SI2100 Manaul R1

advertisement

Silicon Imaging

SI-2100 USB2.0 MegaCamera

2.0 Million Pixel Progressive Scan Digital Camera

Revision 1.0

November 26, 2004

2.0 Million Pixels

1600 x 1200 Image Sensor

4.2 um Square Pixel

½ Optical format

Rolling Shutter

SVGA (800x600) Subsampling

10~40 Frames per Second

10 Bit Digital Sampling

RGB Bayer Color

Auto White Balance

Auto Exposure Control

USB2.0 Interface

**** Company Confidential ****

Silicon Imaging , Inc. 2003

Page 1 of 25

Company Confidential

MegaCamera™ SI-2100RGB

Silicon Imaging Inc.

2.0 Megapixel, 10-Bit, 40MHz

USB 2.0 Smart Color Digital Camera

INTRODUCTION

Silicon Imaging is proud to continue its innovation in high-resolution

color vision camera. Driven by the growing demand for consumer Digital

Still Cameras, CMOS sensors are continuing to break technical barriers

and surpass the performance characteristics of CCD’s in many photonic,

imaging and consumer applications. By utilizing a single highly integrated

CMOS device, which incorporates Megapixel sensing areas, timing

generation, signal processing and high bandwidth outputs, Silicon Imaging

has developed a very compact, low-power, ultra high speed Megapixel

digital camera system.

1600 x 1200 Megapixel - Ultra Resolution

The SI-2100 is an all-digital CMOS camera that delivers 2.0 Million pixels

of resolution and is capable of running at 12 frames/second at its full 1600

x 1200 resolution. The entire package is only 45 x 52 x 50mm (33 x

40mm x 22mm in PCB) and is small enough to placed on a robot for

semiconductor machine vision inspection or placed in an outdoor housing

for remote surveillance. It is ideal for live visualization of documents or

films and scanning of biometrics for handprint or facial recognition.

10-Bits Sampling – Sub-Pixel Accuracy

The SI-2100 MegaCamera uses 10-Bit digitizers to sample the pixel

data. Converting the pixel data directly to digital at the sensor head

eliminates pixel-sampling jitter and enables accurate sub-pixel metrology,

image analysis and improved live video reconstruction. A programmable

clock which ranges from 10~40MHz allows for trade-offs in speed versus

exposure time and lower noise.

40 FPS SVGA Windowing - Fast Preview

Ideal for high speed preview and focusing, the SI-2100 is capable of

generating imagery at over 40 frames per second by reducing the size of

the readout image in color subsampling mode, This entire imager is

readout by skipping pairs of pixels (4:2) to maintain color information of

neighboring bayer groups. In this way, the 800x600 accurately represents

the full size 1600x1200 image.

Automatic Color & Exposure Processing

The SI-2100 has built in Automatic White Balance, Automatic Exposure

and Automatic Gain Controls. As lighting conditions vary, the camera will

automatically adjust the exposure and gain in combination to obtain an

image with a target brightness range, on a frame-by-frame basis. It also

analyzes the distribution of RGB values in the scene and adjusts individual

channel gains to maintain white balance. For controlled lighting and

inspection applications, gain and exposure values can be set manually via

simple commands and software presets.

USB 2.0 High-Speed Interface

The high-speed image capture and connectivity is undergoing a revolution. The

new UBS2.0 standard allows you to connect megapixel vision cameras with a

single 4-wire cable directly into a 480Mbit/sec (megabits per second) port,

found in every new motherboard produced with Intel P4 chipsets. These

new USB 2.0 vision cameras can transfer precision 8 or 10-bit digital gray scale

or color image data, eliminating the sampling jitter of traditional analog RS-170

or NTSC systems, at speeds 40x faster than the predecessor USB1.1

devices. This interface also provides bi-directional serial communication for

camera setup and control, triggering, strobing and other I/O signaling. One of

the most convenient benefits, especially for those imaging executives and sales

engineers traveling with the latest lightweight laptops, is not having to carry an

additional power supply; these cameras are powered thru the same USB

cable. For the vision system end-user, the benefit will be a lower system cost

than previous camera and frame grabber solutions and plug-n-play installation.

Silicon Imaging , Inc. 2003

Page 2 of 25

FEATURES

·

1600 x 1200 Resolution (2.0 Million Pixels)

·

1/2” Imaging Format , 4.2um Square Pixel

·

Rolling Shutter, Progressive scan

·

800 x 600 SVGA Windowing at 40fps

·

10 Bits per Pixel, 40MHz Sampling

·

10 ~ 40MHz Programmable Clock

·

Optical black level calibration

·

Programmable Gain, Exposure & Clocks

·

Auto Exposure and Gain Control (AEC/AGC)

·

Auto White Balance Control (AWB)

·

Color Bayer RGB Model

·

33 x 40mm x 22mm PCB Version

·

USB Interface & Bus Powered

·

C-Mount Precision Machined Housing

Company Confidential

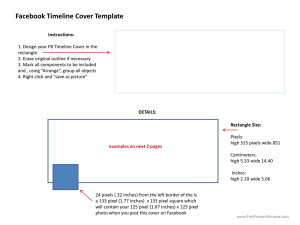

Camera Architecture Overview

The MegaCamera SI-2100 consists of 6 major component sections, which are built on two circuit boards.

