L. Gene Cone

advertisement

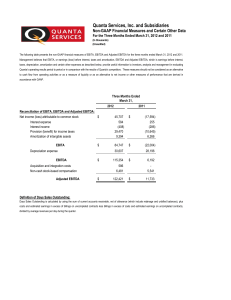

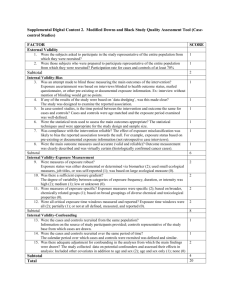

Executive Resume L. Gene Cone 7408 Rolling Bend Court Columbus, GA 31904 Phone: (706) 341-5922- Email: genecone@aol.com Leadership Profile International Sales/Marketing, Operations, Market Penetration, Strategic Planning, Best Practices, Mergers and Acquisitions, Startups, Restructures, and Turnarounds, Product Development, Process Improvement An innovative, entrepreneurial, and results-driven senior leader with a demonstrated track record of exceptional results in highly competitive environments, including top- and bottom-line growth. Detail-driven, technologysavvy, effective business builder and mentor with a keen insight into solving business problems. Adept at creating synergies, building partnerships with key customers, suppliers, and service providers. Possess the creative vision and knowledge of market needs to capitalize on new business opportunities. Led new entries into domestic and international markets at start-up companies, divisions of Fortune 500 companies and mid-size companies; expanded and developed new products, markets, and customers. Defined and led business sales and acquisitions and developed international sourcing strategies. Led the turnaround of a major, once-public company, increasing gross margin income by 10 percent, reducing annual costs by $30 million, and bringing EBITDA from nearly ($10 million) to $20 million, as illustrated below: EBITDA Turnaround $25 $20 Millions $15 $10 $5 $$(5) $(10) Year 1 Year 2 Year 3 Year 4 Professional Experience DRIFIRE, LLC President/CEO Columbus, Georgia/Chicago, Illinois 2007 to 2010 Recruited by a private equity firm to start up this new technology-based business that manufactures advanced protective uniforms for military and commercial markets. Built the organization and infrastructure from the ground up; established a business plan and organization vision. Developed the product line and marketing/branding plan; implemented financial/cash flow management systems; cultivated manufacturing and channel partners, and built a comprehensive customer base. Assembled a full leadership team and a complement of talented staffers. Provided hands-on leadership in implementing an SAP system in less than three months, and forged a multi-functional global supply chain with over 50 partners. Served on the board of directors. Grew the company from zero sales; far exceeded the first year’s revenue and profit projections and doubled revenues in the second year. Led the development of more than 60 new proprietary products focused on market needs, customer expectations, sustainable competitive advantages. Several of the products were submitted for patents. Positioned the company brand as a recognized market leader, evidenced by exclusive positions in several major new market categories. Received 2008 Chicago Innovation Award for DRIFIRE product line, based on high level of acceptance and use of the product in the wars in Iraq and Afghanistan. Directed the development of an award-winning website and ecommerce platform to build brand recognition; achieved first-place level on three of the major Web search engines. L. Gene Cone Johnston Industries Inc. President/CEO Page 2 Columbus, Georgia 2001 to 2007 Recruited by private equity firm to lead the recovery of this troubled $330 million company with 11 domestic manufacturing/distribution locations and international sales in 25 different countries. Conducted a comprehensive evaluation of the management team and recruited top talent in finance, sales, manufacturing, international sourcing, and IT to overcome management deficiencies. Flattened the organizational structure, establishing incentive programs at every level and implementing communication and feedback vehicles. Led the team in developing new products, new markets, cost reductions, gross margin improvements, and international supply chain expansions. Restructured the entire business and positioned it for a successful sale. Served on the board of directors. Directed the identification and implementation of $50 million in annual cost reductions in operations; boosted EBITDA $30 million in the first year. Increased gross profit margin 10 percent in the first two years. Provided leadership in the launch of 25 new products, yielding $45 million in new revenues. Expanded business into six new U.S. markets and ten new countries. Established international supply chain systems with 20 foreign countries, slashing costs 20 percent. Negotiated with financial partners to facilitate the final full debt restructuring. Completed the process in 10 months, reducing debt by $70 million. Recognized as supplier of the year for 2002 to 2005. American Fiber & Finishing, Inc. President/CEO Westford, Massachusetts 1994 to 2001 Recruited by the purchasers of a division of Colgate Palmolive to rationalize the business, develop the strategic growth plan, and build the needed management team to facilitate growth. Opened new markets, led the development of new products, secured new strategic customers, negotiated long-term agreements, and led the modernization of manufacturing, including construction of a new state-of-the-art facility. Directly negotiated and secured long-term contracts with new customers such as J&J, Kendall, Baxter Healthcare, 3M, Boeing, Lockheed/Martin, Wal-Mart, Pfizer, and Merck. Led the development of 20 new products