In brief

advertisement

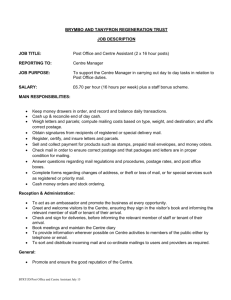

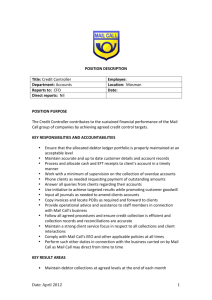

19 DECEMBER 2014 OPTIMISED MAIL PREPARATION: POSTAL COMPARATORS The Postal department is currently in talks with Royal Mail regarding Optimised Mail Preparation including ‘Bench Merging’. The Postal Executive was recently given a slide presentation showing a number of European postal operators who use the same or similar methods. The following information has been requested for each of these comparator postal operators: How many days per week they deliver mail; What time constraints there are within their universal service obligation; The date they moved to optimised mail preparation and the impact; Any other relevant points for comparison. The information that is available on each of these points is detailed in the following pages. 1 International Comparisons Although it doesn’t cover all of the requested postal operators, the November 2013 WIK-Consult report for Ofcom: ‘Review of Postal Operator Efficiency’1 provides a comparison of the mail operations at Austria Post, Deutsche Post, Post Danmark, PostNL, Posten and La Poste in 2012: The table below summarises key indicators among these postal operators: 1 WIK-Consult, ‘Review of Postal Operator Efficiency’ November, 2013, p.28: http://stakeholders.ofcom.org.uk/binaries/post/postal-efficiency/wik.pdf 2 The report also identified the following trends in new mail sorting technology:2 2 WIK-Consult, op.cit., p.26 3 Deutsche Post Universal service obligations Deutsche Post delivers 6 days per week.3 The German USO includes single piece letters and parcels.4 Delivery timescale requirements for priority letters are D+15 >80% and D+2, 95%; and for parcels D+2 >80%.6 3 WIK-Consult (2013) Review of Postal Operator Efficiency’, p.28. ERGP (2014) Report on the Benchmarking of the Universal Service Tariffs, p.8. 5 Day of posting plus one working day. 6 UPU, Country information on the universal postal service: Germany, p.6: http://www.upu.int/fileadmin/documentsFiles/activities/regulatoryIssues/deuEn.pdf 4 4 Optimised mail preparation details 5 6 7 8 9 Post NL Universal service obligations Post NL used to deliver 6 days per week, however, it was successful in pressuring the Dutch government to downgrade the USO to five days per week and so in 2014 Monday deliveries were stopped.7 The Dutch USO includes single piece letters and parcels.8 The Dutch Postal Act 2009 does not require PostNL to offer domestic services for the delivery of bulk parcels, bulk mail or unaddressed mail items. International outbound bulk mail and parcels are also part of the Universal Postal Service.9 Post NL is required to deliver on average no less than 95% of all standard single-rated domestic letters posted the day before, except on Sundays, public holidays and, as of 1 January 2014, Mondays. Urgent medical items and funeral cards are still delivered on Mondays.10 7 http://postandparcel.info/61050/news/companies/postnl-in-buoyant-mood-after-axing-mondays/ ERGP (2014) op.cit. 9 PostNL Annual Report 2013, ‘Postal Regulation in the Netherlands’: http://annualreport2013.postnl.com/report-ofthe-board-of-management/regulatory-environment/postal-regulation-in-the-netherlands 10 Ibid. 8 10 PostNL (formerly TNT) is the only fully privatised postal operator in Europe. PostNL evolved from the demerger of TNT Express and TNT in 2011 and is focused on the Dutch mail and parcel business as well as mail operations in Germany, Italy and the UK. PostNL is organised in three divisions: “Mail in the Netherlands”, “Parcels” and “International” Since 2001, the company has been reorganizing its delivery operations in order to reduce labour costs (“Master plan”). The “Master plan” has been subject to several revisions since. Employment (in full time equivalents, FTE) has declined by 20 per cent between 2008 and 2011. In 2012 around 72 per cent of the FTEs were assigned to “Mail in NL”. More importantly, the share of part-time workers, that is traditionally very high in Dutch postal operations, increased substantially: from 56 per cent in 2008 to nearly 80 per cent in 2011. This increase reflects one of the major instruments of the “Master plan”: the substitution of full-time postmen by part-time deliverers. Optimised mail preparation details PostNL has about 19,000 post boxes and 2,375 franchised postal outlets (post shops). Additionally, PostNL has 225 business centres mainly located in business areas. Mail collection is organised by a dedicated transportation unit within PostNL (“Autobedrijf” became operational in 2011). This unit is responsible for all small transportation movements in the organization, including pick-up services for business customers and delivery services to business customers. Mail from post boxes, post shops and business customers is transported to local hubs (usually delivery offices) where the mail is consolidated for transport to the next sorting centre. 