1.) 2.0 Megapixel Sensor

2.) Digital Clock Synthesizer

3.) Digital Control Logic

4.) Microprocessor

5.) USB Interface

6.) Power Regulation

7.) Trigger & Strobe Controls

Register

Programming

Digital

Logic

Strobe Out

DATA (10)

FVAL

LVAL

CLOCK

Trigger

Controller

Trigger In

Image

Sensor

&

A/D

Converter

uP

Control

USB 2.0

5VDC

Power

Supply

PLL & Timing

Generator

SI-2100 Camera Block Diagram

PCB OEM Version

44 x 33 x 14mm - 2PCB

Actual size

Silicon Imaging , Inc. 2003

Page 3 of 25

Company Confidential

1.)

2.0 Megapixel CMOS Image Sensor (1600 x 1200)

The MegaCamera SI-2100 utilizes a proprietary 2.0 Million pixel high-speed CMOS image sensor. Each pixel is

4.2um square, ideal for image processing, and the entire array fits the 1/2” format for flexible optic choices. This

reduction in process geometry allows for both an increase in transistors and fill factor without compromising

performance, plus offers more advanced readout controls, greater speeds and lower power dissipation. This new

sensor technology offers a more responsive pixel design with added circuitry for increased dynamic range, greater

sensitivity, decreased fixed pattern noise and low dark current for long exposure applications. Unlike CCD, which

leak charge to adjacent pixels when the registers overflows (blooms), the SI-2100 provides inherent anti-blooming

protection in each pixel, so that there is no blooming.

The array has 1600 pixels on a line and 1200 rows, which result in a 4:3 aspect ratio. The sensor array design is

based on a field integration read-out system with line-by-line transfer and an electronic shutter with a synchronous pixel readout scheme (aka. Rolling Shutter Method)

Analog Gain Amplifier & Color Balance

When the column sample/hold circuit has sampled one row of pixels, the pixel data will shift out one-by-one thru

an analog amplifier with Global Gain. The amplifier gain can either be manually programmed by the user or controlled by the

internal automatic gain control circuit (AGC). The amplified signals are then color balanced with a channel balance block. In

this block, the Red/Blue channel gain is increased or decreased to match Green channel luminance level. The adjustment

range is +54 dB. Red/Blue Channel Balance can be done manually by the user or by the internal automatic white balance

(AWB) controller.

10-Bit A/D Conversion

The balanced signal is then digitized by the on-chip 10-bit ADC. It can operate at 40 MHz and is fully synchronous to

the pixel clock. The actual conversion rate is determined by the programmable clock rate.

Black Level Compensation

After the pixel data has been digitized, black level calibration can be applied before the data is output. The black level

calibration block subtracts the average signal level of optical black pixels to compensate for the temperature and exposure time

generated dark current in the pixel output. The user can disable black level calibration.

RGB Bayer Digital Output

The color balanced and black level corrected data is output from the sensor in 10-bit raw Bayer Digital format and

fed through the programmable logic to the USB2.0 High-Speed Interface.

Silicon Imaging , Inc. 2003

Page 4 of 25

Company Confidential

SI-2100 Sensor Specifications

Lens Size

1/2"

Pixel Size

4.2 µm x 4.2 µm

Array Size

1600 x 1200

Image Area

6.72 mm x 5.04 mm

A/D Resolution

10-Bits

Output Format

8/10-bit digital raw RGB Bayer Data

Color Subsampling

800 x 600 (SVGA)

4:2 Subsampling

Transfer Rate

UXGA: 10 fps

SVGA: 40 fps

Scan Mode

Progressive

Dark Current

28 mV/s

S/N Ratio

54 dB

Fixed Pattern Noise

< 0.03% of V PEAK-TO-PEAK

Dynamic Range

60 dB (due to ADC limitations)

Electronics Exposure

UXGA Up to 1230:1

SVGA Up to 614:1

Gain Control

Global Gain: 1x ~ 8x

Blue Gain: 1/5 x ~ 5x

Red Gain: 1/5 x ~ 5x

Auto White Balance (AWB)

Manual / Automatic

AWB Threshold, AWB Speed

Auto Exposure Control (AEC)

Manual / Automatic

AEC Target Min/Max, AEC Speed/Steps

Histogram Counters

R/Gr/Gb/B Channel Average

Luminance Average

Silicon Imaging , Inc. 2003

Page 5 of 25

Company Confidential

SI-2100 Spectral Response Curve

2.)

10-Bit Digital Sampling System

A 10-Bit Analog-to-digital (A/D) converter samples each pixel value and quantizes it into 1024 levels inside the

sensor. Pixel clock sampling ensures precise measurement of the photonic charge without the jitter and sampling

uncertainty associated with traditional analog video systems, such as RS-170 and CCIR. The produces images

which can deliver improved photometry accuracy and sub-pixel metrology. The use of 10-bit converters versus

traditional 8-bit systems further enhances the image dynamic range. The combination of 10-bit vertical resolution

and pixel clock sampling provide precise sub-pixel measurement accuracy (ex. 1/10 pixel).

3.)