for 4 new markets, boosting sales by $50 million in six years. Built a top-talent sales and marketing team to increase sales to $75 million/year; boosted gross margins from 20 percent to more than 40 percent. Reorganized manufacturing management areas—directed the implementation of cost reductions of $15 million/year, improved quality levels from 88 to 98 percent, and increased on-time deliveries to 99 percent. Directed the shutdown of a high-cost 150-year old manufacturing site and the start-up of a new modern manufacturing facility, doubling manufacturing capacity and reducing manufacturing costs by 25 percent. Received recognition as supplier of the year for 1995 to 2001. Bulwark Protective Apparel, Inc. President Houston, Texas 1993 to 1994 Hired by private equity group to work with company founders to expand manufacturing, sales, and marketing from Canada into the United States. Recruited and provided leadership for the U.S. sales team—established territories, quotas, and incentive plans. Initiated quality and process controls, developed new products and designs, and secured new major customers. Served on the board of directors. Led the development of more than 25 new U.S. customers, doubling the business. Established a modular manufacturing and distribution center in Houston that facilitated doubling of the company’s revenue. Key player in positioning the company for successful and profitable sale. L. Gene Cone Springs Industries Inc., Protective Fabrics Division Division President/Corporate VP/General Manager Page 3 New York, New York 1988 to 1993 Recruited by company chairman to develop a new technical fabrics business for this $2 billion textile manufacturing corporation. Authored a business plan, recruited and hired a top-talent team of finance, R&D, sales, marketing, manufacturing, quality, and IT professionals. Provided leadership in the development of new products, strategic manufacturing and marketing/branding plans, systems, processes, and controls. Initiated the business platform to grow the new company from zero to $85 million in sales in five years. Positioned the business for sale to a group of investors. Led the development of over 20 new proprietary products, 10 resulting in patents. Led the start-up and management of two new manufacturing facilities with new proprietary manufacturing processes and technologies, achieving gross margins of over 45 percent. Received innovator of the year award in 1990. Miltex Textiles, Inc. President/Founder Guttenberg, New Jersey 1987 to 1988 Founded this business to assist service apparel/textile manufacturers in the improvement of their cost structures, to effectively bid on contracts, and to supply products to U.S. and foreign governments. Built the customer base to include 25 corporate clients, including Springs Industries, whose CEO subsequently invited me to drive a new venture for Springs Industries. Established systems and processes, training prime military contractors in the entire qualification and supply process to successfully bid on and secure U.S. government contracts. Provided training and mentoring to contractors in meeting the stringent requirements of the U.S. government. Employment Prior to 1987 Served as vice president of sales for the specialty industrial fabrics division of Burlington Industries, leading the both international and domestic marketing, sales, forecasting, and new product development for all specialty industrial fabrics. Within one year, established a system to sell fabrics directly to the U.S. Military, resulting in the establishment of the new military fabrics division; promoted to vice president/general manager of this division. Significant accomplishments during this period include: Evaluated all management systems and processes; implemented new systems, cutting costs by 15 percent. Led the development of numerous new coated, dyed, or uniquely finished products for the awning, tent, truck tarp, marine, bill board, ballistics, fire fighter, and chemical protection markets worldwide. Launched over 30 new military products, most having civilian and foreign military applications. More than 20 new patents issued. Led the growth of sales in the new military fabrics division from zero to $100 million in less than two years. Directed the efforts of all 10 company divisions in marketing and sales of apparel, home-furnishing, industrial, and other technical fabrics to the domestic and foreign governments, generating $300 million in sales. Received the industry award of excellence in 1985 and the division manager of the year award in 1986. Education/Professional Development Ongoing professional development courses, including training in Six Sigma, lean manufacturing, Kepner Tregoe systematic problem solving, and a three-week leadership and team building training course with Tom Steitz, former Olympic Coach. Master of Science in Management, LaSalle University, Manville, LA—1992. Number one position in Masters of Science-Management class—4.0 GPA. Bachelor of Science in Engineering, University of Florida, Gainesville, FL—1980. Key Accomplishment Summary L. Gene Cone Rescued a Company from Bankruptcy and Successfully Sold It Situation: A 50-year-old public company that manufactured premier technical textile products for the automotive, power transmission, wind energy, office, hospitality, medical, and general industrial markets worldwide had grown to annual revenues of $500 million through