FME34 - Edibon

EDIBON

Issue: ED01/14

Date: June/2014

FME34

FLUID STATICS AND MANOMETRY MODULE

TENDER SPECIFICATIONS

A- STRUCTURAL SPECIFICATIONS:

1) Stainless structure.

2) Screws, nuts, plates and all the metallic elements in stainless steel.

3) Diagram in the front panel with similar distribution to the elements in the real unit.

4) Quick connections for adaptation to feed hydraulics source.

B- TECHNICAL DATA:

5) The module is mounted on an aluminum structure and painted steel panels and consists of a vertical tank (made of methacrylate, diameter: 100 mm and height: 575 mm) containing water that is connected to different vertical manometer tubes (460 mm length):

One “U” shape vertical tube.

Two parallel vertical tubes.

One vertical tube with variable section.

One vertical tube with a pivot that allows it to incline from 0 to 90º.

6) These tubes can be used individually or in combination for the different demonstrations.

7) Vernier hook and point gauge.

8) Piezometric tube.

9) Manual air pump.

10) Purge valve.

11) Plug to close the tank, so that it is not open to atmospheric pressure.

12) Dimensions: 700 x 350 x 800 mm. approx.. Weight: 15 Kg. approx.

C.A.I. Software System

C- COMPUTER AIDED INSTRUCTION (C.A.I.) SOFTWARE SYSTEM:

This complete software package consists of an Instructor Software (INS/SOF) totally integrated with the Student/Module Software (FME../SOF):

13) INS/SOF. Classroom Management Software (Instructor Software):

The Instructor can:

- Organize Students by Classes and Groups.

- Create easily new entries or delete them.

- Create data bases with student information.

- Analyze results and make statistical comparisons.

- Generate and print reports.

- Detect student’s progress and difficulties.

...and many other facilities.

The Instructor Software is the same for all the modules, and working in network configuration allows controlling all the students in the classroom.

IMPORTANT: Only one package is needed per classroom.

14) FME../SOF. Computer Aided Instruction Software (Student/Module Software):

It explains how to use the module, run the experiments and what to do at any moment.

Each module has its own Student Software.

The options are presented by pull-down menus and pop-up windows.

Each Software contains:

Theory: gives the student the theoretical background for a total understanding of the studied subject.

Exercises: divided by thematic areas and chapters to check out that the theory has been understood.

Guided Practices: presents several practices to be done with the module, showing how to perform the exercises and practices.

Exams: set of questions to test the obtained knowledge.

FME/CAL. Software

D- COMPUTER AIDED LEARNING SOFTWARE (RESULTS CALCULATION AND ANALYSIS):

15) FME../CAL. Computer Aided Learning Software (Results Calculation and Analysis):

This Computer Aided Learning Software (CAL) is a Windows based software, simple and very easy to use, specifically developed by EDIBON.

CAL is a class assistant that helps in doing the necessary calculations to extract the right conclusions from data obtained during the experimental practices.

With a single click, CAL computes the value of all the variables involved and performs the calculations.

Also, CAL allows to plot and print the results. Within the plotting options, any variable can be represented against any other.

Available different plotting displays.

It has a wide range of information, such as constant values, unit conversion factors and integral and derivative tables.

1

EDIBON

Issue: ED01/14

Date: June/2014

FME34

FLUID STATICS AND MANOMETRY MODULE

BDAS. Data Acquisition System

E- BDAS. BASIC DATA ACQUISITION SYSTEM AND SENSORS.

F- MANUALS:

This module will be supplied with the following manuals:

1.

Required services manual.

2.

Assembly and installation manual.

3.

Interface and control software manual (if it is necessary).

4.

Starting-up manual.

5.

Safety manual.

6.

Maintenance manual.

7.

Calibration manual (if it is necessary).

8.

Practices manual.

G- PRACTICES:

This module is designed to be able to do the following practices:

1.

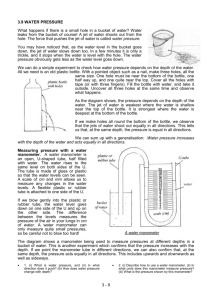

To study the basic principles of hydrostatics and to demonstrate the behaviour of liquids at rest.

2.

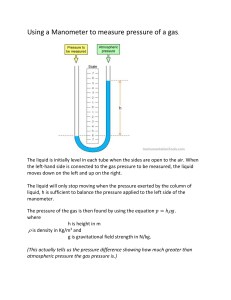

To use manometer tubes to measure differential pressure.

3.

To use a manometer tube to measure head.

4.

To use a ‘U’ tube manometer to measure pressure differences in a gas (air over liquid).

5.

To use a U-shaped manometer for determining the differential pressure.

6.

To use liquids with different densities to change the ‘U’ tube manometer sensitivity.

7.

To use an inverted pressurized ‘U’ tube manometer to measure pressure differences in a liquid.

8.

To use an inclined manometer with different inclinations.

9.

Level measurement using Vernier hook and point gauge.

10.

To measure the liquid level using a scale.

11.

Demonstrating that the level of a free surface is not affected by the size or shape of the tube.

12.

Use of a piezometric tube to measure pressure.

13.

Observing the effect of a liquid in motion (losses due to friction).

2