Digital Clock Synthesizer

A wide range a master clock frequencies (eg. 10 to 40MHz) can by precisely generated using the Digital Clock

Synthesizer. The frequency of the clock synthesizer can be set by vendor command. A table with associated clock

frequency is found in the serial programming section of the manual. Due to frequency restriction on the digital

transmission link and processor clocks, the pixel clock frequency cannot be lower than 5Mhz or higher than

50MHz. In 10-bit mode, the sustained data rate on the USB2.0 is up 2x the pixel clock rate. In order to maintain

full 10-bit resolution the clock rate needs to be reduced to half the maximum. Alternatively, the camera is capable

of switching to 8-bit mode and the clock rates increased.

4.)

Embedded Microprocessor

A microprocessor in the camera provides the control interface between the PC and the functional block in the

camera (Sensor, Clock Synthesizer, Register Memory, triggers & USB Interface. The Microprocessor receives

commands thru the USB interface and issues commands to the other internal devices. It also can store preset

values for camera setting, which can be recalled.

Silicon Imaging , Inc. 2003

Page 6 of 25

Company Confidential

5.)

USB2.0 Interface & Power

The UBS2.0 interface connect the camera to the PC with a single 4-wire cable. The port provides sustained data

rates of over 40MB/sec and also provides +5VDC to the camera for operation. The interface also provides bidirectional serial communication for camera setup and control, triggering, strobing and other I/O signaling.

6.) Camera Control Signals & Power

Several digital I/O and power signals are available on the processor from PCB header points for custom OEM

applications.

Silicon Imaging , Inc. 2003

Page 7 of 25

Company Confidential

Digital Clock Synthesizer Programming

The SI-2100 has a Digital Clock Synthesizer capable of generating a range of frequencies from 10MHz to 40MHz.

The pixel data output rate is the same as the sampling clock rate in 8bit mode and 2x the data rate in 10-bit mode.

The clock frequency is set by a USB vendor command. A range of preset frequencies are listed below:

Command

30688e

328e90

306886

30b689

37cb8f

35d40b

306882

Clock

MHz

10

15

20

25

30

35

40

2.1MP

SVGA

1600 x 1200

800 x 600

4

6

8

10

12

14

15

15

24

35

40

48

56

60

Note: The factory can generate the command to achieve a targeted clock rate.

Sample Command:

There are multiple setting to achieve each frequency. Some might be better than others for a particular application.

Frame Rate Calculation

To calculate the frame rate for any clock rate the equation is:

(

clock rate(Hz)

)

=

# Frames Per Second (fps)

( # of clocks/row) * ( # of rows) + VSYNC

Clocks/Row (UXGA) = 1948

Clocks/Row (SVGA) = 974

Example:

What is the frame rate, at 25MHz clock rate for an image size of 1280 x 1024?

25 x 106

( 1280 + 164) * (1024) +

=

10 Frames Per Second (fps)

*** Subsampling frame rates are based on the resulting size of the subsampled image.

Silicon Imaging , Inc. 2003

Page 8 of 25

Company Confidential

SI-2100 Register Programming

Image Size/Subsampling

The SI-2100 will default into the full 2.1Megapixel resolution image of 1600x1200. The image readout rate (frame

rate) will depend on the camera clock speed. The display update rate will depend on the PC CPU speed and color

processing selections.

Reg

12

(x20)

Image Size

1600 x1200 UXGA (Set to x20)

800 x 600 SVGA (Set to x60)

In order to increase these update rates, the camera supports subsampling mode. The entire sensor array is

readout and sub-sampled in horizontal and vertical directs to a ratio of 4:2, as illustrated in figure below, in order to

maintain correct bayer color representation. The 1600x1200 image will be reduced to an 800x600 representation

of the full field of view, with almost 4x the output frame rate. Set Register 12 to 0x60 to enable SVGA subsampling

mode.

Silicon Imaging , Inc. 2003

Page 9 of 25

Company Confidential

Global Gain & Color Balance

Each row of pixels is sampled and the pixels shifted out one-by-one thru an analog amplifier with Global Gain. The amplifier

gain can either be manually programmed by the user (Reg 13 = 0) or controlled by the internal automatic gain control (AGC)

circuit (Reg 13 = xC5 or xC7). The AGC mode is enabled at the same time as Auto Expsoure (AEC) mode, in order to maintain

a target image brightness level.

The amplified signals are then color balanced. In this block, the Red and Blue channel gain is increased or decreased to match

Green channel luminance level. The adjustment range is +54 dB. Red/Blue Channel Balance can be done manually by the

user or by the internal automatic white balance (AWB) controller (Reg 13 = xC7).

13

(xC7)

00

(x00)

Auto/Manual

Exposure

GLOBAL

GAIN

0x00 = Manual Exposure & Gain

0xC5 = Auto Exposure Control / Auto Gain Control (AEC/AGC) or

0xC7 = Auto White Balance & Exposure (AWB/AEC/AGC)

Global Gain – 6 Bits ( Range: 1x to 8x)

Bit[7:6]: Unused

Bit[5:0]: Gain = (Bit[5]+1) x (Bit[4]+1) x ((1+Bit[3:0])/16))

Register [00]

000000

000001

000010

000011

000100

000101

000110

000111

001000

001001

001010

001011

001100

001101

001110

001111

010000

110000

111111

01

(x80)

02

(x80)

03

(x40)

Gain

1

1+1/16

1+2/16

1+3/16

1+4/16

1+5/16

1+6/16

1+7/16

1+8/16

1+9/16

1+10/16

1+11/16

1+12/16

1+13/16

1+14/16

1+15/16

2*(1+0/16)