acquisitions and mergers. This created an unsustainable debt load of $130 million and overextended credit. Its stock price declined and the company became a prime candidate for takeover. A major private equity firm bought the company and took it private. The first order of business was a major reengineering, as costs had spiraled out of control, employee morale had hit bottom, and the management team was without leadership due to the recent death of the CEO. Business processes were inefficient and the product line had been neglected to a point where it was in free fall. There was no capital for a much-needed modernization. Gross margins continued to decline with commodity cost increases and market pricing pressures. Action Plan: Created a long-term strategic plan focused on building sustainable competitive advantages in the worldwide marketplace; designed a comprehensive restructuring plan to right-size operations and eliminate excess costs. Evaluated existing management structure and team—flattened the organization, hired top talent, and established focused key performance indicators (KPI) and goals for managers. Conducted a company-wide meeting to present the reengineered company vision, core values, and build a basis for a team-oriented culture to achieve bottom-line goals. Implemented $30 million in annual operational cost reductions through lean manufacturing and six sigma processes to ensure ongoing cost reductions and profits improvement. Implemented company-wide compensation programs to reward superior performance and improve team efforts. Implemented comprehensive pricing and cost models, increasing gross margin income 10 percent in two years. Led the total rationalization of the company’s product line, eliminating 20 marginal or unprofitable products– replaced these with new products exceeding 40 percent GM targets. Established a focused product development team and led the development and launch of over 25 new products. Established international supply chain systems, including purchasing, production planning, inventory control and cost reductions. Sourced products from over 20 foreign countries. Modernized the manufacturing plants, increasing production and cutting costs within two years. Negotiated debt restructuring with financial stakeholders; reduced debt by $100 million within three years. Created the marketing presentation that resulted in the sale of the three divisions of the company to two different private equity firms and a strategic investor. Results: The reengineering process yielded swift results. Within six months, reduced annual expenses by $25 million while maintaining the continuity of distribution systems. Streamlined the operational infrastructure to increase efficiency within budget constraints. By the end of the first year, developed and launched 25 new products to 30 new customers and expanded the international supply chain to include 20 foreign countries—doubled margins while cutting costs 20 percent and realizing a $30 million EBITDA improvement. Secured $45 million in ongoing, sustainable revenue. Grew EBITDA to $20 million within the two years; consumer confidence and employee morale were restored. The company was successfully sold within three years. Key Accomplishment Summary L. Gene Cone Envisioned and Grew a Startup Company from Zero to $85 Million in Five Years Situation: The U.S. protective uniform market was growing rapidly due to OSHA regulations designed to protect firefighters and workers in other hazardous environments. The primary product in the market was limited in its performance attributes and there was no major competition for its primary suppliers. Customers, including the U.S. Military, were looking for improvements in performance, quality, design, and service that were not being provided by existing suppliers—this opened a large opportunity to become a successful provider for this market. Major fires at hotels, dormitories, and hospitals had also created a need for fireproof mattresses and bedding. Action Plan: Envisioned the business concept, secured an investor, and led the start-up of a new technology company to meet the needs of customers in the commercial, military, and bedding markets worldwide. Recruited a top-graded management team and established success metrics. Hired and trained all sales, marketing, research and development, quality, customer service, and operations staff. Provided leadership in the design of all systems, procedures, installing an ERP system in record time. Led the development of over 20 new proprietary products, 10 resulting in U.S. patents that provided solutions to meet customer needs and gain a competitive advantage. Collaborated with the marketing staff to design create trademarks and patents to gain a dominant market share. Positioned company brands as recognized market leaders with exclusive positions in major market categories. Negotiated partnerships and contracts with domestic and international technology suppliers, developing numerous sustainable competitive product and market advantages. Identified new manufacturing technologies to greatly increase quality and productivity and reduce manufacturing costs. Oversaw two new manufacturing facilities with these proprietary manufacturing technologies, achieving gross margins of over 45 percent for new products. Identified opportunities for flame -resistant protective mattresses and bedding for worldwide hotel, college dormitory, and