8917 - Patent Agent | Patent Attorney | Patent Lawyer in India

advertisement

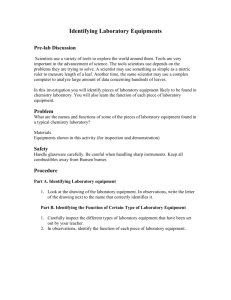

GOVERNMENT OF INDIA. THE PATENT OFFICE. 1, COUNCILHOUSESTREET, CALCUTTA. SPECIrICATION No. 8917. 15th January 1923. ACCEPTED 25TH JUNE1923. AN IMPROVED BURNER FOR LIQUID FUEL, CHIEF LY ADAPTED F OR H EATIN G IN VERTED IN CAN DESCEN T MAN TLES. ALFRED HUTCHISON, OF 6, STONE BUILDINGS, LINCOLN'S INN, LONDON, ENGLAND, SOLICITOR, ADMINISTRATOR OF THE ESTATE OF EDWIN CLEARY, DECEASED. The following specification particularly describes and ascertalos the nature of the inventton and the manner in which the same is to be performed. This invention relates to a modified form of the burner for liquid fuel described in the specification of Letters Patent No. 7466 of 1921, and is intended to enable such burner to be used for heating inverted incandescent mantles. According to this invention the burner comprises a heat conducting plate that is heated at its underside by the bunter proper and has extending from its underside a vertical gauze filled tube, to the lower end of which the liquid fuel is admitted and through which extends the stem of a combined pricker and valve that controls the delivery of the fuel vapour from the upper end of the gauge filled tube to the nozzle or nipple from which a jet of vapour passes into the injector tube, such injector tube being arranged on the upper side of the heat-conducting plate. In the accompanying drawing. I have shown how the said invention can be conveniently and advantageously carried into practice. In these draw ings :— Figure 1 is a side elevation and Figure 2 a vertical central sectiOn of a burner constructed according to the in vention. Figure 3 is a vertical central section illustrating a modification. A is the heat-conducting plate, into the lower side of which there is secured a tube B to receive a tubular filling of wire gauze C. Through the centre of the wire gauge there extends the stem D of a combined valve and pricker E. which engages in the bore of the nozzle F, that is screwed into a socket on the upper side of the plate A. In the burner shown in Figures 1 and 2, the lower part of the valve stem D is provided with a screw thread G which engages with a corresponding screw thread in the inner part of a stuffing box H through which the valve stem D extends to the exterior. By providing t he valve stew D with an operating handle J, it can be turned so as to open and closJ the passage through the nozzle F by means of the needle E and the conical valve E' below such needle. The lower end of the vertical tube B is mounted on a bracket - 8917 2 Price: ONE RUPEE. K provided with a screw threaded tubular piece L adapted to screw into the inlet of the fuel container, the bore of such tube communicating with the interior space of. the tube B through a passage M. The piece L may have a tubular exteneion, or may fit into the mouth of a tube gktending to the bottom of a liquid fuel container in tie upper part of which ari. air pressure is main tained in a well known manner. On the upper side of the heat conducting plate A there is mounted the U-shaped combined injector tube and mixing chamber, one end part N of which is made bulbous and provided with one or more air inlets 0, 0. This end fits over the socket of the nozzle F and communicates through the vertical tube N with the other limb P of the inverted U-tube, the lower end of which is drawn down on to the top of the plate A by means of screw threads on the tubular mixing chamber proper Q which is screwed in from the underside of khe plate A and is made with a collar or flange Q' for bearing against such plate. The lower end of the tube Q is closed by a perforated plate R of nickel, wire gauge or other suitable material. The plate A is further provided with a cylindrical downward extension S having bayonet-slots 5 , S' to receive the projections on the supporting ring of an incandescent mantle as shown. The top of the U -tube Nt, P i s provided with a pin or projection T to receive a shade of reflector. In the modification shown in Figure 3, the valve stem D is provided with a screw thread 1 at its upper end, such screw thread engaging a corresponding screw thread in the plate A and having one or more longitudinal slots 2 to permit the passage to the nozzle F of the oil vapour from the vertical tube B. In this burner, the air-inlet for the injector-tube is made in the form of a separate piece 3 having a lateral opening 4. An annular cup 5 is arranged around the tubular piece L to receive methylated spirit or other suitable light hydrocarbon for use in heating up the burner on starting. . 1 1 I claim : 1. A liquid fuel burner for heating inverted incandescent mantles, such burner being of the kind wherein there is a heat conducting plate that is heated by the burner proper, and wherein there is a wire gauge filled tube which extends downwards from the underside of the heat conducting plate and to the lower end of which the liquid fuel is admitted, characterised in that the delivery of the fuel vapour to the air-injector is controlled by means of a needle valve which is adapted to fit into the bore or thoroughfare of a nozzle at the upper end of the gauze-filled tube and the stem of which valve extends axially through the gauze filled tube, the oil vapour passing from the nozzle into a curved air-injector tube that is arranged above the heat conducting plate and from whence the combustible gaseous mixture delivered to the burner proper, which is arranged on the underside of the heat con ducting plate. 2. A constructional form of the burner claimed in Claim 1, wherein the valve-stem also bears an annular valve wafting with a valve seat at the upper end of the gauge-filled tube, substantially as described. 3. The improved burner constructed substantially as hereinbefore des cribed with reference to the accompanyinw drawings, for the purposes specified. ALFRED HUTCHISON. By his Attorneys, REMFRY & SON. Dated thu 14d day of January 1923. A. HUTCHI Sal. Sheet 1. IVA. wo.praor 1923. 11 Ur. 3 .