fusion six sigma methodology and case studies

Header Space reserved for Publication

FUSION SIX SIGMA: METHODOLOGY AND CASE STUDIES

Jaran Sabseree.

1 , Vinit Thueakthong 2 and Pichit Sukchareonpong 3

(1),(2) Department of Quality Management Suan Sunandha Rajabhat University Bangkok, Thailand

(3) Industrial Engineering Department, Faculty of Engineering, Kasetsart University Bangkok, Thailand e-mail: jaransabseree@hotmail.com

ABSTRACT:

This paper introduces a new problem solving methodology, known as the Fusion Six Sigma. It enhances problem solving capability over the traditional Six Sigma methodology by adding various powerful tools with some modification such as Shainin’s method, Fusion DOE, TRIZ, lean manufacturing, value engineering, P-M analysis, and etc. The methodology consists of 8 parts which are define, measure, technical analysis, historical data analysis, experimental data analysis, 7 support tools , improve and control. The 6 key features of Fusion Six Sigma are as the following: (1) Still be based on DMAIC platform (2) Emphasize on discovering Y=f(Xs) with minimum resources (3) Improve qualitative analysis

(4) Integrate various effective quality tools with some modification into the methodology (5) Improve problem solving capability form traditional Six Sigma and (6) Simplify statistical and problem solving methods. Case studies from textile, metal and electronic industries are shown to illustrate how the methodology was applied to solve real quality problems in manufacturing industries. The results of the application of Fusion Six Sigma showed that when this methodology was properly applied, the industrial quality problems were efficiently solved.

Keywords : Fusion Six Sigma, P-M Analysis, TRIZ, Shainin’s method

INTRODUCTION

Six Sigma methodology is a systematic problem solving methodology containing statistical tools and problem solving techniques which are properly arranged in DMAIC (Breyfogle, 2003; Pydek, 2003) .

Although traditional Six Sigma methodology can solve various industrial problems, there are some drawbacks. Authors identified 4 types of problem which are difficult to be solved effectively by using traditional Six Sigma. They are (1) problems with possible many root causes (2) problems in cycle time improvement (3) problems in achieving robustness and variance reduction and (4) problems to generate practical solutions. To overcome the problems above, authors develop a new problem solving methodology called “Fusion Six Sigma”, adding and fusing various powerful tools together such as P-M analysis, Shainin’s method, Fusion DOE, TRIZ, lean, VE, Taguchi’s method and multivariate statistics etc. Authors expect that Fusion Six Sigma methodology will become powerful and effective methodology due to more problem solving methods and synergy between tools. The purpose of this article is to discuss the overall methodology of Fusion Six Sigma and how it was applied to solve real problems from various industries.

FUSION SIX SIGMA METHODOLOGY AND CASE STUDIES

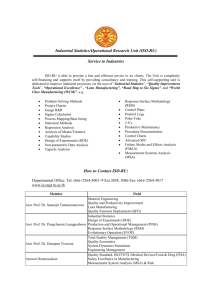

Using DMAIC as a platform, Fusion Six Sigma methodology was developed to enhance power of quality problem solving and to correct the drawback of traditional Six Sigma methodology. The main components of the methodology are divided into 8 parts as shown in figure 1. Analyze phase from

DMAIC is divided into 3 new phases which are technical analysis, historical analysis and experimental analysis and 7 support tools are introduced to create practical solutions.

1

Header Space reserved for Publication

Figure 1 - Fusion Six Sigma Methodology

Define

Same as traditional Six Sigma, this phase defines the problem and other sub-elements such as topic, scope, baseline, target, team member, benefit and (Pydek, 2003; Breyfogle, 2003). There are no new elements developed in the phase. The summary of define phase of 4 case studies are shown in Table 1.

Table 1 - Summary of Define Phase from 4 Case Studies

Case # Industry Project Metric Baseline Target

1

2

3

Project Title

Improve Needle Breakage

Detection

Improve Capability of

Magnet Outer Diameter

Reduce Testing Failure

Textile

Metal

Electronic

Yard/Breakage

Ppk

% defect

18.6

1.33

0.75

2

1.67

0.25

4

Reduce Solder Defect in

PPC

Electronic % defect 22.49 9.6

Measure

Main objective of this phase is to measure current process performance and to validate measurement system. Basic statistics, measurement system analysis, process capability analysis are key tools in this phase. Some qualitative analysis tools in traditional Six Sigma are moved to technical analysis phase while the rest are still no further development. The metric of the processes before improvement of each project were measured as Table 1.