hospital markets. Created cost-effective solutions for safety issues, leading to U.S. government legislation for these types of products in all mattresses sold in the U.S. today. Results: Grew company revenues from zero to $85 million in five years with an annual EBITDA of $14 million, as illustrated below. The two new state-of-the-art manufacturing facilities have forced previously complacent competitors to adapt to stay competitive. The new trademarks are still recognized as market leaders and are recognized internationally for the protective properties they provide to end users. The company was purchased at an ROI of more than 10 times the original investment. Today the company is still a market leader, created from a vision developed to meet market needs. Business Success $90 $80 $70 Millions $60 $50 $40 $30 $20 $10 $Year 1 Year 2 EBITDA Year 3 Revenue Year 4 Year 5 Key Accomplishment Summary L. Gene Cone Catapulted Revenues by $50 Million in Record Time Situation: Two executives purchased the industrial technical textile fabrics division of the Colgate Palmolive Corporation and wished to bring the company into new domestic and international markets. The division had an antiquated product line and declining sales combined with an eroding manufacturing base, which threatened to end the business. There were some good niche markets and proprietary manufacturing capabilities in place, but needed good leadership to build on its strengths and open new opportunities for growth and profitability. One obstacle to growth was outdated manufacturing capacities and capabilities, but capital was tight. Recruited to lead this new company into the future. Action Plan: Envisioned and led the implementation of the company’s long-term strategic plan focused on growing top-line revenue and bottom-line profitability, primarily through organic growth of new products and markets. Established best practices and implemented key performance indicators (KPI) to manage performance. Personally identified, negotiated, and secured long-term supply contracts with major medical, aerospace, industrial, and consumer companies. Provided leadership for the sales/marketing team to build increased sales and margins while establishing worldclass customer service and extensive customer partnerships (both domestic and international). Reorganized manufacturing management areas and directed the implementation of major cost-reduction initiatives, quality improvements, process control procedures, and increased employee involvement. Led the development of numerous new products, markets, and customers, yielding increased sales, margins, and sustainable competitive advantages. Expanded and modernized manufacturing facilities with limited capital by purchasing a closed fully-equipped facility. Sold the excess equipment, which paid for the purchase of the property and new equipment; shut down the high-cost 150-year-old manufacturing site. Established international sourcing relationships and expanded international sales of medical/industrial products. Results: Within the first six months, developed 20 new products and opened 4 new markets. Expanded and modernized the company’s manufacturing for 10 percent of the cost of building new facilities, reducing costs by more than 30 percent. Within four years, tripled revenue from $25 million to $75 million and doubled margins; increased annual EBITDA from $1 million to $12 million, as illustrated below: Company Growth $80 $70 Millions $60 $50 $40 $30 $20 $10 $Year 1 Year 2 Year 3 EBITDA Year 4 Revenue Year 5 Year 6 Executive Insights L. Gene Cone Building Highly Successful Companies in a Global Marketplace Highly Effective Leadership Successful companies are led by highly effective leaders who are results-driven visionaries and innovators. Leadership by example starts right at the top—the CEO must set the example by building and maintaining an execution-focused corporate culture. President Truman said “the buck stops here”; the CEO is ultimately responsible for the company’s success and must lead the team in accountability for achieving its goals. The CEO ensures the company’s goals and milestones are well defined, clearly communicated, understood, and embraced by all employees. Goals and milestones must be constantly reviewed to ensure they are accomplished on time and revised to ensure they continue to meet the company’s vision. A Winning Team of Professionals Teams exist for one reason: to achieve results. Winning teams must be sustainable to continue producing results; it is important to understand that winning teams start with winning individuals who possess superior skills. It begins with the hiring process—leadership must seek out team members who have the critical skills for their positions. Ideal team members are highly intelligent and collaborative; they also have a winning attitude and exercise selfleadership behaviors. Successful leaders set the pace by setting tough goals and working alongside the team to achieve them. When goals are reached, the team celebrates together with a spirit of pride and accomplishment. Strong and Effective Business Processes Successful leaders focus on achieving business effectiveness and efficiency while striving for innovation, flexibility, and technology integration. The purpose of a defined business process is to establish goals, measure, analyze, improve, and purposefully achieve them. Effective processes span all aspects