company profile - DivineAutomation

advertisement

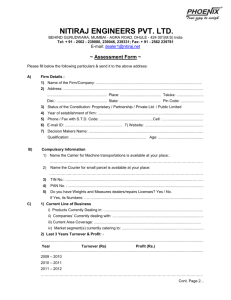

DIVINE AUTOMATION PVT. LTD. 20/4, PLOT NO. 19, NAPCO GEAR COMPLEX, MATHURA ROAD, FARIDABAD-121006 ( HR) Ph-91-11-26645289, Tele fax: 95-129-4069664 Email: divine@divineautomation.in COMPANY PROFILE 1 Ref. No. DAPL/ DATE: M/s. COMPANY Kind Attn. Mr. /Ms. Sub: Introductory letter about our company ‘DIVINE AUTOMATION PVT. LTD.' Dear Mr. Shetty, Let me briefly introduce our company to you before going into technical details. Name of the Company : Divine Automation Pvt. Ltd.. Head Office : E-8, 1043/2, Dadabari Jain Mandir Road, Mehrawali Aptt. Mehrauli, New Delhi-110030, Ph-91-11-26645289, Factory : 20/4, Plot No. 19, Napco Gear Complex, Mathura Road,Faridabad121006 ( Hr.),Sector-5. Tele Fax : 0129-4069664 TIN No. 06881221671. EXCISE. REG. NO. AADCD0101HXM001 SERVICE TAX REG. NO. AADCD0101HST001. IEC CODE. 0509090559. In order to achieve our target we are going for an expansion program with SPM Manufacturing, process control automation, machine control, machine overhauling, hydraulic & pneumatic systems,Robotic welding cells installation/commissioning , instrumentation products, application engineering and “TRAINING PROGRAM FOR MAINTENANCE ENGINEERS/GRADUATE ENGINEERS. 2 We have all qualified engineers working with us having actual field / shop floor experience in different industries like steel plant, Automobile, Precision Engineering plant, Cable manufacturing plant, Consumer Electronics, Electroplating plant, for more than twentysix years. At present our technical Manpower is 18,out of which 10 are Degree and Diploma holders in Electronics/Electricals & Mechanicals . Kindly find enclosed herewith our company profile and product catalogue for your kind perusal. We hope it will help you to understand our capabilities leading to allocation of any automation project going on in your esteemed organization. Thanking & awaiting your favourable reply at the earliest. Yours faithfully, Dwaipayan Mandal Director B-TECH. ( HONS), ELECTRONICS , I.I.T. KHARAGPUR 3 COMPANY PROFILE MISSION : To excel as one of the best turnkey Automation Project Provider under one roof with international Quality Standard. BUSINESS: The company undertakes full turnkey projects right from offering Technical Consultancy / System Engineering to the execution of projects for industrial Automation application. Deals in SPM’s, CNC’s , PLC’s ,operating consoles, Drives, Industrial Robots, Pneumatics, Hydraulics, Servos, Steppers, and instrumentation products, control panels , Solar cell related products and Led Lighting. THE PROCESS CONTENT : Technical feasibility study Conceptualization System Engineering SPM designing as per client’s requirement User friendly operator console designing with MMI modules Selection of various Electrical & Electronic Equipment CNC,PLC interface designing Machine sequence program development Pneumatic & Hydraulic Control System Designing Industrial ROBOT interfacing with PLC and installation & commissioning Pokayoke of Machine Tools Different Industrial Sensors based Automation Projects 4 Robotic Cell Installation Commissioning & job trials DOCUMENTATION OF COMPLETE WIRING/SOFTWARE OF ANY EXECUTED PROJECT ELECTRICAL EXPERIENCE : The company has successfully executed projects related to the following machines and process industries. MACHINE TOOLS : ROUGH & FINE BORING PUNCHING DRILLING & TAPPING GRINDING GEAR HOBBING HYDRAULIC PRESS PNEUMATIC PRESS DIE CASTING ( GRAVITY) ROBOT BASED SPOT AND ARC WELDING ROBOT BASED WELDING JIG PNEUMATIC AUTOMATION, ROBOTIC PICK & PLACE TESTING MACHINES AND JIGS POKAYOKE AND INTERLOCKING OF DIFFERENT MACHINES 5 HYDRAULIC AUTOMATION ELECTRONICS SENSORS BASED AUTOMATION VALUED CUSTOMERS LIST : MARUTI SUZUKI INDIA LTD. JAY BHARAT MARUTI LTD. CAPARO MARUTI LTD. SUNBEAM AUTO PVT. LTD. FANUC INDIA LTD. SUBROS LIMITED ( NOIDA, GURGAON, PUNE ) SIMA LABS PVT. LTD. ( DELHI) HERO HONDA MOTORS LTD, ( HARDWAR ) HF METAL ART ( JAIPUR) TATA MOTORS LTD., ( JAMSHEDPUR) H-ONE INDIA PVT. LTD. ( GREATER NOIDA, U.P.) SATYAM AUTO COMPONENTS LTD. ( GURGAON) SANDEN VIKAS LTD. ( FRIDABAD) VIKEM METALKAT PVT. LTD. ( FARIDABAD) KIRAN UDYOG LTD.