In case #2, measuring outer diameter (OD) can be done in 2 stages, in-process and final inspection. The final OD, customer’s requirement, is found to be correlated with in-process OD. Thus in-process OD can be used as a secondary measurement in Case #2.

Technical Analysis

This phase is to analyze the process by using qualitative tools such as process mapping, C&E diagram,

C&E matrix, FMEA from traditional Six Sigma. P-M analysis (Shirose, Kimura & Kaneda 1995), TRIZ functional analysis (Yang & El-Haik, 2003) and TRIZ problem formulation (Terninko, Zusman &

Zlotin, 1998) are added in order to enhance the power of qualitative analysis and to improve the linkage between qualitative and qualitative tools in the problem solving methodology. Process is analyzed not only from the view points of value stream and factors affecting the process but it is also analyzed into functionality of the components and mechanism of the system. Potential factors as well as the methods to

2

Header Space reserved for Publication

investigate them are identified in this step. This part can be considered as the heart of the Fusion Six

Sigma because it functions as the centre which links other tools together.

P-M Analysis is a tools usually used for problem solving in TPM (Shirose, Kimura & Kaneda 1995). The advantage of P-M analysis over other technical analysis tools is that it forces problem solvers to scrutinize phenomena (symptom of the problem) and mechanism in the system. Mechanism based on relationship between quantitative factors forming phenomena together with picture or diagram of the elements in the system should be shown before identifying potential conditions and possible root causes. This method facilitates problem solvers to have deep understanding in process knowledge, focusing on the mechanisms related to the relevant symptom at the early stage. In Fusion Six Sigma, there is an important modification from traditional P-M analysis that is the investigation based on qualitative tools (such as hypothesis test, DOE, regression etc.) is preferred rather than comparing the values of potential root causes to predetermined values as in traditional P-M analysis. An example of P-M analysis from case # 1 used in technical analysis phase is shown Table 2

Table 2 An Example of P-M analysis from Case #1

Phenomena: No signal when needle break

Physical and mechanism analysis: Intensity of the sensor is not appropriate

Potential Condition

Poor signal

4M Evaluation

- Distance between cloth and sensor

- Cloth tightness

- Process speed

- Signal intensity

Investigation

Use DOE to investigate the effect of factors to the appropriate signal

TRIZ functional analysis (Yang & El-Haik, 2003) and/or problem formulation (Terninko, Zusman &

Zlotin, 1998) can be used to analysis mechanism of the system in the process. Objects (or substance) and field (or action) together with their interaction and linkage are formulated in order to understand relationship between objects and contradiction in the system. This analysis is helpful in finding potential solutions from TRIZ tools at the later stages of the methodology. In Fusion Six Sigma, P-M analysis and functional analysis and/or problem formulation can be used together with other quantitative tools as the case studies #2 and #3 (Table 3 & 4).

Table 3 - An Example of P-M analysis with Functional Analysis from Case #2

Phenomena:

OD has too much variation. Parts have trend to above target.

Physical Analysis and Mechanism:

Forming dimension change

Potential Condition

Mold dimension changes

Poor process parameters

Material’s properties changes

4 M

- Mould diameter

(Mould)

- Position1

- Temp1

- Temp2

- Powder Ratio

(Ratio)

- Material Flow

Rate (Flow)

Investigation

Multi-vari Chart

Reversed Hypothesis Test

Multiple Regression

DOE

3

Header Space reserved for Publication

Table 4 - P-M analysis with Problem Formulation from Case #3

Phenomena:

Part does not generate output signal as the specification

Physical Analysis and Mechanism:

Voltage generating process malfunction or voltage signal.

Potential

Condition

Some critical distances on fixture change

4 M

- Thickness 1

- Thickness 2

- Height

Investigation

Reversed Hypothesis Test

Parameter setting at the tester is not appropriate.

- Shift

- Voltage at position 7 (V7)

- DC1

- DC2

- Delay

- Connection 1

- Connection 2

DOE Taguchi L18

Distance at some connection change

Reversed Hypothesis Test

In case #4, simple process mapping and fishbone analysis was used in technical analysis phase and 5 potential factors were identified as follow: (1) snap off speed (2) snap off distance (3) snap off gap (4) printing speed and (5) printing force. These factors were studied by using DOE at experimental data analysis phase.

