H20QLCTL_Proposal_Te.. - Southern Illinois University

advertisement

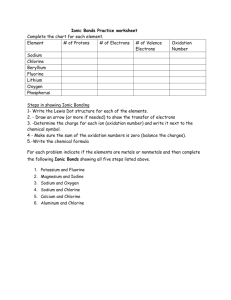

Saluki Engineering Company Engineers for Tomorrow F07-53-H2OQLCTL Water Quality Controller Proposal By Saluki Engineering Company Team 53 Adam Miller Darin McCoy Ean Seals Mitchell Ward November 14, 2007 November 14, 2007 Saluki Engineering Company Southern Illinois University Carbondale College of Engineering - Mailcode 6603 Carbondale, IL 62901-6603 miller.siu@gmail.com Dr. N. Botros Engineering Innovations, Inc. Southern Illinois University Carbondale Carbondale, IL 62901-6603 (618) 453-7028 Dear Dr. N. Botros, On September 18th, 2007 we received your request for a proposal for the design of a water quality controller. We would like to thank you for giving us the opportunity to bid on this project. Lately there has been a national need to monitor natural resources, specifically water quality, for the purpose of early warning of rapid environmental changes due to either natural or man-made threats. Through the use of remote sensing and wireless communications, natural resources can be effectively monitored to aid in the protection of vital infrastructure. The design described in the proposal is of a water quality control system developed to automatically sense and correct various factors of water quality. The project involves using a microcontroller to receive water quality information for a body of water using sensors and communicate via the Internet to a personal computer. The different parameters we plan to measure include pH, temperature, pressure, and chlorine and the parameters to be corrected are pH and chlorine. Thank you again for the opportunity to bid on this project. If you have any questions please feel free to contact us. We are looking forward to working with your organization. Sincerely, Adam Miller Project Manager, Water Quality Controller Saluki Engineering Company 2 Executive Summary The monitoring of water supplies is vital to the health and safety of a population. If a water supply is not monitored, the population’s safety can be at risk due to inadequate water treatment. With a water quality controller, changes can be immediately detected and, if possible, corrected back to proper levels. Since water quality is a worldwide concern, a general purpose water quality controller could be used in thousands of different places and applications. This paper is a proposal for a water quality controller. The controller will take sensor readings of water temperature, pressure, pH, and chlorine. A microprocessor will input these readings and calculate whether corrective action is needed. If correction is needed, the microprocessor will activate pinch valves that will dispense the calculated dosage of correction chemical. The readings and amount of corrections done will then be recorded, with periodic results being sent via email to a remote computer. The system will also be set up to email an alert message via the XPort if there is a sudden change in one of the parameters, alerting the remote user to potential problems immediately. The projected cost for the design and testing of this water quality controller is $565. 3 Non-Disclosure Statement RESTRICTION ON INFORMATION OF DISCLOSURE The information provided in or for this proposal is the confidential, proprietary property of the Saluki Engineering Company of Carbondale, Illinois, USA. Such information may be used solely by the party to whom this proposal has been submitted by Saluki Engineering Company and solely for the purpose of evaluating this proposal. The submittal of this proposal confers no right in, or license to use, or right to disclose to others for any purpose, the subject matter, or such information and data, nor confers the right to reproduce, or offer such information for sale. All drawings, specifications, and other writings supplied with this proposal are to be returned to Saluki Engineering Company promptly upon request. The use of this information, other than for the purpose of evaluating this proposal, is subject to the terms of an agreement under which services are to be performed pursuant to this proposal. Validity Statement This proposal is valid for a period of 30 days from the date of the proposal. After this time, Saluki Engineering Company reserves the right to review it and determine if any modification is needed. 4 Table of Contents List of Figures ................................................................................................................................. 6 List of Tables .................................................................................................................................. 6 Introduction (MW) .......................................................................................................................... 7 Literature Review............................................................................................................................ 8 Introduction (ES) ........................................................................................................................ 8 Microprocessor (DM) ................................................................................................................. 8 Xport Direct ™ (DM) ................................................................................................................. 9 Solenoid (ES) ............................................................................................................................ 10 Thermistor (MW) ...................................................................................................................... 10 pH Electrodes (ES) ................................................................................................................... 11 Water Treatment (MW) ............................................................................................................ 12 CHEMTROL-PC7000 (AM) .................................................................................................... 13 SCADA Systems (DM) ………………………………………………………………………13 Works Cited (AM) .................................................................................................................... 15 Basis of Design (DM) ................................................................................................................... 17 Project Description (MW)............................................................................................................. 