( IMT MANESAR ) SHRIRAM PISTONS & RINGS LTD.( GHAZIABAD) HINDALCO INDUSTRIES ( RENUKOOT) ARYA PRECISION INDUSTRIES PVT. LTD. AMTECH AUTO ( SOHNA & GURGAON) BENDA AMTEK ( GURGAON) MARK AUTO LTD. ( GURGAON ) CONTINENTAL ENGINES (BHIWARI) ORIENT CRAFT ( MANESAR) TECH AUTO PVT. LTD. ( LUDHIANA) INDIAN AIRLINES LTD. ( IGI AIRPORT, NEW DELHI) PRANAV VIKAS ( INDIA) PVT. LTD. ( FARIDABAD) GLOBAL AUTOTECH LTD.( NOIDA, U.P. ) EMC ELECTROMECH CONTROLS PVT. LTD. SATA VIKAS PVT. LTD. 6 PROJECTS COMPLETED WITH ROBOTS : ( A) 23 NOS. OF FANUC ROBOTS INTERFACING WITH LINE PLC OF ALTO IN MARUTI UDYOG LTD. ( B ) 12 NOS. OF FANUC ROBOTS INTERFACING IN OLD ZEN LINE IN MARUTI UDYOG LTD., GURGAON. ( C) 4 NOS. OF FANUC ROBOTS & 9 NOS. OF KAWASAKI ROBOTS FOR MODIFICATION WITH OMNI LINE . ( D ) 9 NOS. OF FANUC ROBOTS INTERFACING IN H-ONE INDIA PVT. LTD., GREATER NOIDA, U.P. ( E ) 2 NOS OF FANUC ROBOTS INTERFACING IN SATYAM AUTO COMPONENTS LTD., GURGAON (HR) ( F) 5 NOS. OF FANUC ROBOTS INTERFACING IN TECH AUTO PVT. LTD., LUDHIANA. ( G ) 7 NOS. OF FANUC ROBOTS FOR INTERFACING IN TATA MOTORS LTD. , JAMSHEDPUR ALONG WITH ALL MECHANICALS. ( H ) ONE NO. OF FANUC ROBOT INTERFACING IN MUNJAL SHOWA LTD. GURGAON. ( I ) 4 NOS. OF YASIKAWA ROBOTS IN JBML ALONG WITH ALL MECHANICAL ITEMS LIKE PEDESTAL,FENCING ,CABLE TRAY AND ALL CONTROL PANELS AND JUNCTION BOXES. ( J ) WAGONR LEFT & RIGHT SIDE BODY AUTOMATION IN MARUTI UDYOG LTD. ( K) 4 NOS. OF MOTOMAN ROBOTS INTERFACING IN JBML,GURGAON FOR YR-9 SPOT WELDING PROJECT. ( L) 7 NOS. OF MOTOMAN ROBOTS INTERFACING IN JBML,MANESAR FOR YP-8 SPOT WELDING PROJECT. ( M) 4 NOS. OF MOTOMAN ROBOTS INTERFACING IN CAPARO MARUTI 7 LTD.,BAWAL FOR YP-8 SPOT WELDING PROJECT. ( N) 5 NOS. OF FANUC ROBOTS INTERFACING IN CAPARO MARUTI LTD. GURGAON FOR YL-8 PROJECT WITH COMPLETE CELL. ( O) 2 NOS. OF MOTOMAN ROBOTS IN JBML,MANESAR FOR YP-8 WHEEL HOUSING. NATURE OF JOB DONE : The manually controlled pneumatic valve system was replaced with Mitsubishi make PLC along with Remote input/ output and CC LINK. Introduction of 100% Remote input / output is done first time in M/s. Maruti by us In Wagon-R Left and Right side door assembly.. CC Link and Remote input / output is introduced to provide de-centralized control system where the main Mitsubishi PLC CPU is placed in small operational boxes placed in a remote panel and input / output cards are placed in small operational boxes placed in each welding jig. The main CPU Communicates with the input/ output cards through the twisted pair cable only, ruling out the requirement of connecting all input / outputs to the main CPU. All input /output wiring is limited up to decentralized Remote operational boxes only . Thus it reduces the possibility of wiring fault and also loose connection & saves cost of wiring. ( P ) REPLACE MENT OF MARUTI -800 MAIN CONTROL PANEL IN WELD SHOP-1 : NATURE OF JOB DONE : The original MARUTI -800 Main jig control Panel was with sharp PLC ( Around 500 I/O.).The reason to replace this panel was to adopt 6 KAWASAKI ROBOTS in the main jig to introduce high level automation to reduce man power & improve productivity and quality. We have replaced the SHARP PLC with Allen Bradley PLC and later on 6 Nos. of KAWA SAKI ROBOTS’ interfacing are added in the same panel. ( Q) COMPLETE AUTOMATION OF MARUTI 800 INNER HOOD MSW IN WELD SHOP-1 : NATURE OF JOB DONE : The welding jig was fabricated in house by KAIZEN, Production deptt., WELD SHOP-1. The electrical interfacing with ALLEN BRADLEY PLC was done by us. This project was done to automate the manual welding done by operator.It reduced man power and cycle time thus improving Productivity. 