Analyze: Historical Data

This phase is to analyze the data colleted from the process without interruption or modification of the current process. The aim of this phase to find vital few Xs and the relationship between Xs & Ys with minimum resources by applying principle of “talking to the part” from Shainin’s method (Bhote & Bhote,

2000). Key tools used in this phase are multi-vari study, hypothesis test, concentration chart, basic statistics/graphical tools, multiple regression and reversed hypothesis test. Many tools in this phase are from Shainin’s clue generation tools and traditional Six Sigma, but some tools are modified to enhance problem solving capability. When these tools are used properly, more powerful screening techniques are obtained, allowing problem solver can identify vital few Xs or even getting relationship Y=f(Xs) while spending few resources without interruption of the production. This is an important strategy in solving problems with many possible root causes in a real process in industry which usually has time and resource constraint.

In Fusion Six Sigma, Shainin’s clue generation tools are used with modification. Steiner, MacKay &

Rambert (2006) suggested that t-test or nonparametric test can be used as substitution for Tukey’s test in paired comparisons TM and the author added F-test as screening tool for comparing “best of the best”

(BOB) and “worst of the worst” (WOW). F-test and t-test used or other non-parametric test in this sequence are called “Reversed Hypothesis test” because the dependent variables (BOB or WOW) are treated as independent variables while independent variables are treated as dependent variables. Reversed hypothesis test allows bigger sample size to avoid beta error and changes the analysis methods, being able to use computer software.

In case #3, 2 reversed hypothesis tests (Table 5) were used to screen 2 significant factors out of the 5 ones. Too high gap in connection 1 and wrong height of fixture were identified as root causes for high defect rate in testing failure.

4

Header Space reserved for Publication

Factor

Connection

1

Connection

2

Table 5 - Reversed Hypothesis Test from Case #3

Connectors with Lowest Defect Rate

(BOB)

Connectors with Highest Defect Rate

(WOW)

Mean SD Mean SD

42.28 .413 40.79 .632

Factor

14.05 1.43

Fixtures with Lowest Defect Rate

(BOB)

Mean S.D.

13.50 1.36

Fixtures with Highest Defect Rate

(WOW)

Mean Mean t-test

.005

.550

Sig.

F-test

.430

.927

S.D.

Sig.

F-test

THK 1 6.007

7.49

.020

.039

6.005

7.48

.024

.039

.847

.540

.625

.942 THK 2

Height 74.34 .039 74.27 .05 .004 .365

In case #2, reversed hypothesis tests (Table 6) was used to screen 3 significant factors out of the 6 ones.

Mold diameter, position 1 and temperature1 were identified as root causes for high variation in outer diameter.

Table 6 Reversed Hypothesis Test for Case #2

High Diameter (WOW) Low Diameter (BOB)

Factor

Mean SD Mean SD

P-value

(t-test)

P-value

(F-test)

Mold

Position 1

Temp 1

Temp 2

Ratio

30.17

7.580

15.35

180.18

20.1

.0017

1.630

1.73

.81

11.1

30.16

5.254

18.69

179.92

22.5

.0080

.226

1.89

.49

11.7

.000

.000

.000

.329

.561

.005

.000

.730

.089

.843

Flow 11.23 .258 11.21 .347 .886 .269

Multiple regression in Fusion Six Sigma utilizes the technique modified from historical data analysis developed by Schmidt, Kiemele, & Berdine (1999) with the capability to obtain quadratic and interaction terms of interested factors. This can be achieved by transforming the data into coded unit and treating multiple regression data as defined custom DOE. Suspected interaction and quadratic terms can be analyzed if (1) there are enough degree of freedom and (2) multicollinearity among factors, interaction and quadratic terms are low. The rules of thumb are correlation between each term should be -0.7 < R <

0.7 and tolerance of each factor is less than 0.5. Multiple regression with interaction terms and quadratic relationship has advantage over ordinary multiple regression in prediction and optimization of some complicated processes such as chemical processes and metallurgical processes where quadratic relationship and interactions between factors are usually expected. An example of multiple regression with interaction and quadratic terms from Case# 2 is showed in equation 1.