17 Subsystems .................................................................................................................................... 18 Testing Rig (AM) ...................................................................................................................... 18 Power Distribution Subsystem (AM)........................................................................................ 19 Sensor Subsystem (MW) .......................................................................................................... 19 Correction Subsystem (ES) ....................................................................................................... 21 Xport Subsystem (DM) ............................................................................................................ 22 Microprocessor Subsystem (MW) ............................................................................................ 23 Organizational Chart (ES) ............................................................................................................ 25 RASI Chart (ES) .......................................................................................................................... 25 Action Item List (MW) ................................................................................................................ 26 Team Timeline (DM) ................................................................................................................... 27 Resources Needed (ES)................................................................................................................. 28 Appendix A: Resumes (MW) ...................................................................................................... 29 5 List of Figures Figure 1 Block Diagram for Xport System ......…………………………………………………...9 Figure 2 Solenoid Operation …………………………………………………………………….10 Figure 3 Wheatstone Bridge.…………………………………………………………………….10 Figure 4 pH Electrode Circuit...………………………………………………………………….11 Figure 5 E Coli Culture.………………………………………………………………………….12 Figure 6 CHEMTROL-PC7000 Water Quality Controller…...………………………………….13 Figure 7 Block Diagram of Water Quality Controller…..……………………………………….17 Figure 8 Circulation Pump……………………………………………………………………….18 Figure 9 pH Electrode……...…………………………………………………………………….20 Figure 10 Xport Direct Device...…………………………………………………………….......22 Figure 11 PSoC Diagram…………………………………………………………………...........23 Figure 12 Organizational Chart..………………………………………………………………...25 List of Tables Table 1 Necessary Chlorine Residual..…………………………………………………………..12 Table 2 RASI Chart.……………………………………………………………………………..25 Table 3 Action Item List…..…………………………………………………..………………....26 Table 4 Schedule for Water Quality Controller (Team 53)…….……………..………………....27 Table 5 Resources Needed...…………………………………………………..………………....28 6 Introduction In recent years, growing concern over the quality of our environment has prompted a need to develop new technologies for the purpose of monitoring environmental changes. Whether the types of changes are natural or man made, long term or rapid, keeping a close watch is believed to benefit the public and private sectors. The focus of this project is directed towards intelligent water quality control. This controller will be responsible for sensing chlorine, pH, temperature, and pressure, and for keeping the levels of chlorine and pH at the desired parameters. For example, assume an individual has a private water supply that is to be used for their home. Bacteria in the water can be harmful to humans; thus keeping a safe level of chlorine in the water will help prevent sickness. Maintaining pH at the correct level will also prevent corrosion and buildup from occurring within pipes. By using pressure, we will also be able to determine the total depth of the water and by using this; the volume of the water can be calculated and used for determining corrective action needed. During cold weather, monitoring the temperature of the water can aid in preventing pipes from bursting. Automatic notification of problems with the water system can help to reduce major maintenance issues. The design described in the proposal is of a water quality controller developed to automatically sense and correct various factors of water quality. The project involves using a microcontroller to receive water quality information about a body of water using sensors. The system will then use chemicals to automatically adjust the water to the correct levels and communicate sensor and correction data via email to a personal computer. The different parameters we plan to measure include pH, temperature, pressure, and chlorine and the parameters to be corrected are pH and chlorine. A test-bench will be constructed to develop procedures, device integration, and system parameters. By testing the system, we will be able to develop intelligent correction. The testing will also allow work to be done on increasing the scale of the project and for implementing the system on a much larger water supply. 7 Literature Review Introduction This literature review covers the background information used to design the water quality controller. This information will help the reader understand the key components of the controller. Topics to be covered include microprocessors, Xport devices, solenoids, thermistors, pH and chlorine electrodes, how chlorine is used in water treatment, a similar water controller device, and SCADA systems, which is a type of system that our device falls within. Microprocessor A microprocessor is a complete computer fabricated on a single chip. The invention of the microprocessor was a major step in computer design. Before this, many different components had to be wired together to form the entire computer. Using this single chip architecture, developers were able to reduce both the cost and complexity of the system [1]. Microprocessors are measured on several different criteria. They are measured on the amount of transistors they have, the micron width of the smallest wire on the chip, the clock speed, the width of the microprocessors ALU, and the amount of instructions that it can perform in one second. One of the most crucial ratings of a microprocessor is how many instructions it can perform in one second. Obviously, it is better to have a microprocessor that can perform many instructions per second; however, some applications may not require that much demand on the chip [2]. The main components of a microprocessor include registers, the address bus, the data bus, read and write