required by OSHA andlor base extrusions by an independent lab as shown on drawings. Toeboards shall or manufacturer's lab (if manufacturer's be shipped in stock lengths for field lab meets the requirements of the installation. Aluminum Association) will be an acceptable substitute for calculations. 12. A self-closing gate shall guard openCalculations will be required for ings in the railing (OSHA 1910.23). approval of all other design aspects. Safety chains shall not be used unless specifically shown on the drawings. 8. Posts shall not interrupt the continuation of the top rail at any point along the 13. Finish shall be Aluminum Association railing, including corners and end M I 0-C22-A41 (215-RI). The pipe shall terminations (OSHA 1910.23). The top be plastic-wrapped. The plastic wrap is surface of the top railing shall be to be removed after erection. smooth and shall not be interrupted by projected fittings. 14. Aluminum surfaces in contact with concrete, grout or dissimilar metals 9. The mid-rail at a corner return shall shall be protected with a coat of bitumibe able to withstand a 2OOlb load with- nous paint, Mylar isolators or other out loosening. The manufacturer is to approved material. determine this dimension for their As witnessed by this PSI letter, TUFRAILSystems and components are load tested by independent laboratories t o validate our design calculations. TUFRAIL, Aluminum Component Handrails Designed to meet the load requirements of the International Building Code for Factory-Industrial Applications (Occupant Load Greater Than 50) " Typical Guardrail *. .- - -- -. -%- Typical Guardrail with Offset Handrail at stairs a N lE m MAY BE lwYOU(TEDOR mu STUB #TSM-1.50 2 PC. Side-Mt. Bracket -SIOEYOUNTTOM))(Q(EIE- #TBF-3.4 Base Flange -TOPUUmTTOCOWCI(EIE- #TBF-3.2 Base Flange -lWYOUlT~~CRElECUI- See pages 12 thru 14 for typical details - 1I p; International Building Code Design Specifications for Factory+'Industrial Applications (Occupant Load Greater Than 50) 1. ~uaidrailsand Handrails shall be the product of a company normally engaged in the manufacture of pipe railing. Railings shall be shop assembled in lengths not to exceed 24 feet for field erection. withstand a uniform load of 50 Iblft 9. The mid-rail at a corner return shall be applied horizontally to the top rail. able to withstand a 2001b load without Uniform loads are not to be applied loosening. The manufacturer is to detersimultaneously with the concentrated mine this dimension for their system and loads. provide physical tests from a laboratory to confirm compliance. 5. lntermediate railings shall be provided such that a 21-inch diameter sphere 10. Concrete anchors shall be stainless cannot pass through any opening. steel type 303 or 304 wedge anchors and shall be furnished by the handrail 6. lntermediate railings shall be designed manufacturer. The anchor design shall to withstand a horizontally applied include the appropriate reduction normal load of 501b on an area not factors for spacing and edge distances in to exceed one square foot including accordance with the manufacturers openings and spaces between rails. published data. 2. The handrail shall be made of pipes joined together with component fittings. Samples of all components, bases, toeboard and pipe must be submitted for approval at the request of the engineer. Components that are pop-riveted or glued at the joints will not be acceptable. All components must be mechanically fastened with stainless steel hardware. Handrail 7. The manufacturer shall submit calcuand components shall be TUFRAIL, lations for approval at the request of the as manufactured by Thompson Engineer. Testing of base castings or Fabricating, LLC, Birmingham, AL or base extrusions by an independent lab or manufacturer's lab (if manufacturer's an approved equal. lab meets the requirements of the 3. Railings shall be 1%"Schedule 40 alu- Aluminum Association) will be an minum pipe alloy 6105-~5,A S T M - B - ~acceptable ~~ substitute for calculations. or ASTM-B-~ZI. posts shall be 1%" Calculations will be required for Schedule 80 aluminum pipe of the same approval of all other design aspects. alloy, Post spacing shall be a maximum of 6'-0". 