of the business, including employee goals/objectives, manufacturing performance, product attributes, sales performance, marketing effectiveness, customer satisfaction, and the company’s ultimate profitably. Implementing “best practices” in each area will ensure excellence and continual improvement. “If it is not measured it is not managed.” Comprehensive Strategic Planning The world and the marketplace are constantly changing; therefore, it is critical to have a comprehensive strategic plan for guiding the company. The plan starts with the identification of strengths and weaknesses and an analysis of the company’s competitive position in its target markets. Once these factors are determined, a strategic plan will build on the company’s strengths and overcome any weaknesses. Strategic planning should be an integral part of a business—every action taken should have alignment with the company’s overall plan. This means that every employee knows the plan and, more importantly, his or her role in making it happen. Strategies should be dynamic and be revisited and revised at regular intervals, related to how quickly the industry is changing. Global Competitive Advantage The world seems to be getting smaller as time goes on, yet it is a larger market for today’s “globally minded” business leaders. Successful 21st-century companies recognize that their business strategy must have a global focus to remain competitive. Global strategies include international sales and marketing strategies, integrated supply chain systems, e-commerce sales strategies, strong branding strategies, continuous product innovations, and joint ventures. Executive Insights L. Gene Cone Creating Value in a Twenty-First Century Company Sustainable Competitive Advantage The best way to create economic value in a company is by developing sustainable competitive advantage. Competitive advantage exists when an organization develops attributes that allow it to outperform its competitors in the marketplace. The most important elements of competitive advantage are uniqueness, superiority to the competition, difficulty in replicating, sustainability, and repeatability. Competitive advantage promotes sustainable growth, provides the competitive edge, builds long-term value, and produces extraordinary profits. Innovative companies that develop products, processes, services, intellectual properties, brands, competencies or strategies will continually deliver superior rewards to its stakeholders. Customer-Focused Partnerships Customers demand quality products, superior service, and response to their issues and needs. Customer feedback provides the opportunity to create solutions that will build customer loyalty. This involves truly listening to a customer’s issues/needs and partnering with them to develop solutions. Solutions developed in partnership with customers will provide a win-win situation. The company gains sustainable competitive advantage in revenues, profitability, customer retention, and customer loyalty. Customers feel valued and will share their superior customer experience with others. These relationships must be the DNA of all companies and must be led from the top. Strategic Innovation A successful company recognizes that new product and market developments are the lifeblood of the future. It is crucial to develop and maintain an abundant pipeline of new products and service concepts based on the company’s markets. These can be product line extensions or new intellectual property. Innovation must be an integral element of the strategic plan; processes and procedures must be put in place to continually drive innovation throughout the organization. It is everyone’s job to be an innovator—the sales force talking to customers about new opportunities, manufacturing personnel developing new processes, R&D evaluating new technologies, corporate management evaluating new acquisitions, to name a few. Everyone in the company must participate and be measured/rewarded for innovation. Market Leadership One of the most important characteristics in becoming a good company is market leadership. It can come in many forms, but the critical element is the reputation that comes along with it. Superior companies know and understand their markets, their competitors, and the barriers to entry in their given markets. Overcoming sustainable barriers to entry will create tremendous value in a company and should be a center point of a company’s strategic plan. Market leadership can be achieved by building strong brands, developing new technologies, integrating strong supply chain systems, and implementing effective e-commerce sales. Other key factors can be joint ventures, acquisitions, and international sales/marketing strategies. Significant value creation comes when the company achieves the label "market leader" and should be the goal of all superior companies. Best Practices A “best practice” can be defined as the most efficient and effective method, process, activity, or incentive that can deliver superior results in all aspects of company management. Highly successful companies will continually refine and improve the implementation of best practices in all areas. “Key performance indicators” are put in place to measure and manage company practices, including sales, marketing, human resources, product development, customer service, branding, e-commerce, and financial indicators (revenue, costs, margins, profits, cash flow).