control signals, a clock input, a reset input, and the ALU (Arithmetic Logic Unit). The ALU is the part of the microprocessor that performs the mathematical operations on the rest of the chip. If a chip has a very large and powerful ALU, it will reduce the number of instructions needed to run complex codes; thus, the chip will operate “faster” and more efficiently [3]. To get a microprocessor to work for a particular application, however, requires a couple of other key components. First, a memory system is needed that is large enough for the application. This memory system may be constrained by size of the processor that is chosen. If the processor that is being used only has 8 bits (thus, 8 address line bits) available, the maximum amount of RAM or ROM memory that can be accessed would be 28 or 256 Bytes. Second, for the system to be usable, it must have some form of input/output system. This system would allow for control from the outside world into the realm of the microprocessor. Finally, the system would have to be wired with all the control signals in the right place for the application. 8 Xport Direct ™ The technological invention of the Ethernet network has been around for years; however, devices that can connect to an Ethernet network have usually been limited to computers, printers, or other large commercial electronic components. As time has progressed, custom engineering solutions have emerged on ways to connect ordinary electric devices (such as building lighting, energy readings, or metering applications) to an Ethernet network. Xport Direct™ is a chip level solution to the problem of connecting an ordinary device (such as a toaster, stove, or stereo) to an Ethernet network [4]. Xport Direct ™ is a computer chip equipped with a microprocessor, an Ethernet jack, and the capability of network enabling a device to the internet. Figure 1 shows the block diagram as well as the pin numbers for the major signals of the Xport system. Central to the Xport system is the Lantronix ® custom made DSTNi microprocessor. This communicates from within the Xport chip to the rest of the output of the system. The printed circuit board conditions the output of the microprocessor to a format usable by the rest of the circuit. The main output, described as “Data Out” on Figure 1, is an asynchronous serial UART output type. Communication from the output of this pin can be connected to another device that accepts UART such as another microprocessor, ASIC, or FPGA. XPort allows configurations using any of the following: 7 or 8 stop bits Odd, Even, or No parity bits 1 or 2 stop bits RS-232C or RS-485 communication [4] Figure 1 – Block Diagram for Xport System1 The XPort system runs on a 16-bit, x86 architecture microprocessor that uses a 48MHz clock. It has 256KB of SRAM and 128KB flash memory. It has two GPIO (general purpose input output) pins, an external reset (Reset#), and several communication pins (CTS, DTR, RTS). [5] 1 Figure 1 - Referenced from http://www.lantronix.com/pdf/Xport-Direct_IG.pdf Retrieved October 24, 2007 9 Solenoid A solenoid is a mechanical device capable of linear motion. There are three main types of solenoids: hydraulic, pneumatic, and electromechanical. These solenoids all operate on the same basic principal; when supplied with electrical energy, the solenoid will produce a mechanical force [6]. The basic operation of a solenoid is similar to that of an electromagnet. As seen in Figure 2, the basic construction of a solenoid consists of a wire coil wound around a movable slug of steel or iron. When the coil is energized, it repels or attracts the slug, causing it to move [6]. Most linear solenoids are pull type solenoids, in that when the magnetic field is induced it causes the slug to move into the coil. Solenoids can also be built with a hole on the inner side of the coil, allowing the slug to produce a pushing motion in that direction. When the coil is not energized, the energy required to return the slug to its normal position comes from either the load the solenoid is pushing against or from an internal spring [7]. Figure 2 – Solenoid Operation2 Thermistor A thermistor is simply a resistor whose resistance changes with temperature change. Thermistors are used in virtually any application where a temperature reading is needed; including water temperature readings, disposable medical thermometers, and in electronic devices for temperature compensation. Thermistors are often used because they can accurately measure very small temperature changes, have a very low excitation power requirement, and are very reliable in terms of resistance output and longevity [8]. Figure 3 – Wheatstone Bridge3 There are two types of thermistors that are produced: a negative temperature coefficient (NTC) thermistor and a positive temperature coefficient (PTC) thermistor. An NTC thermistor will decrease in resistance as temperature increases, while a PTC will increase in resistance as temperature increases [9]. NTC thermistors are created by mixing powders of metal oxides together and firing them at temperatures of around 1000° C to harden them. Various metal oxides used include manganese, iron, cobalt, and nickel [8]. PTC thermistors are made of doped polycrystalline ceramic on the basis of barium titanate [10]. 2 Figure 2 - Referenced from http://www.societyofrobots.com/actuators_solenoids.shtml Retrieved November 11, 2007 Figure 3 - Referenced from http://www.omega.com/toc_asp/frameset.html?book=Temperature&file=THERMISTOR_APP_REF Retrieved Oct. 25 2007 3 10 Although thermistors can be used in many types of circuits, one of the most common ways of measuring temperature is to put a thermistor as one leg of a Wheatstone bridge circuit and three equal and known resistances as the other three legs as seen in Figure 3 [11]. The circuit works by applying a known voltage across the bridge and then measuring the voltage across the middle of the bridge as seen in Figure 3. The measured voltage will then change based on the resistance of the thermistor. This measure voltage can then be compared to a table or entered into an equation to determine what the temperature is. pH Electrodes A pH electrode is a device that produces a voltage proportional to the pH of the solution it is located in. In order to understand how this voltage is created, one must first understand the pH scale and how it is determined. The pH of solutions normally lies between 0 and 14 pH with 7 being neutral; however, higher positive values and negative values are possible. All water solutions