11 12 13 14 15 16 17 18 19 Austria Post Universal service obligations The Austrian USO requires deliveries 5 days per week (Monday to Friday)11 (although 6 days per week for newspapers)12 and includes single price letters and parcels, bulk letters and bulk parcels.13 The delivery timescale requirement for priority letters is 95% D+1 and for parcels 90% D+2.14Since 2011, business customers have had the option of using a D+3 letter delivery service at a cheaper price, provided they post at least 1,000 items.15 Around 21,100 employees (headcount) work for the parent company, of which about 16 per cent are on a part-time basis (mainly female employees). This share has not changed since 2007. Nearly half of the employees are civil servants. Around 9,000 employees work in mail delivery. Nearly 1,700 employees (including temporary staff) work in parcel operations, of which less than 100 have part-time contracts.16 Optimised mail preparation details 11 WIK-Consult (2013) op.cit. ERDP (2014) op.cit., p 10. 13 Ibid. 14 UPU, Country information on the universal postal service: Austria, p 6: http://www.upu.int/fileadmin/documentsFiles/activities/regulatoryIssues/autEn.pdf 15 WIK-Consult, op.cit. p.38. 16 WIK_Consult, op.cit. p.43-44 12 20 21 22 23 24 Post Nord Post Nord operates its mail services chiefly in Sweden and Denmark. Its subsidiaries, Posten AB and Post Danmark A/S, hold the respective universal service obligations in Sweden and Denmark.17 Sweden Universal service obligations The Swedish USO requires deliveries 5 days per week18 and includes single price letters and parcels, as well as ‘bulk letters’.19 The delivery timescale requirement for priority letters is 85% delivered D+1 and at least 97% of mail should be delivered within 3 days.20 The timescale requirement for parcels is also D+3.21 The USO in Sweden is held by Posten AB.22 Posten 17 Post Nord Annual Report 2012: http://www.postnord.com/arsredovisning2012/en/Consolidatedfinancialreview/Universalserviceobligations.html 18 UPU, Country information on the universal postal service: Sweden, p.4: http://www.upu.int/fileadmin/documentsFiles/activities/regulatoryIssues/sweEn.pdf 19 ERDP (2014) op.cit. 20 Post Nord Annual Report 2012, op,cit. 21 UPU, Country information on the universal postal service: Sweden, p.6. 22 UPU, Status and structures of postal entities: Sweden: http://www.upu.int/fileadmin/documentsFiles/theUpu/statusOfPostalEntities/sweEn.pdf 25 26 27 28 Optimised mail preparation details 29 30 31 32 33 34 Denmark Universal service obligations The Danish USO requirement is for deliveries 6 days per week and includes single price letters and parcels, bulk letters and bulk parcels.23 The USO in Denmark is held by Post Danmark A/S.24 Addressed priority mail is delivered overnight and non-priority mail within 2–3 business days. The quality requirement for letters and parcels is set at 93%.25 23 Ibid. UPU, Status and structures of postal entities: Denmark: http://www.upu.int/fileadmin/documentsFiles/theUpu/statusOfPostalEntities/dnkEn.pdf 25 Post Nord Annual Report 2012, op.cit. 24 35 Optimised mail preparation details 36 37 38 39 40 41 42 Posten Norge Universal service obligations The Norwegian USO requires deliveries 6 days per week26 and includes single price letters and parcels, as well as ‘bulk letters’.27 Delivery timescale requirements for priority letters are D+1 85% and D+3 97%; and for non-priority letters D+4 85% and D+6 97%. Timescale requirements for parcels are D+4 85% and D+6 97%; and for incoming cross-border priority letters from EU/EEA countries D+3 85% and D+5 97%.28 In brief The Group has around 19,000 employees. The Group has more than 1 400 points of sale in Norway in the form of post offices and Post in Shops. Posten Norge is divided into two brands: Posten and Bring, Posten covers services to private customers, the post office network and daily postal distribution to the entire Norwegian populace. Bring is aimed at business customers within mail and logistics in the Nordic area, and consists of specialists who each have key skills within their areas. In 2013 Posten Norge delivered 37,8 million parcels and 2 074 million letters. The delivery quality for A mail (the proportion delivered overnight) was 86 % in 2013 In 2013 81.2 % of all letters were sorted by machine. From Annual Report 201329 By the end of 2014, Posten's sales network will consist of over 3,000 service points, with 30 post offices, around 1,400 Post in Shops and 1,600 rural postal routes, as well as a number of business centres. We deliver letters, advertising and small parcels to over two million mailboxes across the country. New technology in the delivery process The main efficiency measures in the delivery process are volume adaptation and investment in new technology. In 2012, we introduced technology to enable machines to sort by recipient name rather than just the address. This technology was extended in 2013 to cover automated forwarding of forwarded mail. This reduces the need for manual processing and helps to improve quality. 