5

Header Space reserved for Publication

OD = 30.3484 - .082 Mold +0.0132 Position1 -0.010 Chiller + 0.0d6 Mold 2

– 0.0176 Mold*Position1

Note: Coded Equation ; S = 0.0043 R 2 = 0.883 Adj R 2 = 0.867

(1)

Analyze: Experimental Data

These tool set applies the principle “asking the process” which is the attempt to change or modify the process and to observe the results in order to obtain the effect of factor and relationship Y=f(Xs).

Experimental tools such as data comparison, hypothesis testing and DOE are used to achieve the objective. To obtain an effective experiment strategy, Fusion DOE is developed from classical DOE

(Pyzdek, 2003), Taguchi DOE (Taguchi, Chowdhury & Wu, 2004), Shainin DOE (Bhote & Bhote, 2000) and blended DOE (Schmidt & Launsby,1998) with some modification. The advantage of Fusion DOE over other DOE approaches is the ability to solve problems with many Xs with less resources while being able to obtain critical information. From the view point of Fusion DOE, author has standpoint and philosophy in DOE which may be different from other approaches as follow:

Sample Size

While most literatures, such as Montgomery (2001) and Anthony (2003) and etc., strongly prefer sample size with replication which includes between-setup variation in DOE. The advantage of replication is more precise estimation of factor/interaction effect. However, some other DOE practitioners, such as

Moen, Nolan, & Provost (1991) and Schmidt & Launsby (1998), accept sample size with repetition which includes only within-setup variation in DOE. The advantage of repetition is fewer resource required in conducting DOE. In Fusion Six Sigma, large sample size for standard deviation model is preferred. Rule of thumb is that each level should have at least 20 samples. For example, L8 requires at least 5 samples per runs (5*4 = 20). With large sample size required, it is usually not practical to collect the data with replication, therefore, repetition is preferred in this situation. Another advantage of using repetition in this context is better ability to detect the factor effect on within variation. Because the data collection with repetition will not include the variation between set up, then set up in the experiment should have to be done with great care in order to reduce error from estimation of the factor/interaction effect. In Fusion Six

Sigma context, the setup variation is usually reduced through other previous improvement phases thus it is reasonable to use repetition. When the situation allows, randomization between runs and combination between repetition and replication are also recommended. For the case studies in this paper, replication was used in case #1 while repetition was used in case # 2, #3 & #4.

Y-hat and S-hat Model

Y-hat model as well as S-hat model should be used together whenever possible. In case #1&2, central composite designs (with

= 1) for 3 factors were used. The sample size per run for case#1 was 3 and that of case #2 was 32. The output response of DOE in case# 1 was intensity for detector and the output signal of DOE in case# 2 was in-process OD. The models from the DOE are shown in Table 7. These models could be used for process optimization in improve phase.

Using Screening Design

When number of variables to be studied in DOE are more than 5 factors, resolution III design with partial aliasing pattern, such as L12, L18 and Master Search, are preferred than fractional DOE and OFAT hypothesis testing. The advantages of these screening DOE are (1) using few resources in finding variance reduction factors and (2) ability to torture the data at later stage.

In case #3, L18 for 5 factors was used. The output response of the DOE in case# 3 was output voltage and the sample size per run was 5. The model from the DOE is shown in Equation 2. The model could be used for process optimization in improve phase.

Output Voltage = 134.046 - 0.010 Shift + 4.987 TP7 - 0.002 DC1 - 0.002 DC2 + 0.008 TP7

- 0.010 DC1

Note: Coded Equation , S = 0.047

2 - 0.010 DC2 2 - 0.004 Delay2 + 0.012 Shif*TP7 (2)

2

6

7

8

5

6

3

4

1

2

9

10

11

12

Header Space reserved for Publication

Term

Constant

A

Table 7 - Y-hat model and S-hat model from Case # 1&2 (Coded Equation)

Y-hat Model for

Case #1

S-hat Model for

Case #1

Y-hat Model for

Case#2

S-hat Model for

Case#2

-13.059 0.1772 30.3406 0.001394

3.097Tightness - 0.0067 Mould 0.000858 Mold

B

C

A 2

B 2

C 2

-.288Speed

-29.037 Space

-

-

-0.0031 Position1

0.0014 Temp2

-

-0.000396

Temp2

0.000754 Mold 2

AB

AC

-.0982 Tightness 2

.009 Speed 2

22.394 Space 2

-.010

Tightness*Speed

.979

Tightness*Space

.1772

-

-

-

-

-

-0.0010 Mold 2

-

-

-

-0.0004

Mould*Chiller

.002443

-

-

-

-

S

R 2 .673

-

- .872

.0005

.841

Adj R 2 .611 - .871 .777

Master Search

Shainin’s variable search TM and component search TM are modified to be Master Search by adding more sample size – replication or repetition (Sabseree, Thueakthong & Sukchareonpong, 2007). Master Search

(as an example from case #4 in Table 8) has less beta error than Shainin’s methods because of larger sample size. In case #4, Master Search for 5 factors was used. The output response of the DOE in case #4 was number or defect per unit (DPU) and the sample size per run was 4.