contain both H+ and OH- ions, with their proportion in the solution determining the pH value. If the values of both ions are equal, the solution is neutral and is given a pH value of 7. If the solution contains more H+ ions than OH- ions, the solution is acidic and has a pH value lower than 7. When the solution contains more OH- than H+ ions, the solution is basic and has a pH value higher than 7 [12]. The equation that determines the actual value of the pH is pH = log10([H+]) [13]. Most pH electrodes are glass electrodes that feature thick glass side walls and end with a thin glass bubble. The glass used in the measuring electrode is normally composed of alkali metal ions. The ions of the glass react with the H+ ions of the solution and create a potential difference. The electrode also contains a reference electrode which reacts with a reference solution to generate a constant voltage. These combination electrodes output a varying voltage from the measuring electrode and a constant voltage from the reference electrode. The output has a very high impedance which prevents Figure 4 - pH Electrode Circuit4 connecting the electrode directly to a voltage meter [14]. The voltage generated by the pH electrode ranges from -420 to 420 mV with a voltage of 0 being generated at 7 pH. The voltage change is approximately 60 mV per pH and increases/decreases linearly. For example, a pH of 4 would generate 180 mV. Buffer solutions with known pH values are used to calibrate the electrode and ensure that the electrode is reading solutions at the correct pH. Reading the voltages from the pH electrode requires the circuit shown in Figure 4. The op-amp shown in the circuit must be able to input a voltage coming from a high impedance source [15]. The reason for this is that the pH electrode will have an impedance in the range of 50 to 500 MΩ [16]. 4 Figure 4 - Referenced from http://www.66pacific.com/ph/simplest_ph.aspx Retrieved October 25, 2007 11 Water Treatment In water treatment, a major concern is the level of bacteria in the water. Bacteria, such as E coli seen in Figure 5, can result in diseases such as typhoid, dysentery, cholera, hepatitis, and giardiasis. In order to make the water safe for human consumption, the harmful bacteria in the water must be killed. There are several treatment methods available to accomplish this: boiling water, chlorine treatment, treatment with iodine, and ultraviolet light. Although all of these methods have advantages and disadvantages, the most commonly used and reliable way to do the Figure 5 – E Coli Culture5 treatment is by adding chlorine [17]. Chlorine has been used for water treatment since 1908 due to its many advantages over other treatment methods. Chlorine works great as a bacterial disinfectant, but it also treats other water problems such as iron, manganese, and hydrogen sulfide by binding with them. In addition to being readily available, chlorine is reasonably priced and is capable of treating large volumes of water. Perhaps the greatest advantage of chlorine treatment is that it leaves residual chlorine in the water. Residual chlorine in the water will treat bacteria and other contaminants that might get into the water supply after initial chlorine treatment [17]. Although chlorine is very effective in deactivating bacteria and other contaminants, treatment is not instant and depends on several factors; these relationships can be seen in Table 1 [17]. Table 1. Necessary chlorine residual to disinfect water for various contact times, water temperatures and pH6 Water Temp. 50 degrees F Contact time (minutes) 40 30 20 10 5 2 1 5 6 Necessary chlorine residual (mg/l) pH 7 pH 7.5 pH 8 0.2 0.3 0.4 0.3 0.4 0.5 0.4 0.6 0.8 0.8 1.2 1.6 1.6 2.4 3.2 4 6 8 8 12 16 Figure 5 - Referenced from http://en.wikipedia.org/wiki/Image:EscherichiaColi_NIAID.jpg Retrieved November 11, 2007 Table 1 - Referenced from http://ohioline.osu.edu/b795/b795_7.html Retrieved November 11, 2007 12 Water Temp. 32 – 40 degrees F Necessary chlorine residual (mg/l) pH 7 pH 7.5 pH 8 0.3 0.5 0.6 0.4 0.6 0.8 0.6 0.9 1.2 1.2 1.8 2.4 2.4 3.6 4.8 6 9 12 12 18 24 Contact time (minutes) 40 30 20 10 5 2 1 As the concentration of the chlorine increases, the required contact time to disinfect decreases. Chlorination is more effective as water temperature increases. Chlorination is less effective as the water's pH increases (becomes more alkaline). Chlorination is less effective in cloudy (turbid) water After the initial chlorine treatment, residual chlorine still remains. If this residual level is too high for human consumption ( > 4mg/L), additional treatment is needed to remove chlorine to a safe level. Chlorine levels in water can be detected by the use of a chlorine electrode. The electrode works by producing an electric potential when the sensor comes in contact with chlorine in the water, with great potential being produced at higher chlorine concentrations. This electric potential can then be measured and the total chlorine level can be determined [18]. CHEMTROL-PC7000 The CHEMTROL-PC7000 is a microprocessor-based programmable controller for automated control of water chemistry and filtration, with a solid state sensor for free chlorine and duplex operation by remote computer. It is an ideally suited control system for automated water treatment in swimming pools, spas, cooling towers, and industrial water treatment. Figure 6 – CHEMTROL-PC7000 Water Quality Controller7 7 Figure 6 - Referenced from http://www.sbcontrol.com/pc7000.htm Retrieved November 11, 2007 13 The CHEMTROL-PC7000 is a controller that incorporates automated control of water chemistry and filtration in a single unit with choice of backwash programs for single or multiple filters. The menus are displayed in either US or metric units. Each unit is supplied with an operation manual, onsite startup, and training. As shown in Figure 6, this device provides: PPM (Parts Per Million) Control ORP (Oxidation Reduction Potential) Control pH Control Heater Control Main Pump Control with Flow Rate Influent/Effluent Pressure Automated Backwash Langelier Saturation Index (water chemistry / corrosion and scale-formation) Automatic Data Logging Conductivity Control Total Dissolved Solids (TDS) monitoring Water Level Control Remote Computer Operation and Graphic Data Display Voice Telephone status reports, remote control, and alarm callouts [19] SCADA Systems Supervisory Control and Data Acquisition Systems (or SCADA) are currently being used to monitor a variety of environmental and industrial systems. These