26 ERDP (2014) op.cit. ERDP defines bulk letters as comprising one or more of Bulk Mail, Direct Mail, or Periodicals included in the universal service obligation definition. 28 UPU, Country information on the universal postal service: Norway, p. 6: http://www.upu.int/fileadmin/documentsFiles/activities/regulatoryIssues/norEn.pdf 29 http://www.postennorge.com/annual-report/results/segments 27 43 We have also initiated a programme for 2013–2015 to improve barcode technology. This will increase the proportion of mail that can be routed automatically, while reducing the proportion requiring video coding. The proportion of machine-sorted mail in the mail sorting centre – in other words, mail sent from terminals to distribution centres and P.O. box facilities – increased from 79.6 per cent to 81.2 per cent in 2013. Centralised distribution In terms of distribution, we continued to work on centralising manual sorting, while making delivery more specialised. Throughout the country we are working on concentrating smaller distribution centres, introducing alternative vehicles and modifying routes to distribute mail as efficiently as possible. Despite lower letter volumes and new ways of working, we are striving to keep as many full-time employees as possible. From half year presentation 201430 MNOK = Million Norweigan Kroner 30 http://www.postennorge.com/financial-information/annual-and-quarterlyreports/_attachment/522324?_ts=1483f61ff20 44 45 B Post Universal service obligations BPost delivers 5 days per week31 under the Belgium universal service obligation. Bpos’s performance is assessed by reference to an index based on a “small-user basket” of USO postal services: o Priority domestic single piece item (D+1) o Domestic single piece registered mail (D+1) o Incoming priority cross-border single piece item (D+1) o Domestic single piece parcels (D+1) o Non-priority domestic single piece item (D+2) o Domestic single piece parcels (D+2)32 Bpost aims for at least 95% of single piece items to be distributed within the delivery times outlined above. It aims for at least 97% to be distributed within the delivery times outlined above increased by one day.33 Under European rules, the Belgian postal market opened to full competition in January 2011. Bpost operates its business through the following two business units: • the Mail and Retail Solutions unit (MRS), which focuses on the sale of mail products and manages relationships with business and residential customers. This also offers banking and insurance products (85% of income). • the Parcels & International unit (P&I), which specializes in parcels (domestic and international) and international mail and e-commerce logistics solutions (15% of income). Optimised mail preparation details Since 2011 Bpost has been engaged in a cost control programme called Vision 2020, in which it is increasing automation levels for sorting activity, consolidating sorting centres and reducing its network of more than 400 delivery offices into a new-look network of 60 mail centres. This is part of Bpost’s strategic plan for 2011-2015 which involves a restructuring of its sorting and distribution operations over the five years. Five current sorting centres (Antwerp, Brussels, Charleroi, Ghent and Liege) will be transformed into Industrial Mail Centres (IMCs). Operations at the IMCs will be expanded considerably. 31 Bpost website: http://www.bpost.be/en/aboutus/history/index.html Entrustment of Universal Service Obligation and Services of General Economic Interest to bpost, 5th Management Contract, Unofficial English Translation, May 2013, p.9-11: http://www.bpost.be/en/pdf/RD_May_29_2013_5th_Management_Agreement.pdf 33 Ibid. 32 46 The five IMCs will ensure the regional sorting addresses are put in order of the rounds of the postal workers. Regular mail will thus be ready for delivery, as soon as the deliverer leaves the IMC. The strategic plan is aimed at safeguarding Bpost’s commitment to the Universal service, whilst optimising efficiency in logistics in light of a drop in mail volumes. Bpost forecasted at the time that addressed mail volumes were likely to drop 20% by 2015, with costs rising around the EUR 200m mark. This is likely to have a negative impact of EUR 600m upon the business. As a part of the strategy, 416 distribution centres will be streamlined into 60 Mail Centres (MCs) throughout Belgium. The cost of the optimisation plan is EUR 200m, which includes the cost of establishing the new MCs. The restructuring will be implemented gradually over several years, largely finished by 2015, but fully completed by 2017. This will also involve a reduction in employment levels, although BPost stated this would be done through natural attrition, and not through compulsory redundancies.34 From BPost Annual Report 201135: The Georoute program first introduced in the mail business in 2003 enables us to determine the daily workload of all delivery members of staff, based on measured