Polymer Processing Technologies, Inc

advertisement

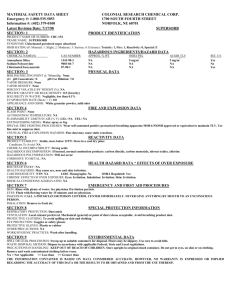

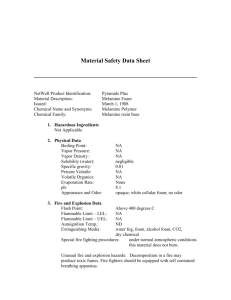

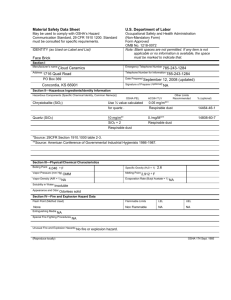

1 Polymer Processing Tech Material Safety Data Sheet page 1 of 6 XpresS-141 A. GENERAL INFORMATION TRADE NAME (COMMON NAME) XpresS-141 . CHEMICAL NAME AND/OR SYNONYM Proprietary Blend FORMULA Proprietary MOLECULAR WEIGHT Mixture ADDRESS (NO. STREET, CITY, STATE, AND ZIP CODE) Polymer Processing Tech. 811 14th St. Galveston, TX 77550 CONTACT Product Safety PHONE NUMBER (409) 770-9809 LAST ISSUE DATE Feb 2012 CURRENT ISSUE DATE March 2005 B. COMPOSITION/INFORMATION ON INGREDIENTS This product is considered hazardous according to the OSHA Hazard Communication Standard 29CFR1910.1200 due to flammable dust potential. If this product is used in a manner that could generate particulates (dust), refer to MSDS Section G, Handling and Storage, and Section H, Recommended Exposure Limits and Personal Protective Equipment. C. HAZARDS IDENTIFICATION EMERGENCY OVERVIEW: WARNING! Product is in powder form. Powdered material in air may form an explosive mixture. Static charges generated by emptying package in or near flammable vapors may cause flash fire. No other significant immediate health, physical, or environmental hazards are associated with this material. POTENTIAL HEALTH HAZARDS: SKIN: Particulates may cause mechanical irritation. EYES: Particulates may cause mechanical irritation. INHALATION: Treat powder as nuisance particulates. May cause respiratory irritation. INGESTION: No effects known. Low toxicity. DELAYED EFFECTS: None known. 2 Polymer Processing Tech Material Safety Data Sheet page 2 of 6 XpresS-141 Ingredients found on one of the OSHA designated carcinogen lists are listed below. Ingredient Name NTP Status * No ingredients listed in this section* IARC Status OSHA List D. FIRST AID MEASUSRES SKIN: Wash thoroughly with water and soap. Get medical attention if irritation develops or persists. EYE: Remove contact lenses. Hold eyelids apart. Immediately flush eyes with plenty of low-pressure water for at least 15 minutes. Get medical attention if irritation persists. INHALATION: For inhalation of powder, remove to fresh air. Get medical attention if nasal, throat or lung irritation develops. INGESTION: Not an ingestion hazard under anticipated conditions of use. ADVICE TO PHYSICIAN: No specific advice. Treat according to symptoms present. E. FIRE FIGHTING MEASURES FLAMMABLE PROPERTIES: FLASH POINT: >450°F (>232°C) FLASH POINT METHOD: Open cup. AUTOIGNITION TEMPERATURE: None known. UPPER FLAME LIMIT (Volume % in air): Not applicable. LOWER FLAME LIMIT (Volume % in air): Not applicable. FLAME PROPAGATION RATE (Solids): Unknown. OSHA FLAMMABILITY CLASS: Combustible solid. EXTINGUISHING MEDIA: Carbon dioxide, dry chemical or fine water spray. Avoid water stream on molten burning material as it may scatter and spread the fire. UNUSUAL FIRE AND EXPLOSION HAZARDS: Fire point > 300°C. Melts in proximity to fires causing slippery floors and stairs. Static charges on powders or powders in liquid may ignite combustible atmospheres. See NFPA Bulletin 654, “Prevention of Fires and Dust Explosions in the Chemical, Dye, Pharmaceutical, and Plastics Industries” for safe handling procedures. SPECIAL FIREFIGHTING PRECAUTIONS/INSTRUCTIONS: Wear self-contained breathing apparatus pressure-demand, approved by MSHA/NIOSH (or equivalent) and full protective gear when fighting fires involving this product. Watch footing on floors and stairs because of possible melting and spreading of material. Use water spray to keep containers cool. HAZARDOUS COMBUSTION PRODUCTS If heated to combustion, the following substances may be formed: carbon monoxide, carbon dioxide, aldehydes, carboxylic acids and smoke. FLASH POINT 450°F Cleveland Open Cup F. ACCIDENTAL RELEASE MEASURES IN CASE OF SPILL OR OTHER RELEASES: (Always wear recommended personal protective equipment.) Remove ignition sources from the material. Keep away from heat or flame. Sweep up with a minimum of dusting. Collect in container, e.g. fiberboard drum or carton. 