include factories, manufacturing systems, power systems, water systems, or other biological systems [20]. SCADA systems are being considered by the government to help establish a national cyberspace response system. This system would be able to rapidly identify and respond to cyber incidents and help control the damage done by these attacks [21]. A SCADA system has many components to accomplish its purpose of remotely monitoring and collecting data about its environment. It usually includes signal hardware, controllers, networks, a user interface (or HMI), communications equipment, and software. Together, these subsystems can monitor an entire system in real time. This is accomplished through reading meters, sensors, and other data elements and communicating them to the human interface. The Human Machine Interface (or HMI) is the part of the SCADA system where the data is processed and presented to a human operator. The HMI compiles the information from RTU (Remote Terminal Units) and PLC (Programmable Logic Chip) and displays this information to the user. In summary, this system is used to remotely monitor a variety of different systems [20]. 14 Works Cited [1] “How Microprocessors Work,” http://computer.howstuffworks.com/microprocessor.htm Accessed October 28th, 2007 [2] “Microprocessor Progression: Intel,” http://computer.howstuffworks.com/microprocessor1.htm Accessed October 28th, 2007 [3] “Microprocessor Logic,” http://computer.howstuffworks.com/microprocessor2.htm Accessed October 28th, 2007 [4] “XPort Direct,” http://www.lantronix.com/device-networking/embedded-deviceservers/xport-direct.html Accessed October 24th, 2007 [5] “XPort Direct Product Brief,” http://www.lantronix.com/pdf/XPort-Direct_PB.pdf Accessed October 24th, 2007 [6] “ACTUATORS – SOLENOIDS,” http://www.societyofrobots.com/actuators_solenoids.shtml Accessed October 27th, 2007 [7] “Solenoid Theory 101,” http://www.jewellinstruments.com/soltheory101.htm Accessed October 27th, 2007 [8] J. M. Zurbuchen, “Precision Thermistor Thermometry,” http://www.measspec.com/myMeas/MEAS_download/ApplicationNotes/Temperature/MEAS%20TPG%20T D002_Thermometry%20-%20.pdf Accessed Oct. 29, 2007. [9] “U.S. Sensor: What is a Thermistor?,” http://www.ussensor.com/pdfs /technical_data.pdf Accessed Oct. 29, 2007 [10] “The PTC-Working-Principle,” http://www.ptc-ceramics.com/principal_frame.htm Accessed Oct. 29, 2007 [11] “OMEGA® Interchangeable Thermistor Applications,” http://www.omega.com /toc_asp/frameset.html?book=Temperature&file=THERMISTOR_APP_REF Accessed October 25, 2007 [12] “pH scale,” http://www.ph-meter.info/pH-scale Accessed October 25, 2007 [13] “pH definition,” http://www.ph-meter.info/pH-definition Accessed October 25, 2007 [14] “OMEGA ENGINEERING – Electrode Basics,” http://www.omega.com/techref/ph3.html Accessed October 25, 2007 [15] “The Simplest Possible pH Meter,” http://www.66pacific.com/ph/simplest_ph.aspx 15 Accessed October 25, 2007 [16] “Glass Electrode,” http://en.wikipedia.org/wiki/PH_glass_electrode Accessed October 25, 2007 [17] “Bacteria in Drinking Water,” http://ohioline.osu.edu/b795/index.html Accessed November 11, 2007 [18] “Orion Residual Chlorine Electrode,” http://www.orionelectrochimie.com/orion%AE/ged/fiches+techniques/9770sc-or.pdf Accessed November 11, 2007 [19] “CHEMTROL -PC7000 Integrated Controller,” http://www.sbcontrol.com/pc7000.htm Accessed November 11, 2007 [20] “What is SCADA,” http://www.tech-faq.com/scada.shtml Accessed November 19, 2007 [21] Scada Systems and the Terrorist Threat: Protecting the Nation’s Critical Control Systems, Washington D.C.: U.S. Government Printing Office, 2007 16 Basis of Design The following documents provide the basis of design for Water Quality Controller of Team #53 of the Saluki Engineering Company • Request for Proposal (RFP) September 18, 2007 • RFP Attachment 1: Project Definition September 18, 2007 • RFP Attachment 2: Design Report Deliverables Checklist September 18, 2007 • Team #53 Proposal November 14, 2007 The documents above are listed in order of precedence. In the event of conflicting statements in design, the proposal will be the ultimate authority. Project Description Power System Sensors Electrical Signal Microcontroller Electrical Signal Biological Signal Chemicals Environment Correction Electrical Signal XPort Figure 7 – Block Diagram of Water Quality Controller A water quality controller is a device that will actively monitor a water supply to detect and respond to rapid environmental changes. This water quality controller will monitor the key water parameters of pH, chlorine, temperature, and pressure. Figure 7 shows the subsystems required to create this controller. These subsystems include the power distribution subsystem, sensor subsystem, correction subsystem, Xport communication subsystem, and the microcontroller subsystem. 17 The power distribution subsystem will provide power to the individual subsystems of the device from a power supply. The power supply will convert AC voltage from the power grid into the DC voltages required by the various subsystems. These subsystem voltages range from 5V DC to 12V DC. The sensor subsystem will monitor the quality of the water using various parameters. Chlorine and pH electrode sensors will be used to monitor the chemical makeup of the water. A thermistor will be used to monitor the temperature of the water. This calculation will be used as both a parameter of the water quality and in calculation of the pH and chlorine measurements. The pressure sensor will be used to calculate the amount of water in the reservoir. The volume of water calculated by the pressure sensor will then be used to determine the amount of chemicals needed for correction. The correction subsystem will use the data provided by the sensors to intelligently adjust the pH and chlorine levels to preset values. In order to quickly and evenly distribute the corrective chemicals, the test system will include a pump to circulate water. Correction will be accomplished using gravity fed lines passing through normally closed solenoid pinch valves. The chemical will be dispensed when the controller triggers the valve to open. The Xport subsystem will allow communication between the water controller and a remote computer. Water quality parameter measurements and corrective actions taken will be sent from the microcontroller to the Xport. The Xport system will then send these results via TCP/IP protocols to a pre-specified email address at predetermined time intervals. The microcontroller subsystem