Table 8 - Master Search for 5 Factors from Case #4

Run # A B C D E Rep.1 Rep.2 Rep.3 Rep.4

-

+

-

+

-

+

+

-

-

+

-

+

+

-

-

+

-

+

-

+

-

+

-

+

-

+

+

-

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

+

-

-

+

75

9

12

115

28

29

71

17

20

11

219

20

-

+

-

+

-

+

-

+

-

+

+

-

7

225

138

20

90

40

15

50

14

17

14

215

9

118

25

6

78

51

8

38

7

9

9

242

16

77

35

6

99

53

11

49

33

26

19

268

35

Ball Park

Search for A

Search for B

Search for C

Search for D

Search for E

N

Header Space reserved for Publication

Table 9 - The Analysis of Master Search by Testing Series of 2 2 design for the Data from Table 8

Factor

Snap off speed

(A)

Terms

Constant

A

Rest

A*Rest

Coef.

32.13

1.75

-15.38

-2.75

P-value

.000

.554

.000

.358

Sig.

No

No

Runs # used

1,2, 3 & 4

Snap off distance

(B)

Snap off gap

(C)

Printing speed

(D)

Printing Force

(E)

Constant

B

Rest

B*Rest

Constant

C

Rest

C*Rest

Constant

D

Rest

D*Rest

Constant

E

Rest

E*Rest

58.56

11.19

-24.81

-29.19

41.31

-27.94

14.31

-11.94

22.5

-5.66

-8.0

6.88

78.69

47.19

-60.81

-49.31

.000

.353

.053

.027

.000

.000

.000

.001

.000

.021

.003

.007

.000

.000

.000

.000

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

1,2, 5 & 6

1,2, 7 & 8

1,2, 9 & 10

1,2, 11 & 12

The first step in design analysis, ball parking, t-test is used to determine the significant difference between “all high” and “all low”. If WOW and BOB are significantly different, the step 2 can be continued; otherwise the factors and their setting should be revised. To identify significant factors from screening DOE in stage 2, series of 2 2 DOE of a factor to be studied (X) and other factors (Rest) are used

(as table 9) instead of using decision limits as in Shainin’s methods. The factor to be studied is considered as a significant factor if X or X* rest are significant. When X*rest is significant, the conclusion is that X has interaction with some (but unknown) other factors. The significant between X and the unknown factors may be discovered later by torturing the data from overall Master Search design in the next step.

The analysis of Master Search from case #4 is shown in Table 9, indicating that main effects of C, D and

E are significant and there are interactions among B, C, D and E.

Torturing the Data

Normally interaction terms can not be obtained from L12, L18 and Master Search. We have to runs more modelling DOE to obtain those interaction terms. However, this consumes more resources and may not be practical in various situations in industry. To obtain those interactions, special procedure called

“torturing the data” can be used to estimate suspected interactions (Sabseree, Thueakthong &

Sukchareonpong, 2007). Torturing the data, or extracting the interaction information, is done by treating the screening design as defined custom DOE including suspected interactions into the analysis while treating insignificant factors as constant. Because there some possible risk and error in the analysis, confirmation runs should be performed before using the result of the analysis of the model from torturing the data in full scale. Using the data and the analysis from case #4 in Table 8&9, the model from the

Master Search can be obtained by torturing the data as the equation 3.