mail volumes, and how long they need to complete their work. This information enables us to constantly optimize the delivery rounds. Undoubtedly, the biggest change in our logistical chain was the commissioning in 2006 of our new sorting centers, which are all state of the art. Because of the high-tech capacities of our sorting machines we have been able to gradually introduce mechanized sorting at round level. The next logical step is sorting in the order of the round (sequencing). This has already begun and will be rolled out over several years. The technologies we have introduced in our core business have driven down costs while also improving quality. In 2001, 93.6% of mail was delivered within the delivery term. To reinforce those efforts to improve mail-handling quality, we have introduced a single barcode system (Mail ID), which improves the performance of our sorting machines when it comes to recognizing the addresses written on mail items. For our parcels segment we have 34 “Optimisation plan revealed by bpost” Post and Parcel, 4February 2011, http://postandparcel.info/36206/news/optimisation-plan-revealed-by-bpost/ 35 http://www.bpost.be/site/nl/docs/postgroup/annual_reports/Annual_Report_2011.pdf#page=119&zoom=auto,81,842 47 developed a track and trace tool that enables customers to follow their shipments all the way to their destination. The system was extended to cover registered mail items in 2011. To maximize security around the payment of pensions at home by delivery staff, we have acquired a machine specially designed to prepare envelopes containing cash. Our 2011-2015 strategic plan is based on the complete liberalization of the postal market, the development of physical competition, the proliferation of electronic communication media and the constantly evolving, ever more demanding needs and expectations of customers. This involves introducing new technologies, revising our procedures and working methods, developing our corporate culture and, above all, focusing strongly on improving the quality of our services. Innovation and the introduction of new technologies within our organization have greatly contributed to improving our efficiency in recent years. Thanks to increased automation and centralization in mail handling, today we are able to market high-quality services with regard to delivery terms and mail tracking. Over the coming years we will continue to automate and centralize. The Vision 2020 project set out in our strategic plan will help our organization to adapt efficiently to new volumes and reduce costs by generating economies of scale in infrastructure, without any adverse impact on service quality. 48 From BPost Vision 2020 presentation36 36 http://postalvision2020.com/wp-content/uploads/2014/04/Pushing-the-Package-bpost-by-Appointment.pdf 49 Canada Post Universal service obligations The Canadian Postal Service Charter requires Canada Post to deliver letters, parcels and publications five days per week (except for statutory holidays) to every Canadian address, except in remote areas where less frequent service may be necessary due to limited access to the community.37 However ‘delivering to every address in Canada’ may be delivery to the door, a community mail box, group mail box, a rural mail box, a postal box, general delivery at the post office or delivery to a central point in apartment/office buildings. Canada Post is planning to switch the remaining third of the population to community mailboxes within the next five years – a move that is being legally challenged by the Canadian Union of Postal Workers.38 The other two thirds already receive mail and parcels through community mailboxes, grouped or lobby mailboxes or curbside rural mailboxes. In terms of quality of service, Canada Post is required to deliver letter mail: o Within a community within two business days; o Within a province within three business days; and o Between provinces within four business days.39 The Canada Post segment reported an operating loss of $269 million for 2013. Transaction Mail volumes fell 5.3 per cent, continuing a decline that began in 2007. The Canada Post Group of Companies reported an operating loss of $193 million. The operating losses were reduced by gains mostly from the sale of corporate real estate. As a result, the Canada Post segment (of the Canada Post Group of companies) reported a loss before tax of $125 million. The Group of Companies reported a loss before tax of $58 million. Optimised mail preparation details From Canada Post Annual Report 2013 overview40: We have invested in automation and improved processes since 2008. An addition of $275 million in 2013 brought total spending on our modernization program to $1.7 billion. The program requires a total investment of about $2 billion. At the end of 2013, our total annualized benefits were $207 million, and we are on track to exceed $250 million in savings per year. 37 Canadian Postal Service Charter: http://www.tc.gc.ca/eng/mediaroom/infosheets-canadapost-1770.htm