here

advertisement

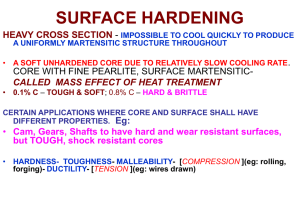

U 12132 Department of materials engineering PROJECT I Material part Task For the given part of a gearbox choose a suitable material and elaborate process of heat treatment. Consider required mechanical properties, constructional, technological and economical aspects. Design an alternative material and heat treatment or chemical-heat treatment suitable for toothed parts of the gearbox. See instructions below. Instructions For the part of the gearbox (tooth wheel or tooth shaft), which is intended for Technological part of the Project, design a suitable material and elaborate an appropriate process of heat treatment. If the material for this component is given beforehand, elaborate only the process of the most suitable heat treatment. Work out a list of fundamental processing steps including a scheme with basic dimensions. Take into account constructional, technological and economical aspects of processing. For the identical part design an alternative material and heat treatment or chemical-heat treatment. One of the alternatives of heat treatment shall be carburizing. List of possible treatments suitable for tooth wheels: 1. Classical hardening treatment (quenching and tempering at high temperature). 2. Classical hardening treatment and subsequent nitriding. 3. Classical hardening treatment and subsequent nitrocarburizing. 4. Carbonitriding and subsequent heat treatment. 5. Case-hardening (carburizing) and subsequent heat treatment. 6. Normalizing and face hardening (less stressed wheels). 7. Classical hardening treatment and face hardening (by inductor or burner). Draw thermograms (temperature vs. time) for both alternatives Compare both alternatives according to material price (use internet), heat treatment duration and final properties. 1 U 12132 Department of materials engineering DESIGN PROBLEMS: Note that all engineering parts must work under complicated mechanical conditions. Accurate choice of suitable material depends on these mechanical requirements (strength, yield point, fatigue limit, wear resistance etc.), influence of surrounding (temperature, corrosion conditions), possibilities of technology (machineability, ductility, weldability) and of course on overall economy. The material (in natural state) without accurate processing including e.g. rolling or forging, machining, heat treatment and or surface engineering could not meet demanded product requirements. HEAT AND CHEMICAL-HEAT TREATMENT PROBLEMS: Temperatures and time consumption during HT The temperatures of heat treatment and heating-up rates and cooling are given by finally achieving properties which depend on structure of material. The recommended temperatures and cooling rates (cooling media) are given in material brochures of each steel. Recommended thickness of layer using other technology of surface hardening Temperatures Heating rates depends on a various characteristics. Dimensions and power of furnace, quantity, size and arrangement of batch and conditions of heat transfer which depend of course on heated material. There are some complicated mathematical models but in praxis graphs, tables and coefficients are used. It is supposed, that the requirement of the Project is that cooling rate of heating is ≈ 150 °C/hour. Cooling Cooling rate of material (velocity) depends on the type of heat treatment and required final structure. Continuous Cooling Transformation diagrams (CCT) and Isothermal Transformation diagrams (IT) of austenite are used for prediction of parameters of heat treatment. Curves of cooling rates of quenching at given conditions (austenitization temperature, dimension and shape of piece and medium) are mapped. This data are models for real cooling routines, which must be mostly tested and than the optimal solution is find. Demonstration diagram of hardness dependence vs. depth under surface on each method of surface hardening 1. nitriding 2. nitrocarburizing 3. carbonitriding 4. case hardening (carburizing) 5. face hardening 2 U 12132 Department of materials engineering Example: for quenching temperature 850°C and diameter of a rod 50 mm the crossection is cooled with help of steady water (20 °C) in about 150 s (surface is cooled after 5 s), using oil (20 °C) cooling takes about 20 min (surface is cooled after 60 s) and the cooling by air lasts about 3 hours (surface is cooled after 20 min). For some slow cooling processes (after some types of annealing e.g. 100°C/hour) furnaces with automatically controlled cooling rates are utilized. Heat treatment Normalizing Normalizing is a common heat treatment to optimize the structure after some technological operations as casting, welding, forging etc. Normalizing is also applied as preliminary treatment for shape-complicated parts before further heat treatment or chemical-heat treatment. Note, that normalizing can not reduce the inner tension in treated parts. Heating must be 30 °C – 50 °C over Ac3 and holding time (usually 1 – 4 hours) must be sufficient for formation of a homogenous austenite, but not too long to prevent harmful graingrowth. Warming through rate depends on thickness of treated part. The empiric rule of 30 min dwelling at annealing tempertaure for each 25 mm of thickness can be used. Afterwards the air cooling is usually applied. Spherodizing (soft annealing) This type of heat treatment is demanded by materials with difficult machinability (mainly hypereutectoid alloyed steel). The annealing is realized at temperature close