coordinates the actions of the other subsystems. The microcontroller will use the sensor data and the preset parameter levels to determine if corrective action is needed. If corrective action is needed, the microcontroller will send a signal to the appropriate pinch valve to dispense the amount of chemical needed for correction. The microcontroller will also store sensor data and corrective actions taken, and will output this information via the Xport to a remote personal computer periodically. Subsystems Testing Rig Since it is not feasible to go and test our water controller on a large water supply, we have elected to construct a small scale model with which we can easily control the water parameters we want to test. Our model will consist of a 10 gallon tank to hold the water, a pump for water circulation, and stand to support the sensors, correction valves, and chemicals. For a pump we intend to use a 10 gallon aquarium filter (as shown in Figure 8). We will use the filter without the filter media so that it will serve only as a pump. The stand will support the correction chemicals above the pinch valves so that gravity can be used to introduce our chemicals into the water. The stand will also serve to hold the sensors at the appropriate level in the water. 8 Figure 8 – Circulation Pump8 Figure 8 - Referenced from http://www.petsandponds.com/c6270p16348414.2html Retrieved November 7, 2007 18 Design Activity List Design/Build sensor and correction chemicals support structure Setup water tank for testing Assemble controller circuit box Install sensors Install correction subsystem Install power subsystem Create different water quality test cases Test system and record data Determine feasibility for larger bodies of water Power Distribution Subsystem The power distribution subsystem will consist of a power supply that will plug into the power grid and convert 120V AC into the needed DC voltages. The power supply will provide +12V and -12V to operate our amplification and conditioning circuits. The +12V will also be used to power the solenoid pinch valves. The microprocessor circuit and Xport will be powered by +5V provided by the power supply. The +5V will also be used to operate the thermistor and pressure sensors. Design Activity List Construct circuits to supply necessary voltage levels from power supply Provide power to every subsystem Deliverables List Power schematic for system 120 AC to DC power supply and conditioning circuits Documentation of design process Sensor Subsystem The sensor subsystem will consist of two electrodes, a passive sensor, and an active sensor. The two electrodes are the pH electrode and the chlorine electrode. Temperature will be measured through a passive thermistor sensor and pressure will be determined using an active pressure sensor. The primary purpose of this subsystem is data acquisition, which will be used as the basis for all corrective actions. 19 The pH electrode, shown in Figure 9, generates a voltage based on the H+ ions in the water. This voltage will be amplified and conditioned by a high impedance input op-amp. The voltage will then be run into an analog to digital converter on the microprocessor. The microcontroller will then use the digital signal for pH correction and data analysis. Figure 9 – pH Electrode9 The chlorine electrode also generates a voltage in the range of -100 mV to 100 mV based on the amount of chlorine in the water. This voltage will be handled in a similar fashion as the pH electrode voltage. The microcontroller will use the chlorine data to detect the amount of chlorine in the water and to initiate corrective actions. The pressure sensor will be used to calculate the depth of the water. The pressure sensor will be located at the bottom center of the tank. This allows for the most accurate reading of total water pressure at the bottom of the tank (which can be used to calculate the depth of the liquid in the tank). The formula for calculating pressure (in kPA) of the sensor is (Vsignal / Vs + .0638) / 0.005413 (Vs = 5.00V). The output of the pressure sensor is dependent on the input voltage (Vs). The temperature will be calculated using a thermistor. The thermistor is a device that changes in resistance with temperature. Our thermistor is a negative temperature coefficient (NTC) thermistor, which means the resistance will increase as the temperature decreases, and vice-versa. We will use the thermistor in a Wheatstone bridge application as shown in Figure 9. By placing the thermistor in any one of the four locations on the bridge and placing three identical resistors on the remaining three locations, we can measure the voltage difference across points B and D to determine the temperature. Design Activities List Test operation of all sensors Build signal conditioning circuits Determine optimal sensor location Create graphs/lookup tables of sensor results Determine optimal ranges for sensors Deliverables List pH electrode and conditioning circuit Chlorine electrode and conditioning circuit 9 Figure 9 - Referenced from http://electrodesdirect.com/section_id/2/category_id/193/product_id/162 Retrieved November 7, 2007 20 Thermistor and conditioning circuit Pressure sensors and conditioning circuit Sensor care/maintenance sheets Documentation of design process Correction Subsystem The correction subsystem will be responsible for maintaining the water pH and chlorine parameters at predetermined levels. The correction subsystem will consist of containers filled with all required corrective chemicals, solenoid pinch valves, and tubing running from the containers through the valve into the water. The solenoid valves will be normally closed, thus pinching the tubing and preventing flow of chemicals. When the microcontroller determines that correction is needed based on the sensor data, it will send a signal to open the appropriate solenoid pinch valve and release the chemical needed for correction. The amount of chemical dispensed will be determined by an algorithm programmed into the microcontroller. Tubing will dispense chemicals near the circulation pump in order to allow for rapid and even distribution. Correction of chlorine and pH will be done with three solutions. Since high concentrations of chlorine do not naturally occur in water, and there is no need to remove chlorine unless it is over treated, our system will only add chlorine to keep the water at adequate and safe concentrations. Chlorine will be added by using a diluted bleach solution (as suggested by the American Red Cross for