DPU = 71.16 – 1.92 B – 41.04 C – 18.37 D +34.08 E +19.47 B*D – 47.61 BE – 10.89 C*D

(3)

S = 30.53 R 2 = .839

Note: Coded Equation

Adj. R 2 = .831

8

Header Space reserved for Publication

7 Support Tools

7 support tools are set of tools providing methods to analyze, to improve and to control a process which are used to guide problem solving for specific areas frequently met in the industry. The list of the 7 tools is as follow:

(1) Poka-yoke: a tool for solving human error

(2) productive maintenance: a tool for solving machine problems

(3) quick changeover: tools for set up time and waste reduction

(4) value engineering: tools for cost reduction

(5) TRIZ: tools for improvement guideline and contradiction solving

(6) process speed improvement techniques: tools for process time reduction

(7) variance reduction techniques: tools for variation reduction

These tools are used and integrated with other Fusion Six Sigma tools at an appropriate step from analyze, improve and control in order to facilitate analysis method and to generate practical solutions, thus enhancing the power of quality problem solving significantly.

Poka-Yoke

Poka-yoke is developed from the guidelines by Shingo (1989) which consists of (1) elimination, (2) facilitation and (3) detection, being a common tool in Lean Six Sigma as an important tool to solve the problem under factors related to man’s error. In case #3, poka-yoke was applied to eliminate handling error, preventing change in fixture’s dimension due to human error

Productive Maintenance

Productive maintenance is extracted from concept of total productive maintenance (TPM) which consists of preventive maintenance, predictive maintenance and autonomous maintenance (Allen, Robinson &

Stewart, 2001). In Fusion Six Sigma, statistical methods and problem solving methods such as reversed hypothesis test, component search, DOE and reliability data analysis are integrated to productive maintenance in order to enhance capability of problem solving related to machine variables. In case #1 ,

#2 and #3, maintenance of some critical Xs, as Table 10, were applied in order to control the processes.

Table 10 - Productive Maintenance in Case #1, #2 and #3

Case # Maintenance Action Reaction Plan

1 Check the detector as schedule Clean and adjust the detector

2 Check the mold diameter and change as schedule Change the mold

3

Check the height of the fixture and connection 1 as schedule

Correct the dimension

Quick Changeover

Quick changeover is a lean tool used to solve the problem in machine setup. The methods used in Fusion

Six Sigma follow the basic principles developed by Shingo (1985) such as (1) separating internal and external setup (2) converting internal to external setup and (3) reducing adjustment. Fusing with statistical tools, a new quick changeover concept is developed by using Y=f(Xs) relationship to find a solution for quick changeover and standardization of set up. In case #1, using Y=f(Xs) from DOE as applied to reduce setup time in adjusting the detector.

Value engineering

Value engineering is developed from total value engineering (TVE) proposed by Bhote (2002) with the concept of integrating value engineering with other quality improvement tools such as B vs C and reliability analysis. In Fusion Six Sigma, more tools are added such as verification with hypothesis test and confidence interval, TRIZ, DOE etc., thus becoming a good tool set for cost reduction.

9

Header Space reserved for Publication

TRIZ

TRIZ is used in Fusion Six Sigma as tools for system analysis and guidelines for improvement and contradiction solving. Yang & El-Haik (2003) suggested various TRIZ tools should be used DFSS such as 40 inventive principle, separation principles, functional improvement methods. Author thinks that theses tools can be used in problem solving also. 40 inventive principles should be used to solve technical contradiction, the condition where one feature is improved while another feature is worsened. Separation principles should be used to solve physical contradiction, the condition where a factor in the system must has 2 opposite properties. Functional improvement methods, an abbreviated version of 76 standard solutions, should be used when system is not complete, not being able to deliver a useful function or creating a harmful function. Using these TRIZ tools facilitates creativity in finding improvement solutions in improvement phase. Moreover, TRIZ functional analysis together with other quality to can function as a qualitative tool for technical analysis which enhances the power to analyze system and mechanism in the zone of conflict as well as improves the ability to identify potential factors to be investigated in subsequent phases. The application of TRIZ in the case studies is shown in Table 11.

Table 11 Application of TRIZ in Cass #1, #2, and #3

Case #

1

Application of TRIZ

Improve positioning the detector by using principle #17 (New Dimension)

2

3

Use functional analysis to analyze the system in P-M analysis

Use problem formulation to analyze the system in P-M analysis

Solve contradiction between accuracy of fixture and maintenance activities by using principle # 1 (Segmentation) by dividing control loop of fixtures into 2 loop. The fixtures in control loop # 1 is for manufacturing, requiring less accuracy and maintenance while the fixtures in control loop is for testing, requiring more accuracy and maintenance.

