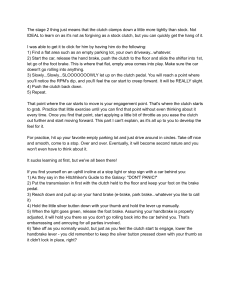

12 Clutch Disengage Travel Adjustment Clutch Assembly

advertisement

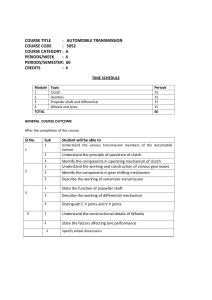

Power Feed Clutch Assembly (showing stepped washer combinations) Clutch Disengage Travel Adjustment Manufacturing tolerance variations combined with wear factors require the need for variable clutch lift off adjustment. Stepped washer (01134) facilitates (4) fixed adjustmnents in .015 increments when used in conjunction with thrust washer (40020) located at the end of the shaft at the gear box. The disengaging lever (01139) mechanism provides overtravel to accommodate the appropriate lift off (not enough stepped washer thickness) will not completely disengage the clutch. A binding will be noticed with manual movement of the slide with clutch disengaged. Proper lubrication between the hub (01124) and segmented ring (01140) will reduce or eliminate the need for readjustment from original factory settings by lubricating the unit periodically at grease fitting (10681) The term “Lift-off” is used to signify the travel of the engagement rod to lift off the clutch -- not including the free-play movement. A minimum of .060 lift off is required to disengage the clutch. The combined stack heights will allow adjustment in .015 increments to obtain the correct measurements. If the lift-off is inadequate, move to the next thicker stack increment. After the clutch disengages properly, remove the four screws and plate covering the observation window. Check to see if the clutch plate and cover are fully meshed together. If not, move to the next thinner stack increment. Clutch Assembly 12 D e tail No. P a rt No. D e sc rip tio n No. R e qd . D e tail No. P a rt No. D e sc rip tio n No. R e q 'd . 1 4 02 91 C onnec to r 1 25 4 03 83 S c re w # 10 -32 2 2 4 04 45 S t rai n r elie f 1 26 4 03 84 S p a ce r, B af fle 1 3 4 02 60 H o us ing , B rus h E nd 1 27 4 02 84 F ie ld A s s y 11 5V (2 w ire ) 1 4 4 02 61 A r ma ture A s sy.- 115 V 1 0 43 08 F ie ld A s s y 11 5V (3 w ire ) 1 4a 0 10 87 A r m ature A s s y. - 2 30 V 1 2 7a 0 10 88 F i eld A s s t 2 30 V 1 5 4 02 62 B e ari ng 2 28 4 02 85 B rush P lug 2 6 4 02 63 S pri ng , F la t 1 29 4 02 86 B rus h C a rb on 2 7 4 02 64 S e al 1 30 4 02 87 B rus h H olde r 2 8 4 02 65 S pri ng , F la t 1 31 L oc tit e 2 71 9 4 02 66 Wa s he r 1 32 4 02 89 S c rew #1 0- 32 x 1/4 " 2 10 4 02 67 B e ari ng 2 33 4 02 90 Wa s he r 1 11 4 02 68 H ous ing, G ea r 1 34 12 4 02 69 G e ar, C lus te r 1 35 4 02 92 R e ta ining R i ng 1 13 4 02 70 G a sk e t 1 36 4 03 48 S e al 1 14 4 02 71 C a p , G ea r H o usi ng 1 37 4 03 49 P lug 1 15 4 02 98 S c re w 1 /4 -20 x 3- 1/2 4 38 4 03 82 B af fle 1 16 4 02 73 Lo ck W as her 1/4 " 4 39 4 04 41 E nd C ap 1 17 4 02 74 B e ari ng 1 40 4 04 49 S p a ce r 2 18 4 02 75 S pri ng , F la t 2 41 4 04 50 S c rew #1 0-3 2 x1 " 2 19 4 02 76 G ea r, O utp ut 1 42 4 02 58 M o to r C o rd ( 2 W ire ) 1 20 4 02 77 P i n, Lo c ati ng 1 0 42 04 M o to r C o rd ( 3 W ire ) 1 9 04 24 C lip , B rus h H olde r 2 21 4 03 50 G re as e , S ynte ch 22 4 02 79 B e ari ng 8 oz 1 23 4 02 80 B a ll 1 24 4 02 81 S lug 1 * 13 L oc tit e 2 42 10925 / 10926 Power Feed Assembly 14 15 10925 / 10926 Mechanical Breakdown 16 Electrical Panel Layout Diagram