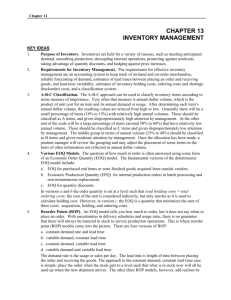

CHAPTER 11 INVENTORY MANAGEMENT (LECTURE 1)

advertisement

INVENTORY MANAGEMENT I. Introduction -- What is inventory? - stored resource used to satisfy current or future demand -- Types of Inventories: Raw Materials/Components In-Process Goods (WIP) Finished Goods Supplies -- Inventory Related Costs: Holding Cost Shortage Cost Order Cost Inventory is costly! -- Why Hold Inventories? Meet anticipated demand Protect against stock-out De-couple successive operations - separate production from distribution Smooth production process Buy/Produce in economic lot sizes - take advantage of quantity discounts Hedge against price increases -- JIT Inventory – minimum inventory needed to keep a system running, small lot sizes Advantages - lower inventory costs - easy to identify problems and potential problems Disadvantages - requires accurate timing and cooperation - breakdowns stop everything -- Inventory Classification Identify important items and more inventory control on important items Measure of importance: ABC analysis: A = 70-80% of total inventory value, but only 15% of items B = 15-25% of total inventory value, but 30% of items C = 5% of total inventory value, but 55% of items -- Monitor Inventory As important as demand forecast for decision making Cycle counting: regular inventory audits, ABC approach -- Inventory Systems Objective: minimize total inventory cost and maintain satisfied service level. Fundamental Questions: - How much to order? - When to order? 1. Continuous Review System: (event-triggered) - Monitor the inventory level all the time, order a fixed quantity (Q) when the inventory level is below the reorder point(ROP) - Calculate: Q and ROP 2. Periodic Review System: (time-triggered) - Place an order every fixed period T. Each time bring the current inventory to a target level M - Calculate: T and M 3. Advantages and Disadvantages? -- Dependent and Independent Demand: Dependent demand: derived demand, lumpy (subassemblies and components) Independent demand: from customer side, smooth (end items and finished goods) II. Inventory Models On Order Quantity -- EOQ Model Assumptions 1. There is one product type 2. Demand is known and constant 3. Lead time is known and constant 4. Receipt of inventory is instantaneous(one batch, same time) 5. Shortage is not allowed visualize the system(picture) Notation and Terminology Q = order quantity(# of pieces/order) Q* = Economic Order Quantity (EOQ) D = demand for the time period considered(units/time period) S = setup/order cost ($/order) H = holding cost/unit/time period($/unit/time period) - in general proportional to the price, H = IP I = Interest rate (expanded) (%/time period) P = unit price ($/unit) IC = inventory cost = setup cost + holding cost TC = IC + product cost Find Out EOQ Average Inventory Level = Annual Holding Cost = Number of orders per year = Order Cost = Total Cost (TC) = Best Order Quantity (EOQ) formula -- Example: Annual demand = 10,000 unit/year, ordering cost = $50/order, unit cost (price) = $4/unit, expanded interest rate = 25%/year. EOQ? TC at EOQ? H = EOQ = IC = TC = Sensitivity of IC w.r.t. Q -- Example (continued) Q D/Q (D/Q)S Q/2 (Q/2)H IC 500 1000 1500 - Conclusion: 1. Inventory cost curve is flat around EOQ 2. Flatter when Q increases than when Q decreases from EOQ - Thinking Challenge: If the order quantity Q = 2EOQ, by how much IC will increase? Sensitivity of EOQ w.r.t. D, H, S, P, I 1. Insensitive to parameter change 2. Directions? -- EOQ with discount Assumptions: same as with EOQ, plus discount on all units Terminology 1. Price breaks: 2. Feasibility: -- Example: Order 0-399 400-699 700 Price $2.2/unit 2.0 1.8 Idea is to compare TC curves under different prices - why TC? Observations: 1. EOQ with a lower price, if feasible, is better than any order quantity with the same or higher price. 2. Potential best order quantity: cheapest feasible EOQ, price breaks associated with lower prices. Solution Procedure: 1. Find the feasible EOQ with cheapest possible price. 2. Calculate TCs of the EOQ (from Step 1) and the price breaks associated with lower prices. 3. Pick the order quantity with lowest TC -- Example (continued) Annual demand = 10,000 unit/year, order cost = $5.5/order. Assuming holding costs are proportional to unit prices and annual interest rate = 20%. Find the best order quantity. III. Models on Reorder Points - When to Order? -- ROP depends on: Lead Time: time between placing and receiving an order Demand Distribution: how uncertain Desired Service Level: probability of no shortage = 1-P(s), where P(s) = probability of shortage -- Constant Demand Rate: Constant demand rate = d, Lead time = L ROP = dL = Lead time demand Remark: - no uncertainty in demand - service level = 100% - safety stock = 0 -- Variable Demand with Stable Average Rate How continuous review system works? - Lead time demand: demand during the lead time - ROP Lead time demand ==> - ROP < Lead time demand ==> - ROP = Average lead time demand + Safety Stock = m + SS Remarks: - Higher the desired service level ---> - More uncertain the demand ---> Determine SS and ROP based on shortage cost inf. (if available) - SS increases Holding cost ? Shortage cost ? - Best SS minimizes total inventory cost -- Example: Consider a light switch carried by Litely. Litely sells 1,350 of these switches per year, and places order for 300 of these switches at a time. Assuming no safety stock, Litely estimates following information related to shortage: Shortage Level Probability no shortage 5 10 15 0.5 0.2 0.15 0.15 The carrying cost per unit per year is calculated as $5 while the stockout cost is estimated at $6 ($3 lost profit per switch and another $3 lost in goodwill, or future sales loss). Find the best SS level and ROP for Litely. # of orders per year = Safety stock Add. Holding cost Avg. shortage (per order) Annual shortage cost Total cost 0 5 10 15 Determine ROP and SS based on lead time demand distribution and desired service level: - Case 1. Empirical Lead time demand distribution -- Example: Lead Time Demand 3 4 5 6 7 8 Frequency Probability ROP Service Level 2 3 5 5 3 2 Find R and SS to achieve the service level of 85% and 95%, respectively. - Case 2. Lead time demand is Normally distributed with (m,) SS = z, R = m + SS, z = z-value of desired service level