Process speed improvement techniques

Process speed improvement techniques are set of lean tools providing practical guidelines how to reduce process cycle time and to improve productivity. The key tools are (1) time analysis, (2) value added steps analysis, (3) layout improvement, (4) inventory reduction, (5) process balancing and (6) pull system

(Adams, Kiemele, Pollck & Quan, 2004). These tools can improve power of process speed improvement in specific situations as same as those in Lean Six Sigma (Gorge, 2002).

Variance reduction techniques

Variance reduction techniques are set of methods collected from various sources (Suh,2001; Schmidt &

Launsby,1998; Taguchi, Chowdhury & Wu, 2004), providing excellent ways how to find robust solutions and to reduce process variation. There are 7 techniques used which are: (1) reducing variation of Xs (2) work standardization (3) compensation (4) setting Xs at variance reduction level (5) taking advantage of interaction (6) taking advantage of quadratic relationship and (7) using robust solution. The application of variance reduction techniques in the case studies is shown in Table 12.

10

Header Space reserved for Publication

Case #

Table 12 Application of Variance Reduction Technique in Cass #1, #2, and #3

Application of Variance Reduction Techniques

Work standardization by writing setting parameter in the procedure

Compensation: compensate the tightness and speed with intensity

Taking advantage of quadratic relationship by setting the distance at 0.3 cm

1

Setting X (mold diameter) at variance reduction level

2

Reducing variation of Xs by using the ranges of BOB as a new specifications

3

11

Header Space reserved for Publication

Improve

Results from the data analysis and ideas from 7 support tools were utilized together in order to generate improvement solutions. The improvement results can be validated by using data comparison, graphical tools, hypothesis testing and confidence interval as in traditional Six Sigma. From case #1-4, the improvement solutions as well as the improvement results are shown in Table 13.

Table 13 - Improvement Solutions and Results in Case #1, #2, #3 and #4

Case # Improvement Solutions

Project

Metric

Before

Improvement

After

Improvement

P-

Value

1

2

3

4

- Redesign method to position the detector

- Set between detector and cloth

= 3 mm

- Set work standard from DOE

- Mold Diameter = 30.164 ±

.005 mm

- Position1 = 15.3 mm

- Temp2 = 15 ± 3 o C

- Connection 1 = 42.3 ± 0.3 mm

- Height of the Fixture = 73.5 ±

0.08 mm

- Voltage at position 7 = 5.4 ±

0.1 V

- Snap off speed = 3 m/s

- Snap off distance = 1.5 mm

- Snap off gap = 2 mm

- Printing speed = 60 m/s

- Printing force = 7 kg/cm

2

Yard/Breakage

Ppk

% defect

% defect

18.6

1.33

0.75

22.49

1.4

1.95

0.25

0.20

.000

.000

.000

.000

Control

Control is creating methods to control the improved process by integrating into quality system and using various tools such as control plan, work standard, SPC, tolerance design etc. The purpose of this phase is to hold the gain from the improvement which is the same as those in traditional Six Sigma (Breyfogle,

2003). From case #1- 4, the process control methods are shown in Table 14.

Table 14 - Control Methods in Case #1, #2, #3 and #4

Case #

1

2

3

4

Process Control

- Process control plan

- Work instruction for parameter setting of detector

- Maintenance plan for machine and detector

- Process control Plan

- Maintenance plan for mould

- Work instruction for parameter setting

- SPC for OD of magnet

- Process control plan

- Work instruction for parameter setting

- Maintenance plan for fixture and connector. The fixtures were divided into 2 control loops. The fixtures in control loop # 1 is for manufacturing, requiring less accuracy and maintenance while the fixtures in control loop is for testing, requiring more accuracy and maintenance

- Tray for moving fixture

- Process control plan

- Work instruction for parameter setting

12

Header Space reserved for Publication

DISCUSSION

From the case studies above, Fusion Six Sigma was proven to be an enhanced methodology to solve industrial problems. Technical analysis was improved by application of P-M analysis together with TRIZ functional analysis and/or problem formulation, facilitating problem solvers to understand the system deeply. Relevant possible factors and tools to study them were identified at this stage. In addition, problems with many possible root caused were efficiently solved in historical data analysis phase and experimental data analysis phase. Additional tools in Fusion Six Sigma, such as reversed hypothesis test, multiple regression with quadratic terms and Fusion DOE, were proven to be useful. These tools allowed problem solvers to gain critical information while using fewer resources than traditional Six Sigma methodology. Moreover, variance reduction methods and practical solution generation were enhanced by applying 7 support tools such as variance reduction techniques, productive maintenance and TRIZ. The results of the application of Fusion Six Sigma showed that this methodology could solve industrial quality problems efficiently.