8 ( R ) REPLACEMENT OF SHARP PLC ( 1024 INPUT/OUTPUTS) WITH MITSUBISHI(4000 I/O) PLC IN ZEN LINE ( YE-2) IN WELD SHOP NO-2. NATURE OF JOB DONE : SHARP PLC with 1024 input / outputs was replaced by Mitsubishi MELSEC A PLC and the complete software was converted one : one from ‘SHARP’ to ‘MITSUBISHI’ without any change. ( S ) REPLACEMENT OF KOMATSU PRESS CONTROL PANEL IN PRESS SHOP AND REPLACEMENT OF HITACHI PLC WITH MITSUBISHI SPM MANUFACTURING : We have manufactured the following machines. 1) Flower Caulking Machine. This is a machine to Caulk the car heater coil with inner and outer water pipes. 2) SIDE PLATE CAULKING MACHINE. 3) CONNECTOR AND SEPARATOR CAULKING MACHINE. 4) CAP CAULKING MACHINE. 5) TWO NOS. OF TANK CAULKING MACHINES. 6) TWO NOS. OF BEARING PRESSING MACHINES (PNEUMATIC). These pneumatic presses are made to press needle bearings inside the compressor block with a load cell to indicate the force applied to press the bearings. If the force required is within the preset value, the compressor block is passed otherwise it’s rejected since the bearing is either too loose or too tight. 7) ONE NO. OF LIP SEAL PRESS. This is specially made to press Lip seal on the compressor block with an optical sensor to sense the orientation of the Lip seal. If the seal is positioned in the correct way, only then the pneumatic press will come down to press the lip seal otherwise not. 8) 2 NOS. OF AUTOMATIC MOTOR CYCLE SPOKE TIGHTENING MACHINES. Here we have made the above machine first time in India. Here a Mitsubishi servo motor is used to index the work table on which motor cycle rim is placed and 4 nos. of TOHNICHI make pneumatic guns with preset torque are used alongwith 4 nos. of pneumatic cylinders to bring the guns to tighten the spokes as per preset torque. 9 We have used the biggest cylinder of SMC, Japan ( 300 mm bore & 400mm stroke length ) to press the rim with a pneumatic force of 7 Ton. The nipples of the spokes are tighten in such a way that there is no ovality on the rim since all the spokes are tightened with equal torque. 9) WHEEL TRUEING MACHINE . Here we have used Marposs make pencil probes to detect any ovality / run out on the motor cycle rim. It’s a testing Machine to ensure that the motor cycle rim is perfect in it’s shape. 10) 5 NOS. OF PERFORMANCE CHECKING MACHINES FOR CAR AC COMPRESSOR PERFORMANCE CHECKING. These machines are used to check the performance of the AC compressors after running on this machines.The machine determines type the fault of the compressor if it is found faulty.These are vacuum testing,air in flow,volume,high pressure flow back etc. 11) OIL RUNNING MACHINE FOR COMPRESSORS 12) 3 NOS OF NITROGEN GAS CHARGING MACHINES FOR CONDENSORS 13) GASKET SENSING MACHINE 14) SEMI-AUTOMATIC SILICA DISPENCING MACHINE IN CONTAINER AFTER WEIGHING ACCURATELY UPTO 0. 5 GRAM AUTOMATICALLY 15) BLOWER CURRENT & POWER CHECKING MACHINE FOR SUNDEN VIKAS. 16) HEATER CORE INTERNAL LEAKAGE TESTING MACHINE 17) 3 NOS. OF HOSE DRYING MACHINES WITH HOT AIR BLOWER. 