simple water treatment). Our pH correction chemicals will allow us to both raise and lower any pH level. The chemical we will use to lower pH, thus making the water more acidic, will be hydrochloric acid (HCl). We will raise pH by using caustic soda, more specifically lye (NaOH), thus making the water more basic. Design Activities List Create chemical solutions Determine correct correction dosages Create correction lookup tables Determine flow calculations Determine timing calculations for pinch valves Determine safe disposal of chemicals Deliverables List Chemical solutions 21 Solution containers and tubing Solenoid pinch valves Chemical mixing directions Document of safe chemical handling and disposal Documentation of design process Xport Subsystem The Xport Direct™, seen in Figure 10, will be used to email the results of the results of the sensing and correction systems. The microprocessor will send the sensor information (ph, pressure, temperature, and chlorine) along with the amounts (if any) of corrective fluid that has been added in the past time period. It will communicate this information by sending an email to a predetermined email address through an 10 Ethernet network. Figure 10 – Xport Direct Device The data contained within the email will allow the user to know how the system is operating. It will communicate every 24 hours, providing the sensor readings and corrective measures that have been taken. With this information, the user will be able to monitor both the short and long term health of the water supply. There will also be email alerts allowing the user to know when dangerous spikes in the monitored parameters occur or when the system is running low on corrective chemicals. Design Activities List Design interface with PSoC Determine TCP/IP emailing protocols Determine email content and frequency Create parameters for email alerts Deliverables List Xport device Programming code Figure 10 – Referenced from http://www.lantronix.com/device-networking/embedded-device-servers/xport-direct.html Retrieved November 7, 2007 10 22 Email format and configuration Documentation of design process Microprocessor Subsystem The device used to control our sensor network and to calculate and control correction will be implemented by using a Programmable System on a Chip (PSoC). Specifically, we will be using the CY8C29466 made by the Cypress Semiconductor Corporation due to its capabilities and availability. The PSoC consists of four main functional blocks; the PSoC core, the digital systems, the analog system, and the system resources, all of which can be seen in Figure 11. The PSoC core is built with a CPU, memory, clocks, and general purpose inputs and outputs. The CPU is a 24 MHz processor utilizing an 8-bit Harvard architecture. The memory consists of 32 KB of flash memory for program storage and 2 KB of SRAM for data storage. Clocks on the system include a 24 MHz internal main oscillator which can be doubled to 48 MHz for use in the digital system, and a low power 32 kHz internal low speed oscillator for use as a sleep timer. Finally, the general purpose inputs and outputs allow for communication with the CPU, digital system, and analog system of the PSoC. Figure 11 – PSoC Diagram 11 The digital system is constructed of 16 8-bit blocks that can be used either individually or in combination with other blocks to form larger (up to 32-bit) peripherals. Peripheral configurations available include pulse width modulators, counters, timers, and digital filters. The analog system consists of 12 configurable blocks, each containing an op-amp circuit. These blocks are configurable for analog functions such as analog-to-digital conversion, amplifiers, and high current output drivers. The system resources of the PSoC give the controller additional capabilities. These capabilities include digital clock dividers, an internal 1.3 V reference, and a power on reset circuit. For our system, the inputs into the controller will be pH, chlorine, pressure, and temperature sensors. From the sensor readings, an algorithm will determine if any correction is needed and, if so, how much chemical needs to be dispensed. Correction will only be done after several consistent readings have been taken, preventing corrective actions from being taken due to erroneous readings. Corrective action will be done by activating a pinch valve on the appropriate corrective chemical for the calculated length of time, allowing it to dispense the amount of chemical needed. The data gathered by the sensors will be stored in the PSoC Figure 11 –Referenced from http://download.cypress.com.edgesuite.net/design_resources/datasheets/contents/cy8c29466_8.pdf Retrieved November 7, 2007 11 23 memory system, along with the records of correction. This data will then be sent to the Xport subsystem for external communication. Design Activities List Create algorithm for measuring water volume Create algorithms for pH and chlorine corrections Construct controller housing Develop code for correction using flow and response calculations Develop code for Xport interface Create sensor and correction taken data storage Deliverables List PSoC with programming encoded Programming code Controller housing Documentation of design process 24 Organizational Chart Dr. Botros Technical Advisor Adam Miller Electrical Engineer Project Manager Microcontroller/Integration Darin McCoy Ean Seals Mitchell Ward Electrical Engineer MatchPort Electrical Engineer Correction Electrical Engineer Sensors Figure 12 – Organizational Chart RASI Chart Table 2 – RASI Chart Responsibility MatchPort System Correction System Sensor System MicroController/Integration Adam Miller I S S R Key Responsibility Approval Support Information R A S I Darin McCoy R I I S Ean Seals S R I S Mitchell Ward S I R S Dr. Botros A A A A 25 Action Item List Table 3 – Action Item List 26 Team Timeline 27 Resources Needed Table 5 – Resources Needed 28 Appendix A: Resumes Mitchell Ward Permanent Address: RR 4 Box 128 Albion, IL 62806 618-445-3361 mward04@siu.edu School Address: 219 Pierce, Thompson point Carbondale, IL 62901 618-302-0030 EDUCATION: Bachelor of Science in Electrical Engineering, May 2008 Plan to attend graduate school at SIUC Fall 2008 to obtain M.S in EE Southern Illinois University, Carbondale, IL Current GPA 4.0/4.0 Relevant Coursework • Technical Writing • Mechatronics System Design • Power Systems Analysis • Digital Circuit Design • Synthesis with Hardware Description Languages • Electromechanical Energy Conversion • Mathematical Statistics