http://postandparcel.info/63068/news/companies/union-in-legal-challenge-against-canada-post-plan-to-enddoorstep-delivery/ 39 Canadian Postal Service Charter, op.cit. 38 40 https://www.canadapost.ca/cpo/mc/assets/pdf/aboutus/annualreport/2013_ar_overview_en.pdf 50 Investments in technology continue to make for a more efficient and cost-effective flow of parcels and mail through our network and to the customer. In 2013, we installed 19 more high-speed Lettermail sorting machines to support the new delivery model and, by the end of the year, 140 were in use, as well as 22 automated flat sorting machines. By the end of 2013, we had installed new parcel and container sorting systems in the Edmonton, Calgary, Winnipeg and Toronto processing plants to support the growth in parcels. We also completed the expansion of our Montréal parcel processing plant. We are well-positioned for the increase in parcel volumes as online shopping continues to grow. Construction of the Pacific Processing Centre is on schedule. The Centre, which opened in February 2014, is equipped with new sorting and handling capabilities for domestic and international mail, and expands our parcel capabilities in this critical gateway to Asia-Pacific markets. Streamlining: The benefits Our high-speed Lettermail machines can sort the mail along a delivery agent’s line of travel on a given street or route. This sharply reduces the time delivery employees spend sorting by hand, which gives them more time to serve customers. In the new delivery model, a single delivery employee with a fuel-efficient Ford Transit Connect becomes a full-service agent who performs several roles: delivering mail and parcels, dropping off mail at relay boxes, collecting from street letter boxes, and picking up mail from businesses. It used to take many people to perform all these tasks. In 2013, we implemented the new delivery model in 50 depots so that by the end of year, 179 depots in 13 cities were using it. We also restructured our delivery routes (more than 1,800 of them) to maximize efficiency as volumes shift. Together, the restructures and the new delivery model allow Canada Post to reduce costs substantially as a result of a wave of retirements. Here are some examples of the savings: • There were 4.3 million fewer paid hours in 2013, achieved mainly through delivery restructures. • Retirement and other departures reduced the number of employees in our plants, depots and delivery network by more than 2,100, after factoring in new hires. Converting 179 depots to our new delivery model produced the biggest savings – 1,265 letter carriers retired or left, 208 fulltime and part-time carriers were hired. • Overall productivity improved from delivery modernization and cost containment measures. • We substantially reduced the amount of manual sorting for our fifth consecutive year. • Labour costs decreased by $46 million or 1.5 per cent compared to 2012, mostly due to productivity improvements. 51 From Canada Post Annual Report 201341: Completing Postal Transformation Canada Post is nearing completion of the $2-billion infrastructure-renewal and cost-reduction project. Investments in plants, equipment, and sorting and delivery processes will continue in 2014, leading to an increase in annual cost savings. We forecast that we will exceed our target of $250 million in annual cost savings. Streamlining Operations Decreasing lettermail volumes have led to excess capacity in our processing functions, particularly for mail sortation and distribution, and there is no longer enough mail destined for local addresses to sort by hand for delivery within a community. Canada Post has been preparing for a future with less mail and more parcels for a number of years. In 2010, the Corporation launched an aggressive plan to replace its aging sortation and delivery processes with more modern and cost-effective approaches driven by technology. The sortation equipment in place today is very fast and accurate and can sequence mail along the delivery personnel’s line of travel for each route. Economies of scale are also being realized by consolidating lettermail processing into major plants within major urban centres to benefit from the use of cost-effective, high-speed automated mail processing equipment. There has also been a massive shift toward motorization, where many carriers now leave their depot with a fuel-efficient vehicle containing mail and parcels for delivery. This improvement provides a better end-customer experience, especially in the Parcels business, at a much lower cost. Canada Post will continue to transform its operations to meet the changing needs of Canadians, allowing it to realize significant annual savings, achieve efficiency improvements and better serve the growing parcel market. 