18) HYDRAULIC PRESS FOR PUNCHING HOLE ON ALUMINIUM PIPE 19) PNEUMATIC DUAL PRESS TO PRESS BEARINGS AND AUTOMATIC LUBRICATION BEFORE PRESSING 20)PNEUMATIC PRESS (QUAD) TO PRESS VALVE GUIDE AND VALVE SEAT SIMULTANEOUSLY INSIDE THE PIAGEO ENGINE BLOCK 21)VISION SENSOR BASED MACHINE TO INSPECT CORRECT ASSEMBLY OF COMPRESSOR BLOCK AND CHECKING NEEDLE BEARING POSITION In this machine three nos. of Banner,USA make cameras are used to check the correct assembly and indicate an OK and NG component using the camera.Correct assembly is stored 10 in the memory and the snaps are compared with the OK one.If it is found matching a green lamp will indicate it is ok otherwise a red lamp will indicate it is NG. 22)VISION SENSOR BASED MACHINE TO INSPECT TWO WHEELER PISTON GROOVING AND THE PISTON HEIGHT AT BOTH THE ENDS AND MARKING Here we have made the machine to clamp the piston under test and it is rotated by stepper motor continuously.During rotation the pistons grooves are photographed 40 times with the help of a Banner USA make colour camera and if any burr or coolant or foreign material is found in the groove,the machine detects it and a red lamp is switched on to indicate a fault. Similarly a Baker Mercer make LVDT gauge is used to check the height of the piston inserted through the piston under test and the height is indicated on the colour touch screen.If the heighr difference is less than 80 microns,the piuston is okeyed otherwise it is rejected and red alarm is glown. If the piston is OK, then only the Telesis engraving marker will come forward and mark the piston otherwise not. 23)LEAK TESTING MACHINE FOR PIAGEO ENGINE BLOCK Here we have used ATEC, France make Leak Testing instruments to check the leakage of the water and the Fuel compartments,after blocking all the other passages by pneumatic cylinders. 24)PIKA PIKA ASSEMBLY AUTOMATION We have automated the compressor assembly of Subros with assembly table with 3 vibrators and 4 magnetic picking system with area sensors and visual displays and alarms for wrong sequence of picking of components. 25)LEAK TESTING M/C. FOR COMPRESSOR BLOCK OF SATA VIKAS LTD. 26)3 NOS. OF PNEUMATIC PRESSES FOR COMPRESSOR BLOCKS PRESSING. POKAYOKE OF MACHINES AND PRODUCTION JIGS FOR MISTAKE PROOFING (i) (ii) (iii) (iv) (v) (vi) (vii) (viii) COIL WINDING MACHINE: KEY WAY MILLING MACHINE: INSULATION TESTING MACHINE: CONDENSER LEAK TESTING MACHINE: EVAPORATOR ASSEMBLY MACHINE: CAP TIGHTENING JIG OF CONDENSER NUT TIGHTENING JIGS CNC MACHINING CENTER DOOR AUTOMATION 11 (ix) (x) (xi) (xii) (xiii) (xiv) (xv) (xvi) (xvii) PNEUMATIC PRESS CLUTCH PLATE GRINDING MACHINE HYDRAULIC PRESS N2 FILLING MACHINE PIPE INSULATOR MISSING PRESSURE SWITCH TIGHTENING JIG OIL FILLING IN COMPRESSOR BLOCK SEPARATION OF OK AND NG COMPRESSORS O RING SENSING AND SILICA POUCH CONDENSER INSERTION IN +++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ NOTE:- Leaving the above jobs we have done a lot of other automation projects which are not possible to describe here in totality. But few of them are mentioned below related to air pressure and temperature. 1) WE HAVE DONE PLC BASED AUTOMATIC TEMPERATURE MAINTENANCE INSIDE STANDARD ROOM IN PISTON PLANT OF SUNBEAM AUTO LTD. HERE THREE NUMBERS OF AC UNITS ARE SWITCHED ON /OFF BASED ON FEEDBACK OF RTDS INSIDE THE ROOM AS IS REQUIRED IN YOUR CASE. 2) WE HAVE USED PRESSURE SENSOR BASED AUTOMATION IN SHRIRAM PISTONS AND SUNBEAM AUTO LTD. TO CONTROL THE AIR PRESSURE OUTPUT OF AIR COMPRESSORS BASED ON THE FEEDBACK OF THE PRESSURE SENSOR ANALOG OUTPUT.THIS WAS USED TO SAVE ENERGY BY 40% DUE TO USE OF MITSUBISHI MAKE AC DRIVE 130 KW AND 90 KW RESPECTIVELY. THE RPM OF THE COMPRESSOR MOTOR WILL VARY BASED ON THE PRESSURE FEEDBACK.IF PRESSURE OUTPUT IS LOW,THE RPM WILL BE AUTOMATICALLY INCREASED AND VICE VERSA. . THANKING YOU, DWAIPAYAN MANDAL (B-TECH(HONS.)ELECTRONICS,IIT,KHARAGPUR.) DIRECTOR,DIVINE AUTOMATION PVT. LTD. 12