to Ac1 or at oscilating temperature around AC1 for 2 ÷ 4 hours. Then a slow cooling about 10 °C/hour is applied until the temperature of 600 °C is reached. Under this temperature the cooling rate can be higher. The spherodised cementite structure is obtained and the steel becomes soft, tough and well machinable. Quenching and tempering Quenching as other heat treatment processes consists of three parts: heating, holding at austenitizing temperature and cooling. Holding time at austenitization temperature is specifiend for each steel by austenitization diagram. Holding time also depends on characteristic dimensions of heat treated pieces. The table gives the orientation holding times at austenitization temperature. The temperature of tempering is given by final requirements and it is mostly between 300 °C and 650°C with holding time 1-2 hours. Cooling rate is given by chemical composition of steel and must prevent temper embrittlement (see the material brochure to find recommended media). Face (shallow) hardening (induction hardening, torch hardening) Surface hardening employs concentrated sources of heat power (inductors, burners, laser beam etc.). Thin surface layer of hardened piece is heated to a quenching temperature while a core remains cool. In case of quick heating, the austenitizing process take place at higher temperature of 150 °C – 250 °C above Ac3 (see austenitization diagram). The heating rates are 3 U 12132 Department of materials engineering (240 – 420) °C/s and quenching by water or oil spray is applied immediately. Usually subsequent tempering at 150 °C – 250 °C is utilized. Hardening using laser is very powerful but technologicaly complicated process which requires experience and testing of optimum parameters. Another possiblity is to apply a special volume heat treatment consisting of quenching and tempering using steels with very low depth of hardenability. This process is relative complicated, expensive and requires special steels and experiences. Toothwheals with module up to 5 mm are heated continuously, in case of big module teeth are heated separately, tooth by tooth (only the sidefaces and bottoms are hardened). The thickness of hardened layer is (1,5 ÷ 4) mm. Keep in mind that the teeth with modulus 3 mm will bee undesirably hardened throughout the whole volume (embrittlement of the core)! Chemical-heat treatment The most common method to reach higher hardness of tooth surface layer is case hardening (carburizing) or carbonitriding which makes 95 % of surface hardening processes. Case-hardening Case hardening consists of carburizing (saturation and diffusion period), quenching and low temperature tempering. Carburizing is proceed in case of 99 % in atmosphere using temperature between 900 °C and 950 °C (higher temperature up to 1100 °C enables quicker diffusion but requires special fine grain steels). Main process parameters are temperature, time and saturation potential of atmosphere. Carburizing speed for different saturates is shown in graph. The second figure shows thermograms of possible heat treatment after carburizing. Quenching directly from carburizing temperature (case 1) is cheapest but gives bad results – internal stress, peeling. Standard tempering parameters are (150 ÷ 200) °C / 2 h / air. Carbonitriding It is a carburizing process in atmosphere containing minor addition of nitrogen (e.g. 5 % NH3). Common parameters are: - temperature of process: 860 – 870°C, - optimal thickness 0,25 - 0,5 mm, - time for carbonitriding: 2 - 5 hours, - subsequential quenching in oil or warm bath (160°C) and tempering at a low temperature. Heat treating after carburizing 4 U 12132 Department of materials engineering Nitriding Nitriding temperature: 500 – 600°C, typical nitriding case depth 0,5 mm. Time for nitriding: 0,3mm - 20 hours, 0,5 mm – 60 hours. Hardness of the layer can exceed 1000 HV. Before nitriding steel is quenchend an tempered at high temperature. However, nitriding process takes place at lower temperature than tempering. Steels must contain chemical element making nitrides (Al, Cr, Mo, V). Nitrocarburizing Nitriding process in an atmosphere containing minor addition of carbon (≈ 10 % some hydrocarbon gas like propane). Temperature of process: 570 – 620°C, optimum thickness of continuous compound layer 10 - 25 m, growing rate of nitrocarburized layer: 4 hours 0,05 mm. Hardness of the layer is close to 1000 HV. The diffusion layer with hardness of 300 – 400 HV is developed under the surface in depth of 0,3 – 0,5mm. This layer improves ultimate load of surface and fatigue resistance of the piece. Quenching is not necessary. Selected wrought steels suitable for application in Material part of the Project Steel by ČSN Steel by ČSN EN Steel by ČSN Steel by ČSN EN 11500 11600 11700 12010 12020 12040 12050 12051 12060 12061 13141 13241 14120 14220 E 295 E 335 E 360 C10E C15E C35E C45E C50E C55E C60E 28Mn6 37MnSi5 15Cr2 16MnCr5 14221 14240 15241 15260 16120 16121 16220 16231 16250 16420 16430 16440 16520 16720 20MnCr5 36Mn5 42CrV6 50CrV4 15CrNi4 17CrNi4 15CrNi6 19CrNi8 45NiCr8 15NiCr14 26NiCrMo8-5 31NiCr14 14NiCr16-4 18NiCrMo16-6 Choosing other suitable materials is also possible. The designation according to European standards is requested. To find corresponding material designation it is possible to use an electronic Lexicon of technical materials. Lexicon is available only in the study room at Charles Square at the building of faculty of mechanical engineering (on the first floor, opposite to Copy Centrum). 5