in Engineering EXPERIENCE: Engineering Corporate Internship, Caterpillar Inc., Summer 2007 Performed Quality Assurance regression and bug testing on CAT Electronic Technician software under Windows XP and Vista Updated over 50 regression tests to be clearer and easier to complete Began creation of an automated installation test of CAT Electronic Technician Factory work, Champion Laboratories, Summer 2006 Volunteer computer work, Albion Public Library, 2003-Present Edwards County Health Office, 2005 Custodial work, Edwards County Community Unit #1 School District May-August 2003 and 2004 SKILLS: Experienced with Windows 95, 98, XP, and Vista Familiar with JAVA, C, VHDL, and Verilog programming languages Troubleshooting and removal of spyware and virus computer infections Familiar with Matlab, Microsoft Word and Excel Co-Organized and hosted 1st Public LAN gaming party in Edwards County HONORS / AWARDS: Member of IEEE, 2006-2007 Member of Alpha Lambda Delta Honor Society, inducted Spring 2005 Member of Active Community Team for Youth, a teen volunteer organization in Edwards County, 2002 - 2004 29 Ean Seals Permanent Address: RR 1 Box 131A Ellery, IL 62833 618-445-2725 eseals@siu.edu School Address: 219 Pierce, Thompson Point Carbondale, IL 62901 618-302-0087 EDUCATION: Bachelor of Science in Electrical Engineering, May 2008 Plan to attend graduate school to obtain Masters in Electrical Engineering in Fall 2008 Southern Illinois University Carbondale Current GPA 3.781/4.0 Relevant Coursework ● Systems and Control ● Systems and Signals ● Mechatronics System Design ● Synthesis with Hardware Description Languages ● Electronics ●Introduction To Data Communication Networks EXPERIENCE: Engineering Corporate Internship, Caterpillar Inc., Summer 2007 Worked in Systems, Controls, and Components Project – designed a control system in Matlab using Simulink/Stateflow, tested the system by interfacing with the device and using an xPC Factory work, Champion Laboratories, Summer 2006 Harvesting and Maintaining of Produce, Seals Orchard, summer of 2003 – 2006 SKILLS: Familiar with Matlab, Simulink, and Stateflow Experienced with building and setting up computers for myself and for hire Familiar with CAN Experienced with Windows XP Familiar with JAVA and C programming Experience with troubleshooting both hardware and software computer problems HONORS / AWARDS Member of Alpha Lambda Delta Honor Society, inducted Spring 2005 Member of Southern Illinois University Carbondale, University Honors Program, joined Fall 2004 Member of Active Community Team for Youth, a teen volunteer organization in Edwards County, 2002 – 2004 Member of IEEE, 2006 Member of Sigma Alpha Lambda, 2006 SIUC Presidential Scholarship award winner 2004 30 Darin McCoy Permanent Address: 706 Westgate Road Washington, IL 309-472-9249 mccoydj1@hotmail.com School Address: 704 E Park Street APT A3 Carbondale, IL 62901 309-472-9249 EDUCATION: Bachelor of Science in Electrical Engineering, May 2008 Plan to attend graduate school at Bradley University Fall 2008 to obtain MBA Southern Illinois University, Carbondale, IL Current GPA 4.0/4.0 EXPERIENCE: Engineering Corporate Internship, Caterpillar Inc., Summer 2007 Worked on Object Detection systems Researched and formulated possible ECM cooling systems Conducted virtual harness audits Engineering Corporate Internship, Caterpillar Inc., Summer 2006 Worked on creating bench setups for new backhoe loader applications Researched quality information Worked on a six sigma project to inventory materials for a move to North Carolina Engineering Corporate Internship, Caterpillar Inc., Summer 2005 Created harness models in Pro/E Researched component health from a financial perspective Gained business interaction experience Engineering Student Trainee, Caterpillar Inc., Summer 2005 Created scripts to run Electronic Control Modules Researched component health from a financial perspective Gained business interaction experience SKILLS: Excel (Arranged and taught a class on the subject) Matlab / Simulink C, C++, Flash, Java, Visual Basic, Visual Test, Matlab programming ACTIVITES, HONORS, AND AWARDS 2006-2007: InterVarsity Vice President 2006-2007: Caterpillar Excellence Scholarship 2006-2007: Omron Electric Scholarship 2005-2006: InterVarsity Exec Member 2004-2006: Dean’s Scholarship – Southern Illinois University Carbondale 2004-2006: College Math Club President 2004-2005: InterVarsity Leader 31 Adam J. Miller Permanent Address: 9177 McLean Rd. Minier, IL 309-392-2153 miller.siu@gmail.com School Address: 713 W. College Carbondale, IL 62901 309-838-5881 EDUCATION Southern Illinois University, Carbondale, Illinois Bachelor of Science in Electrical Engineering May 2008; Current GPA 2.957/4.0 Minor in Mathematics WORK EXPERIENCE Southern Illinois University, Carbondale, Illinois September 06-Present Lab Instructor, Electrical and Computer Engineering Department, September 2006- Present Manage other teaching assistants and organize lab experiments Topics include Xilinx & MATLAB programming, circuit design principles, and lab safety Southern Illinois University, Carbondale, Illinois September 07-Present Tutor & Supplemental Instructor, Engineering Department, September 2007- Present Tutor engineering students in Math, Physics, Chemistry, and Electrical Engineering courses Supplemental Instructor for Math 150 (Calculus I) Newell House Carbondale, Illinois Waiter, May 2006 – September 2007 Serve clientele and provide excellent customer service Southern Illinois University Carbondale, Illinois Student Mentor, College of Engineering, summers of 2006 & 2007 Chosen by faculty and administration to serve as a positive role model for incoming freshmen and transfer students during Engineering Success Week VOLUNTEER EXPERIENCE Engineering Courtyard Cleanup Project Project Coordinator, 2006 – 2007 Coordinate effort by Engineering Student Council to bring life back into the area surrounded by the SIUC Engineering and Applied Sciences Building Handled funds, coordinated volunteers and design proposals Habitat for Humanity Volunteer, Fall 2005 Helped with the construction of a local home CAMPUS ACTIVITIES Engineers Without Borders Fall 2007 Founding Father & President Engineering Student Council 2006-2007 President 2005-2006 Representative SIUC Hovercraft Build & Design Team (06-present) Vice-President, (05-06) Engineering Student Council Rep., (04-06) Treasurer IEEE 2005-07 Member Dean Kenneth E. Tempelmeyer Outstanding Student Leadership Award Committee Dean’s List Summer 2006-Present 32