2013 results: The multi-year Postal Transformation project is progressing as planned and we achieved key milestones for 2013. We installed and deployed 19 new multi-line optical character readers (mail sequencing equipment) and upgraded one automated flat sorting machine. We also replaced critical infrastructure, including four new and six retrofitted depots and implemented the new delivery model in 50 depots and converted three major sites (Edmonton, Calgary, Montréal) to parcels automation. 41 http://www.canadapost.ca/cpo/mc/assets/pdf/aboutus/annualreport/2013_ar_financial_en.pdf 52 To date, we have realized $207 million in Postal transformation annualized benefits, and the savings generated from the project are projected to exceed the target of $250 million in annual cost savings at full implementation. We continued to streamline the retail network to save costs by closing over 50 corporate postal outlets, where customers were already well served by other more convenient locations. We also extended access to customers by establishing agreements with new retailers to sell Canada Post products. We continued to invest in our retail point-of-sale system, developing enhancements that led to increased sales, and improved customer experience and delivered value. We achieved year-over-year labour costs savings of $46 million, primarily through implementation of Postal transformation. We carefully managed attrition, which allowed us to minimize the need for replacement staff and achieve labour savings, while respecting the provisions of our collective agreements. Our network and infrastructure The vast and complex operating network of Canada Post is an intricately coordinated effort between collection activities, mail processing plants, transportation links and delivery agents. Mail enters the postal network through street letter boxes, local post offices or directly at mail processing plants. At the originating processing facility, the mail is separated and sorted by various equipment into common destinations. From there, it is transported to the destination processing plant or a consolidation facility for further sorting, or to depots or post offices for delivery by letter carrier, mail service courier or rural and suburban mail carriers. In 2013, over 9.3billion pieces of mail and parcels were processed, representing roughly 37 million items sorted and delivered daily Canada Post’s processing and delivery network includes the following in approximate numbers: 21 mail processing plants 6,300 post offices, corporately owned or managed by authorized dealers 500 letter carrier depots 15,000 letter carrier routes 1,100 mail service carrier routes 28,000 street letter boxes 184,000 group and community mailboxes sites serving 4 million addresses 1.8 million post office boxes (including general delivery) 7,300 rural and suburban mail carrier routes. All are interconnected by an elaborate transportation network consisting of 138,000 links required to transport and deliver the mail across more than 160 million kilometres each year. The key elements of the end to end network are mail processing and delivery, which have been undergoing significant modernization since 2009. Our infrastructure transformation plan 53 Postal transformation is a critical component of our strategy to stay relevant and grow our business in a rapidly changing marketplace. Our overall goal is to achieve operational excellence through transformation and customer focus, ensuring our relevance in an increasingly digital world and achieving growth in the fast-growing e-commerce segment. Our investment strategy has two main components, both equally important, with one enabling the other: 1. Deal with obsolescence and increase processing efficiency and capability by investing in advanced equipment and technology 2. Improve our competitiveness in the parcels business by investing extensively in automation and adopting a new delivery model. We have carefully planned our investments to ensure that we are ready to compete in the future with fewer letters and more parcels. The entire modernization program requires a total investment of about $2.0billion in equipment, real estate, technology and people of which we invested $275million in 2013, bringing our investment to date to $1.7 billion. At the end of 2013, our total annualized benefits were $207 million, and we are on track to exceed $250 million in savings per year. Investing in our facilities, equipment and processes The sustainability of our business requires investments in equipment and systems, and changes to our plants and depots to ensure business continuity and position us for the future. Construction of the Pacific Processing Centre in Vancouver to replace two obsolete processing plants is on schedule. The expansion of the Montréal bulk mail facility to allow for replacement of obsolete parcel processing equipment was completed in 2013. We also continued our focus on the installation of updated mail processing equipment in our plants. We installed 19 multi-line optical character readers (MloCRs) and upgraded one automated flat sorting machine (AFsM), completing all of the