CONCLUSION

Fusion Six Sigma is a Six Sigma enhancement, focusing to improve problem solving methodology. It has key features as the follows:

Still be based on DMAIC platform

Emphasize on discovering Y=f(Xs) with minimum resources

Improve qualitative analysis

Integrate various effective quality tools with some modification into the methodology

Improve problem solving capability form traditional Six Sigma

Simplify statistical and problem solving methods

When this methodology is properly applied, authors expect that industrial quality problems will be efficiently solved.

ACKNOWLEDGMENT

B vs C, Component Search, Paired Comparisons, Variable Search are registered trademarks of Shainin

LLC.

REFERENCES

Adams, M., Kiemele, M., Pollck, L., & Quan, T. (2004).

Lean Six Sigma : A Tools Guide.

Air Academy

Press & Associates, CO.

Allen, J., Robinson C., & Stewart, D. (2001). Lean Manufacturing : A Plant Floor Guide .

Society of

Manufacturing Engineers, Michigan.

Anthony, J. (2003). Design of Experiments for Engineers and Scientists . Butterworth-Heinemann,

Burlington.

Breyfogle III. F. W. (2003). Implementing Six Sigma : Smarter Solution Using Statistical Methods ,

Second Edition. John Wiley & Sons, New York

Bhote, K. R., & Bhote, K. A. (2000). World Class Quality : Using Design of Experiments to Make it

Happen . AMACOM, New York.

Bhote, K. R. (2002). The Ultimate Six Sigma : Beyond Quality Excellence to Total Business Excellence.

AMACOM, New York.

Gorge, M. L. (2002). Lean Six Sigma . McGraw-Hill, New York.

Moen, R.D., Nolan, T.W. & Provost, L. P. (1991).

Improving Quality through Planned Experimentation .

McGraw-Hill, New York

Montgomery, D.C. (2001). Design and Analysis of Experiments . John Wiley and Sons, USA.

13

Header Space reserved for Publication

Pyzdek, T. (2003). The Six Sigma Handbook : A Complete Guide for Green Belts, Black Belts, and

Manager at All Levels, Revised and Expanded . McGraw-Hill, New York.

Sabseree, J., Thueakthong, V. & Sukchareonpong, P. (2007) Master Search: Method and a Case Study.

The fifth International Conference on Quality and Reliabilty (ICQR2007) Cheingmai, Thailand,

Noverber, 5-7, 2007

Schmidt, S. R., & Launsby, R.G. (1998 ). Understand Industrial Designed Experiment . Air Academy

Press & Associates, CO.

Schmidt, S. R., Kiemele, M. J., & Berdine, R. J. (1999) . Basic Statistics: Tools for Continuous

Improvement . Air Academy Press & Associates, CO.

Shingo, S., & Dillon, A.P. (1985). A Revolution in Manufacturing: A SMED System . Productivity Press,

Oregon.

Shingo, S., & Dillon, A.P. (1989). Zero Quality Control : Source Inspection and the Poka-yoke System .

Productivity Press, Oregon.

Shirose, K., Kimura, Y., & Kaneda, M. (1995). P-M Analysis: An Advanced Step in TPM Implementation .

Productivity Press, Oregon.

Steiner, S.H., MacKay, R.J. & Rambert, J.S. (2006) A n Overview of the Shainin System (trademark) for

Quality Improvement Business and Industrial Statistics Research Group: University of Waterloo

Retrieved August, 14, 2007 from http://www.bisrg.uwaterloo.ca/archive/RR-06-03.pdf

Suh, N.P. (2001) Axiomatic Design : Advance and Application s. Oxford University Press, New York.

Taguchi, G., Chowdhury, S., & Wu, Y. (2004). Taguchi's Quality Engineering Handbook . John Wiley &

Sons, New York

Terninko, J., Zusman, A. & Zlotin, B. (1998). Systematic Innovation: An Introduciton to TRIZ.

New

York: ST. Lucie Press

Yang, K., & El-Haik, B. (2003). Design for Six Sigma : A Roadmap for Product Development . McGraw-

Hill, New York