Basic drive systems

Basic drive systems used on Horticultural Machinery

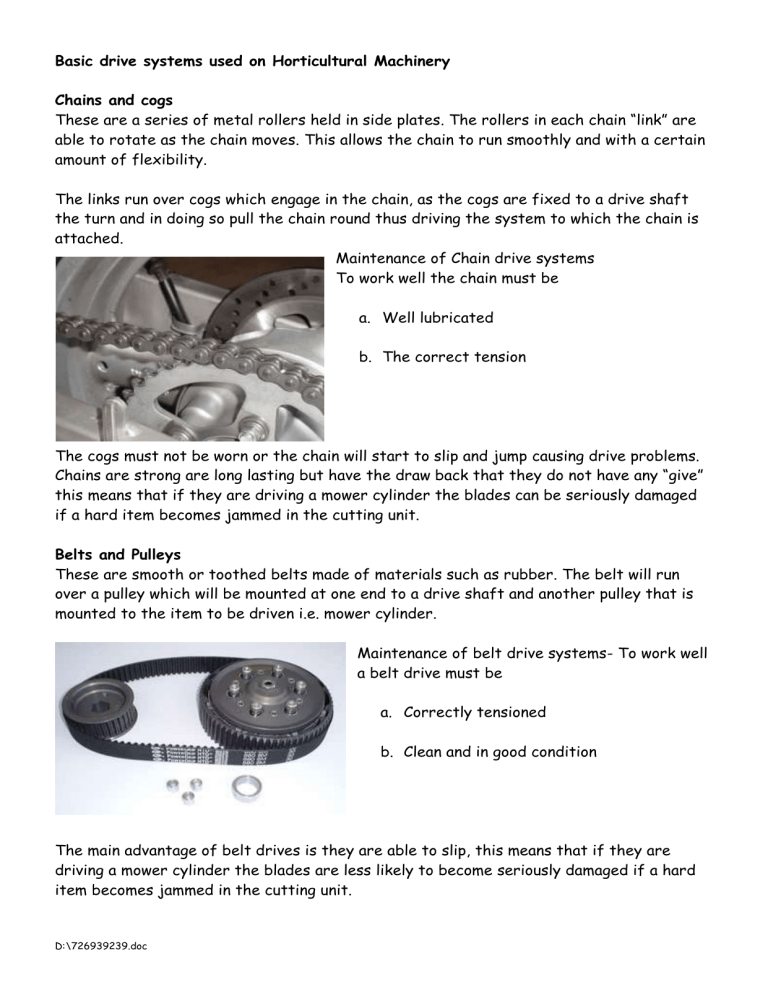

Chains and cogs

These are a series of metal rollers held in side plates. The rollers in each chain “link” are able to rotate as the chain moves. This allows the chain to run smoothly and with a certain amount of flexibility.

The links run over cogs which engage in the chain, as the cogs are fixed to a drive shaft the turn and in doing so pull the chain round thus driving the system to which the chain is attached.

Maintenance of Chain drive systems

To work well the chain must be a.

Well lubricated b.

The correct tension

The cogs must not be worn or the chain will start to slip and jump causing drive problems.

Chains are strong are long lasting but have the draw back that they do not have any “give” this means that if they are driving a mower cylinder the blades can be seriously damaged if a hard item becomes jammed in the cutting unit.

Belts and Pulleys

These are smooth or toothed belts made of materials such as rubber. The belt will run over a pulley which will be mounted at one end to a drive shaft and another pulley that is mounted to the item to be driven i.e. mower cylinder.

Maintenance of belt drive systems- To work well a belt drive must be a.

Correctly tensioned b.

Clean and in good condition

The main advantage of belt drives is they are able to slip, this means that if they are driving a mower cylinder the blades are less likely to become seriously damaged if a hard item becomes jammed in the cutting unit.

D:\726939239.doc

V – Belt

These belts operate on friction, the belt is V shaped in cross section and slots in to a pulley with a similar profile

Section through a V-belt

Clutches

These come in a variety of forms the most common being a dog clutch and a friction plate type clutch.

Dog clutches engage using teeth and are often used in the drive systems of small mowers.

They are robust and are almost maintenance free.

Plate clutches use 2 plates that come together to create drive. The two faces are engaged or disengaged by pulling or pushing on a clutch lever or pedal. This types of clutch are used when the ability to take a machine out of drive for short (i.e. to change gear) periods is required. They are used in cars, tractors and mowers.

As the clutch becomes worn it will begin to slip, this happens because the plates are slowly worn away and after a time no longer have the required grip to operate. When this occurs they require adjustment (normally via a cable) to ensure they operate correctly.

The symptoms of a slipping clutch are a temporary increase in engine revs without forward movement.

D:\726939239.doc