INVENTORY MANAGEMENT

advertisement

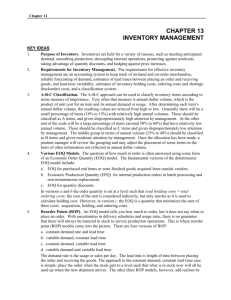

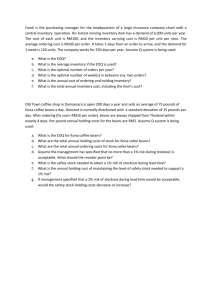

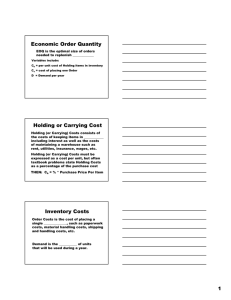

INVENTORY MANAGEMENT Importance of Inventory Management -- Good inventory management is essential to the successful operation for most organizations because of: 1. The amount of money invested in inventory represents, and 2. The impact that inventories have on daily operations of an organization Definitions: Inventory – a stock or store of goods Independent vs. Dependent demand items Independent demand items are the finished goods or other end items that are sold to someone Dependent demand items are typically subassemblies or component parts that will be used in the production of a final or finished product Our focus: inventory management of finished goods, raw materials, purchased parts, and retail items Functions of Inventories 1. 2. 3. 4. 5. 6. 7. To meet anticipated demand To smooth production requirements To decouple components of the production To protect against stockouts To take advantage of order cycles To hedge against price increases, or to take advantage of quantity discounts To permit operations (work in process) Objectives of Inventory Control 1. Maximize level of customer service 2. Minimize costs (carrying costs and ordering costs) Requirements for Effective Inventory Management (1) A system to keep track of the inventory periodic, perpetual, two-bin, and universal product code (UPC) (2) A reliable forecast of demand (3) Knowledge of lead times and lead time variability -lead time time between submitting a purchase order and receiving it -lead time variability reliability of the supplier (4) Estimates of inventory holding costs, ordering costs, and shortage costs Holding cost Ordering cost Stockout cost (5) A classification system for inventory items ABC approach – classifies inventory according to some measure of importance ($ value) where A – very important, C – least important Formula for EOQ with Non-instantaneous Replenishment Qo 2 DS H p p u where: D – annual demand S – setup cost H – Holding (carrying cost) per unit p – production or delivery rate d – usage rate C. Quantity Discounts Model 1. Compute the common EOQ 2. Only one of the unit prices will have the EOQ in its feasible range. Identify the range that: If the feasible EOQ is on the lowest price range, that is the optimal order quantity If the feasible EOQ is in any other range, compute the total cost for the EOQ and for the price breaks of all lower unit costs. Compare the total costs – EOQ is the one that yields the lowest total cost. When to Order (reorder points - ROPs) Models Objective: minimize the risk (probability) of stockouts 4 Determinants of the ROP 1. rate of demand 2. lead time 3. extent of demand and/or lead time variability 4. degree of stockout risk acceptable to management Basic Formula for Computing ROP ROP Expected demand during lead time Safety stock A. Constant demand and constant lead time ROP d LT or simply dLT B. Variability is present in demand during lead time ROP dLT z dLT use this formula if an estimate of expected demand during lead time and its standard deviation are available ROP d LT z LT d use this formula when data on lead time and demand are not readily available Shortages and Service Levels The ROP computation does not reveal the expected amount of shortage for a given lead time service level Information on expected number of shortage per cycle, or per year can be determined using the following: A. Expected number of units short per cycle, E(n) E (n) E ( z ) dLT where : E (n) - expected number of units short per cycle E ( z ) - standardiz ed number of units short using Table 11 - 13 (p. 510) dLT - standard deviation of lead time demand B. Expected number of units short per year, E(N) E ( N ) E ( n) C. D Q Annual Service Level AnnualServiceLevel 1 E ( z ) dLT E ( n) 1 Q Q Service Level for Single-period Model Used to handle ordering of perishables (fresh fruits, vegetables, seafood, flowers), and Items that have a limited useful life (newspaper, magazines) Analysis focuses on two costs: shortage and excess SL Cs C s Ce where : C s shortage cost per unit C e excesscost per unit Problems: 2 – ABC Inventory Classification 3 – Basic EOQ 4 – Basic EOQ 11– EOQ with Non-instantaneous Delivery 13 – EOQ with Discount 28 – EOQ, ROP, Shortages 33 – EOQ for multiple products Problem 2(525) The following classification table contains figures on the monthly volume and unit costs for a random sample of 16 units from a list of 2,000 inventory items at a health care facility. Item K34 K35 K36 M10 M20 Z45 F14 F95 F99 D45 D48 D52 D57 N08 P05 P09 Unit Cost 10 25 36 16 20 80 20 30 20 10 12 15 40 30 16 10 Usage 200 600 150 25 80 200 300 800 60 550 90 110 120 40 500 30 Problem 3(586) A large bakery buys flour in 25-lb bags. The bakery uses an average of 4,680 bags a year. Preparing an order and receiving a shipment of flour involves a cost of $4 per order. Annual carrying costs are $30 per bag. (a) Determine the economic order quantity (b) What is the average number of bags on hand? (c ) How many orders per year will there be? (d) Compute the total cost of ordering and carrying flour. Problem 11 (527) A company is about to begin production of a new product. The manager of the department that will produce one of the components for the product wants to know how often the machine used to produce the item will be available for other work. The machine will produce the item at a rate of 200 units per day. Eighty units will be used daily in assembling the final product . Assembly will take place 5 days a week, 50 weeks per year. The manager estimates that it will take almost a full day to get the machine ready for production run, at a cost of $60. Inventory holding costs will be $2 per unit per year. (a) What run quantity should be used to minimize total annual cost? (b) What is the length of a production run in days? © During production, at what rate will inventory build up? (d) If the manager wants to run another job between runs of this item, and needs a minimum of 10 days per cycle for the other work, will there be enough time? Problem 13 (527) A mail-order house uses 18,000 boxes a year. Carrying costs are 20 cents per year per box, and ordering costs are $32. The following price schedule applies. Determine: Number of Boxes 1000 to 1999 2000 to 4999 5000 to 9999 10000 or more Price per Box 1.25 1.2 1.18 1.15 (a) The optimal order quantity Problem 28 (529) A regional supermarket is open 360 days per year. Daily use of cash register tape averages 10 rolls. Usage appears normally distributed with a standard deviation of 2 rolls per day. The cost of ordering tape is $1, and carrying costs are $0.40 per roll. a year. Lead time is three days. (a) What is the EOQ? (b) What ROP will provide a lead time service level of 96%? © What is the expected number of units short per cycle with 96%? Per year? (d) What is the annual service level? Problem 33 (530) Given the following list of items, Item H4-010 H5-201 P6-400 P6-401 P7-100 P9-103 TS-300 TS-400 TS-041 V1-001 Estimated Annual Ordering Demand Cost D S 20000 50 60200 60 9800 80 16300 50 6250 50 4500 50 21000 40 45000 40 800 40 26100 25 Holding Cost (%) Unit Price P 20% 2.5 20% 4 30% 28.5 30% 12 30% 9 40% 22 25% 45 25% 40 25% 20 35% 40 (a) Classify the items as A, B, and C (b) Determine the EOQ for each item.