8. Posts shall not interrupt the continuation of the top rail at any point along the 4. Guardrails and Handrails shall be railing, including corners and end termidesigned to withstand a 2OOlb conr--n- nations (OSHA 1910.23). The top trated load applied in any direction and surface of the top railing shall be at any point on the top rail, Guardrails smooth and shall not be interrupted by and Handrails shall also be designed to projected fittings. , , MPLIMENTAR ations are available . . 11. Toeboard shall conform to OSHA standards. Toeboard shall be a minimum of 4 " high and shall be an extrusion that attaches to the posts with clamps that will allow for expansion and contraction between posts. Toeboards shall be set %" above the walking surface. Toeboards shall be provided on handrails as required by OSHA andlor as shown on drawings. Toeboards shall be shipped in stock lengths for field installation. 12. A self-closing gate shall guard openings in the railing (OSHA 1910.23). Safety chains shall not be used unless specifically shown on the drawings. 13. Finish shall be Aluminum Association M I 0-C22-A41 (215-RI). The pipe shall be plastic-wrapped. The plastic wrap is to be removed after erection. 14. Aluminum surfaces in contact with concrete, grout or dissimilar metals shall be protected with a coat of bituminous paint, Mylar isolators or other approved material. As witnessed by this PTLINSPECTORATE letter, TUFRAIL Systems and components are load tested by independent laboratories to validate our design calculations. TUFRAIL, Aluminum Component Handrails Designed to meet the load requirements of the International Building Code for Factory-Industrial Applications (Occupant Load No Greater Than 50) Typical Guardrail Typical Guardrail with Offset Handrail at Stairs #TSM-1.50 2 PC. Side-Mt. Bracket -WEYMHTTOWWCREIE- I 5 4 MAX SPMX #TBF-1.4 Base Flange -iOPYOUNTTOCONahTE- #TBF-1.2 Base Flange I -lU'YWNTTOWWCREIECURB- See pages 12 thru 14 for typical details International Building Code Design Specifications for FactoryIndustrial Applications (Occupant Load No Greater Than 50) 1. Guardrails and Handrails shall be the product of a company normally engaged in the manufacture of pipe railing. Railings shall be shop assembled in lengths not to exceed 24 feet for field erection. simultaneously with the concentrated loads. 5. lntermediate railings shall be provided such that a 21-inch diameter sphere cannot pass through any opening. 2. The handrail shall be made of pipes 6. lntermediate railings shall be designed joined together with component fit- to withstand a horizontally applied tings. Samples of all components, normal load of 501b on an area not to bases, toe plate and pipe must be exceed one square foot including opensubmitted for approval at the request of ings and spaces between rails. the engineer. Components that are pop-riveted or glued at the joints will 7. The manufacturer shall submit calcunot be acceptable. All components lations for approval at the request of the must be mechanically fastened with Engineer. Testing of base castings or stainless steel hardware. Handrail base extrusions by an independent lab and components shall be TUFRAIL, or manufacturer's lab (if manufacturer's as manufactured by Thompson lab meets the requirements of the Fabricating, LLC, Birmingham, AL or Aluminum Association) will be an acceptable substitute for calculations. an approved equal. Calculations will be required for approval of all other design aspects. 3. Railings shall be 1%"Schedule 40 aluminum pipe alloy 6105-T5, ASTM-B-429 or ASTM-B-221. Posts shall be 151" Schedule 40 aluminum pipe of the same alloy. Post spacing shall be a maximum of 6'-0". 