planned mail installations. By the end of 2013, a total of 140 MloCRs and 22 AFsMs were operational. This new equipment has allowed us to increase the overall accuracy reliability and efficiency of our mechanized mail processing and improve overall service to our customers. With the increased capacity, speed and capability of the new equipment, Canada Post was able to significantly improve plant productivity in 2013 as well as machine sequencing of mail. 54 We are also modernizing and increasing capabilities for processing parcels of all sizes. By the end of 2013, we had installed new parcel and container sorting systems in the Edmonton, Calgary,, Winnipeg, and Toronto processing plants, and installation is nearing completion in Montréal and Vancouver. These systems offer fully automated sorting capabilities and can handle the expected increase in parcel volumes from the growing e-commerce market. Packets, parcels and containers flow through the plants where they are scanned; their size and weight are confirmed; they are distributed to the correct sorting area and scanned again before being dispatched on trucks. As items are transported through the plants using automated conveyance, these upgraded systems reduce the requirement for material-handling equipment and offer significant improvements in ergonomics for our employees and reliability for our customers. In 2013, we continued to invest in technology to increase product visibility from end to end, reduce our reliance on personal knowledge and manual processes, and further integrate our network. As the brains of our processing equipment, the Centralized Computer system (CCs) enabled the capability to automatically sequence mail for an increased number of depots. The CCs also helped standardize sorting strategies across the network and transfer data downstream to better support operational forecasting and planning for all products. The new Quality and security of the Mail (QsM) system, which correlates data from a variety of corporate systems, has continued to be valuable in identifying operational issues and trends. In 2014, our focus will be to continue our progress in parcel processing and transform delivery operations. The new Montréal parcel and container sorting systems will be operational in 2014. The new Pacific Processing Centre provides Canada’s west coast with sorting and handling capabilities for domestic and international mail. Addressing the cost of labour The Canada Post group of Companies is one of Canada’s largest workforces with 66,000 people, including 14,000 among its subsidiaries. The workforce is diverse and is found in every urban, rural and remote community in the country. Canada Post has a much higher labour cost structure than that of competitors, and this is not sustainable. The health of the business depends on the ability to be as cost-competitive and as operationally flexible as possible. This is essential in a highly competitive parcel market of an increasingly digital world. A realignment of labour costs to reflect changes to the business is crucial to our success. We plan to bring the cost of labour, as well as pension and employee benefit costs, in line with that of competitors through attrition and collective bargaining. With around 15,000 employees expected to retire or leave the Corporation over the next five years, we will have an opportunity to reduce the workforce by between 6,000 and 8,000 positions as we implement changes laid out in the Five-point Action Plan. We will continue to work with the unions to strengthen our competitiveness and sustainability, while trying to minimize the impact of changes on existing 55 employees. Regulations introduced by the government of Canada in February 2014 provide relief from the need to make special payments into the RPP for four years (from 2014 to 2017). This relief will give us time, as we work with our unions and other representatives of pension plan members, to take necessary steps to permanently address the sustainability of the pension plan. A leaner workforce will make us more flexible, more competitive, and more able to respond quickly to the changing marketplace. Labour agreements: Roughly 95% of Canada Post employees are represented by four bargaining agents and five collective agreements. Complex and rigid collective agreements remain a constraint on Canada Post’s ability to compete in the marketplace and implement changes to its business model, including employee benefit plans. With collective agreements expiring almost every year, Canada Post finds itself continuously in negotiations with one or more of its unions; for example, negotiations on a new agreement with almost 1,500employees represented by PSAC/UPCE will continue in 2014. PSAC/UPCE has committed to putting the Corporation’s final offer to a vote and communicating the results by April 27, 2014. New negotiations with employees represented by APOC and the CPAA will also start in 2014. CWU Research 19 December 2014 56