4*(1+0/16)

4*(1+15/16)

dB

0

.375

.75

1.125

1.5

1.875

2.25

2.625

3

3.375

3.75

4.125

4.5

4.875

5.25

5.625

6

12

~18

BLUE

GAIN

[8 MSB]

Blue gain [9:0] - 10 Bits (Range: 1/5x to 5x)

BLUE[9:2] = Reg01[7:0] = 8MSB

BLUE[1:0] = Reg02[3:2] = 2LSB

RED

GAIN

[8 MSB]

Blue Gain Value=

If BLUE[9] = 1, then Blue gain = 1 + BLUE[8:0]/128

If BLUE[9] = 0, then Blue gain = 1/(1 + BLUE_B[8:0]/128),

where BLUE_B[8:0] is the bit reverse of BLUE[8:0].

Red gain [9:0] – 10 Bits (Range: 1/5x to 5x)

RED[9:2] = Reg02[7:0] = 8MSB

RED[1:0] = Reg02[1:0] = 2LSB

Blue Gain [2LSB]

Red Gain [2LSB]

Silicon Imaging , Inc. 2003

Red Gain Value=

If RED[9] = 1, then Red gain = 1 + RED[8:0]/128

If RED[9] = 0, then Red gain = 1/(1 + RED_B[8:0]/128),

where RED_B[8:0] is the bit reverse of RED[8:0].

Bit[7:4]: AWB update threshold (0~15)

Bit[3:2]: BLUE Gain - lower 2 bits of Blue gain control

Bit[1:0]: RED Gain - lower 2 bits of Red gain control

Page 10 of 25

Company Confidential

Auto White Balance (AWB)

The SI-2100 continuously collects image statistics of the average output level data for the R/Gr/Gb/B channels and places them

in registers (x05, x06, x07, x08) for calculated image white balance. The values are calculated from 128 pixels per line (64

pixels per line in SVGA). The average of these 4 values is also calculated and placed in Reg 2F (Luminance Avg) to be used

for AEC control.

Set Reg 13 to 0xC7 to enable Auto White balance (AWB). The AWB circuit will calculate Red & Blue gain values and

automatically update registers x01,x02 and x03 to balance the colors in the image, until they are within a threshold range

(Reg3[7:4]). The number of steps and speed of adjustments are set in Reg4. The stability of the White Balance will vary on the

lighting conditions and the tolerance of the AWB threshold.

13

(xC7)

Auto/Manual

Exposure

03

(x40)

Auto White

Balance

Threshold

&

Red/Blue Gain

(2LSB)

Auto White

Balance

Speed

Bit[7:4]: AWB update threshold (0~15)

&

Bit[5:4]: AWB Update Speed Selection

00: Slow

10: Fast

01: Slowest 11: Fast

04

(x00)

Exposure

(3LSB)

0xC7 = Auto White Balance & Exposure (AWB/AEC/AGC)

Bit[3:2]: BLUE Gain - lower 2 bits of Blue gain control

Bit[1:0]: RED Gain - lower 2 bits of Red gain control

Bit[7:6]: AWB Step Selection

00: 1023 steps 10: 511 steps

01: 255 steps

11: 255 steps

Bit[3]: Reserved

Bit[2:0]: Exposure lower 3 bits – EXP[2:0]

05

(x00)

06

(x00)

07

(x00)

08

(x00)

2F

(x00)

BLUE

Average

B Channel Average

BAVG[7:0] – Calculated from all Blue pixels in the image

GREEN (b)

Average

Gb Channel Average

GbAVG[7:0]- Picked G pixels in the same line with B pixels.

GREEN (r)

Average

Gr Channel Average

GrAVG[7:0] - Picked G pixels in the same line with R pixels.

RED

Average

Average

Luminance

Silicon Imaging , Inc. 2003

R Channel Average

RAVG[7:0] – Calculated from all Red pixels in the image

Luminance Average = Calculated from the B/Gb/Gr/R channel average:

AVG = (BAVG[7:0] + GbAVG[7:0] + GrAVG[7:0] +RAVG[7:0])/4)

Page 11 of 25

Company Confidential

Manual/ Auto Exposure Control (AEC)

The camera exposure time can be controlled manually or automatically. To enable manual control, set Reg13 to

x00. The Adjust the values in Reg10 and Reg4 to the desired levels. The total exposure is the sum of exposure

register and vertical blanking time of approximately 2msec.

Exposure Time = (Exposure Register * Line_Time) + Vertical_Blanking_Time (~2msec)

Line_Time = 1948 * Pixel_clock (UXGA)

Line_Time = 974 * Pixel_clock (SVGA)

To enable the Auto Exposure Control (AEC) and Auto Gain Control (AGC) function, set register 0x13 to xC5 or

xC7. The AEC/AGC will control the image brightness based on the values in Registers 0x24 (high threshold target

value) and 0x25 (low threshold target value.)

When the image luminance average (Yavg), found in Register 2F, is within the specified range of min/max values,

the AEC/AGC will not change the Exposure Time (Reg10 & 04) or Global Gains (Reg 0). When Yavg, is greater

than the value in register 0x24, the AEC will automatically decrease the image exposure and gains. When Yavg, is

less than the value in register 0x25, the AEC will increase the image exposure and gains. Accordingly, the value in

register 0x24 should be greater than the value in register 0x25. The difference between the min/max values

controls the image stability and brightness. The recommended spread between min and max is x10 to x20.