4. Guardrails and Handrails shall be designed to withstand a 2001b concentrated load applied in any direction and at any point on the top rail. Guardrails and Handrails shall also be designed to withstand a uniform load of 20 Iblft applied horizontally to the top rail. Uniform loads are not to be applied 8. Posts shall not interrupt the continuation of the top rail at any point along the railing, including corners and end terminations (OSHA 1910.23). The top surface of the top railing shall be smooth and shall not be interrupted by projected fittings. 9. The mid-rail at a corner return shall be able to withstand a 2001b load without loosening. The manufacturer is to determine this dimension for their system and provide physical tests from a laboratory to confirm compliance. Design Drawings arlu gifications are available at or write for a CD-ROM Q ~ ~ X - U , 10. Concrete anchors shall be stainless steel type 303 or 304 wedge anchors and shall be furnished by the handrail manufacturer. The anchor design shall include the appropriate reduction factors for spacing and edge distances in accordance with the manufacturers published data. 11. Toeboard shall conform to OSHA Toeboard shall be a standards. minimum of 4" high and shall be an extrusion that attaches to the posts with clamps that will allow for expansion and contraction between posts. Toeboard shall be set % " above the walking surface. Toeboards shall be provided on handrails as required by OSHA and/or as shown on drawings. Toeboards shall be shipped in stock lengths for field installation. 12. A self-closing gate shall guard Openings in the railing (OSHA 1910.23). Safety chains shall not be used unless specifically shown on the drawings. 13. Finish shall be Aluminum Association M I 0-C22-A41 (215-RI). The pipe shall be plastic-wrapped. The plastic wrap is to be removed after erection. 14. Aluminum surfaces in contact with concrete, grout or dissimilar metals shall be protected with a coat of bituminous paint, Mylar isolators or other approved material. TUFRAIL, Aluminum Component Handrails Designed to meet the load requirements of OSHA for Factory-IndustrialApplications Typical Guardrail Typical Guardrail at Stairs d k B 3 COME- MAY BE-/ n]PYOUmDCR SDE W E lO B TOCONCRETEOR mu STARS MTSM-1.50 2 PC. Side-Mt. Bracket - S D E Y W W T T O ~ - - #TBF-1.4 Base Flange -IOPWTTOawaEIE- #TBF-1.2 Base Flange - T O P Y M ] N T ~ ~ m - a- See pages 12 thru 14 for typical details OSHA Design Specifications for Factory-Industrial Applications 1. Guardrails and Handrails shall be the product of a company normally engaged in the manufacture of pipe railing. Railing shall be shop assembled in lengths not to exceed 24 feet for field erection. 5. Intermediate railings shall be provided manufacturer. The anchor design shall such that a 21-inch diameter sphere include the appropriate reduction cannot pass through any opening. factors for spacing and edge distances in accordance with the manufacturers 7. The manufacturer shall submit calcu- published data. lations for approval at the request of the Engineer. Testing of base castings or 11. Toeboard shall conform to OSHA 2. The handrail shall be made of pipes base extrusions by an independent lab standards. Toeboard shall be a minijoined together with component fit- or manufacturer's lab (if manufacturer's mum of 4 " high and shall be an tings. Samples of all components, lab meets the requirements of the extrusion that attaches to the posts with bases, toeboard and pipe must be sub- Aluminum Association) will be an clamps that will allow for expansion and mitted for approval at the request of the acceptable substitute for calculations. contraction between posts. Toeboard engineer. Components that are pop-riv- Calculations will be required for shall be set 114" above the walking surface. Toeboard shall be provided on eted or glued at the joints will not be approval of all other design aspects. acceptable. All components must be handrails as required