3 Polymer Processing Tech Material Safety Data Sheet page 3 of 6 XpresS-141 G. HANDLING AND STORAGE GENERAL MEASURES: Ground all equipment. Blanket vessel with inert gas when emptying where flammable vapors may be present. Ground operator and pour material slowly into conductive, grounded chute. Store in a cool, dry, well-ventilated area at approximately 68°F (20°C). Keep container closed when not in use. MATERIALS OR CONDITIONS TO AVOID: Avoid conditions that generate dust; product may form flammable dust-air mixtures. Avoid emptying package in or near flammable vapors; static charges may cause flash fire. Keep away from heat, flame, sparks and other ignition sources. H. EXPOSURE CONTROLS/PERSONAL PROTECTION WORK PRACTICES & ENGINEERING CONTROLS: Eyewash fountains and safety showers should be easily accessible. Use process enclosures, local exhaust ventilation, or other engineering controls to control airborne levels below recommended exposure limits. Discharge from the ventilation system should comply with applicable air pollution control regulations. GENERAL HYGIENIC PRACTICES: Avoid contact with eyes, skin, and clothing. Avoid breathing dust. Avoid contamination of food, beverages, or smoking materials. Wash thoroughly after handling, and before eating, drinking or smoking. Remove contaminated clothing promptly and clean thoroughly before reuse. RECOMMENDED EXPOSURE LIMITS PARTICULATES (dust): If used under conditions that generate particulates (dust), the ACGIH TLV-TWA of 3 mg/m³ respirable fraction (10 mg/m³ total) should be observed. PERSONAL PROTECTIVE EQUIPMENT: Safety glasses Impervious gloves Appropriate protective clothing Appropriate respiratory protection is required when exposure to airborne contaminants may exceed acceptable limits. Respirators should be selected and used in accordance with OSHA, Subpart I (29 CFR 1910.134) and manufacturers recommendations. PROTECTIVE MEASURES DURING REPAIR AND MAINTENANCE Eliminate ignition sources and prevent build-up of static electrical charges. Completely isolate and thoroughly clean all equipment, piping, or vessels before beginning maintenance or repairs. Keep area clean. Product will burn. 4 Polymer Processing Tech Material Safety Data Sheet page 4 of 6 XpresS-141 I. PHYSICAL AND CHEMICAL PROPERTIES APPEARANCE: White powder. PHYSICAL STATE: Solid. ODOR: Characteristic waxy odor. SPECIFIC GRAVITY: (Water = 1.0) 0.93-1.1 SOLUBILITY IN WATER: (Weight%) Negligible at 20°C pH: Not applicable. BOILING POINT: Not applicable. MELTING POINT: 97-104°C (207-220°F) VAPOR PRESSURE: Negligible at 20°C. VAPOR DENSITY: (Air = 1.0) Not applicable. EVAPORATION RATE: Not applicable. Compared to: Not applicable. % VOLATILES: Negligible at 20°C. FLASH POINT: > 450°F (>232°C). (Flash point method and additional flammability data are found in Section D.) J. STABILITY AND REACTIVITY NORMALLY STABLE? (Conditions to Avoid) Stable under recommended handling and storage conditions. INCOMPATIBILITIES: Strong oxidizing agents and amines. HAZARDOUS DECOMPOSITION PRODUCTS: Depending on conditions of fire, CO, CO , carboxylic acids, aromatic aldehydes and combustible gases may be generated. HAZARDOUS POLYMERIZATION? Not anticipated under normal or recommended handling and storage conditions. 