13

(xC7)

10

(x43)

04

(x00)

24

(x50)

25

(x40)

2F

(x00)

Auto/Manual

Exposure

Exposure

Time

[8 MSB]

Exposure

[3LSB]

Luminance

Max

AEH

Luminance

Min

AEL

Average

Luminance

0x00 = Manual

0xC5 = Auto Exposure Control / Auto Gain Control (AEC/AGC) or

0xC7 = Auto White Balance & Exposure (AWB/AEC/AGC)

Exposure [10:0] = t LINE x EXP[10:0]

EXP[10:3] = Reg10[7:0] = 8MBS

EXP [2:0] = Reg04[2:0] = 3LSB

Bit[7:3]: AWB Step Selection & Update Speed Selection

Bit[2:0]: Exposure lower 3 bits – EXP[2:0]

Luminance Signal High range for AEC/AGC operation

AEC/AGC value is decrease in auto modes when average luminance is greater than AEH [7:0]

Luminance Signal Low range for AEC/AGC operation

AEC/AGC values will increase in auto mode when average luminance is less than AEL [7:0]

Luminance Average

Calculated from the B/Gb/Gr/R channel average as follows:

AVG = (BAVG[7:0] + GbAVG[7:0] + GrAVG[7:0] +RAVG[7:0])/4)

Long Exposure (Extended Vertical Blanking)

In order to increase the maximum exposure time over 2048 line counts, the Vertical blanking period can be

extended using Registers 2D & 2E. A minimum blanking period of approx 7msec must be maintained for proper

camera operations. At 40MHz, Reg 2D must be a minimum of 0x90 (144 row times).

2D

(x90)

2E

(x00)

Vertical

Blanking LSB

Line periods added to Vertical Blanking Period. Each count will add 1 * Line_Time to the VSYNC

Vertical Blanking Period. A minimum of approx 7ms blanking is required.

Vertical

Blanking MSB

Line periods added to Vertical Blanking Period. Each count will add 256 lines.

Silicon Imaging , Inc. 2003

Page 12 of 25

Company Confidential

Bayer Interpolation and Color Correction

White Balance and Color Correction are processing operations performed to ensure proper color fidelity in a

captured digital camera image. In digital cameras an array of light detectors with color filters over them is used to

detect and capture the image. This sensor does not detect light exactly as the human eye does, and so some

processing or correction of the detected image is necessary to ensure that the final image realistically represents

the colors of the original scene. In addition, each bayer pixel only represents a portion of the color spectrum and

must be interpolated to obtain an RGB value per pixel.

Bayer color filter array is a popular format for digital acquisition of color images. The pattern of the color filters is

shown below. Half of the total number of pixels are green (G), while a quarter of the total number is assigned to

both red (R) and blue (B).

G

B

G

B

R

G

R

G

G

B

G

B

R

G

R

G

To convert an image from this format to an RGB format, we need to interpolate the two missing color values in

each pixel. Several standard interpolation methods (nearest neighbor, linear, cubic, cubic spline) can be applied to

fill in the missing values in each pixel, resulting in a full size image with each pixel containing an R,G,B value.

The RGB interpolated data is then processed thru a color correction matrix which is used to eliminate the crosstalk

induced by the micro-lens and color filter process and compensates for lighting and temperature effects. The same

matrix can be used to increase overall color saturation.

The recommended default SI-2100 color matrix settings are in Table 4 below:

R’ =

G’ =

B’ =

Silicon Imaging , Inc. 2003

R

1.268

<0.872>

<0.101>

G

<0.094>

1.821

*<0.126>

Page 13 of 25

B

<0.051>

<0.051>

1.227

Company Confidential

Color Saturation Matrix

The operation for saturation, can be applied at the same time as the color correction matrix. Unlike the color

correction matrix, the saturation matrix does not rotate the vectors in the color wheel:

[m00 m01 m02] [ R ]

[m10 m11 m12] * [G ]

[m20 m21 m22] [ B ]

m00 = 0.299 + 0.701*K

m01 = 0.587 * (1-K)

m02 = 0.114 * (1-K)

m10 = 0.299 * (1-K)

m11 = 0.587 + 0.413*K

m12 = 0.114 * (1-K)

m20 = 0.299 * (1-K)

m21 = 0.587 * (1-K)

m22 = 0.114 + 0.886*K

K is the saturation factor

K=1 means no change

K > 1 increases saturation

0<K<1 decreases saturation, K=0 produces B&W , K<0 inverts color

A sample table of matrix values are calculated and shown below:

Saturation

Saturation

Saturation

Saturation

R

R

R

R

G

B

1

1

0

0

1.7

1.4907

-0.4109

-0.0798

1.9

1.6309

-0.5283

-0.1026

2

1.701

-0.587

-0.114

G

G

G

R

G

B

0

1

0

-0.2093

1.2891

-0.0798

-0.2691

1.3717

-0.1026

-0.299

1.413

-0.114

B

B

B

R

G

B

0

0

1

-0.2093

-0.4109

1.6202

-0.2691

-0.5283

1.7974

-0.299

-0.587

1.886

Monochrome Saturation Matrix

A monochrome image can now be easily obtained from a color image by setting K=0

m00 = 0.299

m01 = 0.587

m02 = 0.114

Silicon Imaging , Inc. 2003

m10 = 0.299

m11 = 0.587

m12 = 0.114

m20 = 0.299

m21 = 0.587

m22 = 0.114

Page 14 of 25

Company Confidential

SI-2100 REGISTER TABLE

00

00

01

(x80)

GLOBAL

GAIN

BLUE

GAIN

Global Gain – 6 Bits ( Range: 1x to 8x)

Bit[7:6]: Unused

Bit[5:0]: Gain = (Bit[5]+1) x (Bit[4]+1) x (1+Bit[3:0]/16)

Note: In Automatic Gain Controls (AGC) mode this register is automatically updated.