by OSHA andlor as mechanically fastened with stainless 8. Posts shall not interrupt the continua- shown on drawings. Toeboard shall steel hardware. Handrail and compo- tion of the top rail at any point along the be shipped in stock lengths for field nents shall be TUFRAIL, as manufac- railing, including corners and end installation. tured by Thompson Fabricating, LLC, terminations (OSHA 1910.23). The top Birmingham, AL or an approved surface of the top railing shall be 12. A self-closing gate shall guard opensmooth and shall not be interrupted by ings in the railing (OSHA 1910.23). equal. projected fittings. Safety chains shall not be used unless specifically shown on the drawings. 3. Railings shall be 1%" Schedule 40 9. The mid-rail at a corner return shall be aluminum pipe alloy 6105-T5, ASTM-B429 or ASTM-B-221. Posts shall be able to withstand a 2001b load without 13. Finish shall be Aluminum Association 1W " Schedule 40 aluminum pipe of the loosening. The manufacturer is to deter- M I 0-C22-A41 (215-RI). The pipe shall same alloy. Post spacing shall be a mine this dimension for their system and be plastic-wrapped. The plastic wrap is provide physical tests from a laboratory to be removed after erection. maximum of 6'-0". to confirm compliance. 14. Aluminum surfaces in contact with 4. Guardrails and Handrails shall be concrete, grout or dissimilar metals shall 10. Concrete anchors shall be stainless designed to withstand a 2OOlb concenbe protected with a coat of bituminous steel type 303 or 304 wedge anchors trated load applied in any direction and paint, Mylar isolators or other approved and shall be furnished by the handrail at any point on the top rail. material. OSHA Guardrails for Factory-Industrial Applications Brackets and Flanges #TSM-1.50 Side-Mt. Bracket (2 Piece) -&YOV)(ITOCONCREIE.- #SMB-3 Side-Mt. Bracket -SIOEWU(ImwORQUHIEL- #TSM-1.50 Side-Mt. Bracket (1 Piece) -SDEYOVHlTOCO)(CREIESUB- -mWU(ImWwEL- #TBF-3.4 Base Flange -mF'YWNlTO~- #TBF-1.4 Base Flange -TwUWHTloCM(CREIE6' #TBF-1.2 Base Flange -TOPUOUNlTO(XW(CREIEWRB- #SMB-2 Side-Mt. Bracket - S W E ~ T O ~ a R c M m - 5. , #TBF-3.2 Base Flange - m P ~ l D ~ C U R B - #TBF-2 Base Flange -ToPmmmoRcMHn- Brackets and Flanges #ABF Base Flange #CF-2 Wall Mount Flange -IW(GEfm3crfO44'- m ' ~ ~ - ) #AWF Adjustable Wall Rail Bracket 1 3/16' , , 1 3/16. t-9 Field Splice Locks #SL-1 Splice Lock #ES-1 Expansion Splice t- 5' I #TE-190" Corner Elbow Accessories Self-Closing Gates - - Factory-Industrial Gate Public Access Gate -lEFlHIlDm- Toeboard Details -RK;HIwm- I Section thru Toeboard Typical Handicap Guardrail Handicapped Thompson Fabricating introduces our handrail which complies with the requirements of the American's with Disabilities Act (ADA). This rail is produced in an offset style, which allows complete grasp ability along the entire length of the handrail. our unique design allows this rail to be easily retrofitted to any existing stair rail to bring it into compliance. This rail features a top and mid-rail that are produced from 1'X" schedule 40 aluminum pipe. All of our standard TUFRAILbase flanges and side mount brackets can be used t o mount this rail. 1 I I 2'-6. w l 1 I s'M~. - . I I 30' YH. 3, ~1 1 - -1 Handrail to Post Connection 1/4' ROUHD WD UME Samr (S.S.) 5/16' SOCI(EI EM Additional Products TUFHATCH, Aluminum Access Hatches Setting new access hatch design and quality standards for world-class treatment plants. Available in watertight, gastight and odortight designs. Interior Double Leaf Hatch - I H-20 Exterior Single Leaf Hatch Thompson aluminum component ladders are designed and tested to meet the requirements of OSHA and ANSI. TUFLADDER, is produced using many TUFRAILcomponents and can be joined to TUFRAIL to form an integral system for added rigidity and aesthetics. I 7F THOMPSON FABRICA TING, LLC P 0. Box 170160, Birmingham, AL 352 17-0160 Phone: 205/84 1-0441 Fax: 205/84 1-0822 Tdl Ftee: 1-800/824-6182 www.tfco.com