2 K. TOXICOLOGICAL INFORMATION CARCINOGENICITY INFORMATION Not listed as a carcinogen by NTP. Not regulated as a carcinogen by OSHA. Not evaluated by IARC. REPORTED HUMAN EFFECTS No human toxicity studies have been carried out with this product. Due to the physical nature of this material may cause eye, skin and respiratory irritation. REPORTED ANIMAL EFFECTS PRODUCT/SIMILAR PRODUCT – Not toxic by OSHA?ANSI criteria based on acute animal peroral testing of this or a similar product (LD50>500 mg/kg). OTHER DATA: No other data developed. L. ECOLOGICAL INFORMATION No data have been developed on this subject. This polymeric product is not soluble in water. It is not considered biodegradable. 5 Polymer Processing Tech Material Safety Data Sheet page 5 of 6 XpresS-141 M. DISPOSAL CONSIDERATIONS WASTE DISPOSAL CONSIDERATIONS: The information offered here is for the product as shipped. Use and/or alteration to the product such as mixing with other materials may significantly change the characteristics of the material and alter the RCRA classification and the proper disposal method. Landfilling in a permitted solid or hazardous waste facility is recommended. Handling, transportation, and disposal of material should be conducted in a manner to prevent a nuisance dust hazard. Fully containerize the material before handling, and protect from exposure to the outdoors. Ensure there are no restrictions on disposing of bulk or semi-bulk quantities of waste material. Disposal should be in accordance with all Federal State and local regulations. N. TRANSPORT INFORMATION GENERAL This product is not subject to DOT, ICAO, IMDG or ADR regulations. For additional information on shipping regulations affecting this material, contact the information number found on the first page. O. REGULATORY INFORMATION CHEMICAL INVENTORIES: U.S. TSCA Inventory Status: Product components are listed on the TSCA Chemical Inventory. Canadian CEPA: Product components included on DSL Inventory Australian AICS: Product components included on AICS Inventory SARA TITLE III: RQs & TPQs “Reportable Quantities” (RQs) and/or “Threshold Planning Quantities” (TPQs) exist for the following ingredients. SARA/CERCLA SARA EHS Ingredients RQ (lbs.) TPQ (lbs.) *No ingredients listed in this section* Spills/releases resulting in the loss of any ingredient at or above its RQ requires immediate notification to the National Response Center (1-800-424-8802) and to your Local Emergency Planning Committee. SECTION 311 AND 312: NHH: Not a health hazard HC-3: Fire hazard SARA 313 TOXIC CHEMICALS: The following ingredients are SARA 313 “Toxic Chemicals”. Ingredient Comments *No ingredients listed in this section* STATE RIGHT TO KNOW: The following is listed for state right-to-know purposes: Ingredient Wt.% Comment *No ingredients listed in this section* 6 Polymer Processing Tech Material Safety Data Sheet page 6 of 6 XpresS-141 P. OTHER INFORMATION -HMIS Code: Health Flammability Reactivity 0 1 0 DISCLAIMER: This Material Safety Data Sheet is offered solely for you information, consideration and investigation. The information and recommendations contained in the Material Safety Data Sheet have been compiled from sources believed to be reliable and to represent the most reasonable current opinion on the subject when the MSDS was prepared. No warranty, guaranty or representation is made as to the correctness or sufficiency of the information. The user of this product must decide what safety measures are necessary to safely use this product, either alone or in combination with other products, and determine its environmental regulatory compliance obligations under any applicable federal or state laws. Current Issue: Feb. 2012, Changed co. name