Set Register 13 = 0x00 for Manual Gain control.

Blue gain - 10 Bits (Range: 1/5x to 5x)

BLUE[9:2] = Reg01[7:0] = 8MSB

BLUE[1:0] = Reg02[3:2] = 2LSB

Blue Gain Value=

If BLUE[9] = 1, then Blue gain = 1 + BLUE[8:0]/128

If BLUE[9] = 0, then Blue gain = 1/(1 + BLUE_B[8:0]/128),

where BLUE_B[8:0] is the bit reverse of BLUE[8:0].

02

(x80)

RED

GAIN

[8 MSB]

Note: In Automatic Gain Controls (AGC) mode this register is automatically updated.

Set Register 13 = 0x00 for Manual Gain control.

Red gain – 10 Bits (Range: 1/5x to 5x)

RED[9:2] = Reg02[7:0] = 8MSB

RED[1:0] = Reg02[1:0] = 2LSB

Red Gain Value:

If RED[9] = 1, then Red gain = 1 + RED[8:0]/128

If RED[9] = 0, then Red gain = 1/(1 + RED_B[8:0]/128),

where RED_B[8:0] is the bit reverse of RED[8:0].

03

(x60)

04

(x00)

Auto White

Balance

Threshold

&

Red/Blue Gain

(2LSB)

Auto White

Balance

Speed

&

Exposure

(3LSB)

Note: In Automatic Gain Controls (AGC) mode this register is automatically updated.

Set Register 13 = 0x00 for Manual Gain control.

Bit[7:4]: AWB update threshold (0~15)

Bit[3:2]: BLUE Gain - lower 2 bits of Blue gain control

Bit[1:0]: RED Gain - lower 2 bits of Red gain control

Bit[7:6]: AWB Step Selection

00: 1023 steps 10: 511 steps

01: 255 steps

11: 255 steps

Bit[5:4]: AWB Update Speed Selection

00: Slow

10: Fast

01: Slowest 11: Fast

Bit[3]: Reserved

Bit[2:0]: Exposure lower 3 bits – EXP[2:0]

05

(x00)

06

(x00)

07

(x00)

08

(x00)

BLUE

Average

B Channel Average

BAVG[7:0] – Calculated from all Blue pixels in the image

GREEN (b)

Average

Gb Channel Average

GbAVG[7:0]- Picked G pixels in the same line with B pixels.

GREEN (r)

Average

Gr Channel Average

GrAVG[7:0] - Picked G pixels in the same line with R pixels.

RED

Average

Silicon Imaging , Inc. 2003

R Channel Average

RAVG[7:0] – Calculated from all Red pixels in the image

Page 15 of 25

Company Confidential

10

(x43)

Exposure

Time

Exposure [10:0] = {Reg10[7:0] ; Reg04[2:0]}

EXP[10:3] = Reg10[7:0] = 8MBS

EXP [2:0] = Reg04[2:0] = 3LSB

Exposure Time = t LINE x EXP[10:0]

8 MSB

AEC (Automatic Exposure Control) automatically modifies this register

Note: Set Register 0x13 to 0 to disable the AEC.

12

(x20)

Image Size

UXGA 0x20

SVGA 0x60

13

(xC7)

Auto/Manual

Expsoure &

White Balance

Modes

0x00 = Manual

0xC5 = AEC

0xC7 = AWB/AEC

1600 x 1200 UXGA (Set to x20)

800 x 600 SVGA (Set to x60)

Bit[7]: AEC speed selection

0: Normal

1: Faster AEC correction

Bit[6]: AEC speed/step selection

0: Small steps, slow

1: Big steps, fast

Bit[5:3]: 0

Bit[2]: Exposure control

0: Manual

1: Auto

Bit[1]: AWB auto/manual control selection

0: Manual

1: Auto

Bit[0]: AGC auto/manual control selection

0: Manual

1: Auto

24

(xA0)

Target

Luminance

Max

AEC

Luminance Signal High range for AEC/AGC operation

AEC/AGC value is decrease in auto modes when average luminance is greater than AEH [7:0]

25

(x88)

Target

Luminance

Min

Luminance Signal Low range for AEC/AGC operation

AEC/AGC values will increase in auto mode when average luminance is less than AEL [7:0]

2F

(x00)

Average

Luminance

2D

(x90)

Add

Vertical

Blanking

LSB

Add

Vertical

Blanking

MSB

2E

(x00)

Silicon Imaging , Inc. 2003

Luminance Average

Calculated from the B/Gb/Gr/R channel average as follows:

AVG = (BAVG[7:0] + GbAVG[7:0] + GrAVG[7:0] +RAVG[7:0])/4)

Line periods added to Vertical Blanking Period. Each count will add 1 * Line_Time to the VSYNC

Vertical Blanking Period. A minimum of approx 7ms blanking is required.

