Woody 2000 Project Comparative Analysis Exhibit C

advertisement

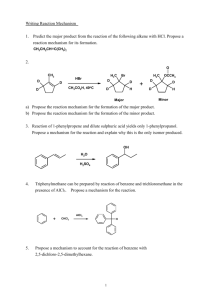

Woody 2000 Project Comparative Analysis EXHIBIT C The following Table is a comparative analysis of the original project management processes to the new proposed Project Management Plan. Preconstruction Phase Original Plan The financial Performa and cash flow was not prepared as a tool to be used during the entire duration of the project. The accounting was performed with the operational bookkeeping and not as a separate accounting system. An inexperienced owners representative was selected who was not aware of the project management processes to be followed. There was not a defined PMLC model designated for the project. There was not a defined design development process that included strategic planning sessions. The project programming was done in an unorganized fashion. The contractor was selected without undergoing a competitive bidding process. The contract was cost plus with an open end with no defined completion dates. There was a lack of communication between all parties causing the building design to be constructed 5 feet short to allow for the production train. A complete project schedule with critical milestones was not completed and there was no accountability for not meeting the schedule. The contract had no provision for not meeting the schedule. There was no provision for maintaining production of new and existing contracts during the construction process causing the loss of key projects and potential revenues. There was not a definite strategy for sales and marketing of the new facility. Proposed Plan A concise and detailed Performa will be completed and the cash flow will be an intricate part of the construction process. A separate chart of accounts will be maintained in order to track expenses on a real time basis. We would recommend an experienced owners representative be selected who is familiar with construction practices. We are proposing the Adaptive Project Framework of the Adaptive PMLC model. We propose to complete a concise design development process that includes a system for documenting needs using strategic planning and departmental focus groups. We propose a complete contractor selection process that is with prequalified competitive bids. The contract would be based on a cost plus with a guaranteed maximum price. We propose a communications plan that has standards and procedures for communicating needs, making decisions, and communicating information to all necessary parties. We propose a concise Overall Project Schedule with critical milestones identified. The GMP contract would be tied into the schedule and there would be liquidated damages levied for not meeting the schedule. A complete project mobilization and sequencing plan would be in effect to ensure that there would be no interruption to existing production lines. Production staff would be involved in focus groups. We would propose that a complete sales, marketing, and promotion strategy be in place. Construction Phase Original Plan There were no processes in place for the approval of submittals and other key construction phase systems. There was not a well defined Risk Management Plan for the project and there were no provisions for identified risks. There was not a schedule management plan in place with clear lines of accountability. There was a regulatory issue with the newly installed paint shop. There were standardized project management processes in place that would interface the owner with the selected contractor. There were no consistent project meetings held and no meeting minutes or documentation There was not a Budget Management process in place for tracking the original budget to actual completion percentages There were problems with the utility tie ins and coordination with the various utility companies. The Certificates of Occupancy and Completion Certificates were not secured by the contractor causing a delay to the schedule. Proposed Plan We propose a well developed implementation plan that includes processes for submittal review and other key processes. We propose a concise Risk Management plan that includes assessment and identification, monitoring and control, and mitigation. We would develop a concise Overall Project Schedule with accountability processes. We would ensure that all necessary approvals would be in place by the regulatory agencies. A complete Project Management Manual would be prepared that define all processes within the project. Weekly project meetings would be held with detailed meeting minutes as defined by Roberts Rules of Order. We would have a complete Budget Management plan in place that includes real time updates to actual expenditures versus projected budgets. We would oversee and manage the coordination of all utility tie ins and schedule accordingly. We would have a process in place for securing the necessary Certificates and have identified these tasks on the Overall Project Schedule. The construction phase would be managed based on the final Project Management Manual. There would be various processes in place that deals with communications management, risk management, quality assurance, and overall project management planning. The original process for the Woody 2000 project was very fragmented with no clear lines of responsibility and accountability. The post construction process would include proper commissioning of systems and the training of personnel on the new systems installed. A post-implementation audit and a Final Report would be completed. The production train start up and employee training would be part of the post construction process and it would be clearly defined and scheduled accordingly to meet expected deadlines. The proposed project management plan would be diametrically different than the original process defined for the Woody 2000 proposed project.