The Default VSYNC is 0x90 (144 row times). At a clock rate of 40MHz this is 7msec.

Line periods added to Vertical Blanking Period. Each count will add 256 lines.

Page 16 of 25

Company Confidential

White Balance and Color Correction

Application Note

1.0

Introduction

White Balance and Color Correction are processing operations performed to ensure proper color fidelity in a

captured digital camera image. In digital cameras an array of light detectors with color filters over them is used to

detect and capture the image. This sensor does not detect light exactly as the human eye does, and so some

processing or correction of the detected image is necessary to ensure that the final image realistically represents

the colors of the original scene.

Bayer color conversion and processing

This note describes conversions from Bayer format to RGB and between RGB and YUV (YCrCb) color spaces. We

also discuss two color processing operations (white balance and color correction) in the RGB domain, and derive

the corresponding operations in the YUV domain. Using derived operations in the YUV domain, one can perform

white balance and color correction directly in the YUV domain, without switching back to the RGB domain.

1. Conversion from Bayer format to RGB

Bayer color filter array is a popular format for digital acquisition of color images [1]. The pattern of the color filters is

shown below. Half of the total number of pixels are green (G), while a quarter of the total number is assigned to

both red (R) and blue (B).

G

B

G

B

R

G

R

G

G

B

G

B

R

G

R

G

To convert an image from this format to an RGB format, we need to interpolate the two missing color values in

each pixel. Several standard interpolation methods (nearest neighbor, linear, cubic, cubic spline, etc.) were

evaluated on this problem in [2]. The authors have measured interpolation accuracy as well as the speed of the

method and concluded that the best performance is achieved by a correlation-adjusted version of the linear

interpolation. The suggested method is presented here.

Silicon Imaging , Inc. 2003

Page 17 of 25

Company Confidential

1.1 Interpolating red and blue components

G

R

G

B G

G R

B G

(a)

G

B

G

R

G

R

(b)

G

B

G

B

G

B

G B

R G

G B

(c)

R

G

R

G R

B G

G R

(d)

Figure 1: Four possible cases for interpolating R and B components

As suggested in [2], R and B values are interpolated linearly from the nearest neighbors of the same color. There

are four are possible cases, as shown in Figure 1. When interpolating the missing values of R and B on a green

pixel, as in Figure 1 (a) and (b), we take the average values of the two nearest neighbors of the same color. For

example, in Figure 1 (a), the value for the blue component on a shaded G pixel will be the average of the blue

pixels above and below the G pixel, while the value for the red component will be the average of the two red pixels

to the left and right of the G pixel.

Figure 1 (c) shows the case when the value of the blue component is to be interpolated for an R pixel. In such

case, we take the average of the four nearest blue pixels cornering the R pixel. Similarly, to determine the value of

the red component on a B pixel in Figure 2 (d) we take the average of the four nearest red pixels cornering the B

pixel.

1.2 Interpolating the green component

By [2], green component is adaptively interpolated from a pair of nearest neighbors. To illustrate the procedure,

consider two possible cases in Figure 2.

R4

G4

R1

G1

R

G3

R3

(a)

G2

R2

B4

G4

B1

G1

B

G3

B3

(b)

G2

B2

Figure 2: Two possible cases for interpolating G component

In Figure 2 (a), the value of the green component is to be interpolated on an R pixel. The value used for the G

component here is

(G1 G3 ) / 2,

if | R1 R3 || R2 R4 |

G( R)

(G2 G4 ) / 2,

if | R1 R3 || R2 R4 |

(G G G G ) / 4, if | R R || R R |

2

3

4

1

3

2

4

1

In other words, we take into account the correlation in the red component to adapt the interpolation method. If the

difference between R1 and R3 is smaller than the difference between R 2 and R4, indicating that the correlation is

stronger in the vertical direction, we use the average of the vertical neighbors G 1 and G3 to interpolate the required

value. If the horizontal correlation is larger, we use horizontal neighbors. If neither direction dominates the

correlation, we use all four neighbors.

Similarly, for Figure 2 (b) we will have

Silicon Imaging , Inc. 2003

Page 18 of 25

Company Confidential

(G1 G3 ) / 2,

if | B1 B3 || B2 B4 |

G( B)

(G2 G4 ) / 2,

if | B1 B3 || B2 B4 |

(G G G G ) / 4, if | B B || B B |

2

3

4

1

3

2

4

1

To conclude this section, note that if the speed of execution is the issue, one can safely use simple linear

interpolation of the green component from the four nearest neighbors, without any adaptation

G (G1 G2 G3 G4 ) / 4

According to [2], this method of interpolation executes twice as fast as the adaptive method, and achieves only

slightly worse performance on real images, while it is actually better than the adaptive method when applied to

synthetic images.

2. Conversion between RGB and YUV

We give two commonly used forms of equations for conversion between RGB and YUV formats. The first one is

recommended by CCIR [3]

Y 0.257 R 0.504G 0.098B 16

U 0.439 R 0.368G 0.071B 128

(2.1)

V 0.148R 0.291G 0.439 B 128

The second form is used by Intel in their image processing library [4], and may be more suitable for

implementation:

Y 9798R 19235G 3736 B / 215

(2.2)

15

U 21208R 16941G 3277 B / 2

128

V 4784 R 9437G 4221B / 215 128

In either case, resulting values of Y, U and V should be clipped to fit the appropriate range for the YUV format (e.g.

[0,255] for a 24-bit YUV format). The inverse conversion may be accomplished by:

R 1.164(Y 16) 2.018(V 128)

G 1.164(Y 16) 0.813(U 128) 0.391(V 128)

(2.3)

B 1.164(Y 16) 1.596(U 128)

3. White balance operation in RGB and YUV domains

The white balance operation is defined as a gain correction for red, green and blue components by gain factors AR,

AG and AB, respectively, i.e.

Rwb AR R

Gwb AG G

Bwb AB B

(3.1)

The new (white-balanced) values for red, green and blue are Rwb, Gwb and Bwb. To derive the equivalent form of

this operation in the YUV domain, we proceed as follows. First, write equation (2.1) as

Silicon Imaging , Inc. 2003

Page 19 of 25

Company Confidential

y Cx v (3.2)

where

x ( R, G, B)T is the vector in the RGB space, y (Y , U ,V )T is the corresponding vector in the YUV

space, v

written as

(16,128,128)T , and C is the appropriate matrix of conversion coefficients. Similarly, (3.1) can be

x wb Ax

(3.3)

x wb ( Rwb , Gwb , Bwb )T is the vector in the RGB space modified by white balance operation (2.4), and

A diag ( AR , AG , AB ) . We want to determine what is the corresponding vector y wb in the YUV domain,

without having to revert back to the RGB domain. Vector y wb is found by substituting x wb for x in (3.2)

y wb Cx wb v CAx v .

where

Let

D CA , so that y wb v Dx . Then x D 1 y wb v . Substitute this expression for x back into (3.2)

to obtain

y CD 1 y wb v v (3.4)

This equation provides the connection between y and

y wb without involving x or x wb (i.e. without going back to

the RGB domain). Manipulating (3.4) and using the fact that for nonsingular matrices

get that white balance operation in the YUV domain is

CD 1 1 DC1 [5], we

y wb DC1 y v v CAC 1 y v v (3.5)

Expressing components of

Y

wb

( 0.299AR 0.587AG 0.114AB )(Y 16) ( 0.410AR 0.410AG )(U 128) ( 0.197AG 0.198AB )(V 128) 16

wb

( 0.511AR 0.428AG 0.008AB )(Y 16) ( 0.701AR 0.299AG )(U 128) ( 0.144AG 0.143AB )(V 128) 128

wb

( 0.172AR 0.339AG 0.511AB )(Y 16) ( 0.236AR 0.237AG )(U 128) ( 0.114AG 0.886AB )(V 128) 128

U

V

y wb from (3.5) we get

Terms with leading coefficient less than 103 have been dropped.

References

[1] B. E. Bayer, Color imaging array, US Patent No. 3971065.

[2] T. Sakamoto, C. Nakanishi and T. Hase, “Software pixel interpolation for digital still cameras suitable for a 32bit MCU,” IEEE Trans. Consumer Electronics, vol. 44, no. 4, November 1998.

{3} http://www.northpoleengineering.com/rgb2yuv.htm

Silicon Imaging , Inc. 2003

Page 20 of 25

Company Confidential

Binary to Hex (ASCII) Table

Binary

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

Silicon Imaging , Inc. 2003

Hex in ASCII

0

1

2

3

4

5

6

7

8

9

a

b

c

d

e

f

Page 21 of 25

Company Confidential

SI2100 Senor Cover Glass Dimensions

FRONT VIEW

Silicon Imaging , Inc. 2003

Page 22 of 25

Company Confidential

SI-2100RGB

SAMPLE COLOR IMAGE

Silicon Imaging , Inc. 2003

Page 23 of 25

Company Confidential

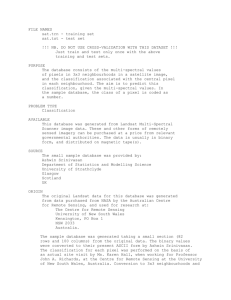

SI2100-RGB Cover Glass Filter Response (IRC-30)

Silicon Imaging , Inc. 2003

Page 24 of 25

Company Confidential

Contact Information

Silicon Imaging, Inc.

www.siliconimaging.com

sales@siliconimaging.com

Ordering Information

SI-2100RGB-U

2.0 Mpixel Bayer Color USB2.0 MegaCamera

Legal Disclaimer

Silicon Imaging reserves the right to make changes to its products or to discontinue any product or service without notice, and advises

customers to obtain the latest version of relevant information to verify, before placing orders, that information being relied on is current and

complete. No license, express or implied to any intellectual property rights is granted by this document.

Specific testing of all parameters of each device is not necessarily performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY,

OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE ("CRITICAL APPLICATIONS"). SILICON IMAGING PRODUCTS ARE NOT

DESIGNED, AUTHORIZED, OR WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF SILICON IMAGING PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT

THE CUSTOMER'S RISK.

The Product described in this datasheet may contain design defects or errors known as errata which may cause the product to deviate from

published specifications. Current characterized errata are available upon request.

Copyright: Silicon Imaging, Inc., 2003

113003-rev 1.0

Silicon Imaging , Inc. 2003

Page 25 of 25

Company Confidential